Choosing the best reflow oven for SMT work is crucial. You need to consider temperature evenness, nitrogen control, lead-free compatibility, and overall performance. Teams often face challenges like solder bridging, tombstoning, and thermal profiling.

| Challenge | Description | Solution Highlights |

|---|---|---|

| Solder Bridging | Solder connects parts by mistake and causes shorts. | Monitor solder amount and set the reflow profile correctly. |

| Tombstoning | Parts lift up from uneven heat. | Use precise thermal profiling and proper pad design. |

| Thermal Profiling | Incorrect heat affects solder joints. | Adjust ramp-up and cooling rates for even heating. |

Chuxin’s N2/Air Reflow Oven is recognized as the best reflow oven with full convection capabilities. It’s ideal for prototyping, small batches, or high-volume production. Its reliable performance and excellent service support help manufacturers achieve consistent, high-quality results.

Key Takeaways

- Pick a reflow oven that keeps the temperature even. This helps make strong solder joints and stops problems.

- Use nitrogen in the oven to stop oxidation. This makes the solder better. Watch how much nitrogen you use to save money.

- Choose ovens that follow lead-free rules like RoHS. Make sure they can handle the higher melting points of lead-free solder alloys.

- Find ovens with many heating zones and changeable conveyor speeds. This helps with different PCB types and how much you need to make.

- Ovens that save energy lower power bills and help the environment. They do this without losing quality.

- Keep up with regular maintenance and get good after-sales help. This keeps the oven working well and cuts down on breaks.

- New ovens have smart controls, data logging, and safety tools. These make the oven easier to use and help track the process.

- When you buy, look at features, price, service, certifications, and total costs. This helps you succeed for a long time.

Selection Criteria

Temperature Control

Uniformity

Temperature uniformity is very important when picking a reflow oven. Even heat across the PCB helps make strong solder joints and stops problems.

- Keeping the same temperature stops bad fillets, skips, holes, solder beading, and broken parts.

- If the heat is not even, soldering may not finish or parts can get too hot.

- This can make weak joints or break parts.

- Even heat keeps all parts safe and protects sensitive devices.

- When the heat is steady, you can set the best profile without going too high or low.

- If the temperature changes too much, fewer boards will turn out right. Good closed-loop control helps keep things steady and improves first-pass success.

- New reflow ovens use many zones, forced air, adjustable speed, and real-time checks to keep heat even.

The soldering temperature should only change by 2–3°C on the PCB. If it changes more, there could be more mistakes and the board may not last as long. Chuxin’s N2/Air Reflow Oven uses strong convection and many zones to keep the temperature even. This helps make good boards for any size job.

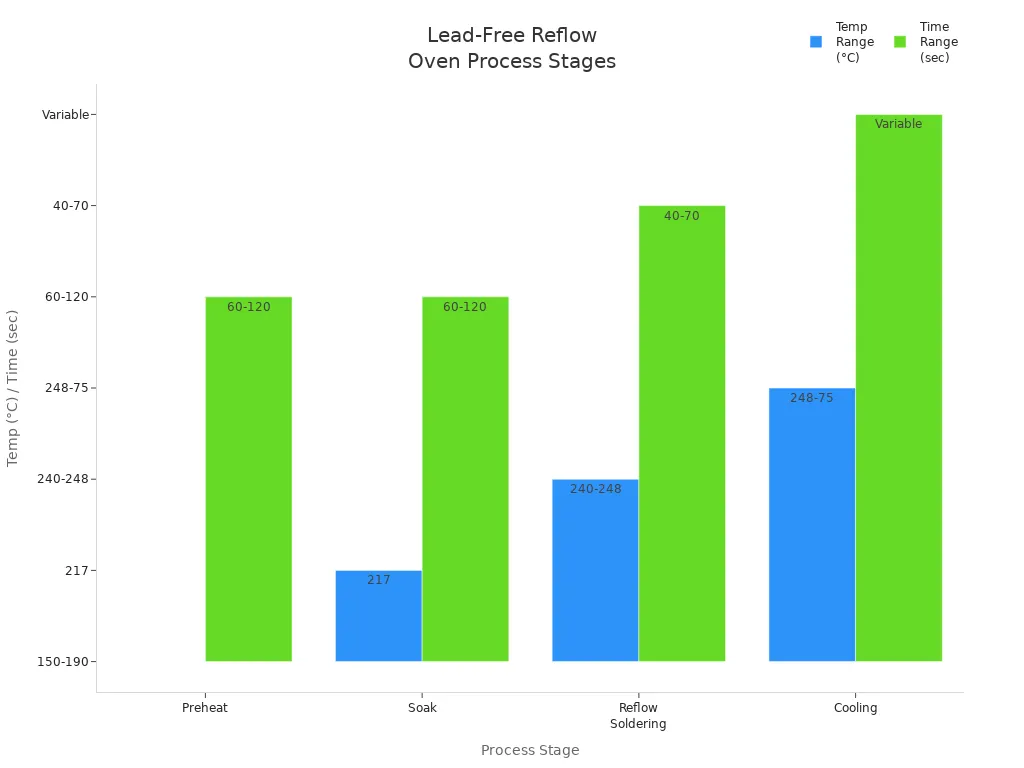

Precision

Good temperature control makes sure each solder joint gets hot enough at the right time. Lead-free soldering needs higher and more exact temperatures than old ways. Ovens must heat up, soak, and cool down at the right speed. This stops thermal shock or bad soldering. Chuxin’s ovens watch the temperature in real time and use feedback. This lets workers set and keep the right heat for every batch.

