How PCB Magazines Loader Enhance Production Efficiency

—

## Introduction to PCB Magazines Loader

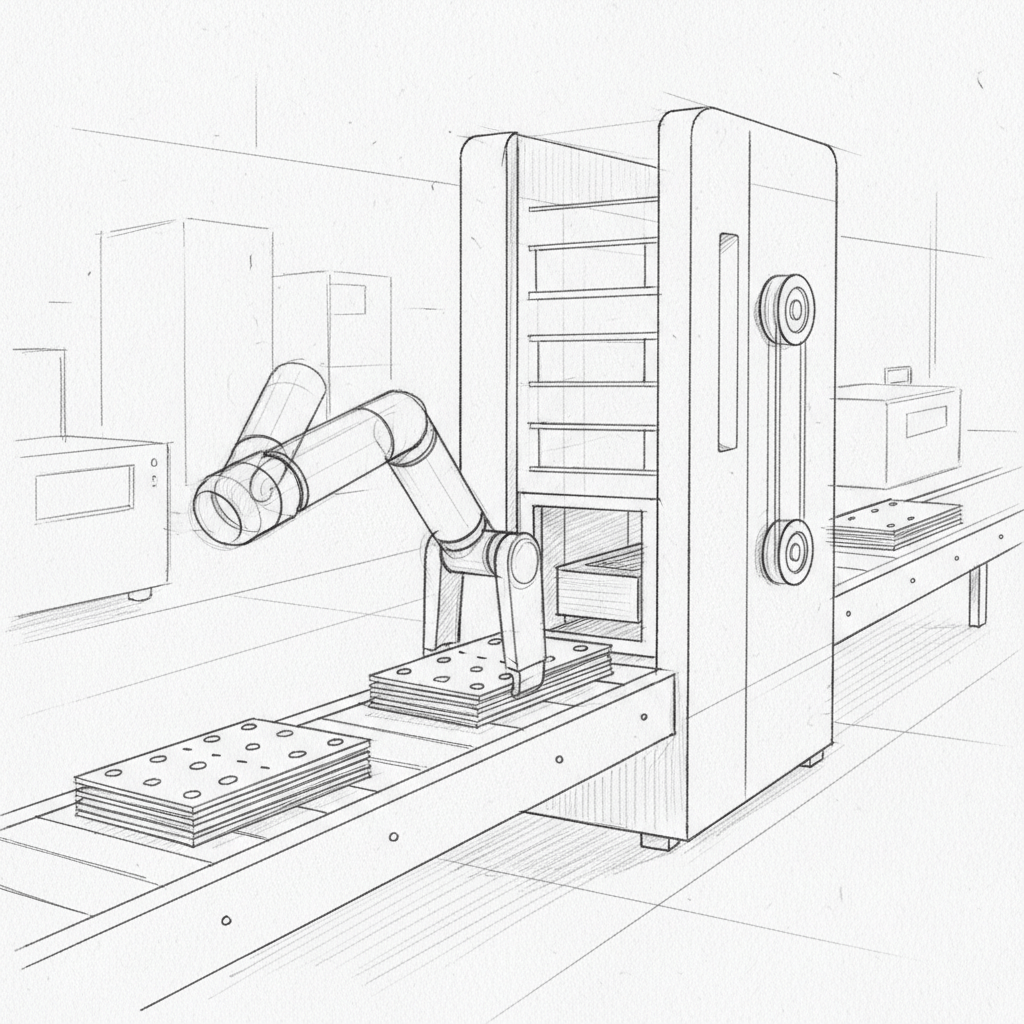

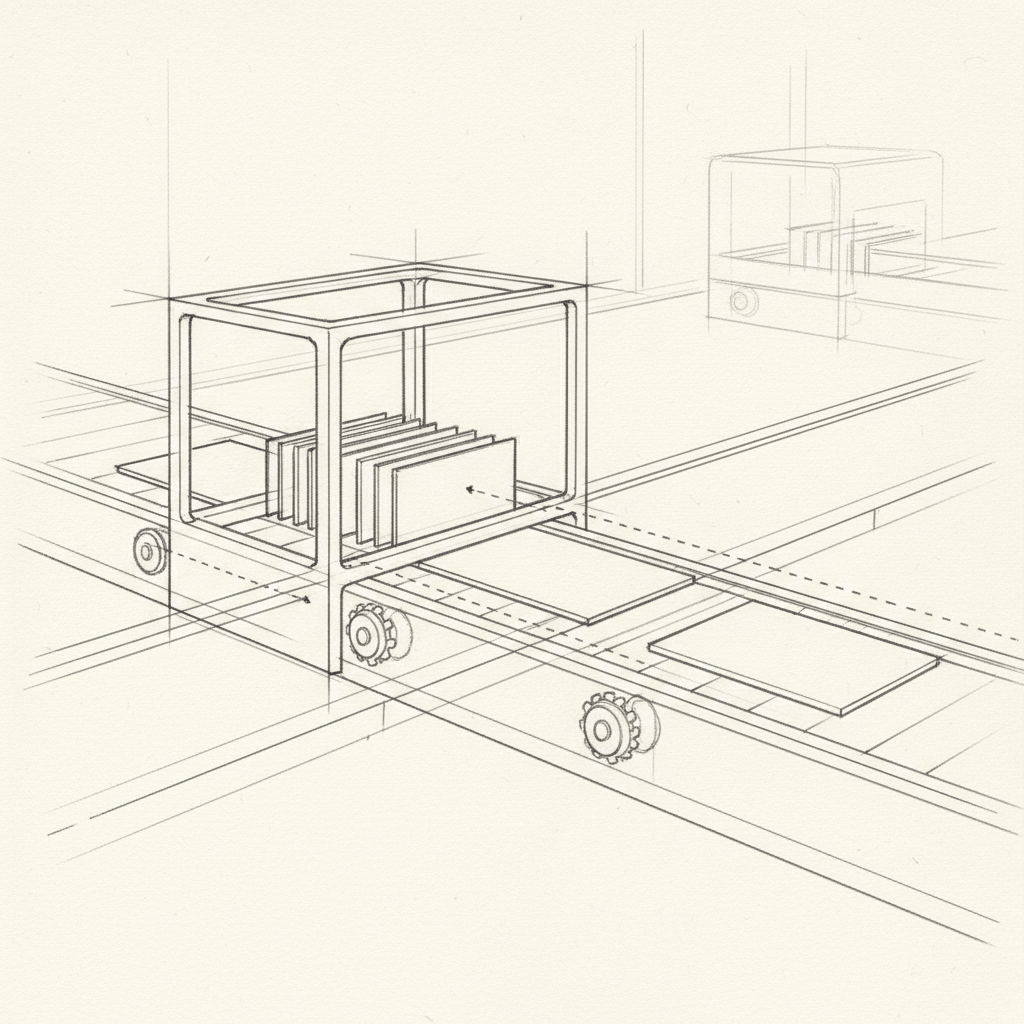

Printed circuit board (PCB) magazines loaders play a pivotal role in optimizing production efficiency within Surface Mount Technology (SMT) equipment. These automated machines are crucial for feeding bare printed circuit boards out of storage magazines and onto SMT production lines, facilitating seamless workflow integration and consistency in operational processes.