You gain a real advantage when you use PCB conveyors in automated line upgrades. These systems keep boards moving smoothly, which helps you avoid common bottlenecks like misalignment and static electricity. Take a look at this table to see typical issues that PCB conveyors help prevent:

|

Bottleneck Type |

Description |

|---|---|

|

Nozzle Blockages |

Dust, flux residue, or solder balls clogging spray nozzles can cause uneven flux distribution. |

|

Conveyor System Misalignment |

Loose chains or worn gears can lead to skewed boards and inconsistent soldering. |

|

Humidity & Moisture |

High humidity can lead to oxidation or flux failure, affecting soldering quality. |

|

Static Electricity |

Inadequate ESD protection can cause micro-damage to sensitive components. |

The value of PCB conveyors comes from their ability to support steady board flow, boost productivity, and offer cost-effective versatility for your assembly line.

Key Takeaways

-

PCB conveyors enhance efficiency by keeping boards moving smoothly, reducing downtime and errors.

-

These systems offer flexibility, accommodating various board sizes and types, which is crucial for high-mix, low-volume production.

-

Automated handling with PCB conveyors lowers defect rates by up to 30%, improving product quality and customer satisfaction.

-

Regular maintenance is essential to extend the life of your conveyors and prevent unexpected breakdowns.

-

Choosing the right vendor and ensuring compatibility with existing equipment are key steps for successful integration.

Value of PCB Conveyors

Efficiency and Productivity

You want your assembly line to run as smoothly as possible. PCB conveyors help you achieve this by preventing bottlenecks and keeping boards moving at a steady pace. When you use these systems, you can minimize downtime and avoid delays caused by manual handling or misaligned boards.

-

PCB conveyor systems boost production speed, letting you reach outputs of up to 500 boards per hour.

-

Integration with automated equipment can reduce cycle times by as much as 20%.

This improvement in cycle time means you can complete more work in less time. You also reduce the risk of errors that slow down your process. The value of PCB conveyors becomes clear when you see how they help you meet tight deadlines and keep your production targets on track.

Flexibility and Versatility

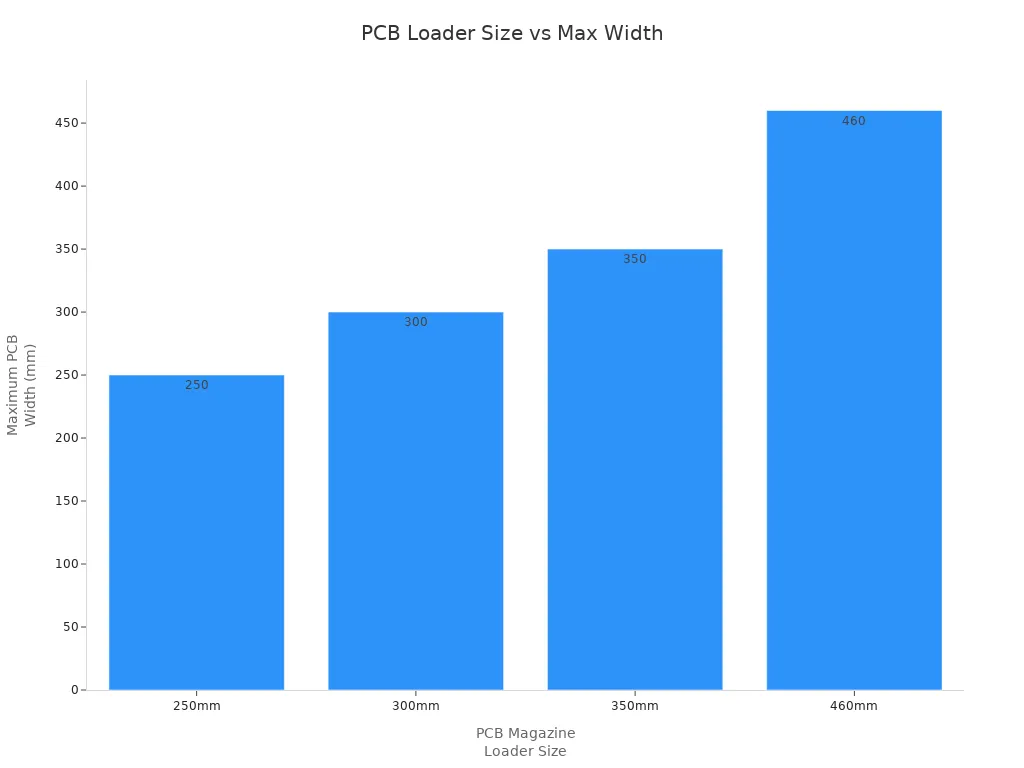

Modern PCB conveyors give you the flexibility to handle a wide range of board sizes and magazine types. You can easily adjust your line to fit different products, which is especially important if you work in high-mix, low-volume environments. The table below shows how different magazine loader sizes accommodate various PCB widths:

|

Maximum PCB Width |

|

|---|---|

|

250mm |

250mm |

|

300mm |

300mm |

|

350mm |

350mm |

|

460mm |

460mm |

You can rely on magazine loaders for frequent changeovers. This feature is essential in industries like medical, aerospace, and industrial electronics, where you often deal with complex assemblies and custom product variants. Flexible PCBA manufacturing solutions let you adapt quickly to design changes and new customer requirements. The value of PCB conveyors stands out when you need to switch between products without slowing down your line.

