Proizvajalci se pogosto odločijo za spajkanje z valovi pri velikoserijski proizvodnji plošč z luknjami, ker omogoča hitrost in prihranek pri stroških. Spajkanje s topljenjem s povratnim tokom je najprimernejše za projekte s komponentami za površinsko vgradnjo ali kompleksne projekte z visoko gostoto, ki zahtevajo natančnost. Izbira je odvisna od več dejavnikov:

-

Vrste komponent na plošči

-

Zahtevani obseg proizvodnje

-

Stroški opreme in namestitve

-

Želena kakovost in zanesljivost

Nedavni tržni trendi kažejo, da obe metodi ostajata prevladujoči, pri čemer je Azijsko-pacifiška regija vodilna na svetu. Izbira pravega postopka zagotavlja učinkovito in kakovostno sestavljanje.

Ključne ugotovitve

-

Obleke za valovno spajkanje velikoserijska proizvodnja s komponentami s prebojem skozi luknjo, ki omogoča hitro in stroškovno učinkovito sestavljanje ter močne mehanske spoje.

-

Spajkanje s topljenjem se odlikuje z napravami za površinsko montažo, ki zagotavljajo natančne in zanesljive spajkane spoje za kompleksne plošče z visoko gostoto in podpirajo postopke brez svinca.

-

Proizvajalci pogosto kombinirajo obe metodi na ploščah z mešano tehnologijo, da bi optimizirali kakovost in učinkovitost.

-

Izbira prave metode spajkanja je odvisna od vrste komponent, zasnove plošče, obsega proizvodnje, potreb po kakovosti in proračunskih omejitev.

-

Z upoštevanjem jasnega kontrolnega seznama odločitev lahko zmanjšate število napak, zagotovite skladnost in uskladite postopek spajkanja z zahtevami projekta.

Primerjava

Primerjalna tabela

|

Merilo uspešnosti |

Spajkanje z valovi |

Spajkanje s topljenjem |

|---|---|---|

|

Hitrost (učinkovitost proizvodnje) |

Serijski postopek; hitrost transporterja 0,5-2,5 m/min; idealen za velike količine komponent z luknjami |

Sekvenčni postopek; hitrost transporterja 0,5-1,5 m/min; vgradne peči za komponente SMT |

|

Stroški (oprema in namestitev) |

Stroški opreme $20,000-$100,000; vključuje stroj za spajkanje in lonec za spajkanje |

Višji začetni stroški $50,000-$300,000; vključuje peč za prekuhavanje, tiskalnik šablon, kontrolne sisteme |

|

Natančnost (kakovost in zanesljivost) |

Robustni spoji; nevarnost premostitve in spajkanja kroglic, če ni optimizirano; dušik izboljša kakovost |

Visoka natančnost za SMT; nadzorovani toplotni profili zmanjšujejo število napak; napreden nadzor temperature |

|

Združljivost komponent |

Najboljši za komponente skozi luknje; ni primeren za občutljive komponente SMT |

Idealno za tehnologijo površinske montaže; podpira miniaturizacijo in komponente z majhnim razmikom |

|

Vpliv na okolje |

Manj energetsko učinkovito; celotno PCB je potopljeno v staljeno spajko; zmeren odpad spajke |

Energetsko učinkovitejša, lokalizirana spajkalna pasta, podpora zlitinam brez svinca, boljša skladnost s predpisi |

Glavne razlike

-

Spajkanje z valovi se najbolje obnese pri sestavnih delih z luknjami in velikoserijski proizvodnji. Zagotavlja hitro zmogljivost in nižje začetne stroške vzpostavitve. Vendar porabi več energije in ustvari več odpadne spajke, saj gre celotna plošča skozi staljeno spajko.

-

Spajkanje s ponovnim tokom se odlikuje s komponentami za površinsko vgradnjo, zlasti na kompleksnih ploščah ali ploščah z visoko gostoto. Zaradi natančnega nadzora temperature zagotavlja boljšo kakovost spajkanja in zanesljivost. Postopek podpira spajkanje brez svinca, zato je okolju prijaznejši. Začetni stroški opreme so višji, vendar metoda omogoča miniaturizacijo in napredne zasnove plošč.

-

Strokovnjaki opozarjajo, da se pri spajkanju s ponovnim topljenjem uporablja nadzorovan profil segrevanja, ki zmanjšuje število napak in podpira komponente z majhnim korakom. Po drugi strani pa spajkanje z valovanjem zahteva skrbno upravljanje temperature in je manj primerno za občutljive dele.

