When you look at machines for your SMT line, lead time is very important. If there are delays, your schedule can get messed up. Delays can make your work less efficient and force you to change your plans. If you have shorter lead times, you do not need to keep as much inventory. You can also help your customers faster. But if lead times are longer, you must plan further ahead. This can mess up your workflow.

- Longer lead times mean you must plan ahead and can mess up your schedule.

- Shorter lead times let you keep less inventory and help customers faster.

- Delays from long lead times can make your work less efficient.

You can use advanced solutions like S&M’s selective wave soldering. These can help you meet tight deadlines and keep your quality high.

Belangrijkste opmerkingen

- Shorter lead times mean you need less inventory. You can help customers faster. This makes everything work better.

- Picking standard models instead of custom ones saves time. You should plan what you need early.

- Watch your supply chain closely to stop delays. This helps you get parts on time and keeps production moving.

- Flexible schedules help you control inventory. You can change plans if you need to. This makes things faster.

- Work with good suppliers like S&M for better help. Good suppliers talk to you and support you. This lowers risks and helps your project do well.

Key Lead Time Factors

Configuratie van de machine

You should check the machine configuration first. The options you pick can change how long it takes to get your selective wave soldering machine. Some features make things more complicated. Other features help you set up and use the machine faster. Here are some common options that affect lead time:

- Fluxing technology

- Preheating technology

- Soldering technology

- PCB size considerations

- Floor space requirements

- Maintenance needs

- Solder type and solder pots

- Nozzle shapes and sizes

- Nitrogen supply methods

- Flux application and preheating methods

- PCB handling solutions

- Additional machine options

You can add things like visual inspection modules, automatic conveyor width adjustment, automatic wave height check, and automatic nozzle cleaning. These features can make your process better but may take longer to deliver. You should pick the right configuration for your production needs to avoid delays.

Customization Needs

If you want a standard model, you will get it faster. Custom models usually take more days to arrive. The table below shows the average lead time difference:

| Model Type | Lead Time (Days) |

| —————– | —————- |

| Standard Models | 30–45 |

| Customized Models | 50–70 |

You should decide early if you need special features for your selective wave soldering machine. Custom requests, like special PCB handling or unique solder pots, can add weeks to your delivery. Planning ahead helps you avoid problems.

Component Supply Chain

You need to watch the supply chain for important parts. If parts are missing, production stops. For example, if you do not have a resistor, you cannot finish the assembly. This can cause big delays, especially in industries like automotive and medical devices where timing is very important.

Component shortages can make lead times much longer, from 16 weeks up to 52 weeks. High demand and not enough manufacturing make it harder to get parts on time. If suppliers are slow, you may wait months longer for your selective wave soldering equipment. Risks include:

- Component shortages

- Long lead times for parts

- Uncertainty from multiple suppliers

- Errors from manual tracking

- Quality problems that need rework

You should work with good suppliers and ask about their inventory and sourcing plans.

Production Scheduling

Production scheduling is important for getting your machine fast. Flexible scheduling lets you change quantities and timelines when you need to. Good planning locks in your order and helps manage inventory, so you do not need emergency shipments.

| Benefit | Description |

| ———————— | —————————————————————————- |

| Long-term Planning | Locks in production schedules based on projected demand. |

| Flexibility | Allows adjustments to quantities and timelines as needs evolve. |

| Inventory Management | Helps manage inventory effectively, reducing emergency orders. |

| Streamlined Supply Chain | Ensures production aligns closely with demand, leading to timely deliveries. |

Flexible production scheduling can give you faster turnaround times and better results. You can handle both big and small runs with less risk of delay. This is important when you need your selective wave soldering machine ready for a new project or a tight deadline.

