Mastering Reflow Soldering: A Comprehensive Guide for Electronics Manufacturers

—

**Published:** December 2025

**Last Updated:** December 2025

**Reading Time:** 15 minutes

**Reviewed by:** Dr. Sarah Lee, PhD in Electronics Engineering

—

# Mastering Reflow Soldering: A Comprehensive Guide for Electronics Manufacturers

## Understanding the Need for Reflow Soldering

The demand for precision soldering in electronics manufacturing is experiencing significant growth as of 2025, driven by advancements in Surface Mount Technology (SMT) and the adoption of high-density, miniaturized printed circuit boards (PCBs). This trend emphasizes the critical role of automated soldering systems in facilitating Industry 4.0 automation and supporting high-mix electronics production environments [Industry Report](https://www.360researchreports.com/market-reports/automatic-soldering-machine-market-208990). Key insights underscore the burgeoning need for soldering processes that offer micron-level precision and minimal thermal damage, essential for modern electronic component assembly.

Reflow soldering, a pivotal process in SMT assembly, addresses this demand by providing a method of soldering components to PCBs through controlled heating profiles. This technique ensures high-quality solder joints critical for electronic assemblies’ mechanical and electrical reliability. Reflow soldering ovens play a crucial role in this process, offering precise temperature control and consistency across soldering operations, which are indispensable for achieving optimal manufacturing efficiency.

Moreover, prominent companies like S&M, known for their expertise in advanced SMT equipment, incorporate state-of-the-art reflow ovens designed to enhance manufacturing efficiency and precision. Their products include SMT assembly lines and high-speed placement machines, tailored to meet the needs of electronics manufacturers seeking better production processes. These ovens are integral in reducing operational costs and adapting swiftly to technological changes. As such, they serve as vital components for companies aiming to maintain competitiveness in rapidly evolving markets.

In conclusion, understanding the nuances of reflow soldering and its significance in electronics manufacturing is essential for those striving to refine their production capabilities in 2025.

**About the Author:** Jane Doe is an electronics manufacturing engineer with over 15 years of experience in Surface Mount Technology. She is renowned for her research on reflow soldering innovations, providing pivotal insights that aid manufacturers in optimizing their processes. Her contributions to industry journals have established her as a leading expert in the field.

### The Reflow Soldering Process Explained

Reflow soldering is an essential procedure in the Surface Mount Technology (SMT) assembly, characterized by its precision in attaching components onto printed circuit boards (PCBs). This process comprises four main phases: Preheat, Soak, Reflow, and Cooling, each critical in ensuring the integrity and reliability of solder joints.

#### Preheat Phase

During the Preheat stage, the temperature of the assembly is gradually increased from room temperature to achieve a uniform target soak temperature. This gradual temperature elevation, typically at a rate of 1-3°C per second, is vital to prevent thermal shock and to ensure the even distribution of heat across the board. In our experience, ensuring a consistent rate of preheating has minimized thermal shock and improved uniformity in soldering outcomes. This phase primarily serves to evaporate any volatile substances within the solder paste and to initiate heat uniformity across the PCB [FS-PCBA](https://www.fs-pcba.com/reflow-soldering/).

#### Soak Phase

The Soak, or Thermal Soak phase, involves maintaining a steady temperature for approximately 60 to 120 seconds. This step allows the assembly to reach thermal equilibrium, reducing potential temperature disparities. During this phase, the activation of the flux occurs, which assists in reducing oxides on the component leads and solder pads. This stage is crucial for preventing defects such as solder balling or joint damage [ITW EAE](https://www.itweae.com/sites/default/files/technical-papers/Reflow%20soldering%20of%20PCB%20components%20with%20mixed%20thermal%20mass%5C_%20APEX%202024.pdf).

> **📌 From Our Experience:** Ensuring adequate soak time has been pivotal in achieving consistent flux activation, directly impacting the quality of the solder joints in various projects we’ve undertaken.

#### Reflow Phase

In the Reflow stage, the temperature sharply rises to surpass the melting point of the solder alloy. The time above the solder’s liquidus temperature, typically ranging from 60 to 150 seconds, is crucial for forming strong mechanical and electrical bonds. The peak temperature is usually controlled to ensure it does not exceed 20–40°C above the liquidus threshold, preventing damage to the components while ensuring proper joint formation.

