S&M is the top company for the best reflow oven for SMT production. Their reflow soldering oven uses new technology and has exact temperature control. This makes it great for any assembly line. S&M is known for new ideas and being dependable in every SMT production line. Many electronics makers trust S&M for their reflow needs. The company gives custom solutions for every electronic assembly. S&M’s reflow soldering oven gives high-quality results and fast assembly. This helps factories stay ahead in technology and reflow work.

Key Takeaways

- Good reflow ovens keep the temperature steady. They use many heating zones. This makes strong and even solder joints. It also lowers the number of defects.

- Picking the right conveyor type keeps PCBs safe. It also helps heat the boards better. This lets factories make more boards faster and safer.

- Choose an oven that fits your production size and budget. This saves money and gives you the best results for your work.

- S&M reflow ovens control temperature very well. They save energy and give strong support. This makes them reliable for any size of production.

- Doing regular maintenance keeps ovens working well. Easy controls help too. This makes sure you get good soldering every time.

Best Reflow Oven Features

Temperature Control

Good temperature control is very important in a reflow oven. New ovens use different steps like preheat, soak, reflow, and cooling. These steps help keep the temperature steady. Closed-loop systems keep the heat even within ±1°C. This helps stop parts from getting too hot or cold. It also makes soldering better. Ovens have many zones and special airflow to spread heat evenly. Some ovens use nitrogen or vacuum to make soldering even better. These features stop damage and help make perfect solder joints. This is very helpful for high-density SMT work.

Tip: Keeping the temperature steady helps make better solder joints. It also helps get more good boards from each batch.

Heating Zones

Great reflow ovens have many heating and cooling zones. Each zone does something special:

| Heating Zone | Description | Effect on Yield and Throughput |

| ——————————————————————– | —————————————————– | —————————— |

| Preheating Zone | Slowly warms up the PCB to stop thermal shock. | Stops damage, helps yield. |

| Soaking Zone | Keeps the heat steady to start flux and clean oxides. | Makes solder joints more even. |

| Reflow Zone | Gets very hot to melt solder and make strong bonds. | Lowers defects, helps yield. |

| Cooling Zone | Quickly cools down the board to harden solder joints. | Keeps joints strong. |

More zones mean better control and better heating. This helps make more boards faster.

Conveyor Type

The conveyor in a reflow oven changes how well it works. There are three main types:

| Conveyor System Type | Load Capacity | Flexibility | Typical Applications | Impact on Production Efficiency |

| ————————————————————————————————– | ————- | ———– | ————————– | ————————————— |

| Rail (Pin Edge/Chain) | High | Moderate | Double-sided, heavy boards | Very accurate, strong, fast work |

| Mesh Belt | Moderate | High | Large, delicate boards | Even heat, easy to clean, less downtime |

| Hybrid (Rail + Mesh) | High | Very High | Mixed production | Quick changes, supports many boards |

Picking the right conveyor keeps PCBs safe and heats them well.

Reliability

A good reflow oven does not break down often. It keeps soldering quality the same every time. Strong build, smart controls, and live monitoring help it run well. Connecting to MES and Industry 4.0 lets you fix problems before they get big. This saves time and lowers mistakes.

Ease of Use

Easy-to-use ovens make work simple and fast. Engineers like these features:

- Touch screens for simple controls.

- Save and load profiles for repeat jobs.

- Live graphs and alarms for quick fixes.

- Auto safety checks and passwords for safety.

These things help workers do a good job and keep soldering quality high.

Price

Reflow oven prices change by type and features:

| Oven Category | Typical Price Range (USD) | Key Features |

| ————- | ————————- | ————————————– |

| Entry-Level | $5,000 – $20,000 | Simple controls, fewer zones |

| Mid-Range | $20,000 – $50,000 | Better temperature control, more zones |

| High-End | $50,000 – $150,000+ | Smart features, many zones, MES |

Oven size, heating, controls, and brand can change the price. Buying the right oven gives better soldering and faster work.

