You can lower energy consumption and cut costs in SMT curing ovens by making small adjustments to your daily operations. Energy efficiency gives you two big advantages: you save money and help the environment. When you use Energy-Saving Tips, you keep product quality high. Take a close look at your oven setup. Stay proactive and look for new ways to improve efficiency.

Key Takeaways

-

Focus on energy efficiency to lower costs and reduce your carbon footprint. Small adjustments can lead to significant savings over time.

-

Regularly calibrate your oven and track temperature to maintain efficiency. Weekly checks help catch issues early and ensure consistent product quality.

-

Upgrade insulation and optimize airflow to prevent heat loss. Good insulation keeps heat inside, while proper airflow ensures even heating.

-

Implement smart controls and automated systems to manage energy use effectively. These technologies help maintain stable conditions and reduce manual adjustments.

-

Establish a routine maintenance schedule to clean components and inspect for wear. Regular maintenance protects your investment and supports energy-saving goals.

Energy-Saving Tips Overview

Why Energy Efficiency Matters

You can make a big difference in your facility by focusing on energy efficiency in SMT curing ovens. When you use Energy-Saving Tips, you lower your energy bills and help the environment. Energy-efficient ovens can cut energy use by up to 30% compared to older models. This means you spend less money on electricity and reduce your carbon footprint. Many facilities now use smart ovens with IoT sensors. These sensors track energy use and emissions in real time. You can see where you waste energy and fix problems quickly. Lower energy use also improves your sustainability metrics. Your company can meet green goals and show customers you care about the planet.

Tip: Small changes in oven settings can lead to big savings over time. Start by checking your current energy use and look for areas to improve.

Systematic Optimization Approach

You get the best results when you follow a step-by-step plan to optimize your ovens. A systematic approach helps you find and fix problems without missing important details. Many companies use these strategies worldwide:

-

Optimize temperature control with regular calibration and smart setpoint choices.

-

Upgrade insulation and improve airflow using energy-saving fans.

-

Maintain ovens with routine checks, filter replacements, and inspections.

You should start by reviewing your oven’s performance. Track temperature, airflow, and energy use. Make changes one at a time and measure the results. This method keeps product quality high while you save energy. You can use Energy-Saving Tips to guide your decisions and reach your efficiency goals faster.

Note: Consistent monitoring and small adjustments help you maintain savings and avoid unexpected issues.

Temperature Control

Baseline Temperature Tracking

You need to know your oven’s baseline temperature before you can improve energy efficiency. Tracking the temperature profile every week helps you spot changes early. Many facilities use control charts to monitor oven temperatures and timings. If you see a drift outside your process limits, you should recalibrate the oven. Some experts recommend checking the temperature profile as often as once a day, while others suggest once a month. Regular verification keeps your oven running smoothly and prevents energy waste.

Tip: Consistent temperature tracking lets you catch problems before they affect your process or increase your energy costs.

Accurate baseline temperature tracking leads to stable and repeatable profiles. You get what you set, and the temperature difference among all thermal couples stays below 1°C. This accuracy means your oven transfers heat efficiently and loses less energy. The external body of the oven stays cooler, which lowers your electricity bill and reduces the need for extra air conditioning.

|

Feature |

Description |

|---|---|

|

“What You Set Is What You Get” |

|

|

Temperature Accuracy |

The temperature difference among all 8 thermal couples and the set temperature is <1°C |

|

Efficiency |

Excellent hot air transfer efficiency with minimum heat loss |

|

Energy Savings |

Huge savings on the electricity bill and air-conditioning with a cooler oven body |

Calibration and Setpoints

You should calibrate your oven regularly to keep energy use low and product quality high. Weekly checks help you maintain efficiency and ensure consistent results. If you wait up to 18 months between calibrations, you risk energy waste and higher defect rates. Setting the right temperature setpoints is just as important. When you choose optimal setpoints, you avoid overheating and save energy without sacrificing quality.

|

Calibration Frequency |

Impact on Energy Usage |

Impact on Product Quality |

|---|---|---|

|

Every 6 months |

Reduces energy waste |

Improves solder joint quality |

|

Up to 18 months |

Potential energy inefficiency |

Increased defect rates |

|

Weekly checks |

Maintains energy efficiency |

Ensures consistent quality |

Note: Use Energy-Saving Tips to guide your calibration schedule and setpoint choices. Small adjustments can lead to big savings over time.

