Electronics factories use different SMT line setups for their work. There are 10 main types of surface mount assembly lines. These are in-line, U-shaped, L-shaped, flexible, single-sided, double-sided, batch, high-mix low-volume, low-mix high-volume, and modular lines. The table below shows the most popular layouts:

|

SMT Line Configuration |

Market Share (2023) |

|---|---|

|

In-line Layout (Linear) |

|

|

U-Shaped Layout |

Second largest |

Each smt line is different in equipment, automation, and layout. If you want to build your own smt line, you should pick one that fits your goals. You also need to think about how hard your products are to make and how much space you have.

Key Takeaways

-

Picking the best SMT line setup depends on what you make, how much room you have, and your money. In-line and U-shaped layouts each help with space and work in different ways. Single-sided lines are good for easy products. Double-sided lines are better for hard designs. Fully automated lines are great for making lots of things all the time, but they cost more at first. Flexible and modular lines let factories change fast for new products or updates.

SMT Line Basics

Key Equipment

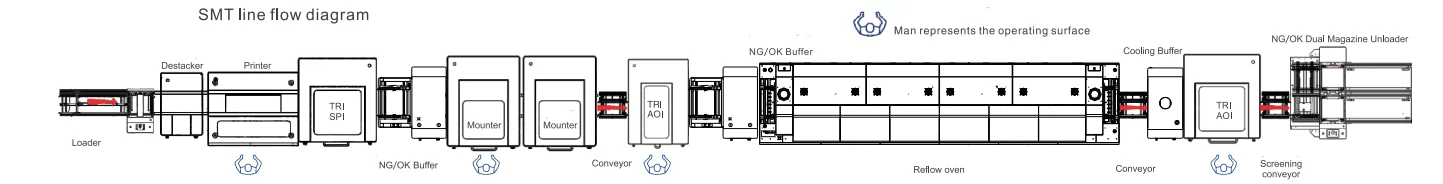

Every smt line needs several important machines. These machines help make good pcb products. The main equipment includes:

-

Solder Paste Printing Machine: This machine puts solder paste on the pcb pads. The paste must go on evenly for strong solder joints.

-

Solder Paste Mixer: Workers use this tool to mix the solder paste. Mixing makes sure the paste is smooth and ready to use.

-

SMT Pick and Place Machine: This machine uses robot arms or vacuum tools to put parts on the pcb. It comes in many sizes for different jobs.

-

Reflow Oven: The reflow oven heats the pcb and melts the solder paste. This makes the parts stick to the board. It has many heating zones to control the process.

-

Automated Optical Inspection (AOI) System: This system uses cameras and software to look for missing or wrong parts after soldering.

-

X-Ray Inspection Machine: For tricky boards, this machine finds hidden problems. It can see things like empty spots in solder joints or issues with BGA packages.

-

SMT Rework Station: Technicians use this station to fix or change bad parts without hurting the pcb.

Tip: Picking the right machines for your smt line helps you work faster and make better electronics.

Main Process Steps

Making a pcb in an smt line follows simple steps. Each step helps make sure the product is good:

-

PCB Preparation: Workers clean the pcb to get rid of dust and oil.

-

Solder Paste Application: The solder paste printing machine puts a thin layer of paste on the pads.

-

Solder Paste Inspection (SPI): Some lines use SPI to check the paste before moving on.

-

Component Placement: The smt pick and place machine puts parts on the pcb.

-

Reflow Soldering: The reflow oven heats the board and melts the solder paste. This makes strong joints.

-

Inspection: AOI and sometimes X-ray machines look for problems after soldering.

-

Testing: Testers check if the pcb works the right way.

-

Cleaning: Workers clean off any extra paste or flux from the pcb.

-

Final Inspection and Packaging: The finished boards get one last check before they are packed.

Each step depends on the one before it. This keeps the work moving smoothly in electronics manufacturing.