-

Proizvajalci včasih kombinirajo obe metodi na eni plošči. Za dele SMT običajno najprej uporabijo spajkanje s taljenjem, nato pa za komponente z luknjami uporabijo spajkanje z valovanjem. Ta hibridni pristop pomaga zadovoljiti potrebe sklopov z mešano tehnologijo.

Nasvet: Izbira pravega postopka spajkanja je odvisna od vrste komponent, obsega proizvodnje in zahtev glede kakovosti. Pregled teh ključnih razlik pomaga proizvajalcem, da svoje potrebe prilagodijo najboljši metodi.

Pregled spajkanja z valovi

Kako deluje

Spajkanje z valovi z nizom avtomatiziranih korakov elektronske komponente poveže s ploščami s tiskanim vezjem. Postopek je učinkovit pri velikoserijski proizvodnji in tehnologiji z luknjami. Tukaj je prikazan tipičen potek dela:

-

Uporaba fluksa: Na spodnjo stran tiskanega vezja delavci nanesejo fluks z razpršilom ali peno. Ta korak preprečuje oksidacijo in zagotavlja močne spajkane spoje.

-

Predgrevanje: Plošča se premika skozi območje predgrevanja, kjer doseže temperaturo med 90 °C in 125 °C. Predgrevanje zmanjša toplotni šok in pripravi ploščo za spajkanje.

-

Val spajkanja Kontaktna oseba: Plošča tiskanega vezja prehaja čez val staljene spajke. Višina vala spajke in hitrost transporterja sta skrbno nadzorovana, da se zagotovi ustrezen stik z vsemi podložkami in odvodi.

-

Hlajenje in pregled: Po spajkanju se plošča ohladi in pregleda, da se preverijo napake.

Ta avtomatizirani postopek proizvajalcem omogoča spajkanje več sto plošč na uro. Avtomatizacija zmanjša stroške dela in poveča doslednost, zato je spajkanje z valovi stroškovno učinkovita izbira za množično proizvodnjo.

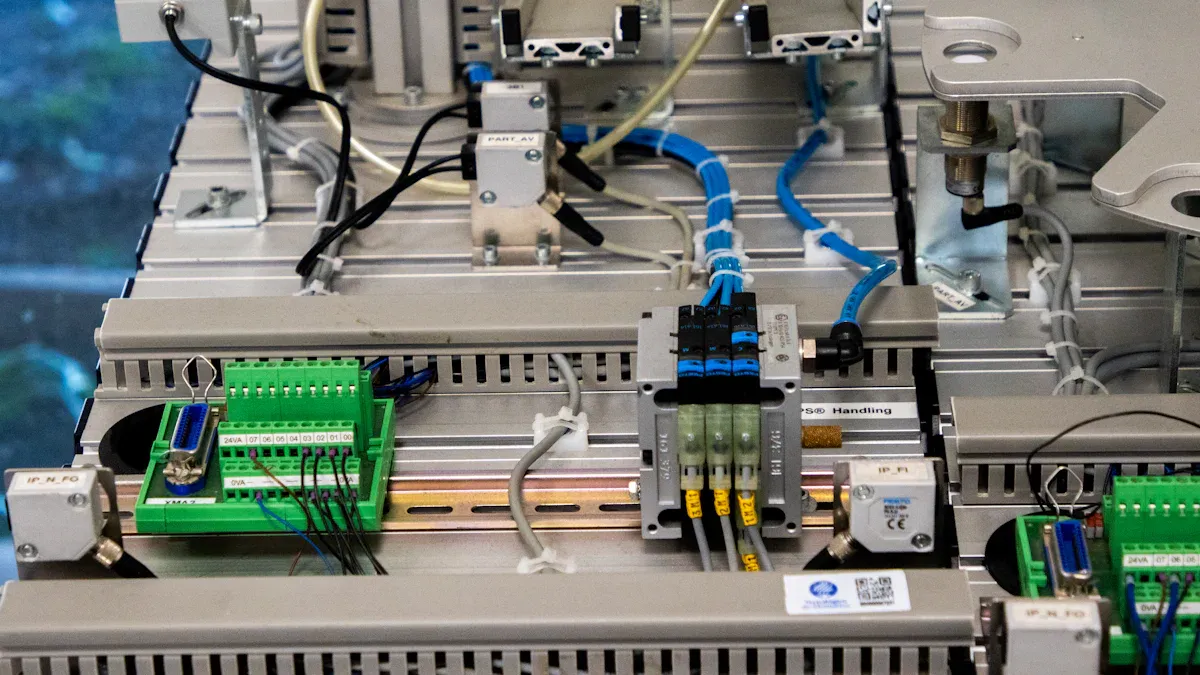

Aplikacije

Valovno spajkanje je najpogostejše pri sklopih, ki uporabljajo komponente s prebojem skozi luknje. Proizvajalci se zanašajo na to metodo za:

-

Plošče s tehnologijo skozi luknje (THT), pri katerih vodniki potekajo skozi luknje v tiskanem vezju.

