You can reduce voids in reflow soldering by changing your process. Try making the preheat time longer so the solvent in the flux can turn into vapor. Increase the soak zone time to allow gases to escape before the solder solidifies. Pick solder paste with less volatile components to cut down on moisture and leftover material. Change your stencil so gas can escape more effectively during reflow. Pay attention to these steps to achieve better results and maintain a steady process.

Key Takeaways

Make preheat and soak times longer so gases can leave before the solder gets hard.

Pick solder paste that does not have much volatile stuff to help stop voids from forming.

Use a stencil with smaller holes so gas can get out more easily.

Use vacuum reflow because it can lower the number of voids in solder joints a lot.

Keep the workspace clean so dirt does not trap gases.

Voids in Soldering

What Are Voids

Sometimes, you see tiny holes or bubbles in solder joints after reflow soldering. These holes are called voids. Voids happen when air or gases get stuck in the melted solder and cannot get out before it cools down. There are different kinds of voids you might find in solder joints:

Starvation Voids: These look like big bubbles. They show up if you use too little solder paste or when gases leave during heating.

Solder Voiding: These are small holes inside the solder joint. They connect surface-mount parts to the PCB and may not be spread out evenly.

General Solder Joint Voids: These are air pockets anywhere in the solder. They can make the joint weaker and lower how well it moves heat and electricity.

Voids can look different. Some are small and spread out. Others are big and close together. You need to know about these types to help stop voids from happening.

Why Voids Matter

Voids can change how your electronics work. If you have voids in solder joints, you might lose strength and trust in your product. Here are some ways voids can hurt your assemblies:

Macrovoids and micro-via voids often show up in solder paste. These can make the joint less strong.

Voids make it harder for solder joints to dissipate heat. Your device could get too hot or break sooner.

The size and spot of voids can change how much force the joint can take. Big voids near the edge can start cracks and cause harm.

Tip: Small, spread-out voids might help solder joints last longer, but big groups or large voids can make damage happen faster.

Here is a simple table to show how voids affect reliability:

Findings | Implications on Reliability |

|---|---|

Small dispersive voids are beneficial | Can help solder last longer |

Clusters of voids accelerate damage | Make solder not last as long |

Large voids at the edges initiate damage | Make reliability much lower |

You should always look for voids and learn how they change your products. This helps you make better choices and improve your process.

Causes of Voids

Solder Paste

There are many reasons for voids in solder joints. Solder paste is a big reason. The type and amount of flux in the paste matter. More volatile compounds in paste can cause macrovoids. Adding silver to solder spheres can make more voids. Small amounts of other metals in SAC alloys also cause more macrovoids than SAC305. The PCB’s surface finish helps solder stick better and lowers voids. Nickel-based finishes make solder joints stronger and reduce voids.

Study | Findings |

|---|---|

Kim et al. [40] | |

Ribas et al. [41] | Small dopants in SAC alloy cause more macrovoids than SAC305. |

Bušek et al. [42] | The amount and type of flux change solder voiding. |

Alakayleh et al. [43] | Paste alloy and how much you use both matter for voids. |

Surface Finish | Makes solder stick better and lowers voids. |

Nickel-based Finishes | Make solder joints stronger and lower voids. |

Reflow Profile

How you heat the board during reflow changes voids. The ramp rate controls how fast flux gases leave. More time above the liquidus lets more gases escape. Too much time can make extra outgassing. Higher peak temperatures help solder stick better and lower voids. Using nitrogen during reflow also helps solder stick and lowers voids. You should watch these settings to keep voids low.

Ramp rate: Controls how fast flux gases leave.

Time above liquidus: More time lets more gases escape.

Peak temperature: Higher heat helps solder stick.

Reflow atmosphere: Nitrogen helps lower voids.

Stencil Design

Stencil design changes how solder paste sits on pads. Large apertures can make parts tip or float. This can hurt the joint. Dividing the stencil into four parts helps stop floating. It also lets gases escape. This design helps gases leave, which lowers voids. Sometimes, using more solder can help, but it depends on the size of the hole and part.

Large holes can make parts float.

Four-part stencil helps gases escape.

More solder can lower voids, but the results are different.

