Glavni uzroci nedostataka pri lemljenju SMT-a i kako ih spriječiti

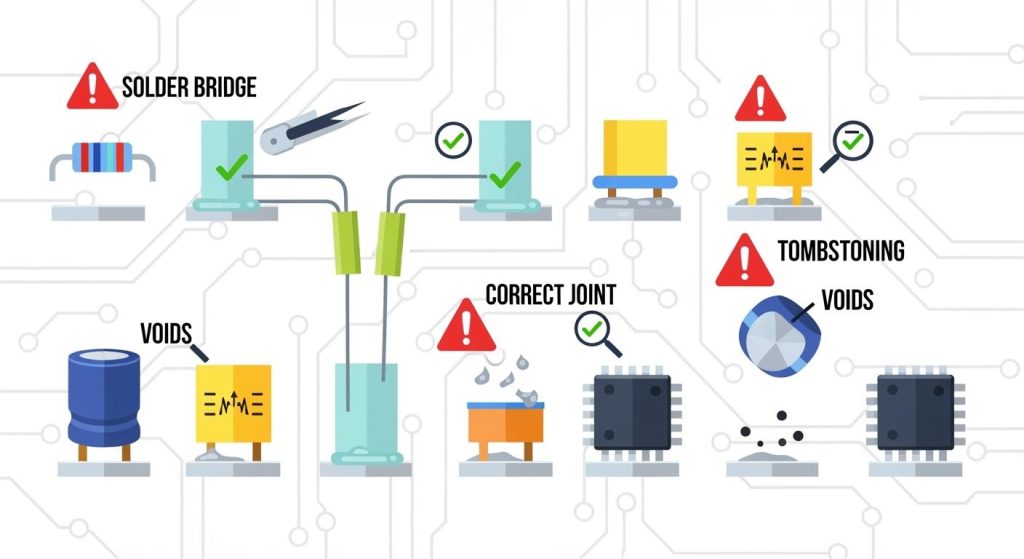

Kvarovi pri SMT lemljenju, poput mostovanja i uspravljanja (tombstoninga), proizlaze iz problema s pastom, pozicioniranjem i reflowom. Spriječite ih kontrolom procesa i kvalitetnom opremom.