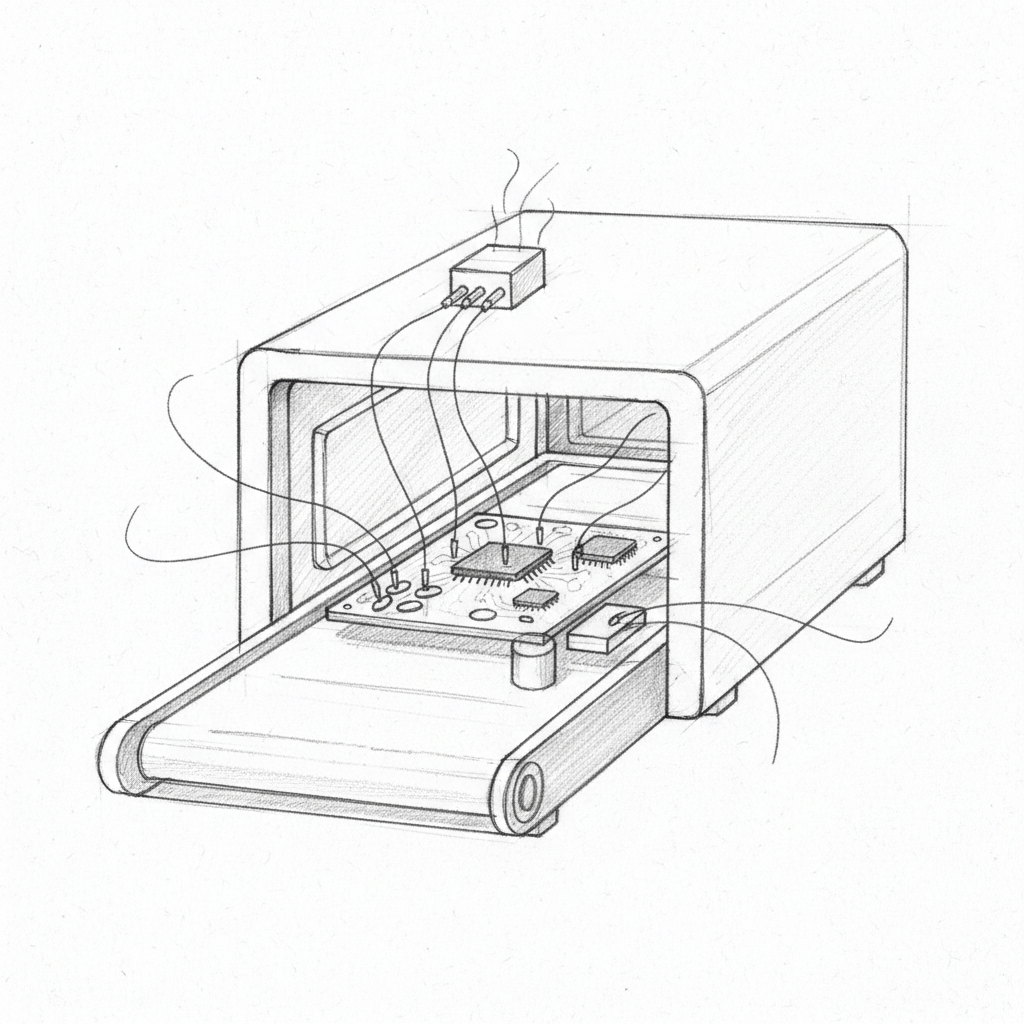

Applications of Reflow Ovens in PCB Manufacturing

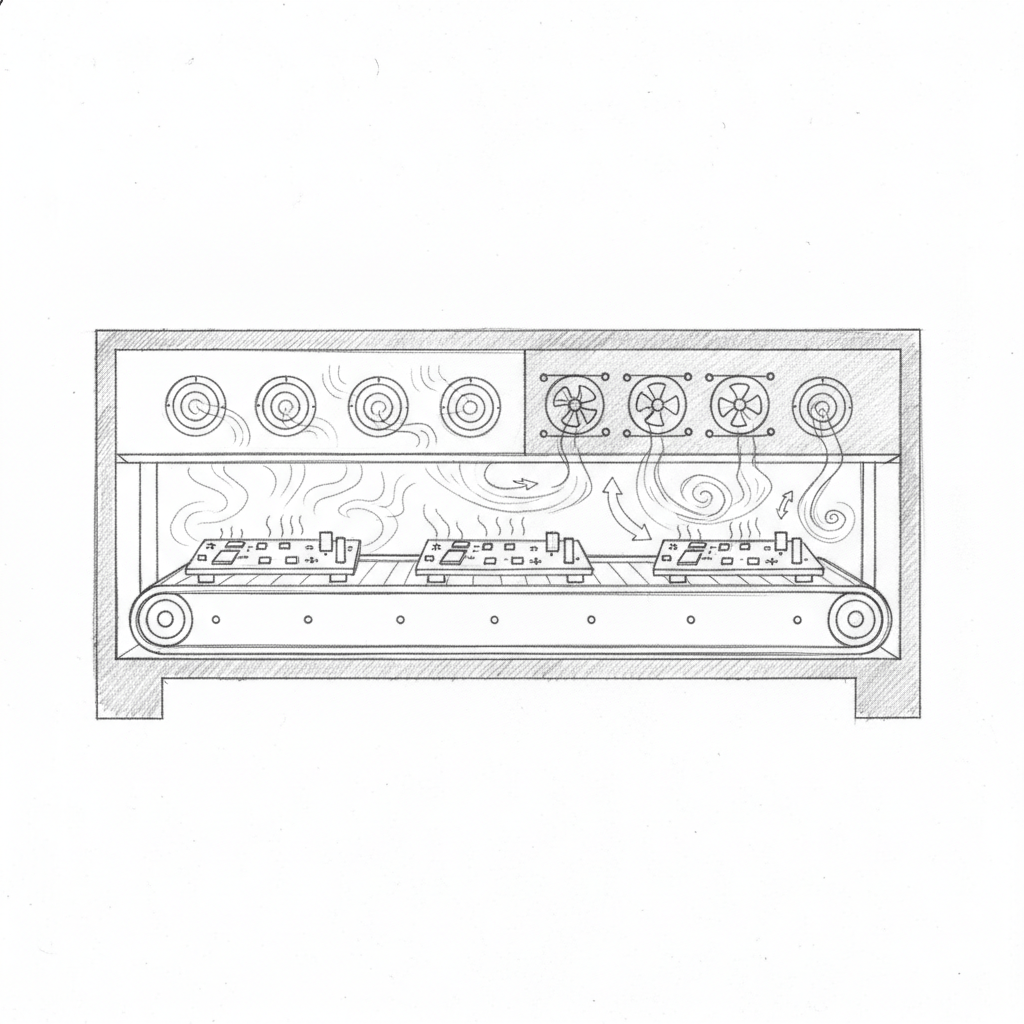