Best Reflow Oven by Scale

Prototype and Small Batch

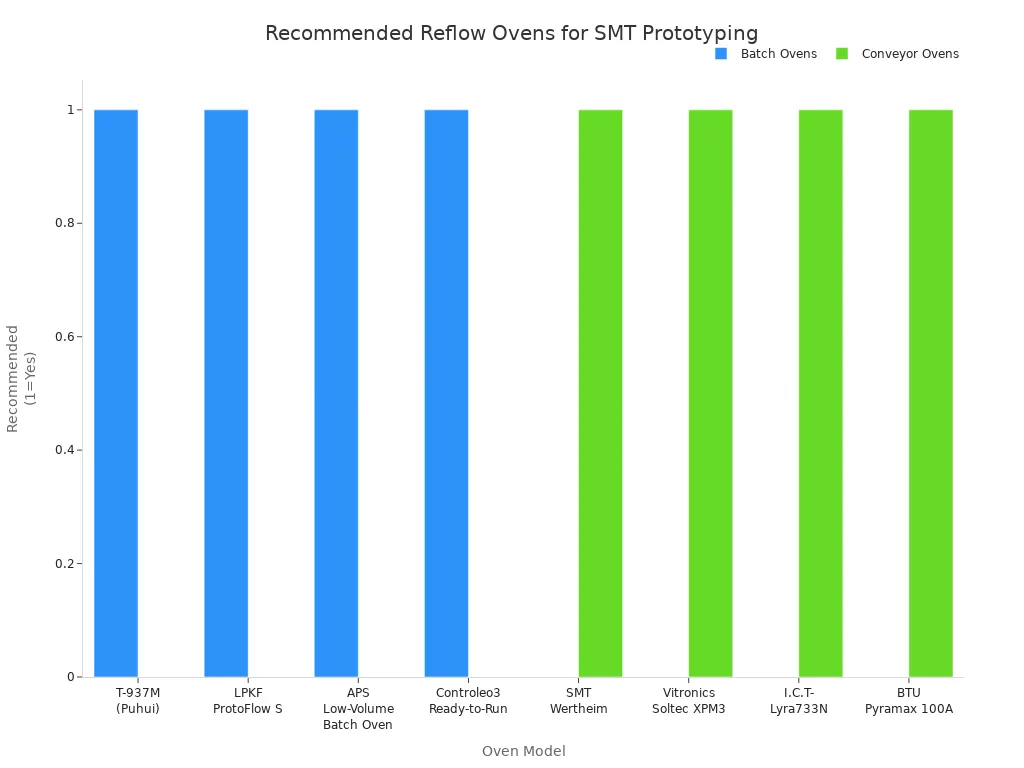

People making prototypes or small batches need ovens that are easy to use and control. Batch ovens like the T-937M (Puhui) and LPKF ProtoFlow S are good choices. These ovens use hot-air convection to heat boards evenly. This helps make better solder joints and lowers the chance of mistakes. The APS Low-Volume Batch Oven and Controleo3 Ready-to-Run are also simple to use and save money for labs or new companies.

S&M has small reflow ovens for little jobs. These ovens let you set temperature programs and move hot air well. Workers can watch the process through big windows. These ovens work for both lead and lead-free soldering. This makes them good for many prototype uses.

Conveyorized ovens like the SMT Wertheim and BTU Pyramax 100A have more heating zones and a moving belt. These ovens are best for small batches that need to be made faster or need special heat steps. The GF-12HT uses Horizontal Convection to keep the board at the same temperature. This helps make soldering even better.

Note: Batch ovens are great for small jobs because they are small and easy to use. Conveyor ovens can help if you need to make more boards as your company grows.

Medium Production

Medium-sized factories need ovens that work fast, save energy, and keep heat steady. Most use convection reflow ovens. These ovens blow hot air to keep the temperature the same. This is important for good soldering. Ovens with many zones let you control each step of the process.

S&M’s medium ovens have many heating zones, smart temperature control, and strong conveyor belts. These ovens work for both lead and lead-free soldering. They fit many types of assembly lines. Workers use touch screens and can save settings. This makes setup quick and helps stop mistakes.

Other top brands like Rehm Thermal Systems, Kurtz Ersa, and BTU International have similar ovens. Dual-lane ovens are popular here. They can work on two boards at once. This makes factories faster and helps car and phone makers. These ovens save energy and can connect to smart factory systems.

- Dual-lane ovens make more boards by working on two at once.

- Smart temperature control keeps heat even and solder joints strong.

- Energy-saving parts help lower bills.

- Connecting to robots and computers helps factories work smarter.

High-Volume Production

Big factories need the best ovens to make lots of boards quickly and with the same quality. Inline and dual-lane ovens are used most. These ovens have moving belts that carry boards through many heating and cooling steps without stopping.