SMT Line Layouts

In-Line Layout

The in-line layout puts machines in one straight row. Each machine is right next to another. This makes a simple path for the pcb to move. It is easy for people to see how things work. Workers can reach both sides of the line. This helps them fix and watch the machines. But this setup needs more space on the floor. Workers may have to walk far between machines. This can slow down the job and make it harder. The in-line layout is good for easy jobs. But it can block other work in the factory. It is best for factories with lots of space and simple work.

U-Shaped Layout

The U-shaped layout puts machines in a U shape. The start and end are close together. This saves space and cuts down on walking. Workers can run more than one machine at once. This lowers costs and helps fix problems faster. The U-shape helps make the process more flexible. But it can make getting materials harder because the space is tight. This layout helps factories use space well. It also lets workers learn more skills.

Note: Picking the right smt line layout changes how well things work. A good layout keeps materials moving and stops slowdowns. It also helps make more products.

-

Main ways layout choice helps SMT production lines:

-

Smooth flow of materials means fewer mistakes and less waiting.

-

Smart machine spots mean the pcb does not move too much.

-

Good use of space lets workers move and fix things easily.

-

Good material systems keep work going without stops.

-

Safe layouts make work better for people.

-

Lean ideas help save time and use less stuff.

-

The best smt line layout depends on what the factory needs, how much space there is, and what products are made.

Single-Sided SMT Line

Features

A single-sided SMT line puts all parts on one side of the board. This makes the design and building steps easier. The table below shows the main features and how they affect making products:

|

Feature |

Single-Sided SMT Line Characteristics |

Effect on Production Capabilities |

|---|---|---|

|

Component Placement |

All parts go on one side of the PCB |

Makes design and building easier |

|

Design Complexity |

Good for simple, low-density circuits |

Not much room, so less features |

|

Cost |

Uses less material and less work |

Makes building cheaper |

|

Repair and Maintenance |

Easier and quicker to fix because only one side is used |

Easier to keep working and less time stopped |

|

Application Scope |

Used for basic electronics, toys, calculators, and LED lighting |

Best for simple things with not many parts |

This kind of smt line is best for things that do not need lots of parts or tricky designs.

Use Cases

Factories pick single-sided or half-smt pcb assembly lines for easy jobs. These lines are good in these cases:

-

Easy to run, even for new workers

-

Saves space, good for small batches

-

Works well in long, thin rooms or tight spaces

-

Used to make simple things like toys, calculators, and LED lights

Half-smt pcb assembly lines help companies make small amounts of easy products.

Pros & Cons

Note: A single-sided SMT line has some good points, but also some downsides.

Pros:

-

Costs less for parts and work

-

Fixing is faster because you use one side

-

Design and building are simple

-

Saves space

Cons:

-

Only works for simple, low-density circuits

-

Not good for fancy or high-tech products

-

Not much space, so hard to add more later

Factories should think about these things before picking a single-sided or half-smt pcb assembly line.

Double-Sided SMT Line

Features

A double-sided SMT line puts parts on both sides of a printed circuit board. This lets the board hold more parts and have harder designs. Some important things about this line are:

-

BGAs, package-on-package, and small passives can go on both sides.

-

Machines put on solder paste, glue, and parts for each side.

-

Stencils help put solder paste in the right spots for strong joints.

-

The process uses smart systems to fix alignment and put parts close together.

-

AOI, x-ray, and other tests check quality at many steps.

These things help factories make strong, high-density PCBs for advanced electronics.

Use Cases

Double-sided SMT lines are used for small, powerful electronics. Factories for industrial equipment, aerospace, security, medical devices, and consumer electronics use them. Medical devices need small, reliable boards for checking and watching health. Aerospace companies use double-sided PCBs in satellites and planes where space and weight matter. Phones and tablets use these boards to fit more features in small spaces. The double-sided process lets workers build on both sides, so products can be lighter and more complex.

Pros & Cons

|

Aspect |

Pros |

Cons |

|---|---|---|

|

Cost |

Making the board costs more because of extra layers and holes |

|

|

Complexity |

Helps make small, advanced products |

Harder to design, test, and fix |

|

Production Flexibility |

Easy to change jobs and make more boards |

Needs careful planning and skilled workers |

Tip: Double-sided SMT lines help make more products and give more options, but they need good quality checks and cost more to set up.