Automated Controls

Automated temperature controls make it easier to manage your oven’s energy use. Many modern ovens use integrated eco-modes that adjust energy usage for optimal efficiency. Some models feature PID intelligent precision controllers that automatically regulate heating volume. These systems keep the temperature balanced and reduce energy consumption.

|

Oven Model |

Feature Description |

Energy Efficiency Aspect |

|---|---|---|

|

jCURE-2UV+ |

Integrated Eco-Mode that adjusts energy usage for optimal efficiency. |

Reduces energy consumption through automation. |

|

I.C.T-IR3 |

PID intelligent precision controller for automatic heating volume control. |

Ensures balanced temperature for energy savings. |

Automated controls help you maintain stable oven conditions. You spend less time making manual adjustments and avoid sudden temperature changes that waste energy. When you use smart controls, you keep your process consistent and lower your operating costs.

Insulation and Airflow

Insulation Upgrades

You can lower your energy costs by improving the insulation in your SMT curing oven. Insulation acts as a barrier that keeps heat inside the oven. When you upgrade insulation, you stop heat from escaping into the workspace. This means your oven uses less energy to maintain the right temperature. You should check the oven walls, doors, and roof for any weak spots. If you find thin or damaged insulation, replace it with high-quality materials. Many facilities use ceramic fiber or mineral wool because these materials resist heat and last a long time.

Tip: Inspect insulation every quarter. Small cracks or gaps can lead to big energy losses over time.

A well-insulated oven stays hot inside and cool outside. This helps you save money on electricity and air conditioning. You also protect your staff from hot surfaces, which improves safety in your facility.

