Importance des systèmes de préchauffage et de refroidissement dans les fours de polymérisation SMT

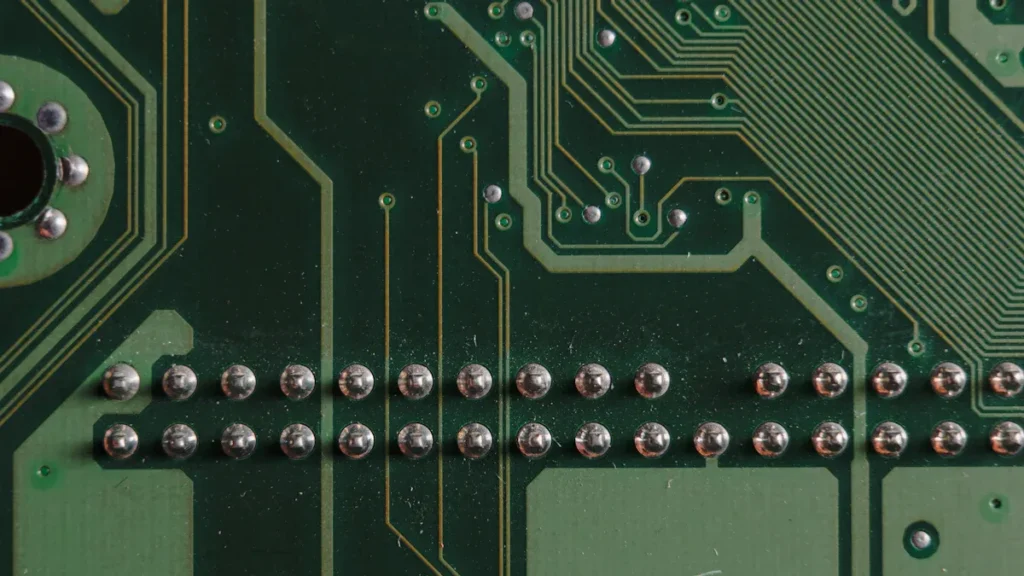

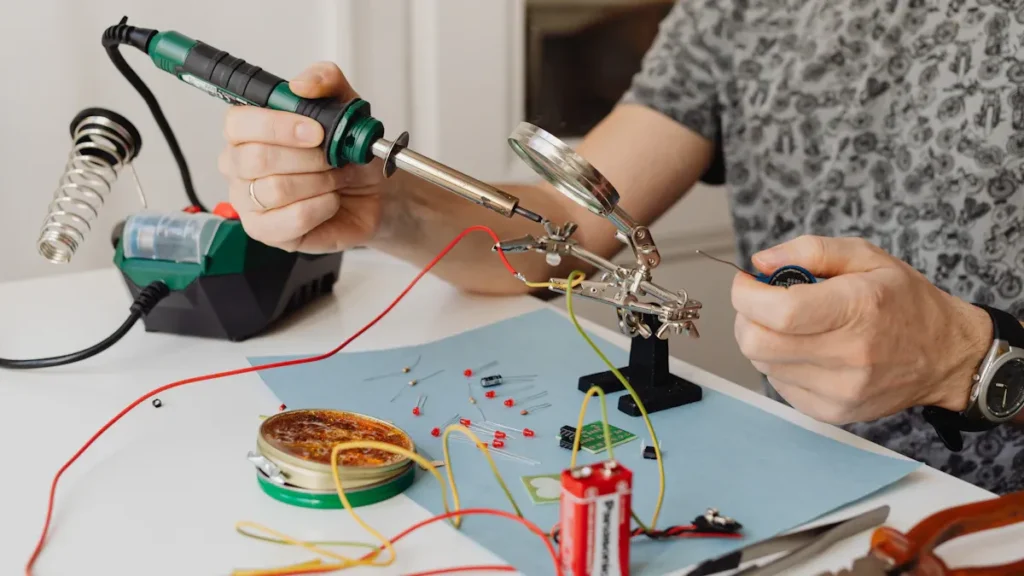

Les systèmes de préchauffage des fours de polymérisation SMT réduisent les chocs thermiques, améliorent la qualité des joints de soudure et renforcent la fiabilité des circuits imprimés grâce à un chauffage et un refroidissement contrôlés.