-

PCB-ji z mešano tehnologijo, ki združujejo komponente THT in površinske montaže. Palete ščitijo dele SMT med spajkanjem.

-

obsežna proizvodnja, kot so industrijska elektronika, avtomobilska elektronika in energetska oprema, kjer so potrebni močni mehanski spoji.

|

Vrsta montaže |

Opis |

|---|---|

|

Tehnologija skozi luknjo (THT) |

spajkanje komponent z vodniki, ki potekajo skozi luknje v tiskanem vezju |

|

PCB z mešano tehnologijo |

Plošče s komponentami THT in SMT z uporabo zaščitnih palet. |

|

Proizvodnja v velikih količinah |

Proizvodne linije potrebujejo hitrost in učinkovitost |

|

Industrijska in avtomobilska industrija |

Elektronika zahteva zanesljivost in robustne povezave |

Prednosti in slabosti

Valovno spajkanje ima več prednosti:

-

zmerni stroški opreme v primerjavi z drugimi avtomatiziranimi metodami

-

Visoka zmogljivost, obdelava več sto plošč na uro

-

Zanesljivi spoji za aplikacije, povezane z električno energijo in mehanskimi obremenitvami

-

Prihranek stroškov zaradi manj dela in manj napak

Vendar obstajajo tudi nekatere pomanjkljivosti:

|

Kategorija pomanjkljivosti |

Opis |

|---|---|

|

Natančnost |

Omejeno za komponente SMT z majhnim korakom; nevarnost poškodb delov, občutljivih na toploto |

|

Selektivnost |

Učinki premostitve spajke in senčenja lahko povzročijo napake |

|

Vpliv na okolje |

Uporaba spajkanja na osnovi svinca, hlapi fluksa in visoka poraba energije |

Opomba: Proizvajalci morajo optimizirati procesne parametre, da zmanjšajo število napak in vpliv na okolje. Valovno spajkanje ostaja prednostna metoda za THT in velikoserijsko proizvodnjo, vendar je manj primerna za občutljive ali kompleksne sklope.