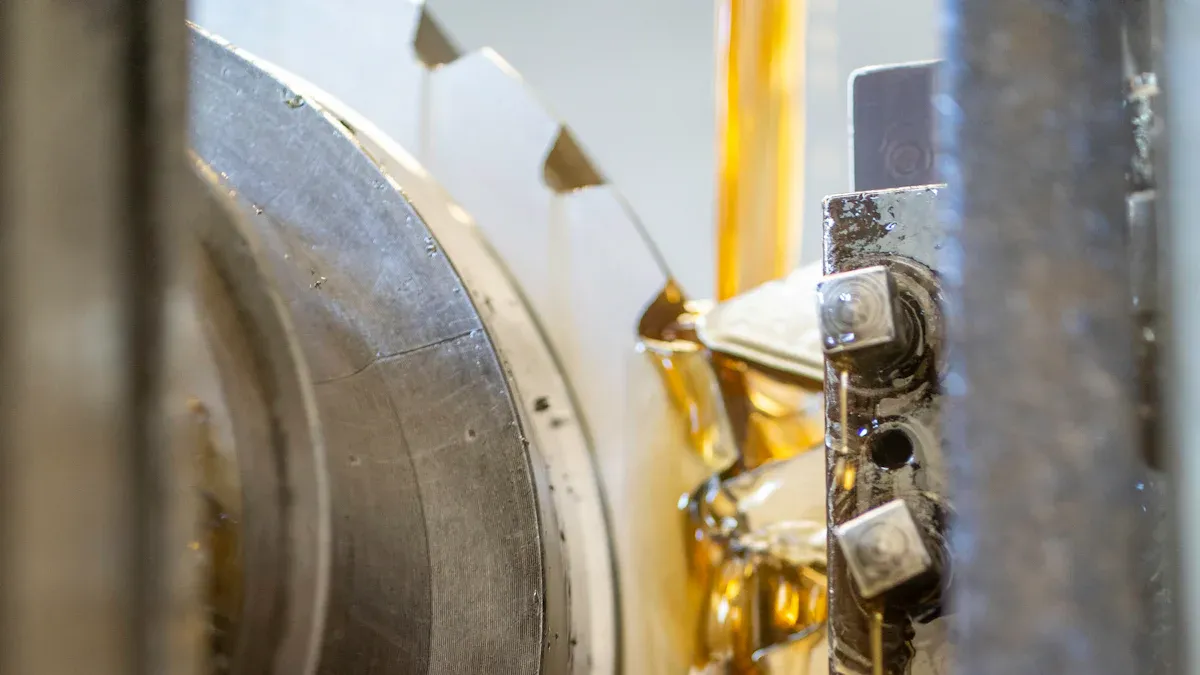

Airflow Optimization

You can boost your oven’s efficiency by managing airflow. Good airflow helps distribute heat evenly and keeps the curing process stable. When you optimize airflow, you recirculate hot exhaust air instead of letting it escape. This process reduces the energy needed for heating and curing. You use less power because the oven reuses heat that would otherwise be wasted.

Many ovens have adjustable fans and dampers. You can set these to control how air moves through the oven. If you notice uneven heating or cold spots, adjust the airflow settings. Some ovens use smart sensors to monitor air movement and make automatic changes. This keeps the temperature steady and lowers your energy bills.

|

Airflow Feature |

Benefit |

Action Step |

|---|---|---|

|

Adjustable Fans |

Even heat distribution |

Set fan speed as needed |

|

Recirculation System |

Lower energy consumption |

Use exhaust air recirculation |

|

Smart Sensors |

Automatic airflow adjustment |

Enable sensor controls |

Note: Effective airflow management not only saves energy but also improves product quality by preventing temperature swings.

Heat Loss Reduction

You can reduce heat loss by sealing entry and exit points on your oven. Heat escapes quickly through doors, conveyor openings, and gaps. When you install tight seals and use insulated curtains, you keep more heat inside. You should check these areas often and replace worn seals right away.

Some ovens use double-door systems or air locks to limit heat loss when loading and unloading. You can also add heat shields around openings to block escaping air. These steps help you maintain a stable temperature and cut down on wasted energy.

-

Inspect doors and conveyor openings weekly.

-

Replace damaged seals immediately.

-

Install insulated curtains or heat shields at entry and exit points.

Callout: Reducing heat loss at entry and exit points is one of the most effective Energy-Saving Tips for SMT curing ovens.

You keep your oven running efficiently when you combine insulation upgrades, airflow optimization, and heat loss reduction. These strategies work together to lower your energy costs and improve your process.

Sealing and Humidity

Door Seals

You can boost your oven’s energy efficiency by upgrading door seals. Superior sealing technology keeps heat inside and stops energy loss every time you open the oven door. The AutoSeal Roll Up Oven Door uses patented air-tight sealing to create a tight environment for curing. This design helps you process more batches each day and keeps your workflow smooth.

-

Energy savings of 10-20% with better seals.

-

Less energy is lost when doors open and close.

-

More batches are processed daily due to stable temperatures.

-

Smaller oven footprint and improved workflow.

Some advanced seals, like the Air Barrier Heat Seal, trap up to 90% of heat that would normally escape. You can see up to 70% reduction in energy usage and costs when you use these technologies. Nearly all heat and smoke stay inside, so your oven runs more efficiently.

Tip: Inspect door seals regularly. Replace worn or damaged seals to keep your oven running at peak efficiency.

Humidity Control

You need to manage humidity in your SMT curing oven to save energy and protect your products. Dry fog humidification gives you precise control. This system creates ultra-fine water droplets that evaporate before they settle. You avoid static buildup and improve ESD protection. Your solder paste stays stable, and you do not get leftover moisture on your boards.

Dry fog humidification helps you keep the right humidity level without wasting energy. You get consistent results and reduce the risk of defects. Your oven uses less power because it does not need to work as hard to maintain stable conditions.

Note: Stable humidity means fewer defects and lower energy bills.