S&M’s big ovens are made for large jobs. They use nitrogen to control the air, keep the temperature just right, and are built strong. These ovens can handle tricky boards and lots of small parts. Workers can check the process live and connect to factory computers to keep things running well.

Other companies like Heller, Manncorp, and ERO-500 also make ovens for big jobs. Their ovens heat up fast, have many heat zones, and work for lead-free soldering. Inline ovens keep running all the time. This is important for factories that make thousands of boards every day.

| SMT Reflow Oven Category | Production Scale | Manufacturing Needs Addressed |

| ———————— | ———————– | ———————————————————————- |

| Batch Reflow Ovens | Small-scale, laboratory | Small size, saves money, good for slow and small jobs. |

| Inline Reflow Ovens | High-volume | Soldering without stopping, good for big factories. |

| Dual-Lane Reflow Ovens | High-volume | Two lanes work at once, best for fast jobs. |

| Convection Ovens | Small to medium-scale | Reliable, keeps heat steady, good for lead-free and careful work. |

| Infrared (IR) Ovens | High-throughput | Heats up fast, good for quick soldering. |

| Vapor Phase Ovens | Sensitive components | Special air to stop overheating, best for parts that need gentle heat. |

| Lead-Free Ovens | Specific manufacturing | Made for lead-free soldering with the right heat steps. |

| Custom Reflow Ovens | Unique production needs | Special features for special jobs, like different belts or heat zones. |

Pros and Cons

Picking the right oven depends on how many boards you make and what you need. Each oven type has good points and some downsides.

| Oven Type | Pros | Cons |

| ———————- | ——————————————————- | —————————————– |

| Batch Ovens | Cheap, simple, small, best for test runs and small jobs | Not fast, needs people to load and unload |

| Conveyor Ovens | Makes more boards, can grow with you, keeps heat steady | Takes up more space, costs more at first |

| Dual-Lane/Inline Ovens | Fastest, keeps running, ready for robots | Needs lots of room, harder to fix |

| Nitrogen/Lead-Free | Better soldering, good for tough jobs | Costs more to run because of gas |

| Custom Ovens | Made for special needs, can change parts | Takes longer to get, may cost more |

Tip: Pick an oven that matches how many boards you make and how hard your jobs are. The right oven will help you solder better and make more boards faster.

S&M Reflow Soldering Oven Review

Key Features

S&M reflow soldering ovens are known for new technology and flexible design. The company makes many types, including lead-free nitrogen hot air models. These ovens use exact temperature control and have many heating zones. This helps keep soldering quality the same every time. Each oven has a strong conveyor system. It can hold both heavy and light printed circuit boards. Workers can set and watch temperature profiles on easy touch screens.

S&M always tries to make better products. Their ovens have smart sensors and closed-loop controls. These help keep the temperature steady and stop mistakes. The ovens can use nitrogen to lower oxidation and make solder joints stronger. S&M lets customers change ovens to fit their needs. The company gives good technical help and after-sales service.

Note: S&M’s team has over 27 years of experience. They fix problems fast and help production go smoothly.

Performance

S&M reflow soldering ovens work fast and heat well. They use new heating technology to save energy and lower costs. Many factories pick S&M because the ovens work for small and big jobs. The oven keeps the temperature just right. This stops soldering mistakes and makes strong results every time.

Factories like these ovens because they work with lead-free jobs and careful parts. Using nitrogen makes soldering even better by lowering oxidation. Smart sensors and tight temperature control help lower mistakes. S&M does not share exact numbers for speed or energy use. But their focus on new ideas and trust matches top brands.

| Feature | Benefit |

| ————————————————————— | ————————————– |

| Precise Temperature Control | Same soldering quality every time |

| Nitrogen Atmosphere | Less oxidation, stronger solder joints |

| Energy-Efficient Heating | Lower running costs |

| Multiple Heating Zones | Good for tricky assemblies |

| Smart Sensors | Fewer mistakes, better control |

User Feedback

People all over the world like S&M reflow soldering ovens. They say the ovens are reliable and the support is great. Many users talk about the company’s good after-sales help and technical support. S&M cares about customers from the first talk to later help.

- A user in Bangalore says the technology and service are “superb” and calls the oven the best.