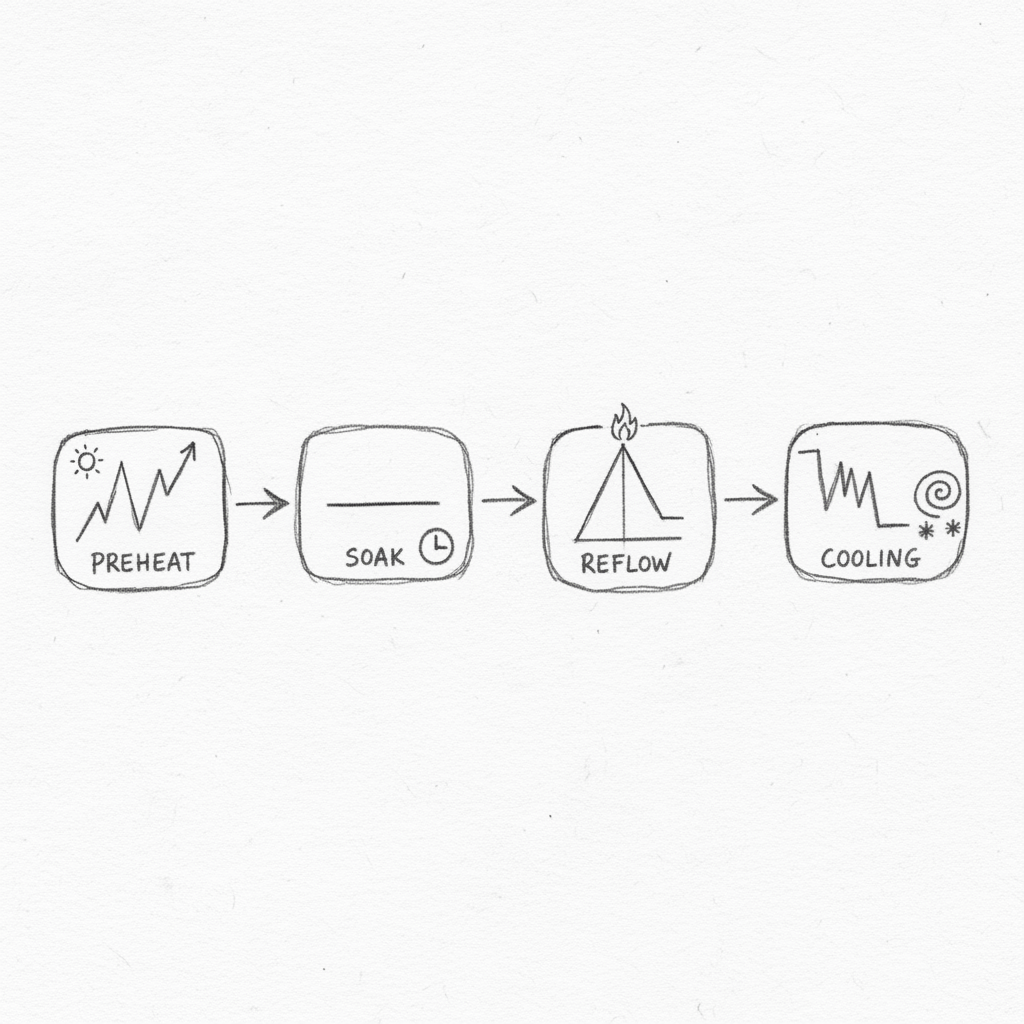

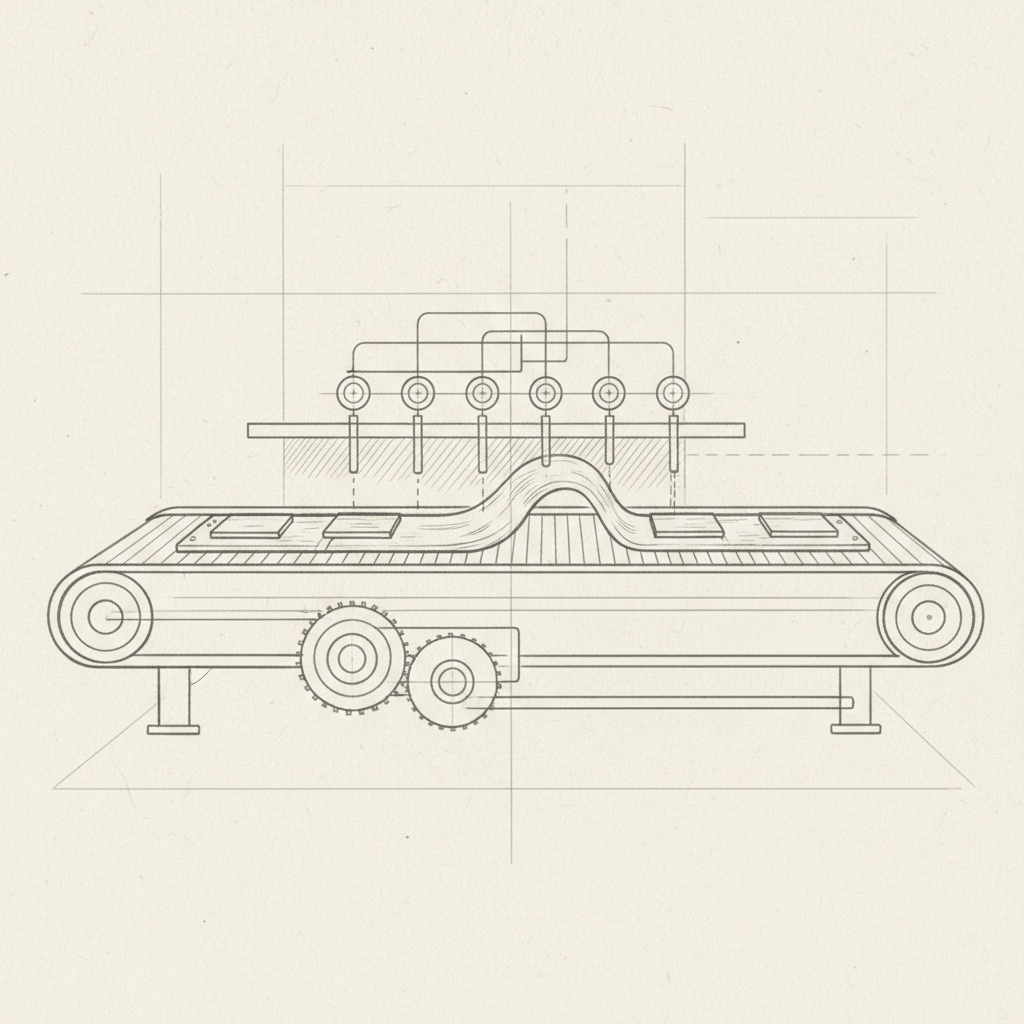

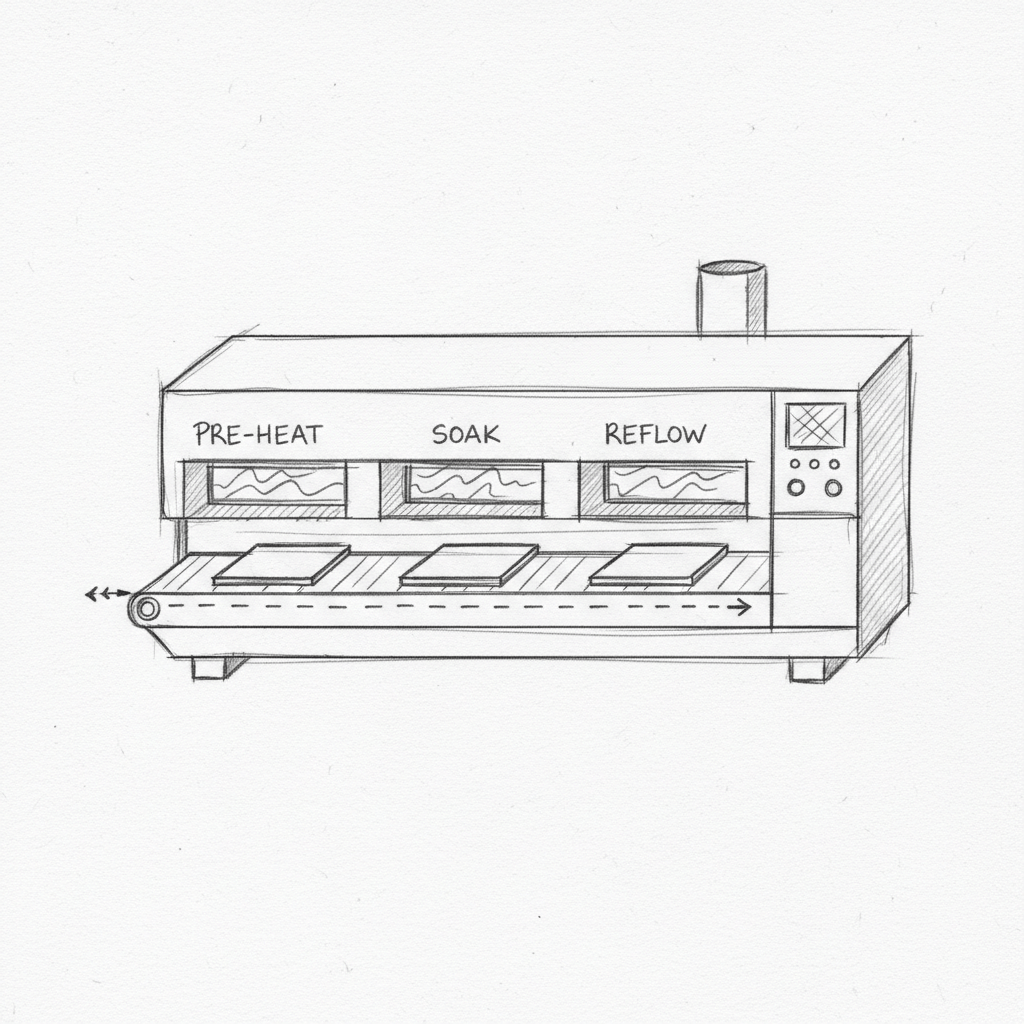