Process Variables

Many process variables change how voids form. You should check the solder paste mix and how much flux you use. Heating speed, flux time, and temperature all matter. Time and temperature above the liquidus are important. Using nitrogen in reflow can help lower voids. Chemicals from making the PCB can turn to gas and make tiny voids. You need to control these things to lower voids and make joints stronger.

Tip: Keep your process steady and watch for changes. Small changes can really help your results.

Ways to Reduce Voids

Solder Paste Selection

You can lower voids by picking the right solder paste. Choose paste with less volatile content. This kind of paste makes fewer bubbles when heated. Newer paste types give better results and fewer problems. Try out different pastes to see which works best for you. Some companies have test kits that check over 20 things about solder paste. You can also change the test plan to match what you need.

Here is a table showing what to check when picking solder paste:

Characteristic Category | Description |

|---|---|

Paste Formulation | Newer paste types can help stop voids. |

Evaluation Process | Test kits check many solder paste features quickly. |

Customization | You can change test plans for your needs. |

Tip: Solder paste with more active flux can help lower voids in solder joints.

You should know that pastes with less volatile content, like some water-soluble types, have a lower chance of making voids than pastes with more volatile content.

Solder pastes with less volatile content help stop voids.

Paste with more active flux lowers voids.

Try different pastes to get the best results.

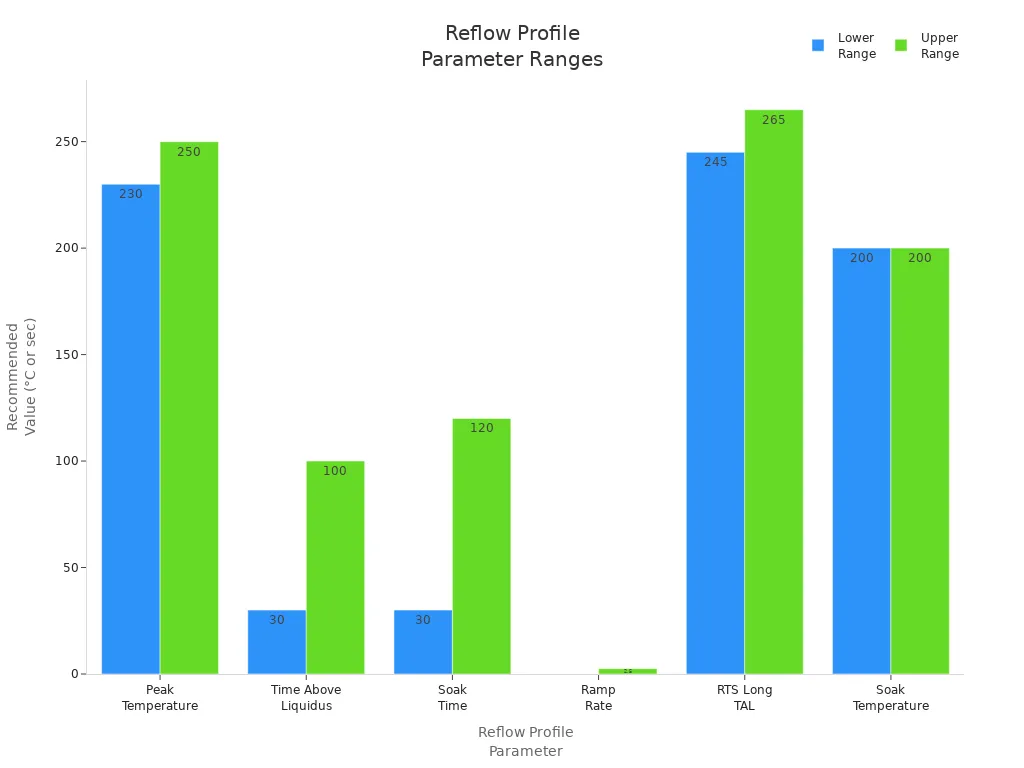

Reflow Profile Optimization

You can lower voids by changing how you heat the board. Set the right peak temperature, soak time, and ramp rate. These settings help gases leave before the solder gets hard. Longer preheat or soak times help heat spread and make the flux work. This is important for area array packages. For lead-free solder, soak time helps less, but it still matters.

Here is a table with good reflow profile settings:

Parameter | Recommended Range |

|---|---|

Peak Temperature | 446 to 482°F (230 to 250°C) |

Time Above Liquidus (TAL) | 30 to 100 seconds |

Soak Time | 30 to 120 seconds |

Ramp Rate | 0 to 2.5 °C/second |

RTS Long TAL | TAL of 60 to 90 seconds, Peak Temp 473 to 509°F (245 to 265°C) |

Soak Temperature | Up to 392°F (200°C) is good for soak |

Note: Making preheat or soak times longer helps lower voids. This lets heat spread and flux work better. It helps gases leave before the solder cools.

Watch your reflow profile and make small changes to see what works. Try a ramp-soak-spike or a linear ramp-to-spike profile. These ways help lower voids and make solder joints better.

Stencil Adjustments

You can lower voids by changing your stencil design. The thickness and shape of the stencil are important. Thicker stencils (5 mil) work better than thin ones (4 mil). If the stencil is too thick, it can cause problems with paste spreading. Check the size and shape of the holes. Smaller holes help gases leave and lower the total area of voids. Using a few small holes for each pad helps the paste move and lets bubbles out.

Here is a table showing how stencil thickness changes voids:

Stencil Thickness (mil) | Voiding Performance |

|---|---|

4 | Not as good |

5 | Works better |

6 | Area ratio too high |

7 | Usually not used |

Make solder paste move better.

Make sure the stencil is of good quality and holes are the right size.

Make holes a bit smaller than the pad to stop too much paste.

For small parts, change the hole size to get enough paste and lower voids.

Tip: Using a few small holes for each pad helps lower voids by letting gas out more easily.

Vacuum Reflow

You can lower voids by using vacuum reflow. This way uses a vacuum to pull out trapped gases during soldering. Regular reflow leaves about 25% voids. Vacuum reflow can lower this to 1% to 5%. Sometimes, it can be as low as 0.5%. This makes solder joints stronger and more reliable.

Regular reflow: about 25% voids.

Vacuum reflow: 1% to 5% voids, sometimes only 0.5%.

Note: Vacuum reflow works well, but it has some problems. You need to control preheating, peak temperature, and cooling. You might have trouble with speed, time, and equipment cost. You also need to watch the temperature, air flow, and how fast things move.

If you want to lower voids as much as you can, vacuum reflow is a good choice. Think about the good and bad points before you change your process.

Process Control

PCB Cleanliness

You can stop voids by keeping PCBs and parts clean. Dirt and dust can trap gas during reflow. This trapped gas makes voids in solder joints. Always store solder paste the right way. Make sure boards and parts do not have oil or fingerprints. Clean parts help stop voids from forming. If your Hi-Pot test is above 500 MΩ, your process is working well.

Keep solder paste in a cool, dry place.

Clean PCBs and parts before you put them together.

Tip: If there is oxidation, solder will not stick well. This can make more voids. Clean boards help solder flow and stick better.

Key Practice | Contribution to Reducing Voids | Metrics for Success |

|---|---|---|

Doing good cleaning | Removes things that hurt insulation resistance |

Placement Accuracy

You must put each part in the right place. If parts are not lined up, solder can bridge or leave gaps. These problems trap air and make voids. AOI helps you find mistakes early. Good placement makes solder joints stronger. This is very important for small parts like BGAs. Even a small void can make the joint weak. It can also cause heat or electricity problems.

Note: In cars or planes, even small voids can cause failure. Always check placement to keep products safe.

Environmental Factors

You need to control the air in your work area. High humidity and heat can make more voids. Water in the air reacts with solder flux. This can cause rust and more voids. Acidic stuff from solder pads gets worse with high humidity. These things can soak up water and cause leaks and more voids.

Keep humidity and temperature steady in your work area.

Use air conditioning or dehumidifiers if you need them.

Check for water-soluble stuff on your boards.

Callout: High humidity and heat make rust and voids form faster. Keep your work area dry and cool for best results.

More Ways to Reduce Voids

Inspection and Feedback

You can find voids early by using special inspection tools. Radiographic testing uses X-rays to look inside solder joints. X-ray PCB inspection lets you see inside boards without breaking them. Ultrasonic testing uses sound waves to find hidden problems. Thermal imaging shows heat changes that can mean there are defects. These tools help you find voids you cannot see with your eyes.

Technique | Description | Benefits |

|---|---|---|

Radiographic Testing (RT) | Uses X-rays or gamma rays to make pictures of the inside parts. | Finds cracks and voids with high accuracy. |

X-ray PCB Inspection | Looks inside multilayer PCBs without damage. | Finds voids in solder joints and keeps the PCB safe for more tests. |

Ultrasonic Testing | Uses sound waves to find problems inside. | Finds hidden defects that can hurt how well products work. |

Thermal Imaging | Uses infrared cameras to see heat changes. | Finds problems you cannot see with regular inspection. |

You should use these tools to catch problems before they get worse. Finding voids early saves money and keeps products working well. X-ray PCB inspection is good for boards with many layers. You can see voids and fix them before you send out your products.

Feedback loops help companies collect and use feedback from different people. This makes things better all the time.

Set up a feedback system in your process. You can set goals, teach your team, and make clear ways to share feedback. Regular feedback helps you see patterns and make changes fast. Let everyone share ideas both ways. Make sure feedback is clear and easy to use.

Set goals for your process

Make a feedback plan

Teach workers and managers

Make clear ways to give feedback

Give feedback often

Let everyone share ideas

Use feedback that is clear and useful

Give help and tools

Check how feedback works

Celebrate wins and improvements

Continuous Improvement

You can lower voids by always trying to make your process better. New studies show changing the thermal profile can cut voids from 22% to less than 8%. Using a thicker stencil, like 5 mil, also helps. Using special solder paste made to stop voids can lower them from 45% to less than 10%.

Try these ideas to keep getting better:

Strategy Type | Description | Impact on Voids |

|---|---|---|

Change process steps and tool paths, use better materials. | Makes fewer voids by improving how things are made. | |

Toolpath Design | Use Medial Axis Transformation for planning. | Cuts down core voids but may use too much material. |

Adaptive Track Width | Change track width to fit the layer shape. | Fills gaps between tracks and makes things more accurate. |

In-situ Techniques | Use heat and ultrasonic vibration while making things. | Heating before and after lowers voids and makes joints stronger. |

You should use data to help you make choices. Watch things like peak temperature, time above liquidus, ramp rate, and soak time. Using data helps you pick the best settings for your process. Profiling gives you feedback right away that changes your results.

‘Profiling is the only real-time input variable that affects outcomes.’ – Tim O’Neil, AIM

Keep testing and changing your process. Celebrate when things get better and share good ideas with your team. Always improving helps you make better products and stay ahead.

Reducing voids in reflow soldering means making good choices and watching your process closely. Here are some important steps you can take:

Step | What You Should Do |

|---|---|

Change the heat and time for strong joints with fewer voids. | |

Pick pastes that make fewer voids and have active flux. | |

Stencil Design | Use holes that let gas out easily. |

Process Control | Keep your work clean and your process steady. |

Keep looking at your results and change your process if needed. Ask experts for help if you have hard problems. Using data and always trying to get better helps you make good products and save materials over time.

FAQ

What causes most voids in reflow soldering?

You often see voids because of trapped gases from solder paste or flux. Fast heating or using paste with high volatile content increases voids. Poor stencil design also lets less gas escape.

How can you check for voids in solder joints?

You can use X-ray inspection to see inside solder joints. This method helps you find hidden voids without damaging your board. AOI and thermal imaging also help spot defects.

Does vacuum reflow always reduce voids?

Vacuum reflow lowers voids in most cases. You must control temperature and timing for the best results. Some boards may need extra adjustments for very low void levels.

Can changing solder paste help reduce voids?

Yes, you can pick solder paste with low volatile content. This choice helps you make fewer voids. Test different pastes to find the best one for your process.

Why does stencil design matter for void reduction?

Stencil design controls how solder paste spreads and how gases escape. Using smaller holes or dividing apertures helps you lower voids. Good design gives you stronger solder joints.