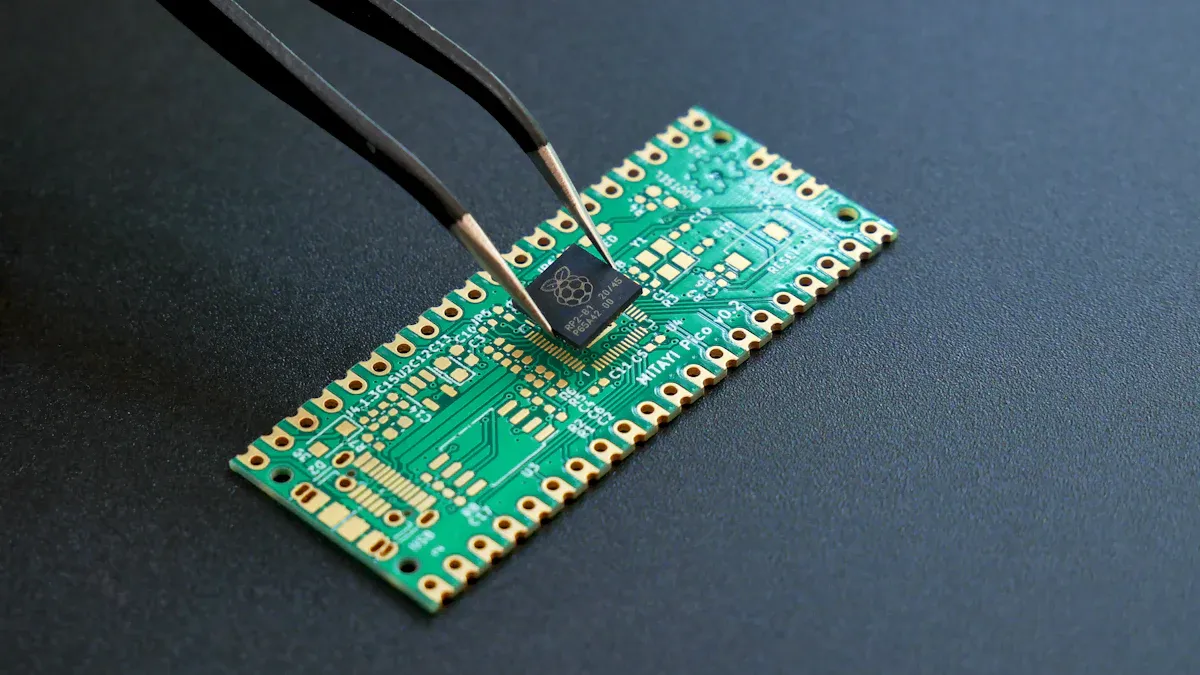

Spajkanje s topljenjem

Kako deluje

Spajkanje s pretočnim spajkanjem z natančnim in nadzorovanim postopkom poveže komponente za površinsko montažo s ploščami tiskanih vezij. Pri tej metodi se uporabljata spajkalna pasta in pečica za prepihovanje za vzpostavitev močnih električnih povezav. Postopek vključuje več pomembnih korakov:

-

Uporaba spajkalne paste: Tehniki nanesejo spajkalno pasto na ploščice tiskanega vezja s pomočjo šablone. Natančna namestitev zagotavlja zanesljive spoje.

-

Razporeditev komponent: Avtomatizirani stroji za pobiranje in nameščanje komponent z veliko natančnostjo namestijo komponente na ploščice, prevlečene s spajkalno pasto.

-

Predgrevanje: Sestav se vstavi v peč za ponovno segrevanje, kjer se s postopnim segrevanjem aktivira fluks in odstranijo oksidi.

-

Namakanje: Temperatura je stabilna, kar omogoča enakomerno segrevanje in stabilizacijo spajkalne paste.

-

Ponovno uplinjanje: Pečica dvigne temperaturo nad temperaturo taljenja spajke. Spajkalna pasta se utekočini in tvori močne vezi med komponentami in podložkami.

-

Hlajenje: Plošča se počasi ohlaja, kar utrjuje spajkane spoje in preprečuje toplotne napetosti.

Skrben nadzor nad temperaturni profili in časovna razporeditev preprečujeta napake, kot so premostitev spajke, hladni spoji ali poškodbe komponent. Spajkanje s ponovnim tokom podpira napredne zasnove tiskanih vezij in zagotavlja visoko zanesljivost.

Aplikacije

Spajkanje s topljenjem je primerno za sodobno proizvodnjo elektronike, zlasti za sklope s tehnologijo površinske montaže (SMT). Proizvajalci to metodo uporabljajo za:

-

Proizvodnja SMT z veliko mešanico, majhnim do srednjim obsegom, kjer sta pomembna prilagodljivost in natančno toplotno profiliranje.

-

Kompleksne zasnove tiskanih vezij z več vrstami komponent in postavitvami z visoko gostoto.

-

Proizvodnja brezosvinčnih tiskanih vezij zahteva skrbno upravljanje temperature.

-

Dvostranske plošče, na katerih so komponente nameščene na obeh straneh.

Spajkanje s ponovnim tokom omogoča spajkanje različnih vrst paketov SMT v enem samem postopku. Omogoča prilagodljivost pri načrtovanju in proizvodnji, zato je idealno za pametne telefone, računalnike, medicinske naprave in avtomobilsko elektroniko.

Nasvet: Spajkanje s pretokom je manj potratno in ga je lažje nadzorovati kot spajkanje z valovanjem. Podpira miniaturizacijo in napredno elektroniko.

Prednosti in slabosti

Prednosti:

-

High precision for small and densely packed SMT components.

-

Supports double-sided PCB assembly with proper process control.

-

Controlled thermal profiles reduce defects and improve joint reliability.

-

Automation enables consistent, high-throughput production.

-

Flexible for complex and high-density board designs.

Proti:

-

Higher initial equipment and material costs.

-

Requires specific stencils and templates for each product.

-

Regular maintenance and calibration increase operational complexity.

-

Specialized technicians must operate and maintain equipment.

