How to Build a Reliable Reflow Soldering Profile

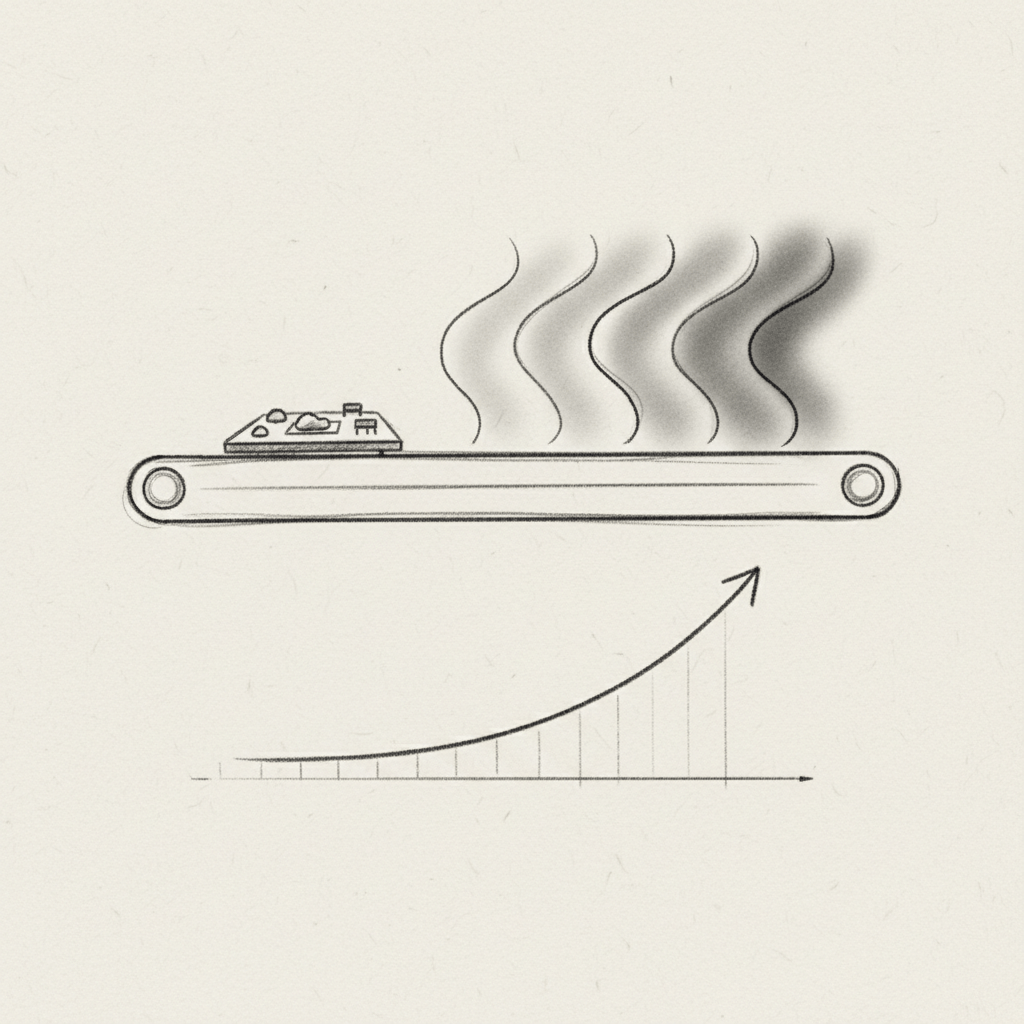

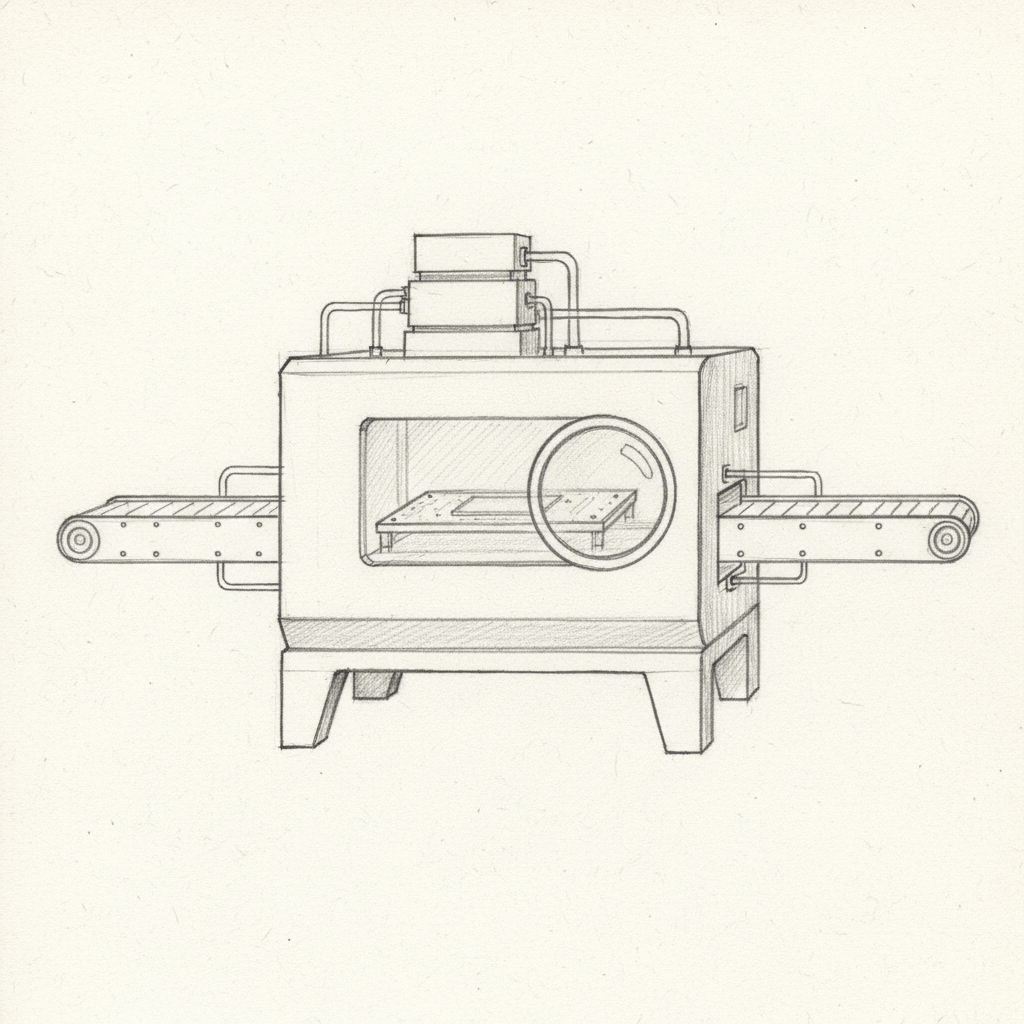

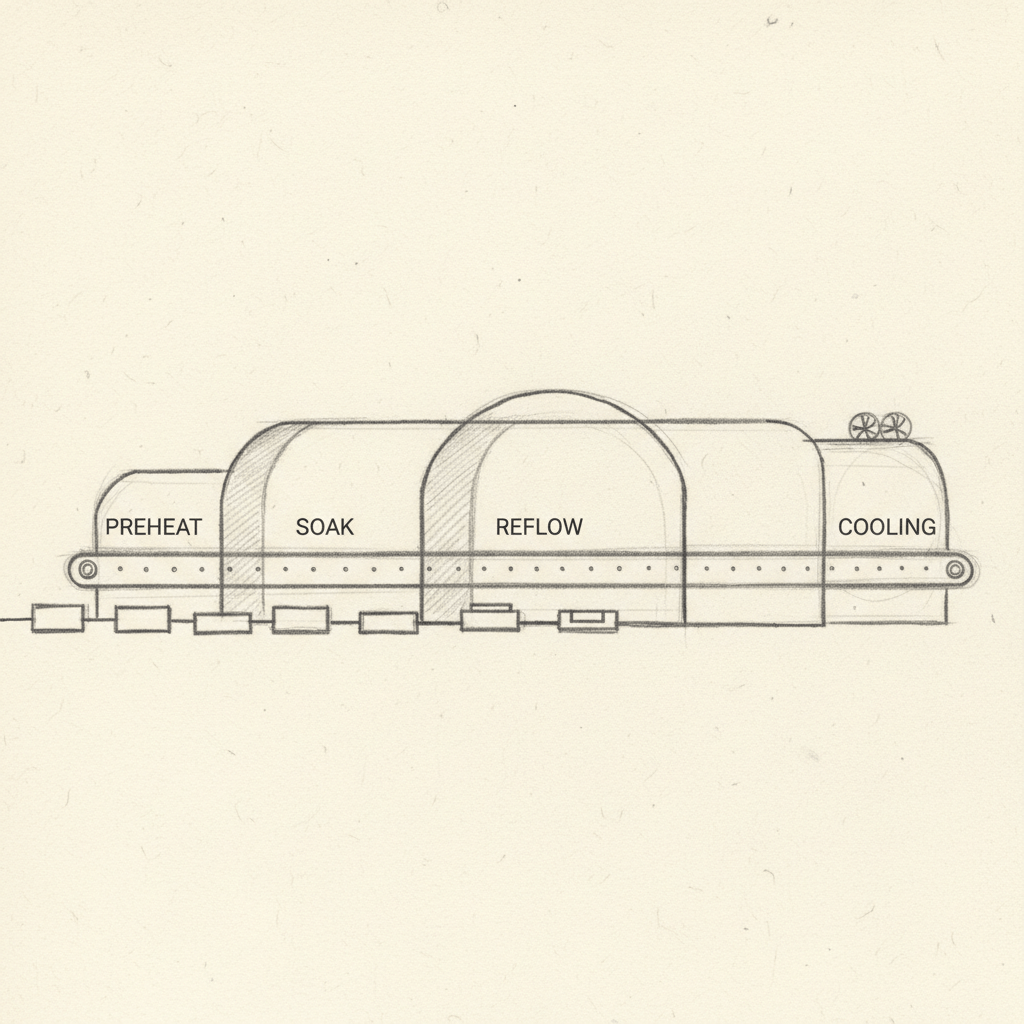

