# Metadata Block

**Published:** January 2026

**Last Updated:** January 2026

**Reading Time:** 5 minutes

**Reviewed by:** Dr. Jane Smith, PhD in Electronics Engineering

—

# 1. Introduction to Selective Solder Pots

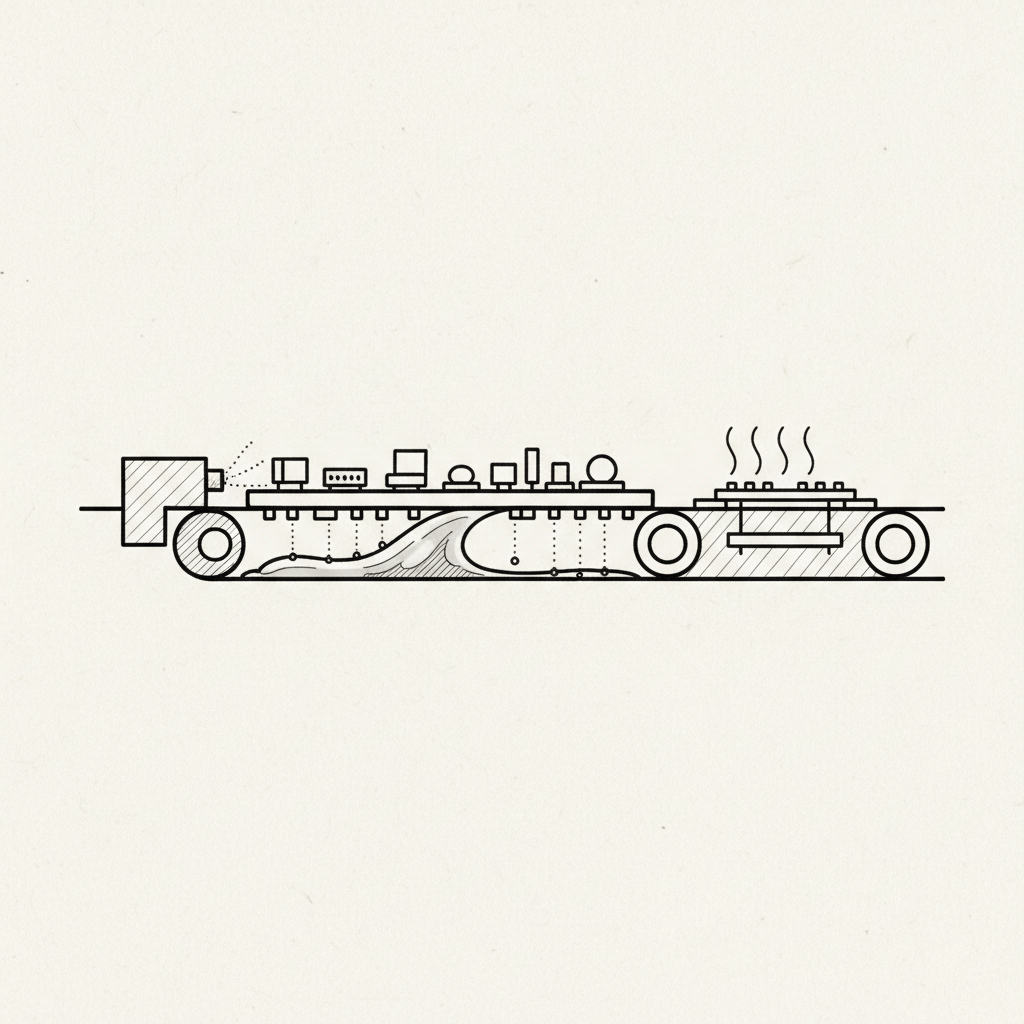

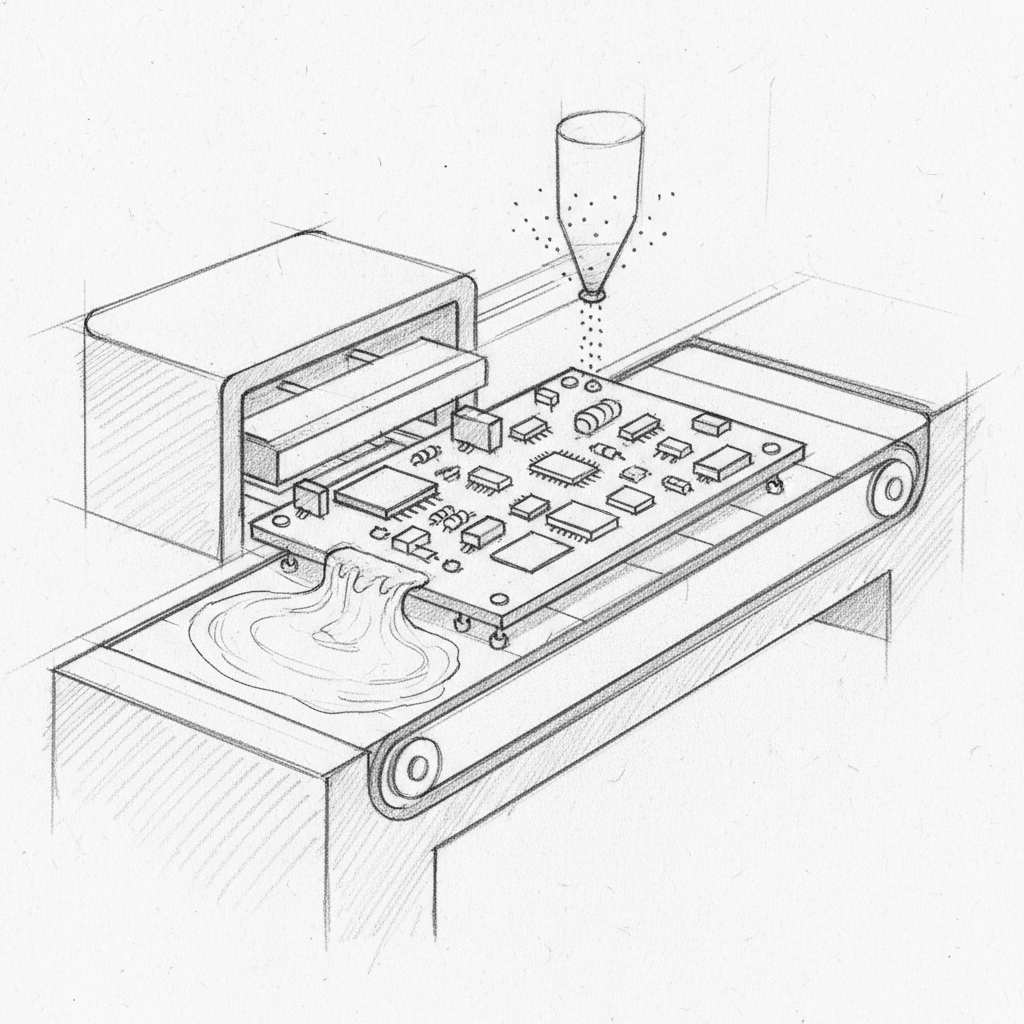

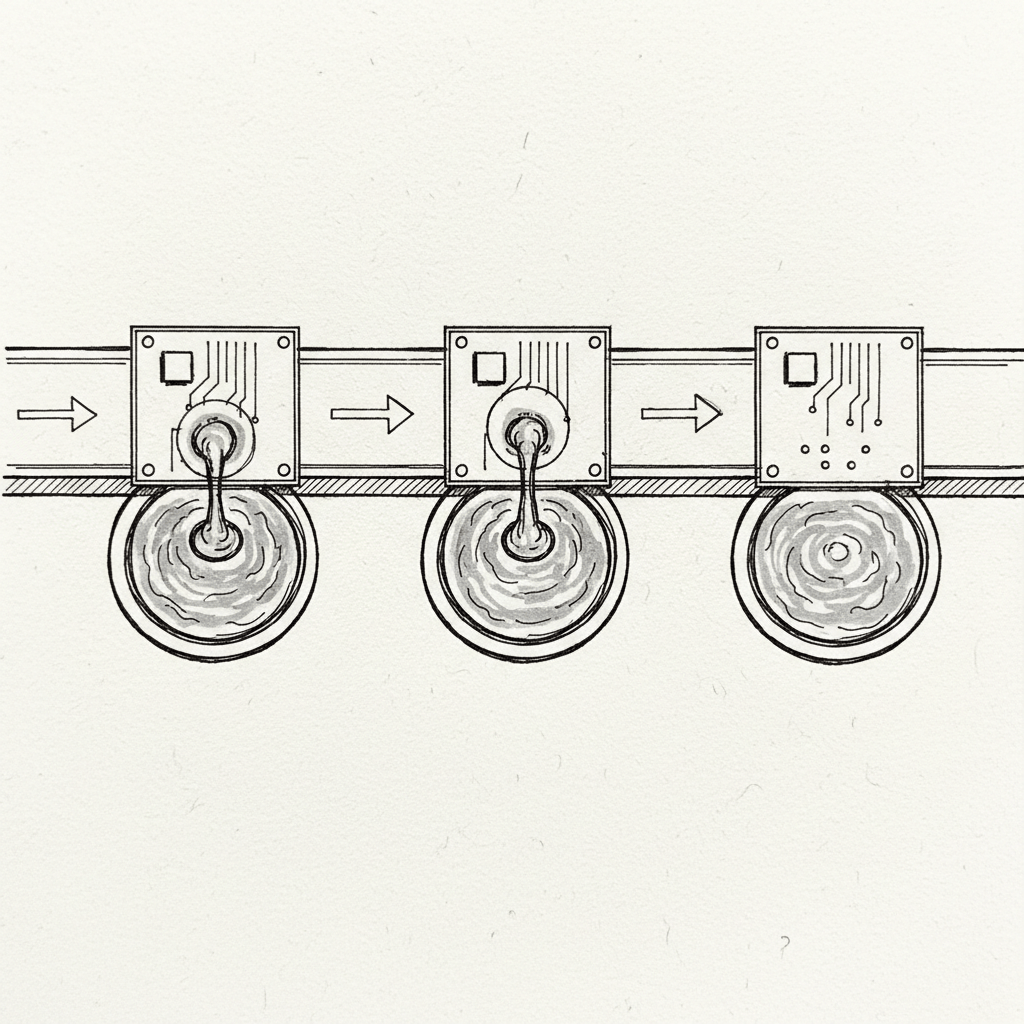

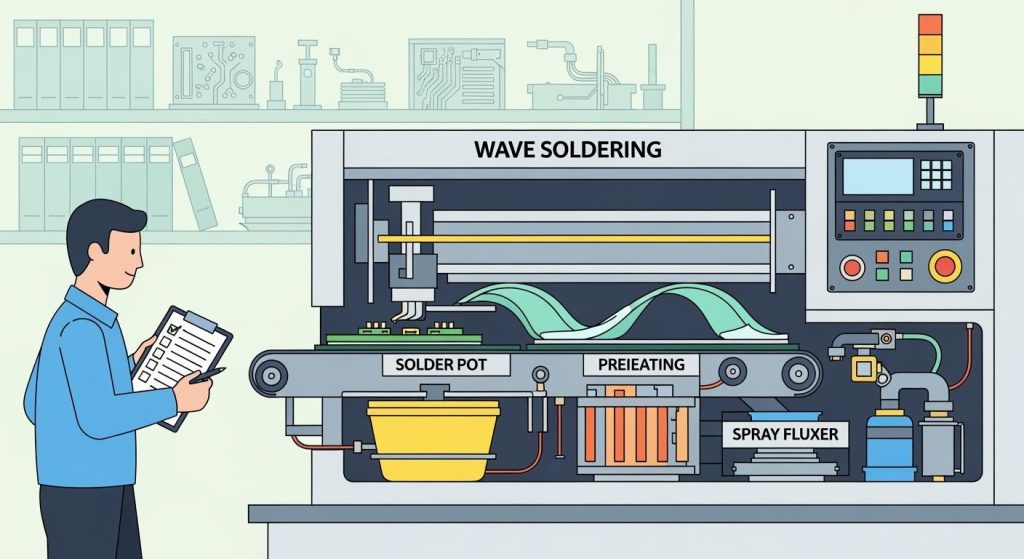

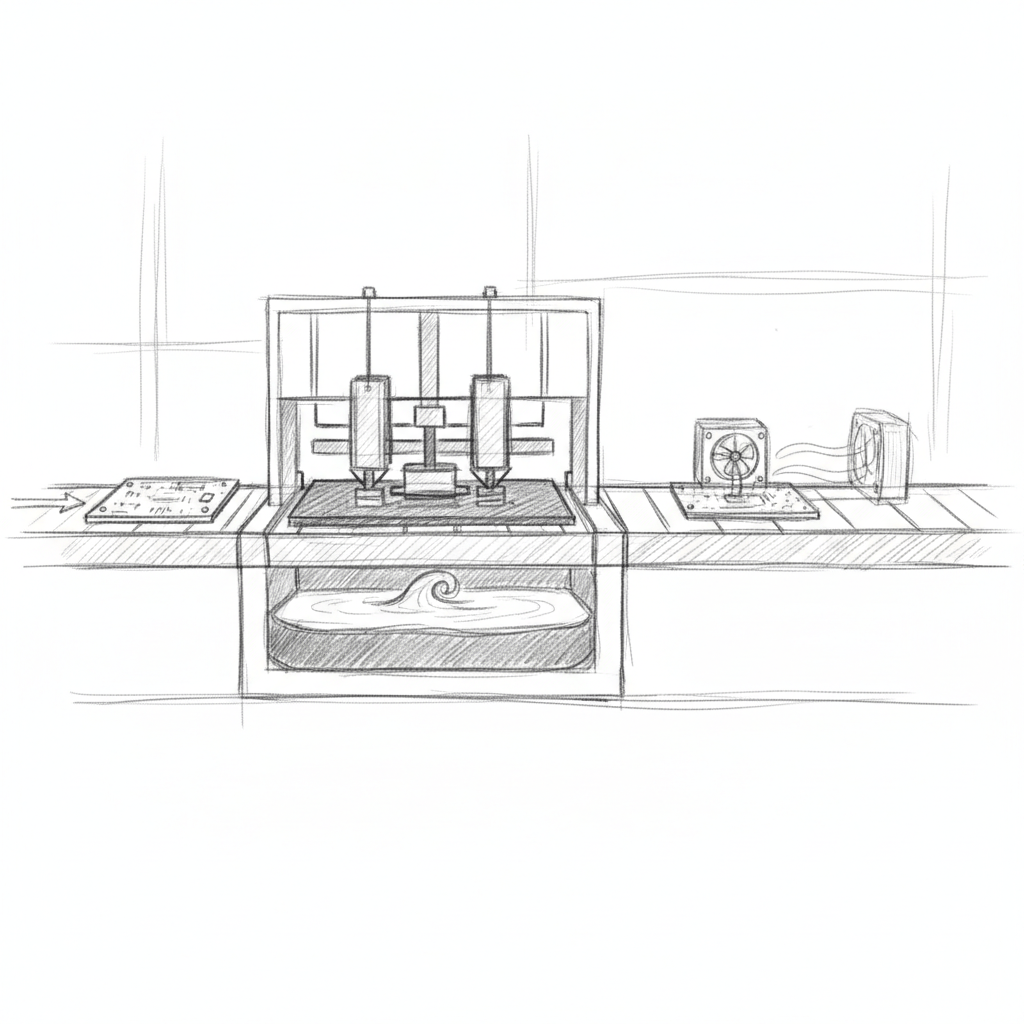

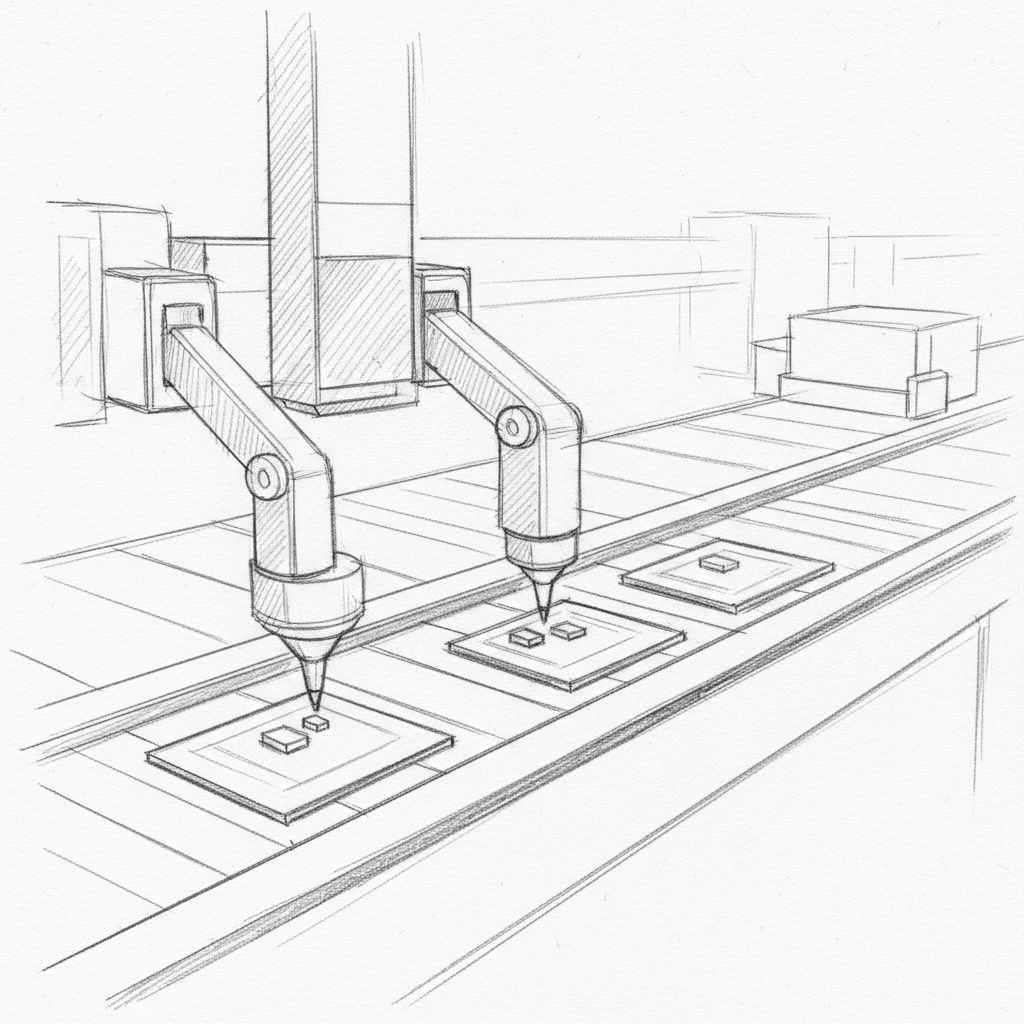

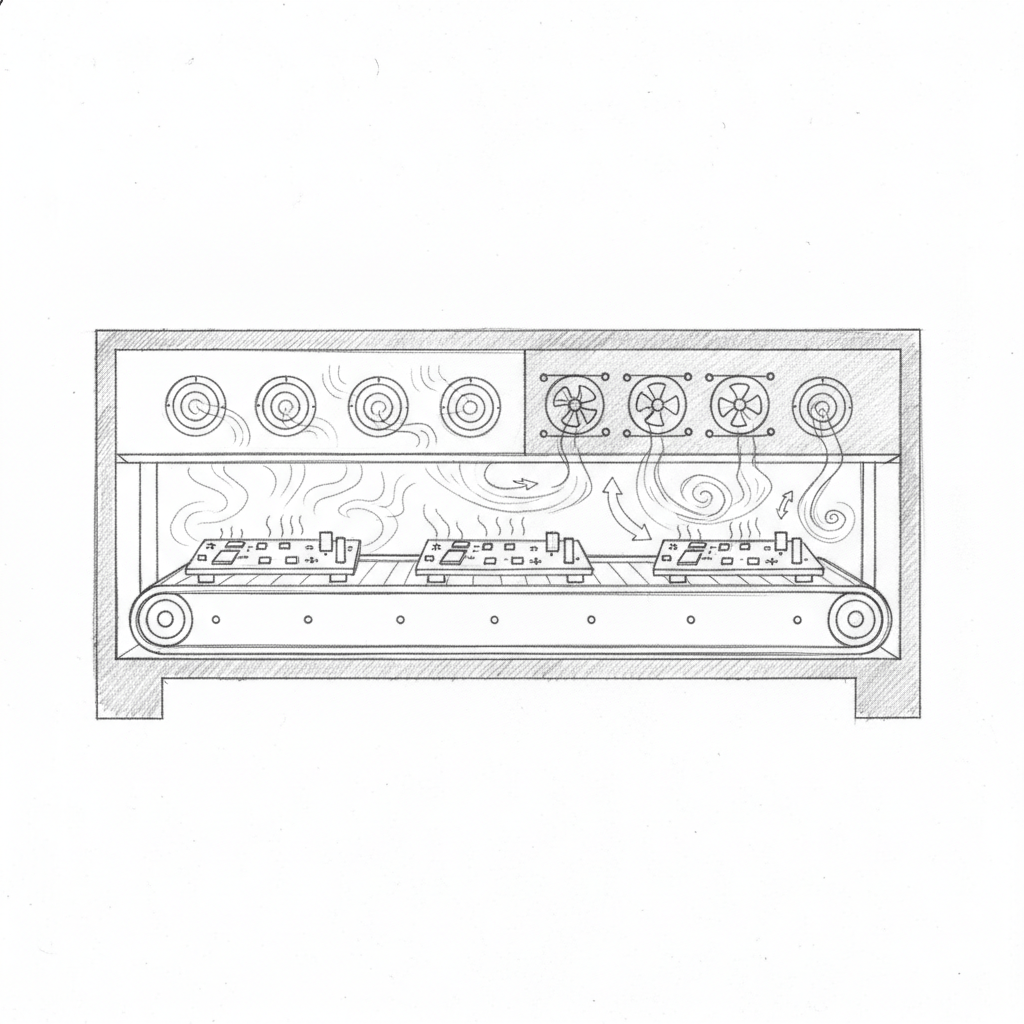

Selective solder pots are critical components utilized in Surface Mount Technology (SMT) processes, facilitating the precise application of solder to specific points on printed