-

Improper temperature settings can cause defects and reduce reliability.

|

Benefit/Drawback |

Opis |

|---|---|

|

Natančnost |

Advanced stencil and printing technologies ensure accurate solder paste deposition. |

|

Dual-pass capability |

Enables double-sided assembly, but risks re-melting bottom-side components. |

|

Kakovost |

Controlled profiles and material science improve reliability. |

|

Stroški |

Equipment, solder paste, and maintenance raise expenses. |

|

Speed |

Setup and changeover times can slow production for high-mix environments. |

Note: Regular monitoring and maintenance help prevent defects and ensure consistent quality in reflow soldering.

Head-to-Head

Process

|

Korak |

Spajkanje z valovi |

Spajkanje s topljenjem |

|---|---|---|

|

Uporaba fluksa |

Flux is sprayed on the PCB before soldering |

Flux included in solder paste, applied with a stencil |

|

Pre-heating |

PCB is heated to activate the flux and prevent shock |

PCB heated to remove solvents from solder paste |

|

Soldering |

PCB passes over the molten solder wave |

PCB passes through the reflow oven at a set temperature |

|

Hlajenje |

Solder joints solidify as the PCB cools |

Solder paste cools and fixes components |

|

Equipment |

Soldering machine with conveyor and solder wave |

Reflow oven, pick-and-place machine, stencils |

|

Kompleksnost |

Requires expert handling and precise control |

Easier to manage, less operator-dependent |

Note: Wave Soldering involves more complex machine setup and operator skill. Reflow soldering uses automated equipment and controlled temperature profiles.

Components

|

Metoda spajkanja |

Compatible Components |

Prednosti |

Limitations |

|---|---|---|---|

|

Spajkanje z valovi |

Through-hole parts (connectors, switches) |

Fast, cost-effective for large boards |

Not suitable for small or delicate SMDs |

|

Spajkanje s topljenjem |

Surface-mount devices (SMDs, microchips) |

Precise placement supports miniaturization |

Higher setup cost, limited for large through-hole |

-

Wave Soldering works best for boards with large connectors and mechanical parts.

-

Reflow soldering fits designs with tiny chips and high-density layouts.

-

Mixed boards often need both methods for best results.

Speed and Cost

|

Vidik |

Spajkanje z valovi |

Spajkanje s topljenjem |

|---|---|---|

|

Production |

High throughput, hundreds per hour |

Moderate throughput, flexible batches |

|

Setup Cost |

Lower initial equipment cost |

Higher equipment and material costs |

|

Changeover |

Fast for single product lines |

Slower for frequent product changes |

-

Manufacturers choose Wave Soldering for mass production and lower costs.

-

Reflow soldering suits smaller batches and complex boards, but costs more to set up.

Quality and Reliability

|

Vidik |

Spajkanje z valovi |

Spajkanje s topljenjem |

|---|---|---|

|

Kakovost spajkanja |

Strong joints for mechanical stress |

Consistent, precise joints for dense electronics |

|

Zanesljivost |

Favored in industrial and automotive boards |

Preferred for consumer and high-tech devices |

|

Defect Risk |

Solder bridging, cold joints are possible |

Tombstoning, component shifting possible |

-

Wave Soldering creates robust connections for power and industrial uses.

-

Reflow soldering delivers reliable results for miniaturized and high-density electronics.

-

Many automotive and advanced boards use both methods to maximize reliability.

Tip: Manufacturers should match their soldering method to the board design and reliability needs for best results.

Izbira prave metode

Project Needs

Selecting the right soldering process begins with understanding project requirements. Manufacturers consider component types, board density, and production scale. Surface mount technology (SMT) projects often require reflow soldering for precise placement and high-density layouts. Through-hole technology (THT) boards benefit from Spajkanje z valovi, which handles larger components and supports high-volume production.

|

Project Requirement |

Spajkanje z valovi |

Spajkanje s topljenjem |

|---|---|---|

|

Component Type |

Through-hole components (THT) |

Surface mount components (SMT) |

|

Component Density & Size |

Larger, high-power components |

High-density, small components (BGA, QFP) |

|

Production Scale |

Cost-effective for large-scale THT |

Favored for mass SMT production |

|

Quality Requirements |

Good mechanical support |

High quality, precise temperature control |

|

Automation & Efficiency |

Efficient for bulk soldering |

Efficient for complex SMT boards |

Manufacturers also evaluate volume, complexity, and turnaround time. Larger production volumes reduce per-unit cost, making Wave Soldering attractive for bulk orders. Projects with complex layouts or mixed technologies may require a hybrid approach.