- A customer from Slovenia felt welcomed and looks forward to working together.

- S&M gives free software updates to all customers.

- You can get help by email, Skype, WhatsApp, phone, or online chat.

- A special team handles marketing, sales, design, making, quality, packing, storage, and shipping.

- S&M wants friendly, open, and steady relationships with customers for shared success.

Tip: Many people pick S&M ovens for their new technology, strong performance, and great support.

S&M ovens work with rules from big industry groups like IPC/JEDEC and IEC. These rules help make sure soldering is done right. The ovens do not have special certificates, but they help factories meet world standards.

Reflow Soldering Machine Comparison

Specs Table

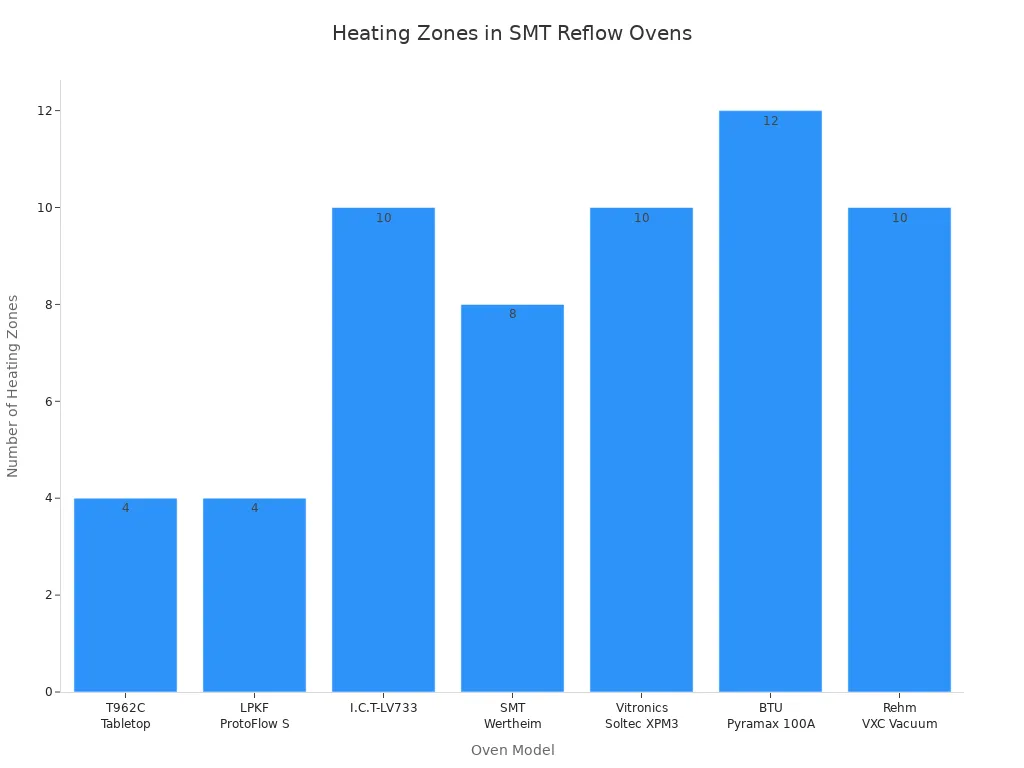

People compare reflow soldering machines by looking at their specs. These details help buyers choose the best machine for their work. The table below shows how top models are different:

| Model | Type | Max PCB Size | Heating Zones | Max Temp (°C) | Vacuum Feature | Nitrogen Support | Conveyor Speed | Special Features | Ideal For |

| ——————— | ———— | ———— | ————- | ————- | ————– | —————- | ————– | ———————— | ———————— |

| T962C Tabletop | Tabletop | 300 x 320 mm | 4 | 250 | No | No | Manual | Compact, easy setup | Prototyping, small runs |

| LPKF ProtoFlow S | Tabletop | 320 x 200 mm | 4 | 320 | No | No | Manual | R&D, education | R&D, education |

| I.C.T-LV733 | Vacuum | 400 x 400 mm | 10 | 300 | Yes | Yes | Auto, precise | Vacuum, nitrogen | High-reliability, BGA |

| SMT Wertheim | Conveyorized | 350 x 350 mm | 8 | 300 | No | Yes | Adjustable | Medium batch production | Medium batch production |

| Vitronics Soltec XPM3 | Conveyorized | 500 x 400 mm | 8-10 | 320 | No | Yes | Adjustable | High-volume, flexibility | High-volume, flexibility |

| BTU Pyramax 100A | Conveyorized | 457 x 457 mm | 8-12 | 350 | No | Yes | Adjustable | High throughput | High power, throughput |

| Rehm VXC Vacuum | Vacuum | 450 x 400 mm | 10 | 350 | Yes | Yes | Adjustable | Advanced, void-free | Advanced, void-free |