Inline SMT Line

Features

An inline SMT line moves PCBs in a straight line. Machines are linked by moving belts and robots. These machines check the boards as they go. This setup lets PCBs move fast and steady. Smart controls change the speed and direction of the belts. This helps the line match what the factory needs. Workers can watch screens to see if there are problems. They can fix issues right away. The line can switch jobs without stopping for long. Machines from different brands can work together in one line. Inline SMT lines often have special ovens with many heat zones. They also use smart feeders for parts. 3D AOI systems check every part and solder spot to make sure they are good.

Note: Inline SMT lines can run by themselves with little help. This means less touching by people and faster work.

Use Cases

Factories pick inline SMT lines when they need to make lots of PCBs. These lines are good for making many different products fast. Electronics companies use them for things like phones, computers, and car parts. Inline SMT lines are great for places that need strong quality checks. The machines can quickly switch to new PCB designs. This makes them good for both big and small orders with many types.

Pros & Cons

|

Pros |

Cons |

|---|---|

|

Costs a lot to buy and set up at first |

|

|

Machines can switch jobs quickly and save time |

Needs skilled workers and careful control |

|

Watching the line in real time helps catch mistakes |

Not the best for small jobs or test runs |

|

Can put many parts on both sides of the board |

If not watched, parts can be put in the wrong spot |

|

Automation keeps costs low and makes work repeatable |

Needs regular care and tech help |

Tip: Inline SMT lines help factories make lots of good products fast, but they need smart planning and trained workers.

Batch SMT Line

Features

A batch SMT line builds circuit boards in groups, not one by one. Workers set up the line to make one product for a few hours. Then, they switch to a new job. This way of working makes a lot of boards wait between steps. Boards move slowly from one test area to the next. Testing and checking do not happen right away, so there are delays. Problems may not be found until later because feedback is not instant. Factories use tray feeders in these lines for big or special parts. Tray feeders help keep delicate parts safe. They also make it easy to change jobs. Batch SMT lines use less automation than inline lines. This makes it simple to adjust for new products or test boards.

Note: Batch SMT lines are made for careful work and easy changes. They are not built for speed. These lines are best when you need to switch jobs fast or handle parts with care.

Use Cases

Factories pick batch SMT lines for small jobs or test runs. These lines work well when making less than 100 boards each month. Aerospace and medical companies use them for special or big parts. Batch SMT lines also help with repairs and quick changes. Engineers can change the design or parts list fast. These lines let factories make new versions or fix problems right away. They help companies fill small orders without waiting for outside help.

-

Common times to use batch SMT lines:

-

Making and testing new designs

-

Small runs for custom electronics

-

Building big or fragile parts

-

Repairs and quick fixes in the field

-

Pros & Cons

|

Factor |

Batch SMT Lines (In-House) |

Outsourcing SMT Lines |

|---|---|---|

|

High: Teams can change parts or fix problems right away |

Low: Must wait for contract manufacturer to make changes |

|

|

Cost |

Medium setup cost, but cheaper per board over time (about $5–6 each) |

Cheap to start, but costs more per board later (about $15 each) |

|

Lead Time |

Strong control: Can make and test boards the same day |

Weak control: Delays and waiting are common |

Batch SMT lines give factories good control over time and money. Teams can fix designs or handle urgent jobs fast. But these lines make more boards wait between steps and can miss problems at first. They need careful planning to save space and keep boards working well, especially with lead-free solder. For small, careful jobs, batch SMT lines are a smart choice.

High-Mix Low-Volume SMT Line

Features

A high-mix low-volume SMT line makes many different products, but only a few of each. It uses smart machines like multi-head pick-and-place, AOI, and X-ray inspection. These machines help catch mistakes and keep quality high. Workers do regular checks to keep machines working well. Staff often change materials, machine settings, and jobs. They need to talk to each other and learn new tasks fast. The line can handle different board sizes and types without much waiting. Using data and working with suppliers helps get parts on time. This setup lets factories react quickly when customers want something new.

