Client Introduction

Tiandi Weiye Technology Co., Ltd. was founded in 1994 and is a global provider of intelligent security solutions. With “builder” as its core value, the company is committed to serving artificial intelligence, blockchain, cloud computing, big data, information technology, and other technologies in various fields. With large laser models as the technical foundation, relying on technological innovation and precision quality, it provides the world with intelligent, efficient, and safe security applications.

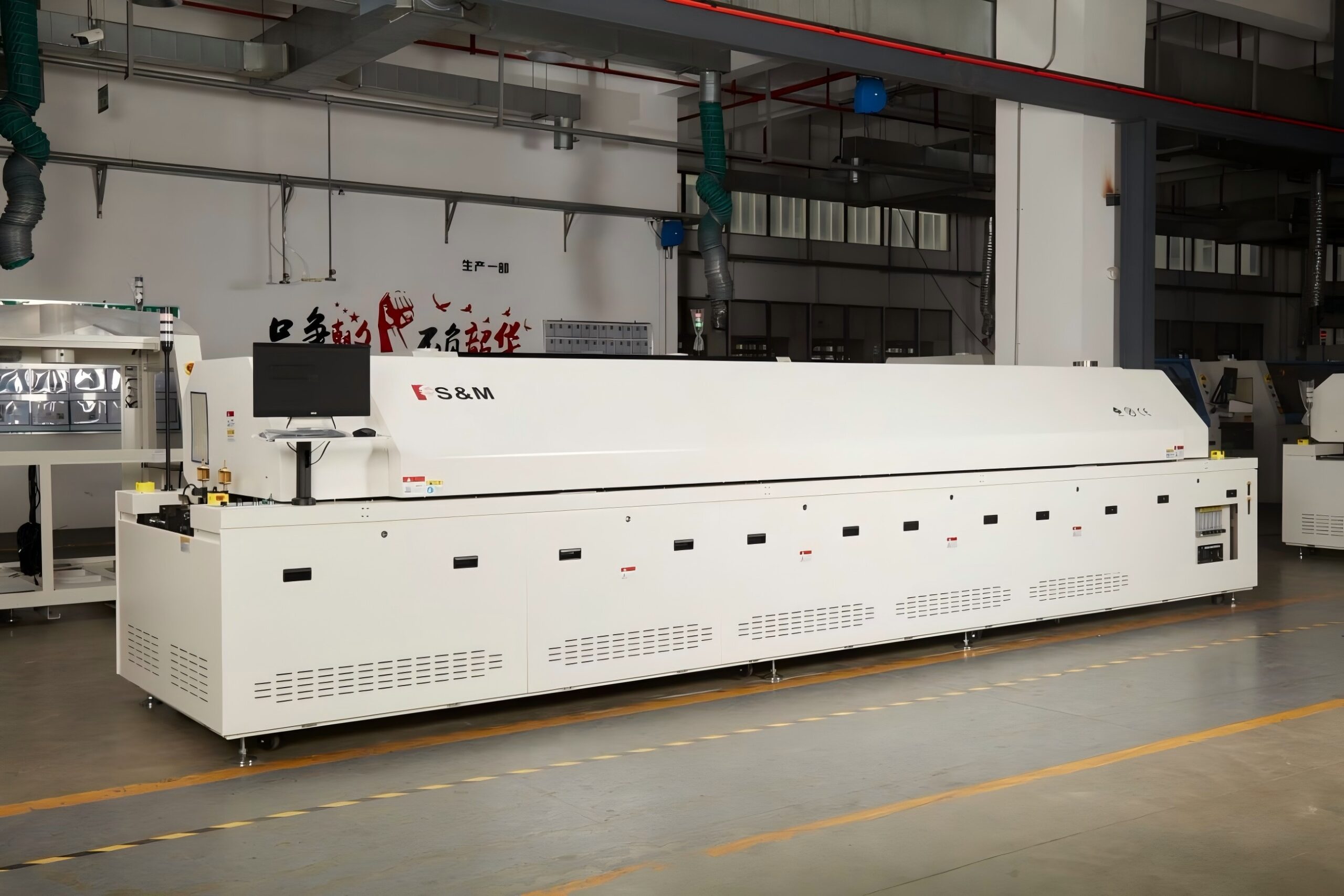

About Equipment

S&M Equipment Features

- Système d'exploitation Windows 10, peut réaliser la commutation libre de l'interface de fonctionnement en chinois et en anglais.

- Contrôle PLC+PID Siemens en boucle fermée pour obtenir un contrôle de température très précis et des profils reproductibles.

- Conception modulaire, entretien pratique et rapide, réduction du temps et des coûts de maintenance.

- La surface du rail est traitée par un processus de durcissement pour la rendre plus stable.

- Fonction d'alarme sonore et lumineuse et de demande d'informations en cas d'anomalies diverses, y compris l'écart de température, l'écart de vitesse, le panneau de retenue et le panneau de chute, l'anomalie du vent, l'erreur de fonctionnement, etc.

- Le nouveau système de gestion des gaz peut améliorer l'efficacité de l'échange de gaz chauds dans le four, afin d'obtenir une meilleure compensation thermique et une meilleure efficacité thermique, et de répondre pleinement aux exigences des différents processus de brasage sans plomb.

Customer workshop

S&M After Sales Team

- Training and Integration: Our experts ensure seamless integration of the new equipment into your existing production line and provide comprehensive training to your staff.

- Our commitment to your success extends beyond the sale. Our after-sales support is designed to keep your SMT line running at peak performance.

- extended warranty Programs: Regular maintenance is crucial for the longevity of your equipment. We offer preventive maintenance programs to minimize downtime.

Equipment Installation

- Install the computer in the reflow oven, install the rosin inlet and outlet, recycle the filter, and the oil tray, power on with UPS, open the oven box, remove the red fixed track bracket on the track, and confirm whether the track has a flared mouth.

- For reflow soldering, it is necessary to confirm that the input voltage is 380V, whether the phase sequence of the customer’s wiring N, R, S, and T is normal, power on the machine for a test, and confirm whether the fan direction and the temperature rise to a constant temperature are normal.

- Debug the process according to customer requirements, debug the process curve to achieve the required state, and test 2PCS boards to confirm whether the board passing effect is normal and whether the signal is normal.

Our Service Highlights

- Perfect Service: Establishing customer satisfaction with our services is the standard concept for testing the quality of our service work.

- High-standard service quality: standardized service process, regular skills training, on-site service order signing

implementation of a customer rating mechanism. - Efficient response speed: Response within 2 hours

On-site processing is within 12 hours within the province and 24 hours outside the province. - High-level service requirements: 7*24 hours all-weather service.