Navigating the Used Reflow Oven Market: A Comprehensive Guide

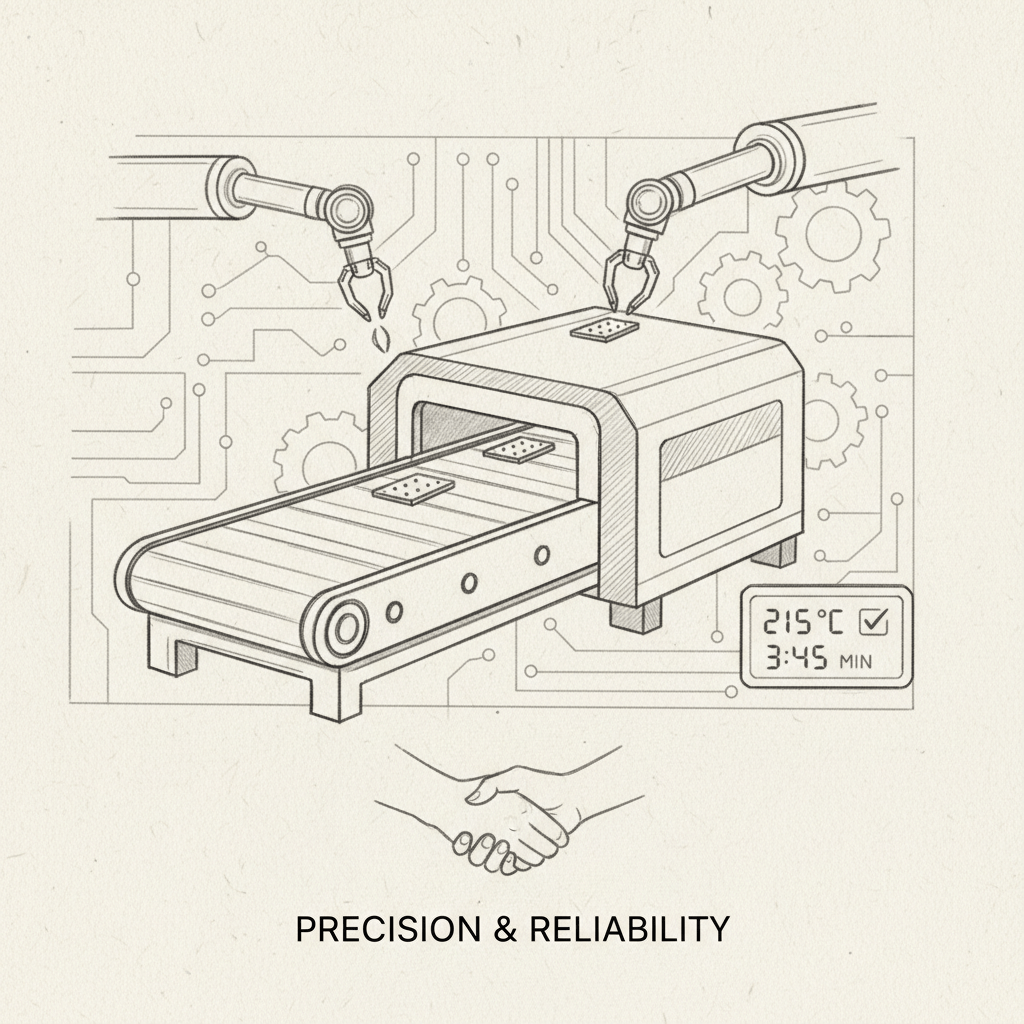

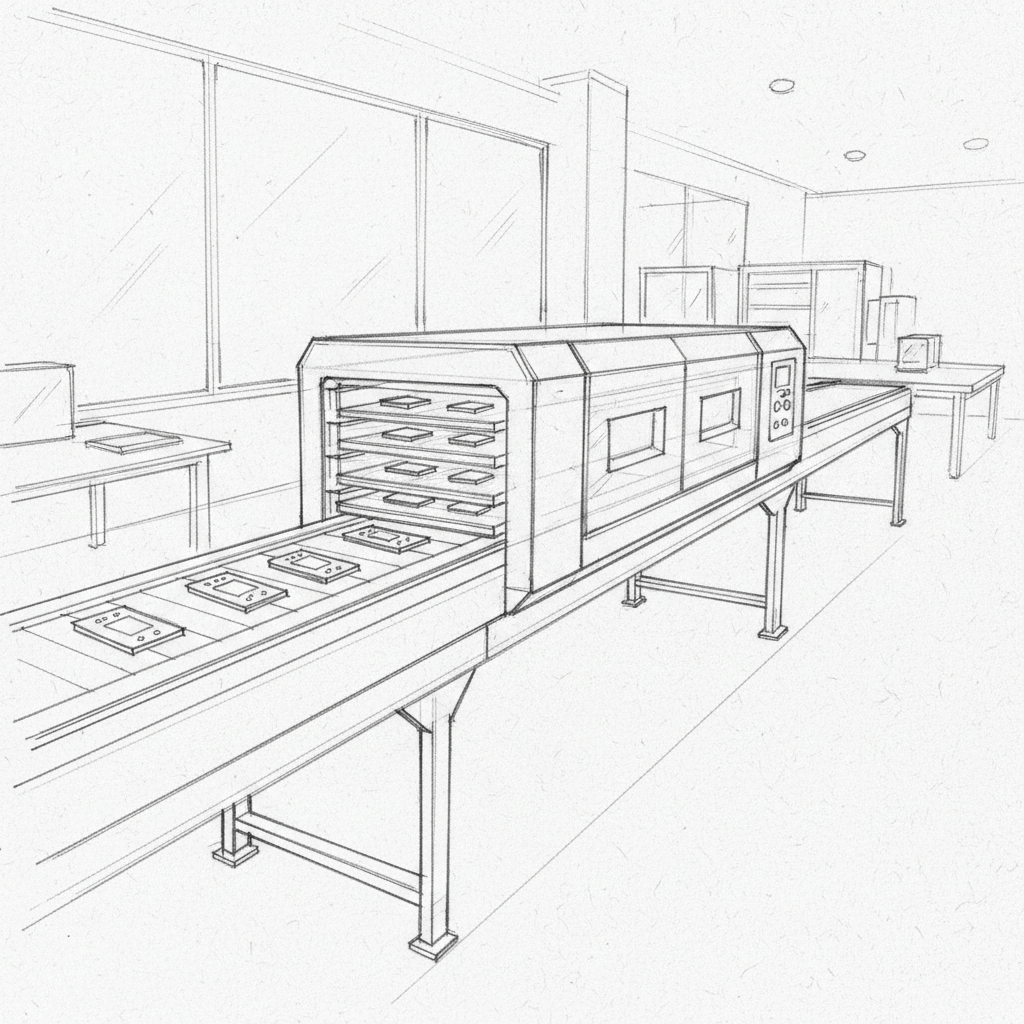

Purchasing used reflow ovens offers substantial cost savings, typically ranging from 50% to 90% compared to new models, making them an attractive option for manufacturers seeking economic and operational efficiency. Major advantages include access to reliable brands, a contribution to sustainability efforts, and the availability of tested and durable equipment from reputable sources. However, potential risks such as hidden defects, outdated technology, and lack of manufacturer support necessitate a thorough pre-purchase evaluation including inspections, thermal profiling, and operational tests. Engaging expert consultation and acquiring from trusted dealers like AdoptSMT ensures high-quality acquisitions and maximizes the benefits of cost-effective production solutions.