Tip: HMLV lines work best when teams are flexible and ready for changes.

Use Cases

Many industries use high-mix low-volume SMT lines for special or tricky products. These lines are good when every order is small or different. Some examples are:

-

Aerospace: Makes special plane parts for each model.

-

Automotive: Builds fancy or custom car electronics.

-

Pharmaceuticals: Makes custom medical devices like implants.

-

Medical, telecom, industrial control, and military also use these lines for test runs and small jobs.

Most orders are only a few dozen to a few hundred boards. Batch sizes are usually under 500, and test runs can be less than 100. These lines help companies try new ideas and fill custom orders fast.

Pros & Cons

|

Aspect |

Advantages |

Disadvantages |

|---|---|---|

|

Flexibility |

Modular machines help the line change jobs quickly. |

Keeping quality high for many products is hard. |

|

Supply Chain |

Fast supply chains help get parts on time. |

Buying small amounts of parts can cost more. |

|

Workforce |

Skilled workers can do many different jobs. |

Needs more training and hands-on work. |

|

Manufacturing |

Making fewer boards means each one costs more. |

|

|

Quality Assurance |

Good testing keeps products working well. |

Balancing cost, quality, and variety is tricky. |

|

Technology |

Smart machines and software help make things faster. |

Buying and running these machines costs a lot. |

Note: HMLV SMT lines let factories make many kinds of products, but they must work hard to keep costs low and quality high.

Low-Mix High-Volume SMT Line

Features

A low-mix high-volume SMT line makes lots of the same product. These lines use smart machines to work fast and steady. Machines can run for many hours without stopping. Workers set up the line once, then let it run. The line has high-speed pick-and-place machines and big reflow ovens. It also uses inline inspection systems to check boards. Many boards are grouped together to save time and materials. This is called PCB panelization. The process uses less hand work and keeps quality high. Conveyor belts and robot arms move boards from step to step. The line checks lots of boards at the same time. This helps find problems early.

Tip: These lines work best when making the same thing for days or weeks.

Use Cases

Factories use these lines to make thousands or millions of the same board. Consumer electronics companies use them for things like smartphones and TVs. They also use them for home appliances. Car part makers use them for dashboard controls and engine modules. Lighting companies use them for LED panels and bulbs. These lines also help make network gear and computer hardware. Companies pick this setup to save money and keep making products without stopping.

Pros & Cons

Pros of Low-Mix High-Volume SMT Lines:

-

Each board costs less because setup costs are shared.

-

Machines work longer without stopping, so more gets done.

-

Grouping boards saves material and uses smart designs.

-

Less hand work means lower labor costs and fewer mistakes.

-

Testing and checking many boards at once saves time and money.

Cons of Low-Mix High-Volume SMT Lines:

-

The line cannot switch to new products quickly, so it is not flexible.

-

If the schedule is not planned well, it can take longer to finish.

-

Some ways to break boards apart, like V-scoring, can hurt them. Safer ways cost more.

-

The process needs good planning to stop waste and keep quality high.

Note: These lines save money and work well for big orders, but they need careful planning to avoid problems and keep things running smoothly.

Modular SMT Line

Features

A modular SMT line is made of separate units. Each unit does one job, like printing solder paste or placing parts. These units connect to make a full production line. Factories can add or move units when they need to. This makes it easy to upgrade or grow the line. A Manufacturing Execution System, called MES, often controls the line. The MES links all the machines, even old ones, using special rules like IPC-CFX. It collects data from each unit and helps workers make fast choices. The MES also checks quality and tracks how many boards are made. Factories can update their lines step by step without stopping work. This setup helps build smart factories in the future. Factories can change the line fast for new products or different batch sizes. This is important because electronics keep getting smaller and harder to make.

In a modular layout, the line is built with units that can be moved or added easily. This makes it simple to change or grow the line when needed. It helps factories handle different jobs and sizes.

Use Cases

Factories pick modular SMT lines for many reasons:

-

They want to spend less on assembly, testing, and machines.

-

They need to make many types of products in small amounts.

-

Their products do not last long or change often.

-

They must switch products or setups quickly.