Air Leak Prevention

You can prevent energy loss by stopping air leaks in your oven. Air seals trap heat inside and block cold air from entering. This keeps your oven at the right temperature and increases efficiency.

-

Air seals can cut energy loss by up to 90%.

-

You maintain peak temperatures for better curing.

-

Your oven uses less energy and runs more efficiently.

Check for leaks around doors, panels, and conveyor openings. Fix any gaps right away. When you prevent air leaks, you keep your oven working at its best and save money on energy costs.

Callout: Strong air seals help you keep heat inside, lower your energy bills, and improve your curing process.

Maintenance Routines

Cleaning Components

You keep your SMT curing oven running efficiently when you clean its components regularly. Dust, flux residue, and debris build up on heating elements, fans, and sensors. This buildup blocks heat transfer and forces your oven to use more energy. When you clean these parts, you help the oven maintain stable temperatures and reduce power consumption. A plant director once lowered energy use from 180 kW to 125 kW by following energy efficiency best practices, including routine cleaning. This change saved the facility €28,000 each year.

Tip: Clean heating elements and air filters every month. You prevent energy waste and extend the life of your oven.

You can realistically cut your oven’s energy use by 20 to 30% with proper cleaning and maintenance. Up to 70% of energy can be lost before it reaches the product if you ignore cleaning and let flue gas exhaust and poor insulation go unchecked.

Preventive Maintenance

You avoid costly repairs and keep your oven efficient when you set up a preventive maintenance schedule. Routine inspections catch wear and tear early. You check heating elements, insulation, and seals for damage. You also calibrate temperature controls to make sure your oven runs at the right setpoints. These steps help you spot problems before they cause energy waste or product defects.

-

Inspect key components every quarter.

-

Replace worn parts right away.

-

Calibrate controls on a regular schedule.

You save energy by turning off unused equipment and optimizing oven profiles. Smarter motors and better heat management also boost efficiency.

Monitoring Efficiency

You track your oven’s performance by keeping detailed maintenance logs. These records help you find patterns and predict failures. You monitor energy use, temperature stability, and airflow. When you see a drop in efficiency, you investigate and fix the issue quickly.

|

Maintenance Task |

Benefit |

|---|---|

|

Log inspections |

Spot trends and prevent issues |

|

Track energy use |

Identify waste and save costs |

|

Monitor temperature |

Ensure a stable curing process |

Note: Consistent monitoring helps you maintain savings and avoid unexpected downtime.

You keep your SMT curing oven running at peak efficiency when you combine cleaning, preventive maintenance, and regular monitoring. These routines protect your investment and support your energy-saving goals.

Smart Controls and Upgrades

Energy-Efficient Systems

You can upgrade your SMT curing oven with the latest energy-efficient systems. The U.S. market now demands solutions that save energy because of new trends in semiconductor reshoring and automation. Many facilities choose in-line vertical curing ovens. These ovens boost productivity, keep curing quality consistent, and use less energy. You see more vertical ovens in Germany as well. The country’s strict energy standards under the ‘Green Deal’ and ‘Industrie 4.0’ push companies to adopt smart energy management systems. When you invest in these advanced ovens, you help your facility meet global standards and lower operating costs.

-

In-line vertical curing ovens improve throughput and reduce energy use.

-

Smart energy management systems help you meet strict efficiency standards.

-

Upgrading to energy-efficient ovens supports automation and reshoring trends.

Tip: Energy-efficient ovens can help your facility save money and stay competitive in a changing market.

Smart Controls

You can control your oven’s energy use with smart technology. Modern ovens come with programmable logic controllers (PLCs) and IoT sensors. These tools let you adjust temperature, airflow, and humidity with precision. You set schedules for heating cycles and monitor performance in real time. Smart controls respond quickly to changes in your process. You avoid overheating and keep energy use low. Some ovens even learn your production patterns and optimize settings automatically.

|

Smart Control Feature |

Benefit |

|---|---|

|

PLCs |

Precise process control |

|

IoT Sensors |

Real-time monitoring |

|

Automated Scheduling |

Lower energy consumption |

Note: Smart controls make it easier to follow Energy-Saving Tips and maintain high product quality.