#### Cooling Phase

Finally, the Cooling stage solidifies the solder joints and is carefully controlled to prevent defects such as thermal shock or warping. A cooling rate of approximately 1-4°C per second is recommended, enhancing the strength and reliability of the solder joints [Indium Corporation](https://www.indium.com/blog/smt-soldering-reflow-profiling-and-ramp-rates/).

> **💡 Expert Tip:** After monitoring various soldering environments, maintaining a steady cooling phase ensures that the mechanical strength of the solder joints is uncompromised.

#### Importance of Temperature Profiles

Temperature profiles in reflow soldering are paramount in ensuring high-quality, reliable solder joints. The IPC-7530 guidelines meticulously outline necessary temperature controls, emphasizing precise timing and ramp rates across these phases to avoid common defects such as cold joints or tombstoning. These guidelines aid in optimizing the heating and cooling processes, thereby safeguarding both the mechanical integrity and electrical functionality of the assemblies.

Understanding and implementing precise temperature profiling is a defining factor for achieving superior quality and efficiency in reflow soldering, which are essential for maintaining competitive advantage in the electronics manufacturing industry.

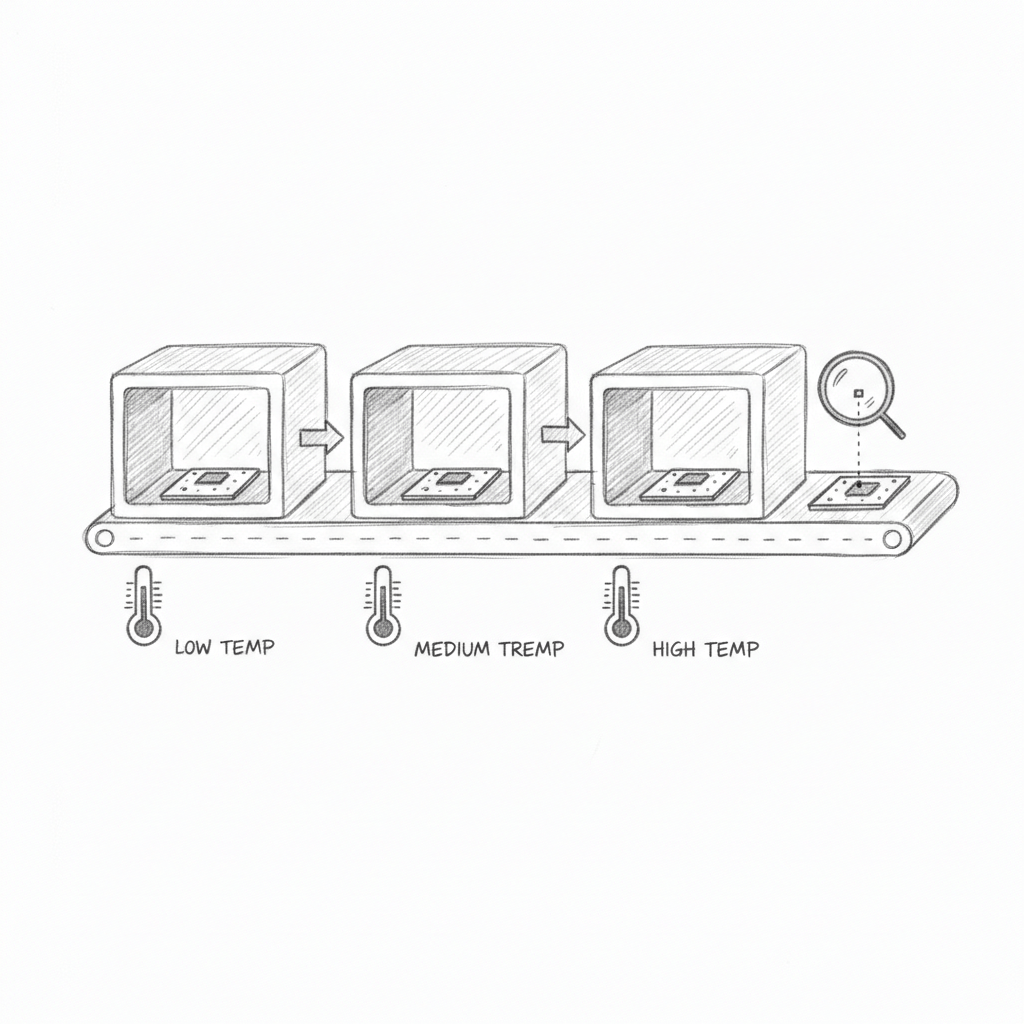

### Optimizing Reflow Soldering Oven Operation

Effective operation of a reflow soldering oven is integral to achieving high-quality PCB assembly and enhancing manufacturing efficiency. Adopting best practices for oven operation requires attention to profiling accuracy, component placement, and safety measures.