Reliability and Quality

You want every board to meet high standards. PCB conveyors help you achieve this by providing precise, automated handling. This reduces the risk of defects and improves overall product quality.

-

Automated conveyors lower defect rates by up to 30% by reducing manual handling.

-

ESD-safe conveyor belts protect sensitive components from electrostatic discharge.

-

Speed control features let you match conveyor speed to your manufacturing needs, preventing jams and ensuring smooth transitions.

You also benefit from advanced inspection technologies built into many conveyor systems. These tools catch defects early, so faulty products do not reach your customers. Companies that use automated conveyors often see faster assembly times and improved accuracy. This leads to higher customer satisfaction and a stronger brand reputation. The value of PCB conveyors extends beyond the factory floor, helping you build trust with your customers and stand out in a competitive market.

Tip: Investing in reliable PCB conveyors not only saves you money on repairs and rework but also boosts your company’s image by delivering consistent, high-quality products.

Integration Considerations

Compatibility

When you upgrade your automated line, you need to make sure your new PCB conveyors work well with your existing equipment. Many modern conveyors use the SMEMA interface, which helps them connect easily with other machines. You should look for these key features:

-

SMEMA interface for seamless integration with other automated equipment

-

Adjustable settings for different PCB sizes

-

User-friendly controls for quick setup and operation

Sometimes, you may face challenges when adding new conveyors to older production lines. Older machines might not match the new systems, which can cause technical problems. You can avoid most issues by checking compatibility before you buy.

Adjustability

You want your conveyor to handle many board sizes and thicknesses. Adjustable conveyors let you switch between products without slowing down your line. Here are some common adjustability features:

|

Feature |

Description |

|---|---|

|

Automatic Width Adjustment |

Uses RS-485 communications, motorized width adjustment, or Ethernet-based center master software. |

|

Manual Width Adjustment |

Lets you change conveyor width with a hand crank. |

|

Conveyor Width Range |

Handles boards from 50mm up to 460mm wide. |

|

PCB Thickness Range |

Supports thicknesses from 0.5mm to 2.5mm. |

These features help you keep your line flexible and ready for new products. You can meet customer needs faster and reduce downtime.

Safety

Safety is a top priority in any automated line. You must follow best practices to protect your team and your equipment. Important safety tips include:

|

Safety Tip |

Description |

|---|---|

|

Use it Properly |

Never climb, sit, or touch the conveyor while it runs. |

|

Turn it OFF before Working ON |

Always disconnect power before maintenance. Never open panels with power on. |

|

Keep It Covered |

Operate with safety guards in place to protect people and products. |

|

Be a Know-It-All |

Only trained staff should use the system. They must know emergency controls. |

|

Write It Down |

Do not change the system outside approved steps. Watch for unauthorized changes. |

|

Maintain Distance |

Keep hair, clothes, and body parts away from moving parts. |

|

Audible Warning Signal |

Make sure the system gives a warning before starting. Train everyone to recognize the signal. |

Following these guidelines helps you avoid accidents and keeps your production running smoothly. When you focus on compatibility, adjustability, and safety, you get the full value of PCB Conveyors in your automated upgrades.

Selecting PCB Conveyors

Assessing Needs

Before you choose a PCB conveyor, you need to understand your production requirements. Start by gathering all the details about your process. Think about the size and weight of your PCBs. Check how many boards you need to move each hour. Look at your available floor space and the layout of your assembly line. Decide if you need a belt, chain, or buffer conveyor. Consider how much automation you want and if you need adjustable features. Make sure your conveyor offers ESD protection and meets safety standards. Check if it will work with your current equipment. Plan for future maintenance and support. Set a clear budget for your purchase.

Tip: Carefully plan your line layout. Use modular or overhead conveyors to save space and improve workflow.