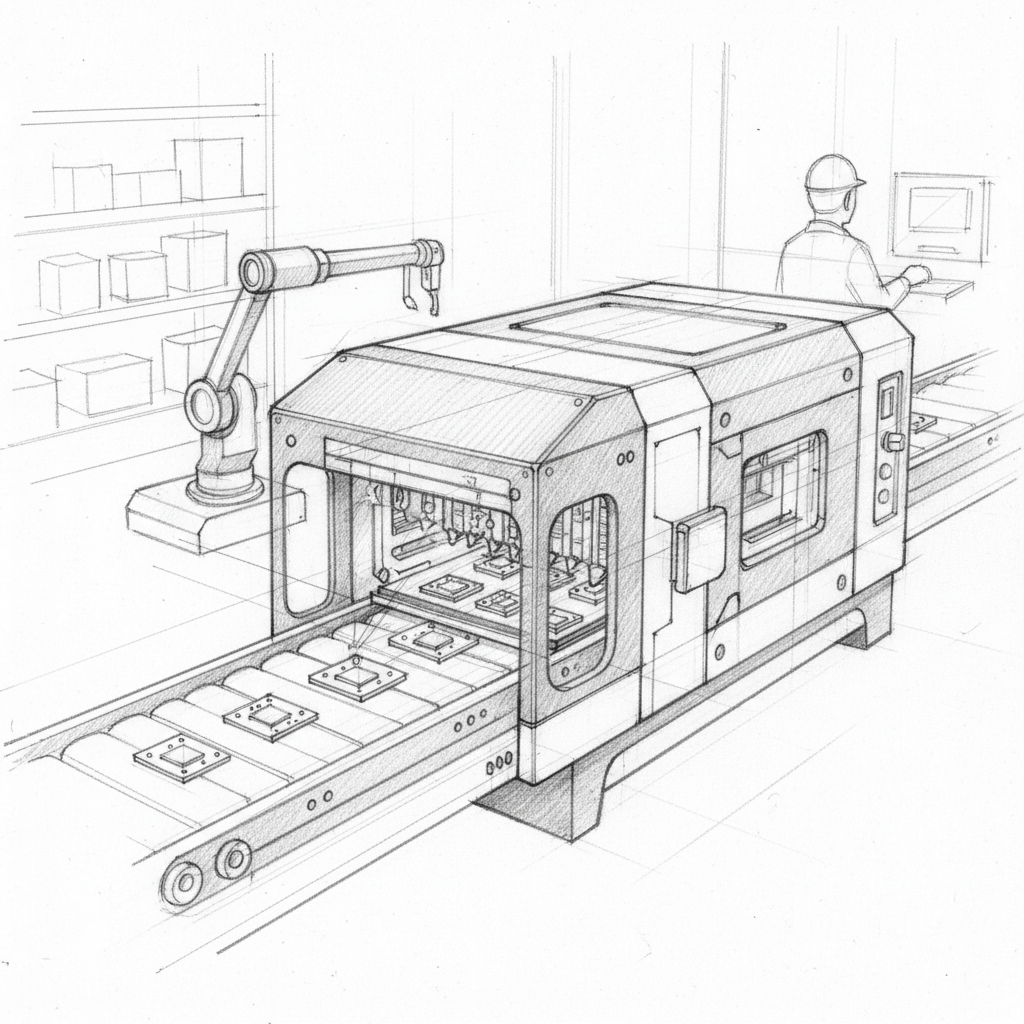

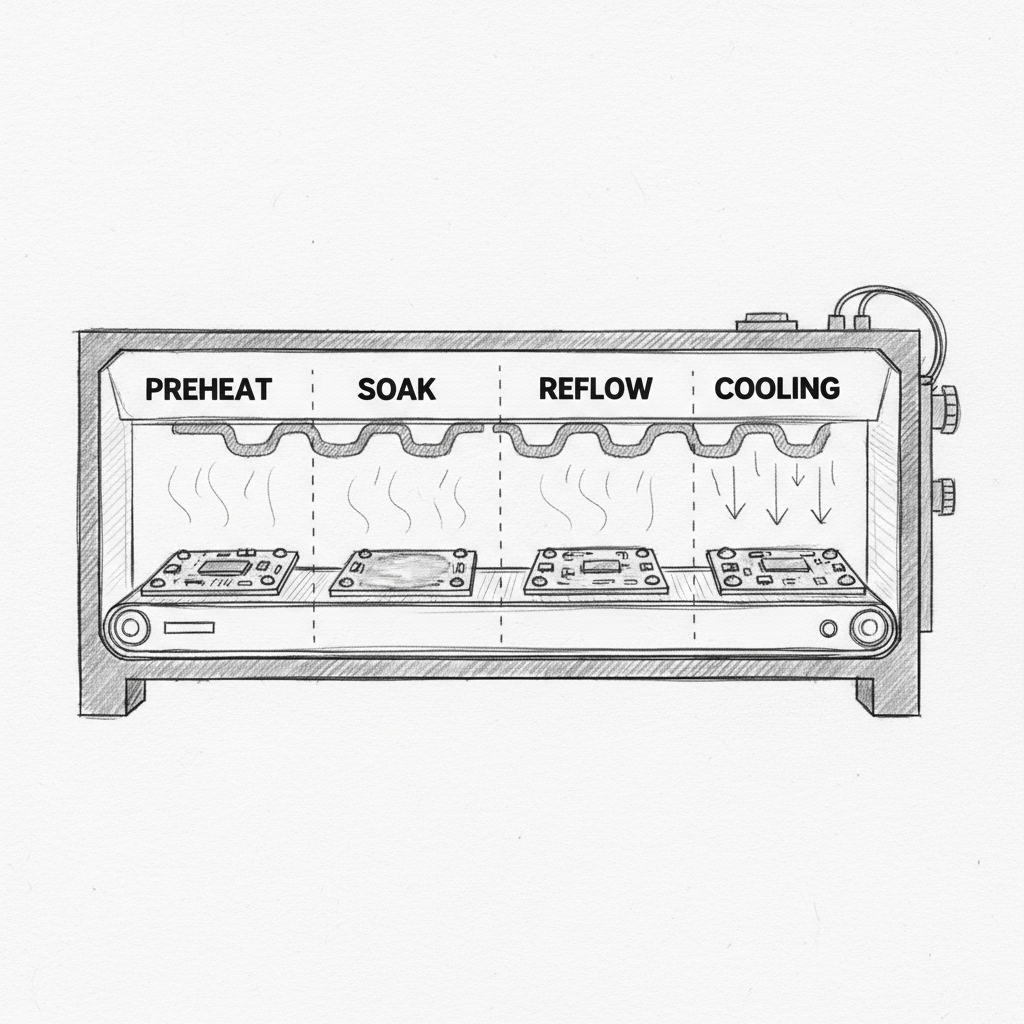

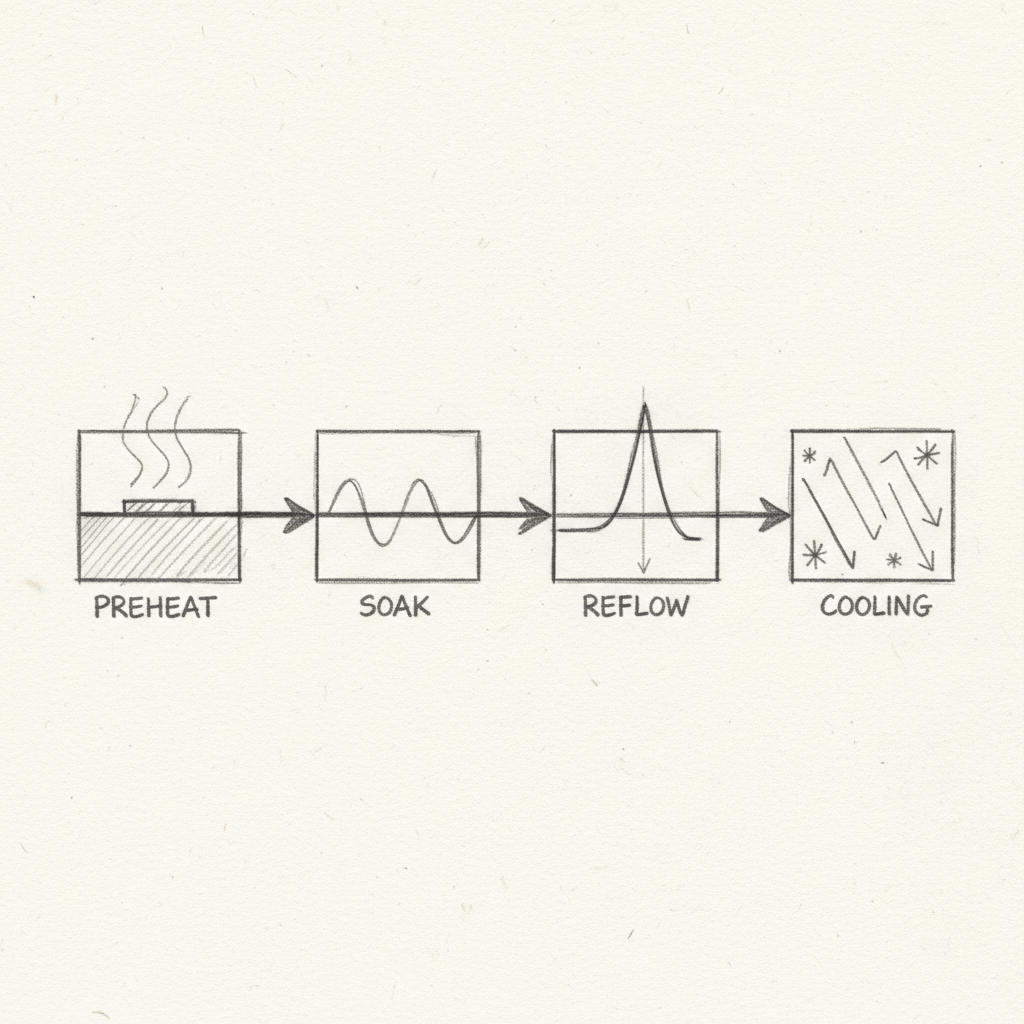

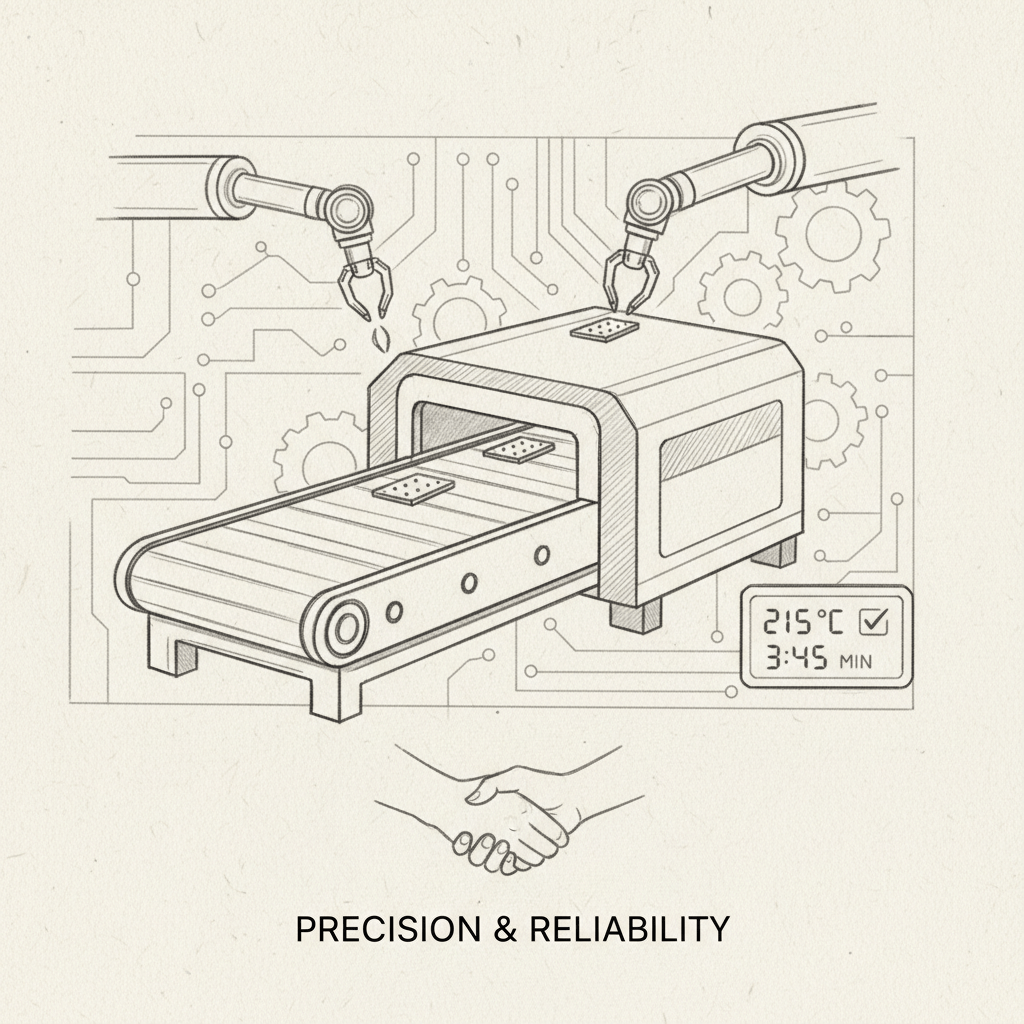