Energy Usage Tracking

You track your oven’s energy use with built-in monitoring systems. These systems show you how much energy your oven uses each day. You spot trends and find areas where you can save more. The U.S. expects to save over $2 trillion by 2030 by adopting energy-efficient technologies. When you track energy use, you set goals and measure your progress. You share results with your team and encourage everyone to look for new ways to save energy.

-

Use built-in monitors to track daily energy use.

-

Review reports to find waste and set savings goals.

-

Share data to motivate your team and improve efficiency.

Callout: Tracking energy use helps you see the impact of your upgrades and supports long-term savings.

Additional Energy-Saving Tips

Preheating Practices

You can lower your oven’s energy use by changing how you preheat materials. When you preheat materials before placing them in the SMT curing oven, you help them reach the target temperature faster. This means the oven does not need to work as hard or use as much power. Using low-temperature curing technology also helps you save energy. You can choose to recycle waste gas from the oven, which further reduces energy use.

Here is a table that shows how different preheating practices affect energy consumption:

|

Preheating Practice |

Energy Consumption Impact |

|---|---|

|

Preheated materials |

Require less energy to reach the desired temperature |

|

Low-temperature curing technology |

Significantly reduces energy consumption |

|

Waste gas recycling |

Reduces energy consumption by 10%-20% |

You should also know that even a small increase in oven temperature can raise energy use. For every 10°C increase in temperature, energy consumption goes up by about 6%. Keeping your oven at the lowest effective temperature helps you save money and energy.

|

Temperature Increase |

Energy Consumption Increase |

|---|---|

|

10°C increase |

6% increase in energy consumption |

Tip: Preheat materials outside the oven when possible. Set your oven to the lowest temperature that still gives you good results.

Heat Recovery Methods

You can use heat recovery methods to capture and reuse energy that would otherwise escape from your oven. Modified waste gas treatment systems collect hot air or gases and use them to preheat incoming air or materials. This process can cut your oven’s energy use by 10% to 20%.

|

Waste Gas Recycling |

Energy Consumption Reduction |

|---|---|

|

Modified waste gas treatment system |

10%-20% reduction in energy consumption |

You can install heat exchangers or recovery units on your oven’s exhaust. These devices transfer heat from outgoing air to incoming air. You save energy and keep your oven running efficiently. Many facilities add these upgrades as part of their Energy-Saving Tips plan.

Note: Heat recovery not only saves energy but also helps you meet environmental goals.

You can make a big impact by using energy-saving strategies in your SMT curing ovens. These changes help you lower costs and support your company’s sustainability goals.

-

Energy-efficient ovens use less power and reduce your environmental footprint.

-

Industrial ovens can use up to 30% of a factory’s energy, so improvements matter.

Start with one or two tips, then add more as you see results. Keep checking your setup and adjust as new technology becomes available. Your actions today help build a greener future.

FAQ

How often should you calibrate your SMT curing oven?

You should calibrate your oven every six months. Regular calibration keeps energy use low and ensures product quality. Weekly checks help you catch problems early.

Tip: Set reminders for calibration to avoid missing scheduled maintenance.

What is the best way to check for air leaks?

Inspect door seals, panels, and conveyor openings every month. Use a smoke pencil or thermal camera to spot leaks.

|

Tool |

Usefulness |

|---|---|

|

Smoke Pencil |

Quick detection |

|

Thermal Cam |

Visual proof |

Can automation really lower energy costs?

Yes, automation helps you control temperature and airflow with precision. Smart controls adjust settings in real time. You save energy and keep your process stable.

Automation reduces manual errors and improves efficiency.

Which insulation material works best for SMT ovens?

Ceramic fiber and mineral wool work best. These materials resist heat and last longer than standard insulation.

-

Ceramic fiber: High heat resistance

-

Mineral wool: Durable and cost-effective