-

They want to use the same machines for new jobs.

-

They hope to fix mistakes faster and make more good boards.

Modular SMT lines work best for factories that make lots of different things. These lines are also good if a company wants to grow or get new machines later.

Pros & Cons

|

Pros |

Cons |

|---|---|

|

Easy to make bigger or change |

Costs more at the start |

|

Lets you upgrade in steps |

Needs good planning |

|

Less time lost when changing |

May need a smart MES system |

|

Good for new products |

Workers need training |

|

Checks quality and tracks work right away |

Gets harder to manage with more units |

Tip: Modular SMT lines help factories get ready for new jobs and changes. They are a smart way to build lines that can grow and last a long time.

Flexible SMT Line

Features

A flexible SMT line uses a modular platform with small placement units. These units are easy to add or swap out fast. The line can work with many PCB types and sizes. It does not need new main machines for each change. Operators can switch from one product to another in 15 to 30 minutes. Flexible placement heads change nozzles by themselves. They adjust to different part sizes and thicknesses. The system gets better when you add new modules or swap old parts. Smart feeding systems help make production changes faster.

The table below shows how flexible SMT lines compare to modular and batch lines:

|

Feature/Aspect |

Flexible SMT Lines |

Modular Lines |

Batch Lines |

|---|---|---|---|

|

Structural Flexibility |

Modular platform with small placement units; easy to add or replace modules |

Multiple functional modules; can combine or expand |

Flexible layouts for small-lot, multi-type production |

|

Adaptability to Changes |

Adapts to different PCB types and sizes; rapid conversion (15–30 min) |

Adjusts capacity by changing modules; less integrated than flexible lines |

Handles changing demands; slower conversion |

|

Component Flexibility |

Adaptive placement heads; automatic nozzle replacement |

Modules for different components; flexibility depends on configuration |

Focus on scheduling and layout, not component adaptability |

|

Upgrade Capability |

Add modules or replace parts to expand or adapt |

Add or replace modules for new requirements |

Less focused on upgrades |

|

Production Conversion Speed |

Rapid conversion with intelligent feeding |

Slower conversion; depends on module reconfiguration |

Slowest conversion; batch scheduling |

Tip: Flexible SMT lines help factories keep up with fast-changing product needs and new technologies.

Use Cases

Flexible SMT lines are used in many industries that need quick changes and high accuracy. Companies making consumer electronics, medical devices, telecom, and cars use these lines. They build things like smartphones, medical monitors, and car control units. These lines also help make smart home devices, industrial controls, and power electronics. Factories pick flexible SMT lines for tricky PCB assemblies and lots of design changes.

|

Typical Products / Use Cases |

|

|---|---|

|

Automotive Electronics |

Engine control units, EV charging piles |

|

Medical Instruments |

Medical devices, beauty devices |

|

Smart Home Appliances |

Smart TVs |

|

Industrial Control |

Power switches |

|

Electronic Products |

Computers, phones, routers, power banks |

|

New Energy |

Solar panels |

|

Security Industry |

Security cameras, monitoring equipment |

|

Semiconductor |

Semiconductor applications |

|

Aerospace and Defense |

Aircraft power control boards |

|

Electrical Power Systems |

Smart meters |

|

EMS / ODM Manufacturing |

Contract manufacturing of diverse electronics |

Pros & Cons

Pros:

-

Fast product changeover in 15 to 30 minutes

-

Works with many PCB types and sizes

-

Easy to upgrade by adding more modules

-

Good for high-mix, low-volume jobs

-

Less downtime and better efficiency

Cons:

-

Costs more at the start than basic lines

-

Needs skilled workers and regular training

-

Complex system may need advanced care

Note: Flexible SMT lines help manufacturers win in markets where products change a lot and speed is very important.

Semi-Automated SMT Line

Features

A semi-automated SMT line uses both machines and people. Workers put PCBs and parts on the line by hand. Machines do jobs like printing solder paste and placing parts. The reflow oven melts the solder to hold parts in place. People check the boards and fix any problems they see. Boards move between stations on simple belts or carts. Some stations need workers to set up or change things by hand. Both machines and people check the boards for mistakes.

