An In-Depth Guide to Types of Wave Soldering for Electronics Manufacturers

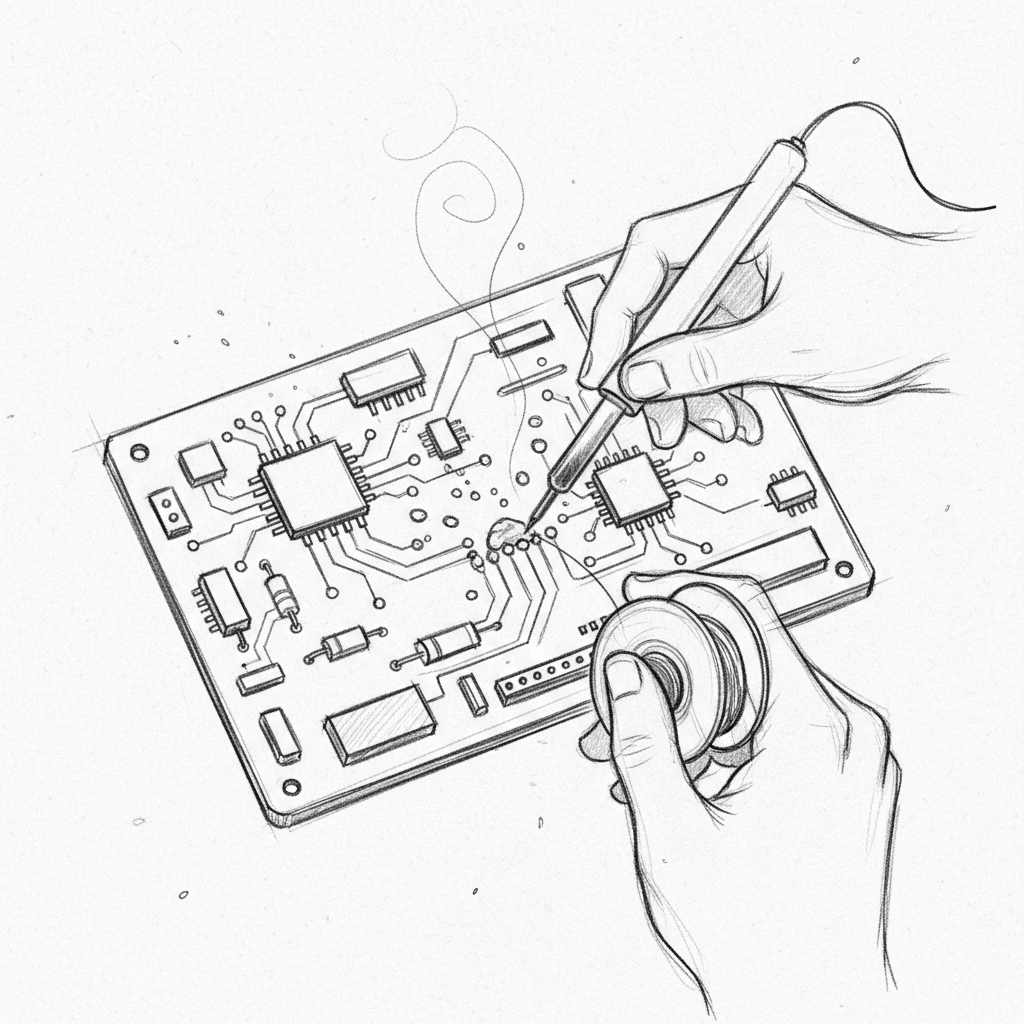

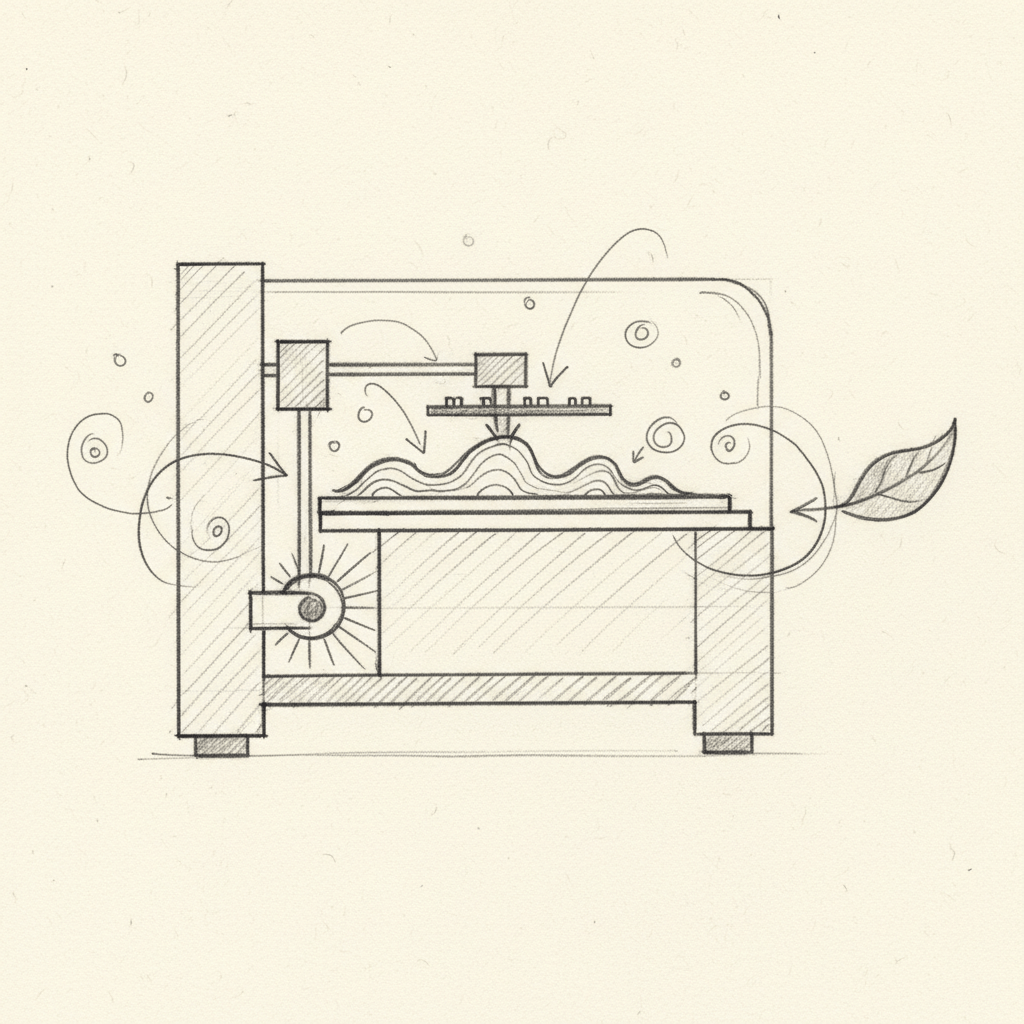

Wave soldering is a vital technique within the domain of surface mount technology (SMT) processes, playing an essential role in the assembly and manufacturing of electronic components. It involves passing printed circuit boards (PCBs) over a pan of molten solder, ensuring efficient bonding of components like capacitors and resistors to the board. As of 2025, wave soldering remains integral to achieving high throughput and precision, crucial for both mid-sized and large-scale electronics manufacturers.