Nitrogen Capability

Atmosphere Control

Nitrogen is very important for lead-free soldering. Pure nitrogen stops oxidation, so solder joints are cleaner and stronger. Most factories need nitrogen that is at least 99.99% pure. For very important products, some need 99.999% purity and less than 1000 ppm oxygen, or even 100 ppm. These settings make a dry, safe place that helps solder spread and lowers mistakes. Chuxin’s N2/Air Reflow Oven has advanced nitrogen control. It uses sensors and alarms to check purity and keep the process good.

Consumption

How much nitrogen you use affects how much you spend. SMT makers must think about the cost of nitrogen gas, plus electricity and solder paste. Good ovens use less nitrogen but still make good boards. This saves money over time.

| Consumable | Typical Use | Ongoing Cost Impact |

|---|---|---|

| Electricity | Every operation | High |

| Nitrogen gas | If required | Medium to High |

| Solder paste | Every batch | Medium |

Chuxin makes ovens that use nitrogen well. This helps companies save money and keep the process steady.

Lead-Free Compliance

Standards

Rules around the world say electronics must be lead-free. The RoHS rule from the European Union is the main standard.

- RoHS limits lead and other bad stuff in electronics.

- Lead must be less than 0.1% by weight in each material.

- Many countries use RoHS or rules like it, so following them is needed to sell worldwide.

- Other rules like WEEE and REACH help protect the environment.

- These rules affect which solder you use, how hot the oven gets, what flux you pick, how you build equipment, and how you check quality.

- Companies must make good plans, train workers, and keep records to follow these rules.

Chuxin’s reflow ovens meet or beat these rules. This keeps production safe and legal.

Materials

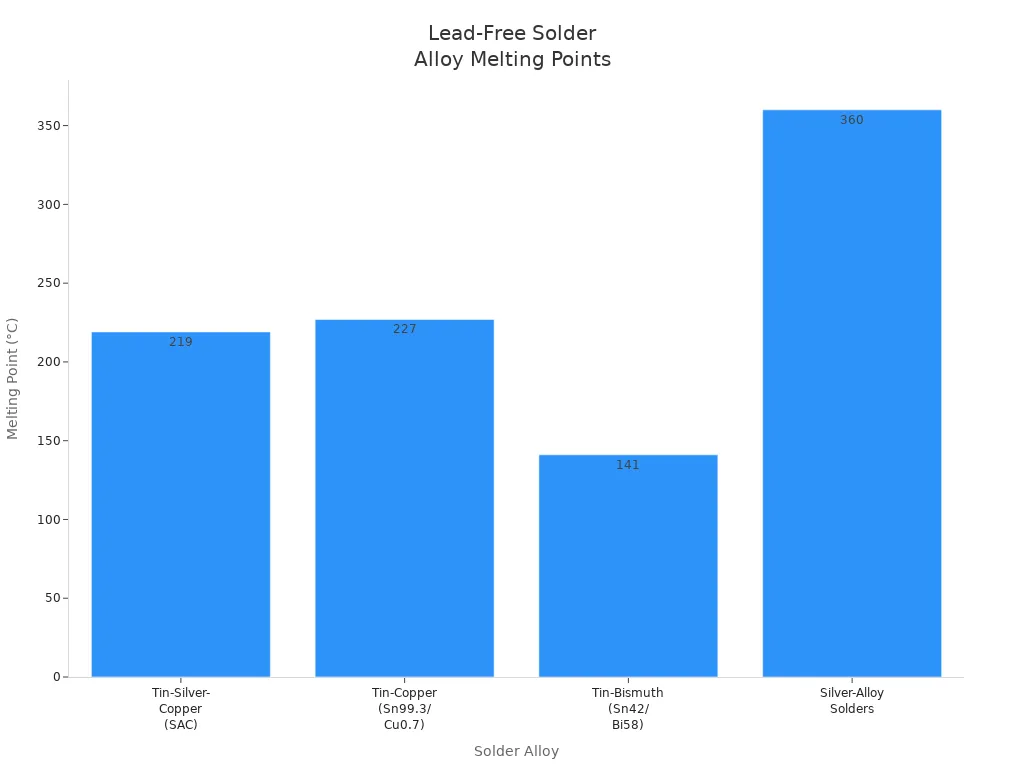

Lead-free soldering uses alloys that melt at higher temperatures than old lead solders. The most used ones are tin-silver-copper (SAC), tin-copper, and tin-bismuth. These need ovens that can get hotter and keep the right temperature.

| Solder Alloy (Lead-Free) | Typical Melting Point (°C) | Impact on Oven Selection |

|---|---|---|

| Tin-Silver-Copper (SAC) | 217–220 | Needs ovens that can hold about 220°C |

| Tin-Copper (Sn99.3/Cu0.7) | 227 | Needs ovens that reach and keep about 227°C |

| Tin-Bismuth (Sn42/Bi58) | 138–144 | