Reflowing a Circuit Board in an oven requires you to work step by step. You prepare your board, apply solder paste, and place your components with care. You can use a kitchen oven or a modified toaster oven for this task. Temperature control makes a big difference in the final quality.

Safety matters most—always wear protective gear and work in a well-ventilated area. With patience and attention, you can achieve strong, reliable solder joints at home.

Key Takeaways

-

Always prioritize safety. Wear protective gear, work in a well-ventilated area, and keep your workspace organized to avoid injuries.

-

Prepare your circuit board by cleaning it thoroughly. Use isopropyl alcohol or an ultrasonic cleaner to ensure strong solder joints.

-

Control the oven temperature carefully. Follow the recommended temperature profiles for your solder paste to achieve reliable solder connections.

-

Monitor the reflow process closely. Watch for the solder to turn shiny, indicating it has melted properly. Avoid opening the oven during this stage.

-

Cool the board slowly after reflowing. Let it sit in the oven for a few minutes before removing it to prevent thermal shock.

What You Need

Tools & Materials

You need the right tools and materials to reflow a circuit board in an oven. Start by gathering your components and equipment. This step helps you work efficiently and avoid mistakes.

-

10K and 4.7K resistors

-

Tactile push button

-

1602 LCD display

-

100K thermistor

-

Male pin headers

-

PCB-mount screw terminals

-

Panel-mount emergency stop button

-

Panel mount indicator light

-

Panel-mount two-position rotary switch

-

Wall outlet with cover

-

Toaster oven

-

12 AWG wire

-

Fused IEC connector with switch

-

PLA filament

-

M4 screws and nuts

-

3mm heatshrink tubing

-

Kapton tape

You also need some basic tools:

-

Soldering iron and 60/40 solder

-

Heat gun or lighter

-

Screwdrivers

-

Wire cutters

-

Pliers

-

Utility knife

-

Super glue

A 3D printer can help you make custom parts, but you can complete most projects without it.

Tip: Always check your parts list before you start. Missing a single component can delay your project.

You must choose the right solder paste for oven reflow. Each type melts at a different temperature. The table below shows common options:

|

Solder Paste Type |

Melting Point (°C) |

|---|---|

|

No Clean OM338 SAC405 |

217 |

|

Leaded Solder Paste |

183 |

|

Lead-Free SAC305 |

217 |

Safety Gear

Protect yourself from fumes and burns during the reflow process. Good safety gear keeps you safe and comfortable.

|

Safety Gear |

Description |

|---|---|

|

Fume Extractor |

Use a small fume extractor with a carbon filter to remove harmful fumes. |

|

Ventilation |

Work near an open window or use a fan to keep the air fresh. |

|

Mask |

Wear an N95 mask if ventilation is limited to block particles. |

|

Safety Glasses |

Put on impact-resistant glasses to shield your eyes from solder splashes. |

Note: Never skip safety gear. Solder fumes and hot components can cause serious injuries. Always work in a well-ventilated area and keep your workspace organized.

Prepare the Board

Clean the Board

Start by making sure your circuit board is spotless. Cleanliness plays a big role in the quality of your solder joints. Dust, grease, or fingerprints can cause soldering defects and reduce the reliability of your project. You have a few effective cleaning methods to choose from:

-

Manual Cleaning with Isopropyl Alcohol: Set up your workspace. Use compressed air to blow away loose dust. Apply isopropyl alcohol to a lint-free cloth or brush, then gently scrub the board. Let it dry completely.

-

Ultrasonic Cleaning: For stubborn residues, use an ultrasonic cleaner. Fill it with a suitable cleaning solution, submerge the board, and set the timer. Rinse and dry the board after cleaning.

-

Automated Cleaning Systems: These are common in factories but less practical for home use.

Tip: Always clean your board before you Reflow A Circuit Board. This step helps solder paste stick better and ensures strong connections.

Apply Solder Paste

Once your board is clean, apply solder paste to the pads. The right amount and pattern matter for a successful reflow. Most hobbyists use a stencil to control the thickness and placement. Standard stencil thickness is about 0.12 mm, but you may need a thinner stencil (0.10 mm) for tiny parts or a thicker one (0.15 mm) for larger components. Make sure the stencil openings are slightly smaller than the pads to prevent solder bridges.

-

Use a plastic card or squeegee to spread the paste evenly.

-

Remove the stencil carefully to avoid smearing.

Place Components

Now, place your components onto the board. The flux in the solder paste will help hold them in place. Pay attention to the orientation of each part. For best results:

-

Place components with steady hands and use tweezers for small parts.

-

Keep similar parts facing the same direction for easier inspection.

-

Surface tension during reflow will help center the components, but accurate placement reduces the risk of movement.

-

For heavy or bottom-mounted parts, consider a small drop of adhesive.

Note: Careful placement now saves you time and trouble later.

Oven Setup

Choose an Oven

You can use either a kitchen oven or a modified toaster oven to reflow a circuit board at home. Each type has its own strengths and weaknesses. The table below helps you compare the two options:

|

Aspect |

Kitchen Oven |

Modified Toaster Oven |

|---|---|---|

|

Thermal Inertia |

Higher thermal inertia, heats and cools more slowly |

Lower thermal inertia, heats and cools faster |

|

Heating Elements |

Typically ceramic heaters |

Can have quartz heaters for faster response |

|

Airflow |

May require modifications for better airflow |

Small fans may cause issues during reflow |

|

Control |

Manual controls preferred for reliability |

Limited external control over the fan |

|

Component Handling |

Better for larger components |

May displace smaller components due to airflow |

|

Cost |

Generally more expensive |

Can be more cost-effective with basic models |

A kitchen oven works well for larger boards and components. A toaster oven heats up and cools down faster, which gives you more control over the process. Always avoid using the same oven for food after you reflow a circuit board.

Temperature Settings

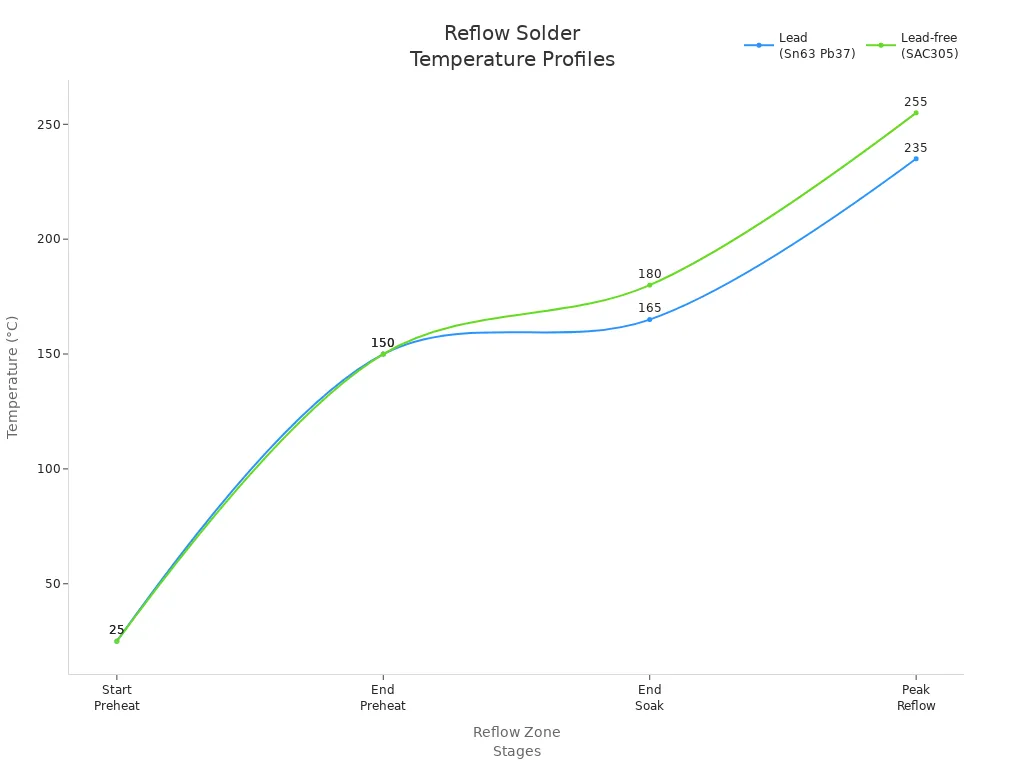

Proper temperature control is key to strong solder joints. You need to follow a temperature profile that matches your solder paste. Leaded and lead-free solder require different peak temperatures and timing. The chart below shows the recommended profiles:

|

Zone |

Lead (Sn63 Pb37) |

Lead-free (SAC305) |

|---|---|---|

|

Preheat |

to 150 °C in 60 s |

to 150 °C in 60 s |

|

Soak |

from 150 °C to 165 °C in 120 s |

from 150 °C to 180 °C in 120 s |

|

Reflow |

Peak 225–235 °C, hold for 20 s |

Peak 245–255 °C, hold for 15 s |

|

Cooling |

-4 °C/s or free-air cooling |

-4 °C/s or free-air cooling |

Uniform oven temperature is crucial. Uneven heating can cause problems like tombstoning, cold solder joints, or bridging. Try to keep the temperature steady across the whole oven to ensure every part of your board heats evenly.

Tip: Use an oven thermometer or multiple sensors to check for hot and cold spots before you reflow a circuit board.

Arrange the Board

How you place your board in the oven affects the quality of your results. Follow these tips for even heating:

-

Place the board on a wire rack or perforated tray to allow air to circulate underneath.

-

Keep the board centered in the oven, away from the walls and heating elements.

-

Avoid stacking boards or placing them too close together.

-

Use convection heating if your oven supports it. Forced hot air helps distribute heat evenly and reduces thermal stress on components.

-

If you use infrared heaters, watch for hot and cold spots. Move the board if needed to avoid uneven heating.

Commercial reflow ovens use conveyor belts and multiple heat zones for perfect results. At home, you can achieve reliable solder joints with careful setup and attention to detail.

Reflow A Circuit Board

Start the Reflow

You have prepared your board and set up your oven. Now you are ready to start the reflow process. Place your board in the center of the oven. Close the door gently to avoid moving any components. Set your oven to follow the temperature profile for your solder paste.

Follow these steps to Reflow A Circuit Board:

-

Preheat: Raise the oven temperature to about 150 °C. Hold this temperature for 60 seconds. This step helps remove moisture and prepares the board for soldering.

-

Soak Zone: Increase the temperature slowly to between 150 °C and 180 °C. Keep the board in this range for 60 to 120 seconds. This allows the solder paste to activate and spread. If you rush this step, you may get poor solder joints. If you stay too long, the flux may lose its effectiveness.

-

Reflow Zone: Raise the temperature to the peak (225–255 °C, depending on your solder paste). Hold this temperature for 30 to 90 seconds. Watch for the solder to melt and become shiny. This is the most important part of the process. Do not let the board stay at this temperature for too long. Too much time can damage your components.

Tip: Use an oven thermometer to check the actual temperature inside your oven. Oven dials are often inaccurate.

Monitor the Process

You need to watch your board closely during the reflow process. Look through the oven window if possible. You will see the solder paste change from a dull gray to a shiny, liquid state. This is a clear sign that the solder has melted and is forming good joints.

To avoid problems, keep these points in mind:

-

Make sure components do not move or float on the solder. Accurate placement before reflow helps prevent shifting.

-

Avoid opening the oven during reflow. Sudden changes in temperature or airflow can cause components to shift or create cold joints.

-

Manage the oven’s thermal profile. High convection rates can push small parts out of place. Use gentle heating and avoid strong fans.

-

Check that the solder paste holds each component securely. If you see any parts moving, stop the process and fix the placement before trying again.

Note: Careful monitoring helps you catch issues early. You can prevent overheating and avoid costly mistakes.

Cooling Down

After the solder has melted and formed joints, you need to cool the board. Turn off the oven and open the door slightly. Let the board cool down slowly in the oven for a few minutes. This helps prevent thermal shock, which can crack solder joints or damage components.

Follow these steps for safe cooling:

-

Do not move the board right away. Let it sit until the temperature drops below 100 °C.