Evaluating Features

When you compare different PCB conveyors, focus on the features that matter most for your operation. Production volume and board size play a big role. High-volume lines often need durable conveyors with buffering abilities. Smaller operations may benefit from adjustable-width conveyors for flexibility. Always check if the conveyor can handle your board’s size and weight.

|

Feature |

Description |

|---|---|

|

Keeps covers closed during transfer for safety. |

|

|

Auto-shutoff |

Protects operators by shutting off during power spikes. |

|

Heavy Bottom |

Adds stability and reduces vibration. |

|

Automated Width Adjustment |

Adapts quickly to different PCB sizes. |

|

ESD Protection |

Shields sensitive components from static damage. |

Premium models use thick aluminum and stable designs for extra durability. Features like automated width adjustment and ESD protection can raise the price, which usually ranges from $600 to $6,000.

Vendor Checklist

Choosing the right vendor is just as important as picking the right conveyor. Use this checklist to guide your decision:

-

Ask about manufacturing capacity and component availability.

-

Review quality control steps, such as AOI testing and traceability.

-

Evaluate supply chain strength and backup plans for parts.

-

Confirm lead times and delivery guarantees.

-

Test communication and technical support.

-

Compare pricing and look for hidden fees.

-

Request references and review past projects.

Note: A reliable vendor helps you avoid delays and ensures your conveyor meets all your needs.

Avoiding Common Pitfalls

Integration Issues

You may face problems if you do not plan integration carefully. Poor integration can cause delays, misaligned boards, or even equipment damage. Always check that your new PCB conveyors match your existing machines. Use standard interfaces like SMEMA to make connections easier. Test the system before full production. Train your team on new controls and safety features. If you skip these steps, you risk costly downtime and lower product quality.

Tip: Involve your equipment suppliers early in the process. They can help you spot compatibility issues before they become bigger problems.

Maintenance

Neglecting maintenance can shorten the life of your PCB conveyors and lead to unexpected breakdowns. You can keep your system running smoothly by following a regular maintenance schedule. Here are some best practices:

-

Lubricate moving parts every 100 to 200 hours to reduce friction.

-

Clean the conveyor weekly or monthly to prevent material buildup.

-

Inspect belt alignment often to avoid uneven wear.

-

Check for unusual noise or vibration.

-

Perform daily visual inspections for alignment and wear.

-

Keep spare parts on hand to minimize downtime.

-

Document all maintenance procedures for quick reference.

Regular maintenance extends the lifespan of your conveyors and improves efficiency. Well-maintained systems have fewer interruptions and help you meet your production goals.

Planning for Growth

You need to think ahead when upgrading your automated line. If you do not plan for future growth, you may outgrow your equipment too soon. Modular conveyor systems give you flexibility. You can expand or reconfigure them as your needs change. Consider these factors when planning for expansion:

|

Factor |

Description |

|---|---|

|

Technological Advancements |

Use IoT and AI for predictive maintenance and process optimization. |

|

Regulatory Frameworks |

Follow industry standards and sustainability rules. |

|

Demand for Sustainable Practices |

Choose energy-efficient and eco-friendly systems. |

|

Market Drivers |

Prepare for rising demand in consumer electronics. |

|

Regional Dynamics |

Watch for growth in areas like Asia-Pacific and Latin America. |

Modular systems make it easy to scale up or adapt your line. This approach helps you stay competitive and ready for new opportunities.

PCB conveyors bring real value to your automated line upgrades. You gain:

-

Improved workflow efficiency through automated board movement

-

Fewer manual errors, which boosts assembly accuracy

-

Higher productivity, letting you focus on complex tasks

Careful selection, integration, and regular maintenance keep your line running smoothly. Use this table to guide your decisions:

|

Design Consideration |

Description |

|---|---|

|

Load Capacity and Throughput |

Match conveyor to board size and weight for best results. |

|

Conveyor Drive System |

Pick direct, chain, or belt drives for your needs. |

|

Automation Integration |

Ensure smooth operation with robotics and sensors. |

|

Material Selection |

Choose durable, compliant materials. |

|

Space and Layout Optimization |

Plan layouts to maximize efficiency. |

Consider consulting with experts or assessing your production line to ensure a successful upgrade.

FAQ

What is the main benefit of using PCB conveyors in automated lines?

You get steady board movement and fewer bottlenecks. This helps you boost productivity and reduce manual errors. PCB conveyors also make your assembly line more reliable.

How do I choose the right PCB conveyor for my needs?

You should look at your board sizes, production speed, and space. Check for features like ESD protection and adjustability. Use a vendor checklist to compare options.

Can PCB conveyors handle different board sizes?

Yes, most modern PCB conveyors let you adjust width and height. You can switch between products quickly. This flexibility helps you meet changing customer demands.

Tip: Always check the conveyor’s adjustment range before you buy.

How often should I maintain my PCB conveyor?

You should inspect and clean your conveyor weekly or monthly. Lubricate moving parts every 100 to 200 hours. Regular maintenance keeps your system running smoothly and prevents breakdowns.