Board Design

Printed circuit board (PCB) design strongly influences soldering method selection. Reflow soldering excels with double-sided boards and fine-pitch components. It minimizes thermal stress and warping, making it suitable for delicate or thin PCBs. Wave Soldering works best for simpler boards with through-hole parts, but it can cause solder bridging or damage to bottom-side SMT components unless protective measures are used.

|

PCB Design Aspect |

Preferred Soldering Method |

Reasoning |

|---|---|---|

|

SMT-only design |

Reflow |

High precision and automation for compact layouts. |

|

THT-only design |

Wave |

Cost-effective for boards with only through-hole parts. |

|

Mixed-technology board |

Hybrid (Reflow + Selective/Wave) |

Reflow for SMT; wave or selective soldering for through-hole parts. |

|

Double-sided SMT |

Reflow |

Safe soldering of both sides with thermal control. |

|

High-volume, low-cost |

Wave |

Fast and efficient for the mass production of THT boards. |

|

Fine-pitch ICs or BGAs |

Reflow |

Accurate soldering with tight thermal control. |

|

Prototypes or small runs |

Reflow |

Flexible for design changes and minimal tooling. |

|

Large connectors and relays |

Wave or Selective |

Strong mechanical joints for power or rugged applications. |

Manufacturers often use reflow soldering first for SMT components, then apply Wave Soldering or selective soldering for through-hole parts on mixed-technology boards.

Budget

Budget plays a key role in process selection. Wave Soldering offers lower initial equipment costs and high throughput, making it ideal for large-scale production. Reflow soldering requires higher investment in ovens, stencils, and inspection systems, but it supports advanced designs and automation.

-

Equipment and setup costs for Wave Soldering range from $20,000 to $100,000.

-

Reflow soldering equipment can cost between $50,000 and $300,000.

-

Maintenance and operator training add to ongoing expenses, especially for reflow soldering.

-

Lead-free soldering, required by regulations like RoHS, may increase costs due to higher melting points and equipment upgrades.

Manufacturers must balance upfront investment with long-term efficiency and quality. Projects with tight budgets and high volumes often favor Wave Soldering, while those needing flexibility and precision choose reflow soldering.

Decision Checklist

A practical checklist helps manufacturers match their needs to the best soldering method:

-

✅ Identify component types: Are most parts through-hole or surface mount?

-

✅ Review board layout: Is the design dense, double-sided, or mixed technology?

-

✅ Estimate production volume: Will the project run in bulk or small batches?

-

✅ Assess quality requirements: Does the application demand high reliability or mechanical strength?

-

✅ Consider heat tolerance: Are components sensitive to temperature profiles?

-

✅ Evaluate budget: What are the equipment, setup, and maintenance costs?

-

✅ Plan for regulatory compliance: Will the process use lead-free solder and meet environmental standards?

-

✅ Factor in operator skill: Does the team have experience with the chosen method?

-

✅ Implement quality control: Are inspection and testing systems in place?

-

✅ Avoid common mistakes: Check datasheets, thermal profiles, and stencil designs before starting.

Tip: Manufacturers who follow this checklist reduce the risk of defects and costly rework. They also ensure compliance with industry standards such as IPC-A-610 and IPC-J-STD-001, which guide process control and inspection rigor.

Manufacturers should match their soldering method to project needs.

-

For high-volume, through-hole, or mixed boards, efficient and cost-effective processes work best.

-

For fine-pitch SMDs or complex, high-density layouts, precise temperature control and reduced solder use are preferred.

The decision checklist helps teams evaluate supplier capabilities and process controls.

Explore guides from ALLPCB and Viasion for deeper insights, or partner with experienced electronics manufacturing services for expert support.

POGOSTA VPRAŠANJA

What types of boards work best with wave soldering?

Manufacturers use spajkanje z valovi for boards with through-hole components. This method suits large connectors, relays, and industrial electronics. It handles high-volume production efficiently.

Can reflow soldering handle double-sided PCBs?

Spajkanje s ponovnim tokom supports double-sided boards. Technicians use precise temperature control to prevent damage. This process allows placement of surface-mount devices on both sides.

Does wave soldering support lead-free processes?

Wave soldering can use lead-free solder. Operators must adjust temperature settings and equipment. Lead-free alloys require higher melting points, which may increase energy use.

How do manufacturers inspect solder joints after reflow?

Technicians inspect solder joints using automated optical inspection (AOI) systems. These machines detect defects like tombstoning or bridging. AOI improves quality and reduces manual errors.

Which method offers better reliability for fine-pitch components?

Reflow soldering provides better reliability for fine-pitch and miniature components. Controlled heating profiles reduce defects. This method supports advanced electronics and high-density layouts.