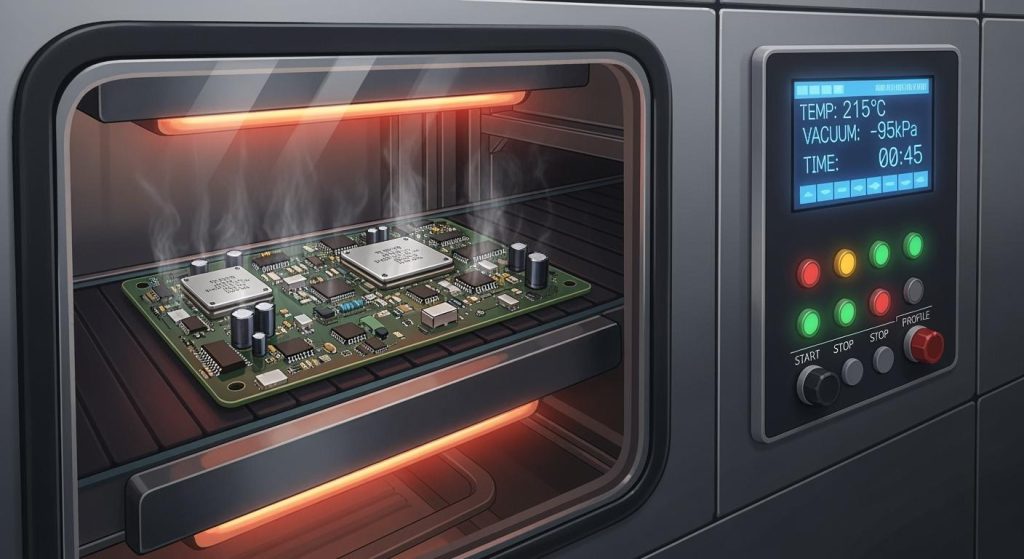

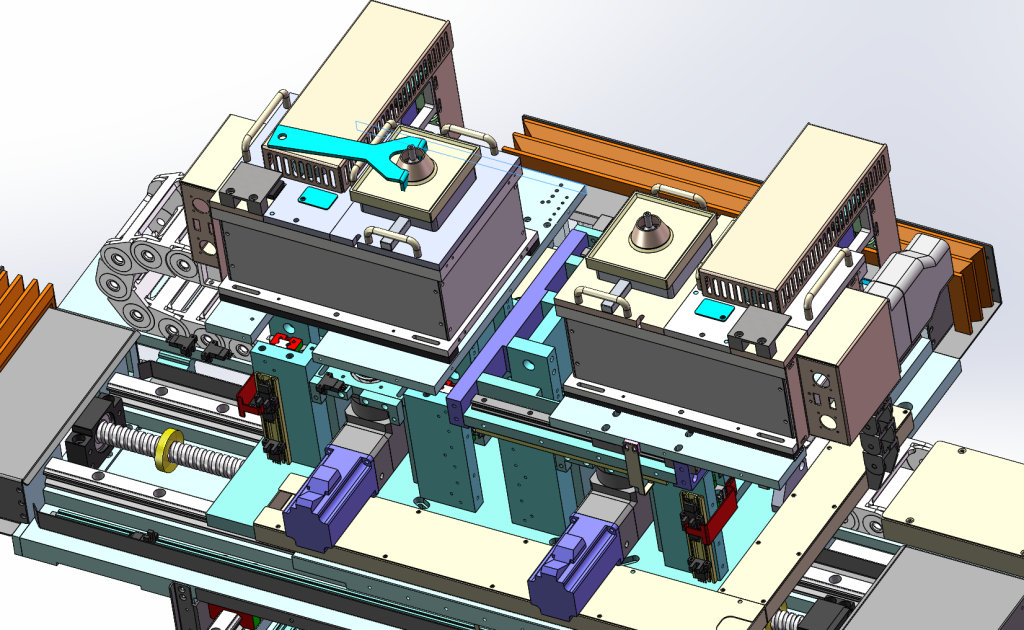

Hoe een vacuüm-reflowoven de betrouwbaarheid bij de productie van printplaten verbetert

De vacuüm-reflowoven-gids vermindert soldeerholtes, zorgt voor een gelijkmatige verwarming en verhoogt de betrouwbaarheid van PCBA's door defecten te minimaliseren en de procescontrole te verbeteren.