Key Differences

Reflow soldering machines are not all the same. They have different features, how well they work, and prices. Here are some things to think about:

- Tabletop machines like T962C and LPKF ProtoFlow S are good for small jobs. They have fewer heating zones and you control them by hand. These are best for labs or making test boards.

- Conveyorized ovens like BTU Pyramax 100A and Vitronics Soltec XPM3 can handle bigger boards and more work. They have more heating zones and you can change the speed. This helps factories make lots of boards with steady quality.

- Vacuum machines like I.C.T-LV733 and Rehm VXC Vacuum use vacuum and nitrogen. These features help stop bubbles in solder and make joints stronger. They are used for jobs that need to be very reliable, like BGA assembly.

- High-end ovens have smart controls, save energy, and keep the temperature just right. These things help stop mistakes and save money over time.

- How much energy a machine uses and how often you fix it is important. Reflow soldering machines use less energy than wave soldering. If you take care of the machine, it will last longer and cost less to fix.

- Programmable controls let you set the heat for each job. This helps with different boards and stops errors.

- Price depends on the type. Cheaper machines have fewer features. Expensive ones work better and last longer.

Tip: Pick a reflow soldering machine that fits your work. This helps you get good solder joints and saves money later.

Choosing a Reflow Oven

Production Volume

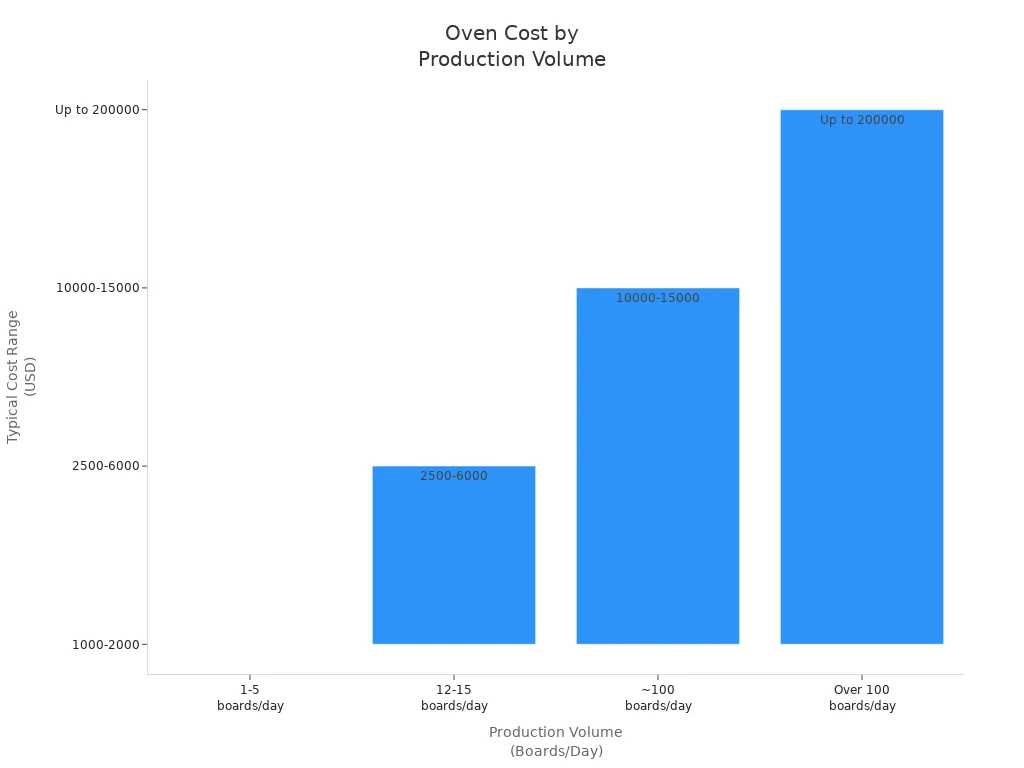

How many boards you make matters when picking a reflow oven. You need to pick an oven that matches how many boards you want to make. If a factory makes 120 boards each hour, it needs a fast oven. The boards are 10 inches long and have 3 inches between them. The belt should move at about 26 inches every minute. The heated part of the oven should be about 104 inches long for this speed. Most ovens have heated parts between 75 and 150 inches long. If you do not have much space, multi-lane ovens can help. They let more boards move through at the same time.

