Specifikacije in tehnični parametri

|

| 1 |

description |

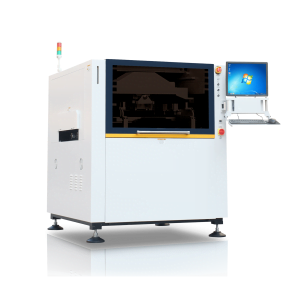

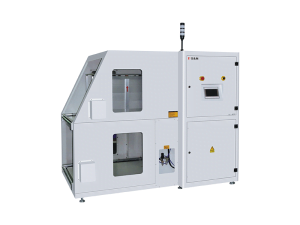

Used between the board loader and the printing machine, suitable for AI and SMT process cleaning needs, or very high-standard cleaning needs. |

| 2 |

Višina prenosa |

900 ± 20 mm |

| 3 |

Smer prenosa |

L→R or R→L |

| 4 |

Efektivna velikost plošče z vezjem |

80(L)*60(W)-510(L)*380(W)mm |

| 5 |

Dimension(L*W*H)mm |

L675*W1030*H1350mm |

| 6 |

Ionic air knife |

420mm long (OT6040A 1 drag 1) |

| 7 |

Roller-type brush |

50*360mm |

| 8 |

Sticky dust drum speed |

Stepper motor 200-1200 rpm (data setting) |

| 9 |

Oskrba z električno energijo in električna obremenitev |

1P 3W AC 220 60/60Hz Power 50W |

| 10 |

Air pressure & air flow |

4~6Kg/cm², intake pipe size 8mm |

| 11 |

Debelina plošče |

Najmanj 0,6 mm |

| 12 |

Rail transmission motor |

Qinglan stepper motor |

| 13 |

Sensors |

Baumer Intelligent Optoelectronics |

| 14 |

Način nadzora |

Kunlun Tongtong 4.7-inch true color touch screen panel control |

| 15 |

PLC |

Taiwan Fengwei |

| 16 |

Rack type |

3mm thick A3 plate bending and square welding powder spray production |

| 17 |

Metoda prilagajanja širine |

Ročna nastavitev |

| 18 |

Audible and visual alarm |

It has a three-color lamp to distinguish the current working state, and there is an audible and visual alarm function when the operation is interrupted |

| 19 |

Vmesnik I/O |

Standard SMEMA interface before and after |

| 20 |

Electronic control |

PLC I/O table is affixed to the back |

| 21 |

Teža (kg) |

165Kg |