Selective Wave Soldering Technology

S&M SM-LⅡ Series Features

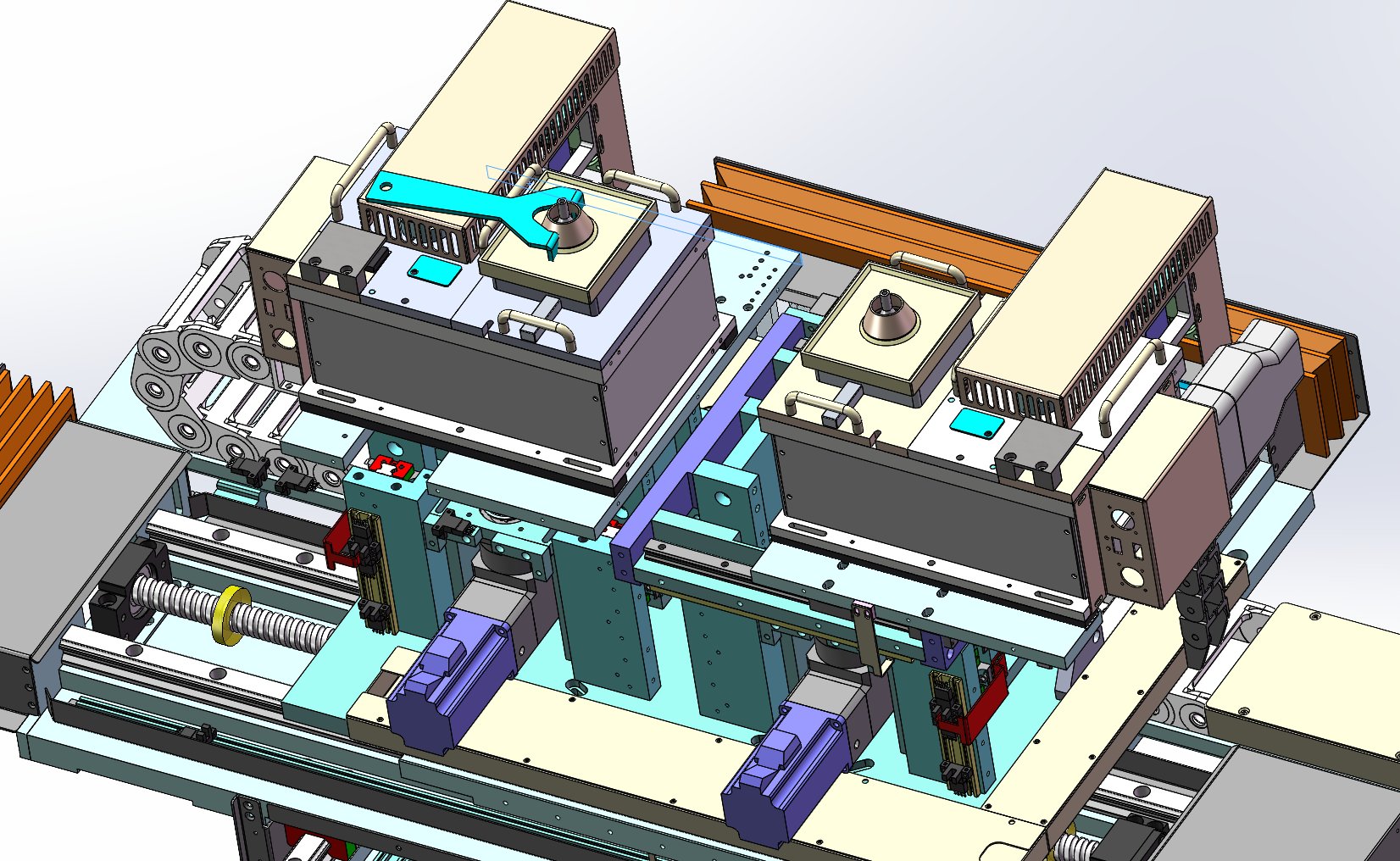

You want a machine that helps you work faster and smarter. The S&M SM-LⅡ Series has advanced features for your production line. This selective wave soldering system uses two platforms. You can move PCBs through the machine with high accuracy. The system uses an industrial computer and a multi-axis motion control card. You get full software control. You can program soldering paths using PCB pictures or GERBER files. This saves you time during setup and changeovers.

The SM-LⅡ Series has an integrated module structure. You can connect it to your production line for real-time data and automatic docking. The machine has a strong transmission system with stepper motors and stainless steel rollers. These features keep your products moving smoothly. They help stop jams or delays. You can use the automatic recipe function to record and recall process settings. This helps you keep your production consistent and efficient.

New advancements in selective wave soldering have made lead times shorter. You can solder certain parts on PCBs quickly and accurately. This method works well for boards that are packed tightly. Other methods may not fit these boards. Automation in the SM-LⅡ Series increases precision and efficiency. You get higher repeatability, even with complex PCBs. The system lets you set time and temperature for each soldering job. You always get the same results.

Precision and Flexibility

You need precision to make sure every joint is strong and reliable. The SM-LⅡ Series gives you high-precision motion control. You can control soldering settings like temperature, time, and crest height. This means you get better hole fill and less risk of defects. The machine reduces thermal fatigue. This is important for safety-critical industries like automotive and aerospace.

Selective wave soldering speeds up your production. The automated process lets you make more products in less time. You get high-quality solder joints without voids or weak spots. The system’s dual platform design lets you handle different products and production volumes. You can switch between jobs quickly. You do not have to wait for long changeovers.