Some companies buy ovens that are too big. This wastes money and takes up too much space. For most small or medium jobs, a 4- to 6-zone oven is enough. These ovens use less energy and can do different jobs. You should figure out what you need by looking at your solder paste and how many boards you want to make. The table below shows how many boards you make, what oven you need, and how much it costs:

| Production Volume (Boards/Day) | Recommended Oven Type / Zones | Typical Cost Range |

| —————————— | ———————————- | —————— |

| 1-5 | Single or dual hot plate; no zones | $1,000 – $2,000 |

| 12-15 | Batch oven, single zone | $2,500 – $6,000 |

| ~100 | Conveyorized 3-zone oven | $10,000 – $15,000 |

| Over 100 | Zones depend on speed & volume | Up to $200,000 |

Tip: Ovens with 4-6 zones are good for lines that make many different boards but not huge amounts. They help you work faster without spending too much.

Budget

You need to plan your money before buying a reflow oven. Try to match what you need with what you can spend. Small projects can use desktop ovens. These cost between $300 and $1,500 and are good for testing ideas. If your boards are tricky, you may need an oven that controls heat very well and works by itself. These cost more. Using your own oven can save money and make things faster than sending work out.

- Spend money on what you really need.

- For small jobs, simple ovens save money.

- Only buy fancy features if your boards need them.

- You can rent or pay over time to help with costs.

- Always look at the total cost, not just the price to buy.

Note: Buy what you need now, but think about growing later so you do not waste money.

Technical Needs

What your boards need will help you pick the right oven. Most people use convection ovens because they heat boards evenly. Infrared ovens heat up fast but do not work for every part. Vapor phase ovens stop boards from getting too hot and are best for hard jobs, but they cost more.

| Technical Requirement | Description/Consideration |

| ————————— | ———————————————————————————————————————————————————————————————— |

| Thermal Performance | Makes sure heat spreads right and stops mistakes. |

| Heating Technology | Pick convection, infrared, or vapor phase for your job. |

| Throughput | The oven must keep up with how fast you work. |

| Maximum Temperature Rating | The oven should not get hotter than your parts can handle. |

| Oven Type | Pick bench top, batch, or conveyor oven for your needs. |

| Conveyor Design | Changes how boards move and how fast they go. |

| Process Gas | Nitrogen or vacuum can make soldering better for tough jobs. |

| Software Control | Lets you set and watch the heat closely. |

| Reliability and Maintenance | Helps the oven work longer and stops delays. |

Tip: Ovens with more zones and nitrogen can help you make better boards for hard jobs.

S&M is a great pick for the best reflow oven in SMT production. Their ovens keep the temperature just right and make soldering strong. This helps stop mistakes and makes boards better. People should check what the oven can do and how easy it is to use. They should also look at support and if it fits their budget. To get the best oven, they can ask for a demo or talk to experts before buying.

FAQ

What is a reflow oven used for in SMT production?

A reflow oven heats up PCBs to melt solder paste. This helps stick electronic parts onto the board. Factories use these ovens to make strong and safe solder joints for SMT assemblies.

How many heating zones does a good reflow oven need?

Most good reflow ovens have between 4 and 10 heating zones. More zones help control the temperature better. This makes solder joints more even and lowers mistakes. S&M has ovens with many zones for different jobs.

Can S&M reflow ovens handle lead-free soldering?

Yes. S&M reflow ovens can do lead-free soldering. They get hot enough and use smart controls. This makes sure both leaded and lead-free jobs are safe and work well.

How often should users maintain a reflow oven?

Users should clean and check the oven every week. Technicians need to look at sensors, belts, and fans each month. Doing this keeps the oven working well and helps it last longer.

What safety features do S&M reflow ovens include?

S&M ovens have auto shutdown, alarms for high heat, and emergency stop buttons. These keep workers and machines safe while using the oven.