-

Once the board is cool enough to touch, remove it from the oven using heat-resistant gloves.

-

Place the board on a flat, heat-safe surface. Allow it to reach room temperature before handling or testing.

Tip: Never use fans or cold air to speed up cooling. Rapid cooling can cause cracks in the solder joints.

You have now completed the main steps to Reflow A Circuit Board. Careful timing, close monitoring, and gentle cooling all help you achieve strong, reliable solder joints.

Safety & Tips

Safety Precautions

When you reflow a circuit board in an oven, safety must come first. High temperatures and electrical equipment can cause serious injuries if you do not follow proper precautions. Always keep these steps in mind:

-

Wear safety work clothes, gloves, and protective glasses.

-

Power down and unplug all equipment before maintenance or moving.

-

Avoid touching heating elements or moving parts during operation.

-

Never bypass safety switches or ignore warning labels.

-

Handle high-voltage components with extreme care.

-

Use a mask and work in a well-ventilated area to avoid inhaling fumes or fibers.

-

Do not operate equipment with faults or hidden dangers.

-

Prevent shaking or vibration during transport to protect your board.

⚠️ Tip: Always double-check that the oven is off and cool before you reach inside.

Troubleshooting

You may face common issues during the reflow process. Use this table to identify problems and find solutions:

|

Issue |

Cause |

Solution |

|---|---|---|

|

Cold Solder Joints |

Not enough heat or poor paste |

Reheat with flux and a hot air tool |

|

Tombstoning |

Uneven heating or misplacement |

Balance copper, improve placement |

|

Solder Balls |

The heating rate is too high |

Lower the heating rate |

|

Cracked Capacitors |

Rapid temperature changes |

Slow down heating and cooling |

|

Delamination |

Moisture in PCB |

Pre-bake boards, store in dry conditions |

If you spot a cold joint, apply a little flux, use a hot air tool at 300–350°C, and let the joint cool naturally. Always inspect your repairs with a magnifier and test with a multimeter.

Best Practices

You can improve your results by following these best practices:

-

Store solder paste in a cool place and let it reach room temperature before use.

-

Clean your PCB with isopropyl alcohol before applying solder paste.

-

Inspect all components for bent pins or damage.

-

Use an external digital thermometer to check oven temperature at key points. This helps you calibrate your oven for precise control.

-

Modify your oven with extra heating elements or insulation for even heat. A convection fan can help, but use it carefully to avoid moving small parts.

-

Regularly calibrate your oven and check for hot or cold spots.

🛠️ Note: Careful preparation and monitoring lead to reliable, professional-quality solder joints every time.

You can master circuit board reflow at home by following these steps: prepare your board, set up your oven, reflow with care, and inspect your work. Pay close attention to temperature control and safety. Common mistakes like misalignment, popcorning, and voiding can be avoided with patience and proper technique.

|

Mistake |

How to Avoid |

|---|---|

|

Misalignment |

Minimize movement, use flux |

|

Popcorning |

Keep components dry |

|

Voiding |

Preheat longer, switch paste |

Try different methods and tools. Use a thermometer for manual control. With practice, you will improve your results and build reliable boards.

FAQ

Can I use my regular kitchen oven for reflow soldering?

You can use a kitchen oven, but never use it for food again. Solder fumes can contaminate surfaces. A dedicated toaster oven works better for electronics projects.

How do I know when the solder has melted properly?

Watch for the solder to turn shiny and form small, smooth beads around each pad. You can see this change through the oven window. Do not open the oven during this stage.

What should I do if components move during reflow?

-

Pause the process.

-

Let the board cool.

-

Reposition the components with tweezers.

-

Restart the reflow cycle.

Careful placement before heating helps prevent this issue.

Is lead-free solder paste safer than leaded paste?

Lead-free solder paste reduces health risks, but you still need good ventilation. Both types release fumes. Always wear a mask and use a fume extractor for safety.

Can I reflow double-sided boards in a home oven?

You can reflow double-sided boards. Place heavier components on the bottom side first. Reflow that side, then add the top components and repeat. Use minimal solder paste to help parts stay in place.