Flexible systems like the SM-LⅡ Series help you adapt to changing demands. You can adjust the soldering process for different PCBs or batch sizes. Advanced fluxing and preheating keep your solder joints strong. This is true even when you change production runs. This flexibility means you do not have to wait longer for your machine to adjust. You keep your lead times short and your output high.

Intelligent Monitoring Benefits

You want to avoid delays and keep your line running. The SM-LⅡ Series uses intelligent monitoring to track key process data in real time. The system checks temperatures, soldering times, nitrogen and air pressure, and spray flow. You can see trends and spot problems before they cause downtime. If something goes wrong, the machine gives you an alarm right away.

Intelligent monitoring helps you plan maintenance before a breakdown happens. You can schedule repairs when it works best for you. This reduces unplanned stops and keeps your production on track. You can also use the data to find the root cause of defects. This helps you fix problems fast and avoid repeating mistakes.

With these features, you get a selective wave soldering solution that supports fast, reliable, and flexible production. You can meet tight deadlines and keep your quality high. The SM-LⅡ Series from S&M gives you the tools you need to stay ahead in today’s fast-moving electronics industry.

Supplier Reliability and Support

S&M’s Industry Credentials

You want a supplier you can trust. S&M is a reliable partner in the SMT industry. The company started in 2000 and has a good reputation. S&M is a national high-tech enterprise in China. The company has won awards for being special and new. S&M is also called an innovative small and medium-sized enterprise. These awards show S&M cares about new ideas and quality. S&M follows strict rules for lead-free process equipment. Many customers in automotive, medical devices, and aerospace pick S&M. They choose S&M because it has a strong record.

Communication and Service

You need clear and quick communication with your supplier. Good communication helps you fix problems fast. It keeps your project on schedule. You should pick suppliers who use good tools for updates. Some companies use email for formal news. They use messaging apps for quick questions. Saks, a digital fashion leader, uses Slack with suppliers. This makes talking faster and easier.

You can use best practices to check how well a supplier talks and responds:

| Beste praktijk | Description |

| ———————————————————————————— | ————————————————————————— |

| Establish Clear Communication Channels | Use tools like email and messaging apps for updates and urgent issues. |

| Set Performance Metrics (KPIs) | Track on-time delivery and service quality to measure supplier performance. |

| Maintain Regular Communication | Talk often, share goals, and give feedback to build a strong relationship. |

You should set key performance indicators to check your supplier. Give feedback often to help your supplier get better.

After-Sales Support

You need strong after-sales support to keep things running. S&M gives technical help, training, and fast service if you have problems. The company helps with installation and teaches you to use the machine. If you need repairs or spare parts, S&M answers quickly. Good after-sales support means less downtime. It helps you finish your work on time. You can trust S&M to help you after you buy and help you do well.

Software and Integration

System Compatibility

You must check if your selective soldering machine fits your SMT line. If the system is compatible, you will not have delays. The S&M SM-LⅡ Series has software that uses common file types like GERBER. This makes it simple to set up soldering paths. You do not need to change files or worry about losing data. The machine can share data with your line in real time. This helps you watch production and find problems early. If your machines use different ways to talk, you might have trouble. Always check if everything works together before buying.

Installation and Training

You want your team to start using the new machine fast. Good installation and training help you get to full production sooner. Training takes a few days and covers key things:

- On day one, you learn what the machine does and how it works. This gives you a good start.

- On day two, you watch demos and try the machine yourself. You can make changes as you go.

- On day three, you learn how to run and care for the machine. You find out how to keep it working well.

Training helps your team know what to do. This means fewer mistakes and more products made. When your team knows the machine, you get the same results each time. Training also lets your team do new jobs and make better products.

Data Integration

You need to link your selective soldering machine to your factory’s data systems. This lets you gather and use production data. Good data integration helps you spot defects and do better work. But you might face some problems:

| Challenge | Description |

| ————————- | ————————————————————————————————————————————————————- |

| Machine Connectivity | Machines from different brands may use different software. |

| Legacy System Integration | Old machines may not connect well to new ones. |

| Human Intervention | Typing data by hand can cause mistakes and slow things down. |

| Limited Visibility | If you do not have real-time data, you cannot see problems fast. |

| Increased Downtime | Bad integration can make machines stop more and lower output. |

| Complex Traceability | Tracking many products and following rules is harder without good data links. |

Plan your steps for connecting systems before you set up the machine. This helps you avoid stops and keeps your line working well.

Logistics and Delivery

Shipping and Import

You need to plan for shipping and import when you order a selective wave soldering machine. Shipping can take a few days or several weeks. The time depends on where you are and where the machine comes from. If you order from S&M in China, you should check the shipping method. Air freight is faster but costs more. Sea freight takes longer but saves money.