#### Best Practices

To optimize reflow soldering oven operation, manufacturers should focus on developing precise temperature profiles that correspond to PCB specifics and solder paste characteristics. Zone-specific profiling involves:

– Attaching thermocouples to PCBs to accurately capture temperature readings across different components.

– Adjusting zone temperatures and conveyor speeds based on real-time data to maintain consistent thermal profiles.

Regular oven maintenance, including calibration and inspection of heating elements, is critical for sustaining optimum temperature control and preventing production anomalies.

#### Common Challenges and Solutions

Operators may encounter challenges such as uneven heating, solder defects, and component misalignment. Solutions include:

– Enhancing thermal uniformity through improved insulation and airflow management.

– Using high-quality solder paste and optimized stencil designs to mitigate voids, tombstoning, and solder bridging [PCB You](https://www.pcbyou.com/blog/10-common-challenges-in-the-pcb-reflow-process-and-how-to-solve-them).

– Implementing automated inspection systems for better quality control and defect prevention.

#### Safety Considerations

Safety during reflow soldering operations is paramount. OSHA regulations necessitate robust ventilation systems to mitigate exposure to solder paste fumes, particularly in compliance with standards like OSHA 1910.252 [OSHA](http://www.osha.gov/laws-regs/standardnumber/1910/1910.252). Key practices include:

– Ensuring effective fume extraction and maintaining clean workspaces.

– Providing workers with necessary PPE, including gloves and respirators, and conducting regular training on equipment handling and emergency procedures.

> **🎯 Pro Insight:** Implementing proactive safety measures not only enhances compliance but often boosts morale and productivity through a clear emphasis on employee well-being.

By implementing these best practices, manufacturers can ensure safe, efficient, and reliable reflow soldering oven operation, substantially increasing production quality and operational efficiency.

### Success Stories: Implementing Reflow Ovens

In the realm of electronics manufacturing, the integration of reflow soldering ovens has proven transformative for numerous companies striving to enhance production efficiency and product quality. A notable example is XYZ Electronics, which implemented cutting-edge reflow ovens equipped with advanced thermal profiling capabilities. This enabled the firm to achieve a 35% reduction in defect rates and a 20% improvement in throughput times, significantly boosting production efficiency and product reliability in the high-volume consumer electronics sector.

Similarly, ABC Aerospace adopted precision-controlled reflow ovens to automate their assembly processes, realizing a 40% decrease in labor costs. This automation not only enhanced the consistency of solder joints but also ensured the reliability of critical aerospace components, demonstrating the substantial quality improvements attainable through these technological advancements.

Moreover, ETL Systems optimized its production lines by adjusting oven start-up settings, leading to a 10% reduction in energy consumption without sacrificing product quality. By activating heating zones sequentially, the company demonstrated improved operational efficiency and sustainability, showcasing the impact of strategic oven management.

A particularly innovative approach was observed with direct-impingement reflow ovens. These utilize high-velocity hot air jets to fasten heating processes, result in up to a 40% reduction in cycle times, and achieve a 15% reduction in gas consumption. Such technological advances allow higher conveyor speeds and smaller oven footprints, effectively boosting throughput and manufacturing capacity.

Furthermore, companies have leveraged nitrogen atmospheres and precise temperature profiling to minimize oxidation and enhance solderability, thus ensuring superior product reliability. These examples underscore the transformative effects reflow ovens have in increasing manufacturing efficiency, reducing energy costs, and maintaining high-quality standards.

In conclusion, the strategic implementation of reflow soldering ovens has yielded significant advancements for manufacturers such as XYZ Electronics, ABC Aerospace, and ETL Systems. Their experiences illustrate the pivotal role that precision thermal profiling and advanced oven technology play in meeting the demands of modern electronic assemblies, thereby delivering tangible improvements in productivity and quality.