Key features include:

-

Workers load and unload PCBs by hand.

-

Machines print solder paste and use reflow ovens.

-

Pick-and-place machines work with help from people.

-

People check boards and fix small problems.

-

Boards move on simple belts or carts.

Note: Semi-automated lines help factories save money and keep good quality. Machines make work faster, and people help when things change.

Use Cases

Factories use semi-automated SMT lines for small or medium jobs. These lines are good where workers do not cost much. Companies use them to make test boards and special products. Schools and repair shops also use these lines. They are good for places with less money or space.

Common use cases:

-

Making test boards or samples

-

Building small groups of boards for tests

-

Putting together special or custom electronics

-

Teaching workers how SMT lines work

-

Fixing or changing boards

Pros & Cons

|

Pros |

Cons |

|---|---|

|

Costs less than full machine lines |

Not as fast as all-machine lines |

|

Can make many kinds of products |

Needs more workers than full-auto |

|

Simple to start and keep running |

Quality depends on worker skills |

|

Good for small or changing orders |

People can make more mistakes |

Tip: Semi-automated SMT lines are a smart pick for companies that want to save money and stay flexible. They help teams learn fast, but need careful watching to keep quality high.

Fully Automated SMT Line

Features

A fully automated SMT line uses machines for every step. Robots put PCBs on the line and take them off. Conveyor belts move boards from one machine to another. Machines print solder paste and place parts on the boards. The reflow oven melts the solder to hold parts in place. AOI and X-ray machines check each board for mistakes. Smart sensors and cameras watch every part and step. Software controls how fast and when things happen. Operators watch the line from a control room. They look at screens to see data and fix problems quickly.

Key features include:

-

Robotic arms load and unload PCBs

-

Solder paste printers and pick-and-place machines work by themselves

-

AOI and X-ray machines check boards as they go

-

Software lets workers watch everything in real time

-

Feeders and smart storage give parts to the machines

-

Data tracking helps find problems and keep quality high

Tip: Fully automated lines help factories make more boards with fewer mistakes.

Use Cases

Factories use these lines when they need to make lots of PCBs fast. These lines are best for jobs that need high quality and speed. Electronics companies use them for phones, computers, and tablets. Car makers use them for control units and sensors. Medical device makers use them for safe and reliable products. Factories that work all day and night pick these lines to meet big orders.

Common use cases:

-

Making lots of electronics for people to buy

-

Building car electronics

-

Putting together medical devices

-

Making telecom and network hardware

-

Building machines for factories

Pros & Cons

|

Pros |

Cons |

|---|---|

|

Very fast and makes many boards |

Costs a lot to set up |

|

Boards have good quality and few errors |

Needs skilled workers to start |

|

Saves money on workers over time |

Hard to fix and keep working |

|

Shows data and tracks boards right away |

Not easy to change for small jobs |

|

Can run all day and night |

Not good for making just a few |

Note: Fully automated SMT lines help companies be the best at making things fast and well. They need a lot of planning and money at first. Factories that use these lines can make many products every day and do a great job.

PCB Assembly Lines Comparison

Side-by-Side Table

Manufacturers look at different pcb assembly lines before picking one. Each line has its own machines and setup. Some lines use more robots than others. The table below shows the biggest differences.

Tip: This table helps teams find the best pcb assembly line for their needs.