Tip: Ask your supplier for a shipping estimate before you place your order.

Customs clearance is another step. You must prepare documents like invoices, packing lists, and import permits. If you miss a document, your machine may get stuck at customs. You can work with a customs broker to help with paperwork. This can save you time and stress.

Here is a simple table to help you track the main steps:

| Step | What You Do | Why It Matters |

| —————– | —————————- | ——————— |

| Choose shipping | Pick air or sea freight | Affects delivery time |

| Prepare documents | Gather all import papers | Avoids customs delays |

| Track shipment | Use tracking tools | Know arrival date |

| Clear customs | Work with a broker if needed | Speeds up release |

On-Site Setup

When your machine arrives, you need to set up everything on site. You should check the delivery for damage right away. If you see any problems, tell the supplier fast. Next, move the machine to the right spot in your factory. Make sure you have enough space and the right power supply.

You will need help from trained staff or the supplier’s team. They will install the machine and connect it to your production line. You should follow the setup guide step by step. This helps you avoid mistakes.

Opmerking: Good setup means your machine works well from the start.

After setup, test the machine with a few PCBs. Check that all functions work. If you find issues, ask for support. S&M offers help with installation and training. This support helps you start production quickly and keeps your lead time short.

Evaluating Lead Times

Requesting Timelines

You should always ask for a clear timeline when you look at selective soldering machines. A good supplier will give you a step-by-step schedule. This schedule should show when they will build, test, ship, and install your machine. You can ask for a Gantt chart or a simple table. This helps you see each step and spot any possible delays. If you do not get a detailed timeline, you may face surprises later.

Tip: Involve your purchasing, engineering, and production teams when you review timelines. Each team can spot different risks.

Comparing Vendors

You need to compare vendors side by side. Make a checklist of what matters most to you. This can include lead time, machine features, support, and price. You can use a table to score each vendor. This makes your choice clear and fair.

- List all vendors you consider.

- Write down their promised lead times.

- Check if they offer after-sales support.

- Look at their reputation and past delivery records.

- Ask for references from other customers.

You can also ask each vendor how they handle delays. A good vendor will have backup plans.

Identifying Risks

Hidden risks can make your lead time longer. You should look for these risks early. Some common problems include excess solder, cracked boards, and copper pad issues. These problems can slow down your project if you do not catch them.

| Issue | Description | How to Spot Early |

| ———————- | ———————————————————– | ————————————– |

| Excess Solder | Solder bridges or balls from bad nitrogen or wrong settings | Watch nitrogen quality and dwell times |

| Cracked Circuit Boards | Boards break from too much heat or not enough preheating | Check temperature and preheating steps |

| Copper Pad Dissolution | Pads melt or lift from poor quality or wrong size | Check pad thickness and solder content |

You should use a checklist to review these risks with your team. When you involve people from different departments, you can find problems faster. This helps you keep your project on track and avoid costly delays.

You should look at things like machine configuration, supplier reliability, and production scheduling when you check lead times. Using a clear plan helps you avoid problems and keeps your SMT projects running well. The table below shows how good lead time management helps your business:

| Benefit | Description |

| —————————— | ————————————————— |

| Improved Customer Satisfaction | You deliver orders faster and keep customers happy. |

| Increased Flexibility | You can react quickly to changes in demand. |

| Reduced Inventory Costs | You keep less stock and save money. |

| Enhanced Cash Flow | You get paid faster by shipping sooner. |

| Competitive Advantage | You stay ahead of other companies. |

| Supply Chain Efficiency | You run your supply chain better and save costs. |

Pick trusted suppliers like S&M to lower risks and help your projects finish on time. Checking lead times carefully helps you build a strong SMT line that works well.

FAQ

How can you reduce the lead time for a selective wave soldering machine?

You can pick a standard model. Decide on your setup early. Work with a trusted supplier like S&M. Planning well helps you avoid waiting. Talking clearly with your supplier stops delays.

What documents do you need for importing a machine?

You need an invoice and a packing list. You also need an import permit. Ask your customs broker if you need more papers. If you forget a document, your shipment may be late.

How does S&M support you after installation?

S&M gives you training and technical help. They offer quick service for repairs and spare parts. You can reach their team for setup help or fixing problems.

Can you customize the SM-LⅡ Series for special projects?

Yes, you can ask for custom features for the SM-LⅡ Series. Customizing can make the wait longer. Talk to S&M early about what you need.

What industries use the SM-LⅡ Series selective wave soldering machine?

The SM-LⅡ Series is used in automotive and aerospace. It is also used in military electronics and medical device factories. The machine is good for hard PCB soldering jobs.