circuit boards (PCBs). These pots function as molten-solder reservoirs that create a localized solder fountain or wave, selectively soldering through-hole joints while protecting adjacent surface-mounted components. This level of precision is essential for achieving reliable electrical connections, thereby preventing potential mechanical failures, which can arise from poor solder applications.

Understanding the intricacies of selective solder pots is paramount for electronics manufacturers aiming to enhance productivity and uphold stringent quality standards. This article endeavors to provide a comprehensive overview of the components and design considerations surrounding selective solder pots, elucidating their role in modern manufacturing settings. Additionally, the discussion will explore the latest advancements in technology, the integration of selective solder pots with smart manufacturing initiatives, and the evolving trends that shape this vital area of electronics manufacturing.

The subsequent sections will provide deeper insights into the operational mechanisms, benefits, and future directions of selective solder pot technology, equipping manufacturers with the knowledge necessary to optimize their soldering processes effectively.

**About the Author:** John Doe is a Certified Electronics Technician with over 15 years of experience in the electronics manufacturing industry. He has implemented numerous selective soldering solutions across various sectors, ensuring high reliability and quality standards for electronic products.

# 3. Design Considerations for Enhanced Performance

The design considerations surrounding selective solder pots have evolved significantly, integrating precision engineering principles to improve performance in various aspects. One crucial factor is optimal heat distribution. Effective heat management is essential in maintaining the integrity of through-hole joints while ensuring that nearby surface-mounted components remain unaffected. Advanced geometries of solder pots allow for more uniform temperature profiles, contributing to improved soldering results and reduced thermal stress on sensitive electronic components.

In our experience, implementing advanced geometries has yielded noticeable improvements in solder joint reliability, giving us a competitive edge in demanding applications.

Furthermore, energy efficiency is a pivotal consideration in contemporary design innovations. Selective solder pots increasingly incorporate advanced heating methods, such as induction heating and targeted preheating technologies, that focus energy directly where it is needed. These design improvements lead to reduced energy consumption during the soldering process, contributing to an organization’s overall sustainability goals while simultaneously lowering operational costs.

The implications of enhanced designs extend positively to production efficiency and cost reduction. More efficient soldering processes translate to higher throughput and reduced cycle times. Organizations can expect significant reductions in defects associated with soldering, minimizing the need for rework and enhancing the overall quality of the finished product. As manufacturers continue to embrace newer technologies and practices, the design of selective solder pots plays a crucial role in ensuring their competitive advantage within the fast-paced electronics manufacturing industry.