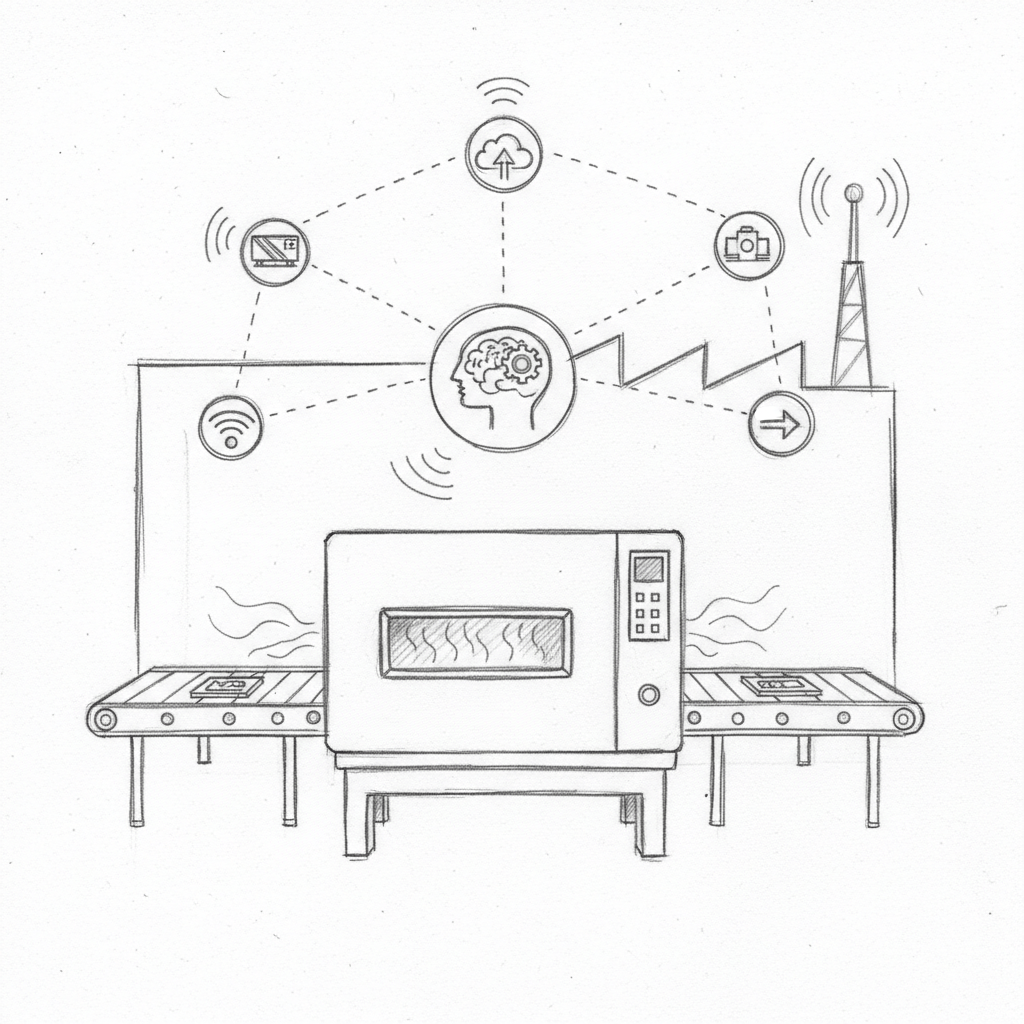

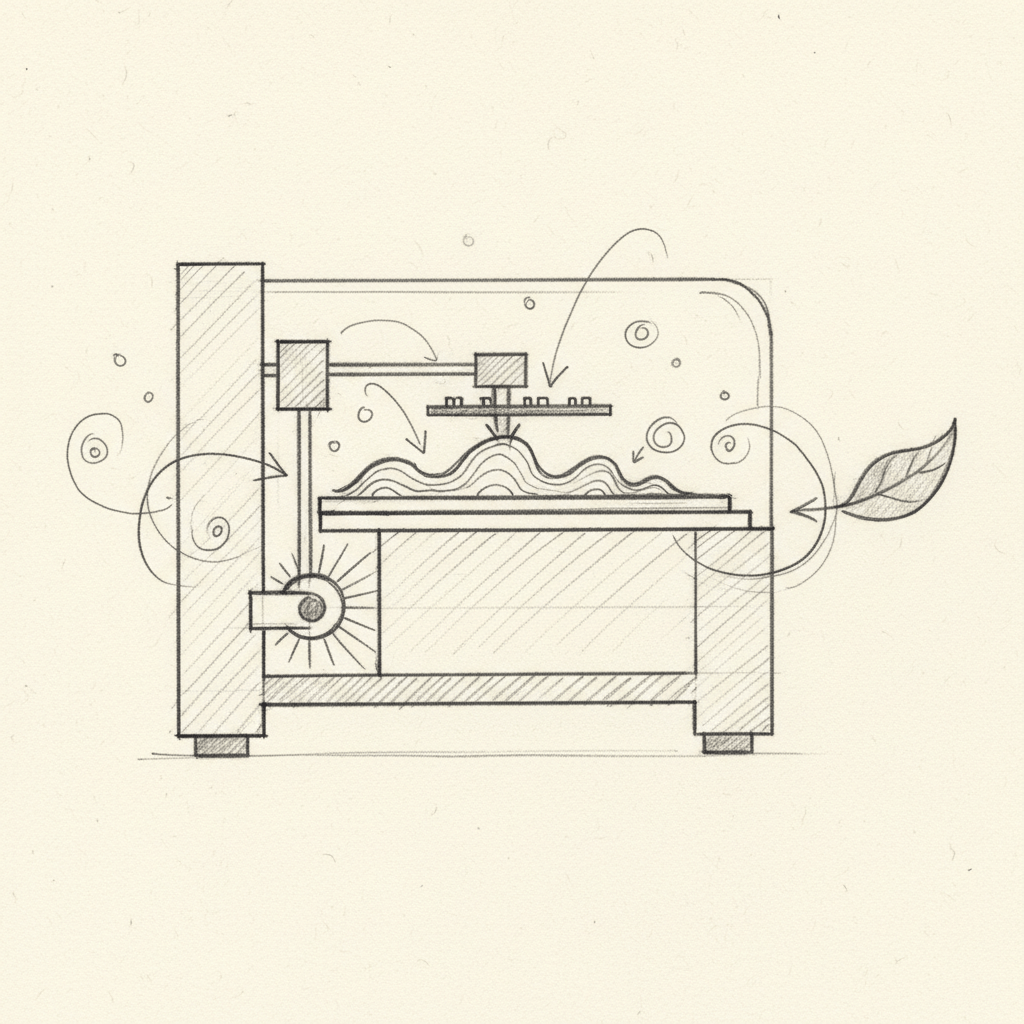

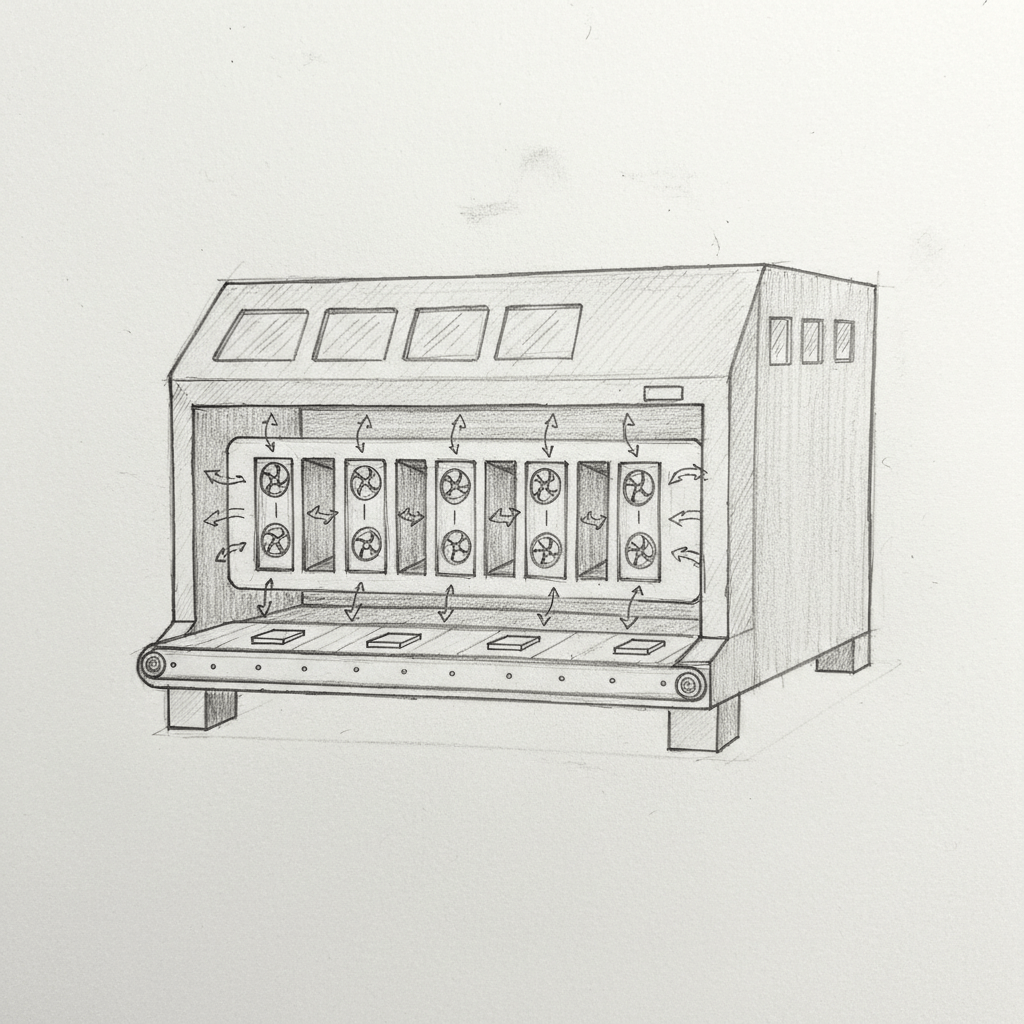

Reflow ovens are essential for soldering surface mount components on printed circuit boards (PCBs). These specialized industrial furnaces utilize controlled heating and cooling processes to melt solder paste, forming reliable electrical and mechanical connections. Reflow ovens operate primarily through convection heating, where recirculating heated air effectively transfers energy uniformly to the assembly. This process adheres to the standards established by the IPC for reflow process control, ensuring the highest levels of quality and consistency in manufacturing.