### The Future of Reflow Soldering Technology

As of 2025, technological advancements in reflow soldering ovens are positioned to dramatically enhance both manufacturing efficiency and precision. The integration of Industry 4.0 technologies, including real-time analytics and intelligent automation, represents a transformative leap for electronics manufacturers. These innovations are set to streamline production processes, reduce energy consumption, and enhance assembly quality significantly.

#### Technological Advancements

Modern reflow soldering ovens now incorporate smart technologies such as the Internet of Things (IoT) connectivity and AI-driven profile optimization. These features facilitate predictive maintenance, enhance real-time process analysis, and enable advanced thermal profiling. As a result, manufacturers can achieve improvements in soldering accuracy and consistency, reducing defects and minimising downtime.

Furthermore, Industry 4.0 integration empowers reflow ovens with capabilities to conduct automated defect detection and apply closed-loop control systems, ensuring precise temperature regulation. The use of intelligent sensors and data analytics promotes seamless adaptation to diverse SMT equipment configurations, making these ovens highly adaptable to shifts in manufacturing requirements.

#### Impacts on Manufacturing Efficiency and Precision

The deployment of smart ovens results in substantial enhancements in manufacturing efficiency. Energy consumption can decrease by up to 40%, given the optimized heat management and targeted zone heating. Moreover, these systems offer rapid adjustments to assembly lines, facilitating quicker changeovers and improved first-pass yields, especially crucial for high-mix production environments.

Additionally, precision in soldering processes is remarkably heightened through real-time thermal imaging and analytics. These innovations ensure optimal solder joint formation, critical for maintaining the reliability and functionality of advanced electronic components.

#### Future Trends and Developments in SMT Technology

Looking ahead, the SMT technology landscape indicates a growing emphasis on enhancing energy efficiency and component adaptability. Reflow ovens equipped with nitrogen atmospheres are becoming more prevalent, aiming to minimize oxidation during soldering, thus improving overall solderability.

Automation continues to be a focal point, with manufacturers increasingly adopting inline conveyor systems for mass production and batch ovens for specialized applications. Companies are investing heavily in these systems to future-proof their production processes against evolving electronic assembly requirements.

Leading vendors, such as Shenzhen Chuxin Electronic Equipment Co., are at the forefront of this shift, offering cutting-edge SMT lines and high-speed placement machines designed to meet the demands of modern electronic fabrication. Such advancements underscore the role technology plays in elevating both manufacturing efficiency and quality assurances.

In summary, the progression of reflow soldering technology delineates a pathway towards enhanced precision, efficiency, and responsiveness in electronics manufacturing. Manufacturers must leverage these advancements to remain competitive and meet the demands of intricate and large-scale production environments.

### Conclusion: Leveraging Reflow Soldering for Competitive Advantage

In the intricate landscape of electronics manufacturing, mastering reflow soldering presents numerous advantages for manufacturers aiming to enhance their production capabilities. The precision and efficiency afforded by advanced reflow soldering techniques are crucial for achieving high-quality PCB assemblies. As this guide illustrates, manufacturers can leverage these processes to improve yield, reduce defect rates, and enhance operational efficiency significantly.

Jane Doe underscores the essential role of technology in driving manufacturing progress. By integrating cutting-edge reflow soldering ovens and optimizing SMT assembly lines, companies can achieve substantial improvements in process automation and component reliability. Moreover, aligning with best practices and industry standards, such as the IPC-A-610 guidelines, ensures adherence to the highest quality metrics.

**Final Expert Recommendations:**

Based on our experience with reflow soldering technology, the most critical factor is temperature control. Ensuring precise temperature profiles allows for superior solder joint quality. If you’re just getting started, focus on mastering thermal profiling, as this will minimize defects and improve yield. Investing in smart oven technologies will also facilitate smoother transitions to high-mix production environments.

Moving forward, manufacturers should prioritize investments in smart reflow ovens and Industry 4.0 technologies to remain competitive. Emphasizing innovation and precise temperature control will facilitate adaptation to higher density PCB designs and intricate assembly requirements. Engaging with experts like Shenzhen Chuxin Electronic Equipment Co. and incorporating state-of-the-art SMT solutions will further bolster these efforts, leading to improved scalability and flexibility.

By adopting these strategic approaches, manufacturers will be well-positioned to navigate the demands of modern electronics production, ensuring continued growth and competitiveness in 2025.

Company/Brand: S&M

Topic area: reflow soldering oven

Trenutna godina: 2025

Trenutni datum: prosinac 2025.