|

SMT Line Type |

Key Equipment |

Layout |

Automation Level |

Typical Applications |

|---|---|---|---|---|

|

In-Line |

Standard SMT machines |

Straight line |

Semi to Full |

High-volume pcb assembly lines |

|

U-Shaped |

Standard SMT machines |

U-shaped |

Semi to Full |

Space-saving pcb assembly lines |

|

L-Shaped |

Standard SMT machines |

L-shaped |

Semi to Full |

Factories with limited floor space |

|

Flexible |

Modular, adaptive machines |

Modular/flexible |

Semi to Full |

High-mix, fast-change environments |

|

Single-Sided |

Basic SMT machines |

Any |

Manual to Semi |

Simple pcb, consumer electronics |

|

Double-Sided |

Advanced SMT, AOI, X-ray |

Any |

Semi to Full |

Complex pcb, medical, aerospace |

|

Batch |

Basic SMT, tray feeders |

Flexible |

Manual to Semi |

Prototyping, small batch pcb assembly lines |

|

High-Mix Low-Volume |

Modular, quick-change SMT |

Modular |

Semi to Full |

Custom, specialty electronics |

|

Low-Mix High-Volume |

High-speed SMT, conveyors |

In-line |

Full |

Mass production, consumer goods |

|

Modular |

Plug-and-play SMT modules |

Modular |

Semi to Full |

Growing or changing pcb assembly lines |

This table makes it easy to see how each line is different. Teams can use this to plan new lines or make old ones better.

Choosing an Efficient SMT Production Line

Key Factors

Picking a good smt production line means thinking about a few main things. How many boards you need to make is very important. If you need to make a lot, a fully automated line is best. These lines run all the time and work fast. They use robots to do jobs and help save money on workers. Robots also make fewer mistakes because they are very exact. But these lines cost more money to buy and set up. They are not easy to change if you want to make new products often.

If you do not need to make as many boards, or if you change designs a lot, a semi-automated line is better. These lines are cheaper to start and can switch jobs quickly. But people have to check boards by hand more often. This can make the work cost more in the long run. You should also think about how hard your products are to build, how much space you have, and how much money you want to make back. Companies need to look at all these things and think about what they want in the future.

Selection Tips

To pick the best smt production line, teams should look at what they need and what each line can do. First, write down what kinds of pcb you will make and how many you need each month. If you make a lot of the same thing, a fully automated line is the best choice. It makes boards fast and each one costs less. If you make lots of different boards or test new ideas, a semi-automated or modular line is better. These lines can change jobs quickly and are more flexible.

The table below shows the main ways these lines are different:

|

Factor |

Fully Automated Line |

Semi-Automated Line |

|---|---|---|

|

Best For |

High-volume, stable production |

High-mix, frequent changes |

|

Changeover Time |

~45 minutes |

|

|

Labor Cost |

Low |

Higher |

|

Flexibility |

Low |

High |

|

Initial Investment |

High |

Lower |

How you set up your line and how many machines you use also matter. In-line layouts are good if you have a big room and simple jobs. U-shaped or modular layouts save space and let you change things more easily. Always make sure your machines and setup fit your budget and what you want to do later. If you do not have much money, a simple smt line might be the best for a small or new company.

Tip: Look at how you build pcbs now and what you want to do in the future. Picking the right line will help your company grow and make better electronics.

Knowing about SMT line setups helps factories work better and make good products. Teams can look at the table and tips to pick what works best for them.

-

Check your assembly lines often to see if they work well.

-

Ask SMT experts for help when you want to make changes.

Picking the right setup now helps you do better later. Planning ahead helps your factory grow and do well in making electronics.

FAQ

What is the main difference between in-line and U-shaped SMT layouts?

In-line layouts put machines in a straight line. U-shaped layouts bend the line so the start and end are close. U-shaped lines save space. They let workers watch and use more than one machine at a time.

How does automation level affect SMT line choice?

More automation means less hand work and fewer mistakes. Fully automated lines are good for making lots of boards. Semi-automated lines are better for small batches or when you change products often. Teams should pick the right automation for their needs.

Can a factory upgrade from a semi-automated to a fully automated SMT line?

Yes, factories can start with semi-automated lines and add machines later. Modular and flexible layouts make it easy to upgrade. Planning for growth saves money and keeps the line running.

Which SMT line works best for prototypes or small batches?

Batch SMT lines or high-mix low-volume lines are best for small jobs. These lines can change setups fast and are easy to use. They help engineers test new ideas without spending a lot.

What factors should manufacturers consider before choosing an SMT line?

Manufacturers should think about how many boards they need to make. They should look at how hard their products are to build, how much space they have, and their budget. They also need to plan for the future and how often they will change products. Good planning helps factories do better work.