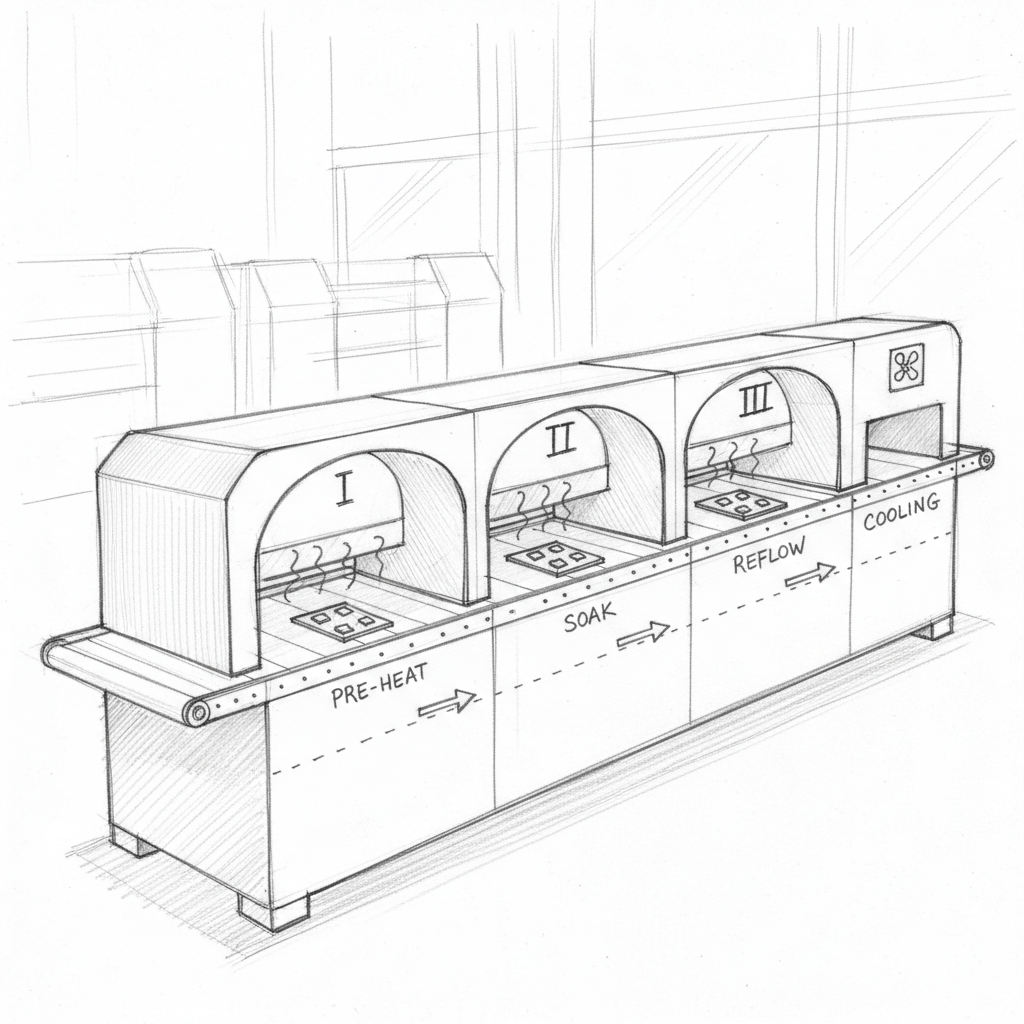

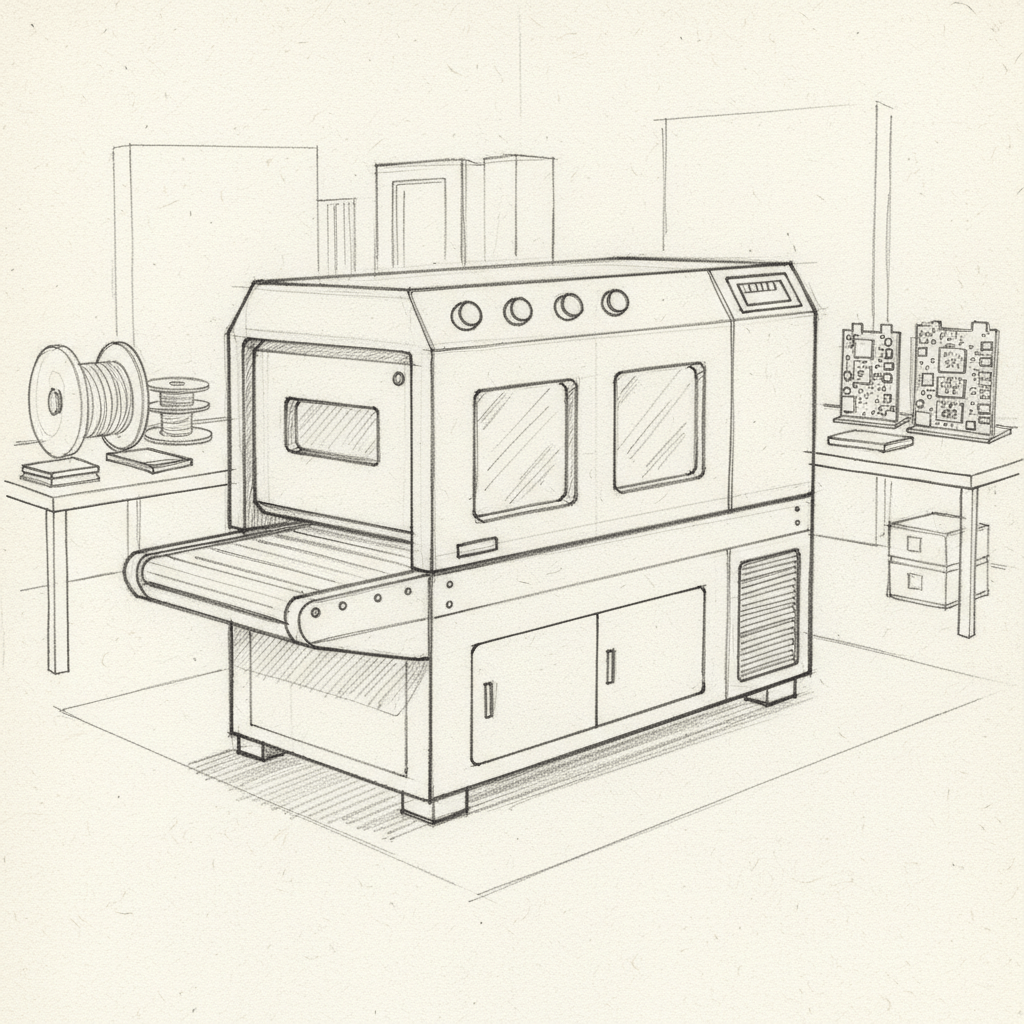

Developing a reliable reflow soldering profile is essential for ensuring the quality of solder joints in electronics manufacturing, requiring meticulous handling of preheat, soak, reflow, and cooling stages. Critical factors affecting the profile include the type of solder paste, PCB design complexity, and component sizes, necessitating precise temperature control and time adjustments. Advanced SMT reflow ovens equipped with automation and smart technologies enhance precision by offering real-time data analytics and predictive profiling. Manufacturers should continuously adapt to technological advancements like AI and machine learning to maintain competitive advantages, ensuring robust solder joints and minimizing defects. Embracing continuous learning and innovative strategies is key for navigating challenges and achieving excellence in the 2026 electronics manufacturing landscape.