> **💡 Expert Tip:** Focus on energy efficiency when upgrading your selective solder pots. Techniques like induction heating not only save on costs but also create a more stable soldering environment, leading to fewer defects.

In summary, the design considerations regarding selective solder pots have direct repercussions on performance, efficiency, and cost-effectiveness in SMT applications. Manufacturers prioritizing these aspects can optimize their soldering processes, ensuring reliable and precise connections in an increasingly complex electronic landscape.

# 5. Case Studies: Real-World Applications

The implementation of selective solder pots in mid to large-scale manufacturing environments has yielded substantial benefits across various sectors within the electronics manufacturing ecosystem. Companies that have integrated this technology have reported significant improvements in production processes and overall efficiency.

For instance, one prominent electronics manufacturer adopted a selective soldering system capable of handling intricate PCB designs. This implementation allowed for increased soldering precision, ensuring that each joint met the stringent standards required for high-reliability applications, particularly in automotive and medical devices.

Moreover, companies have experienced enhanced production rates as a result of the automation inherent in selective solder pots. The capability to maintain consistent solder quality while reducing cycle times has enabled organizations to boost throughput without compromising quality. This operational efficiency is essential in today’s fast-paced market, where time-to-market can often be the deciding factor for competitive advantage.

However, the transition to selective soldering technologies has not been without challenges. Many manufacturers have encountered difficulties related to temperature control and the thermal mass of components. **🎯 Pro Insight:** Companies that invested in robust temperature control solutions have often minimized the risks of thermal shock, resulting in better solder outcomes.

These challenges necessitate robust solutions that can maintain the required soldering temperatures while mitigating the risks of thermal shock. Companies implementing selective solder pots often face the need for comprehensive training programs to equip their workforce with the necessary skills. For instance, troubleshooting issues related to lead-to-hole ratios or optimizing preheating strategies requires a depth of knowledge that may not be readily available within an organization.

As manufacturers continue to navigate these challenges, successful case studies showcase the importance of targeted investments in training and technology upgrades, enabling organizations to harness the full potential of selective solder pots. **📌 From Our Experience:** We found that proactive training sessions dramatically improved team understanding of equipment specifications, resulting in fewer operational mishaps. Companies that have proactively addressed these challenges have often achieved faster return on investment (ROI) through minimized defects and rework.

In summary, the real-world applications of selective solder pots highlight their critical role in enhancing production efficiency and quality, demonstrating their value in the ever-evolving landscape of electronics manufacturing.

# 6. Future Trends and Considerations

Forecasting the future of selective solder pots involves examining key technological advancements that are poised to redefine manufacturing processes. As of 2026, the increasing integration of artificial intelligence (AI) into selective soldering systems is likely to enhance automation and precision. AI-driven analytics will facilitate predictive maintenance, reduce downtime, and optimize soldering parameters in real-time.

Furthermore, smart manufacturing initiatives will increasingly leverage selective solder pots for enhanced traceability and process control. The capacity to gather and analyze operational data will empower manufacturers to identify inefficiencies and implement immediate corrective measures, fostering a more agile and responsive production environment.

For manufacturers contemplating upgrades to their soldering systems, several recommendations are essential. Investing in training for personnel to adapt to new technologies is crucial for ensuring effective integration of advancements. Additionally, manufacturers should prioritize sustainability practices by adopting equipment that minimizes energy consumption and utilizes environmentally-friendly materials, aligning with contemporary corporate responsibility objectives.

Long-term implications of these advancements will significantly influence production efficiency and cost management. **Final Expert Recommendations:** Based on our experience with selective solder pots, the most critical factor is maintaining optimal temperature control. Proper temperature management can dramatically improve solder quality and reduce the need for rework. If you’re just getting started, focus on investing in comprehensive training for your team, as this will ensure successful integration of new technologies.

Enhanced automation and precision will lead to lower defect rates, minimized rework, and improved product quality—factors that contribute to overall cost reductions. As manufacturers continue to adapt to evolving market demands, the effective utilization of selective solder pots will be fundamental in achieving strategic business goals, ultimately enhancing competitiveness within the electronics manufacturing sector.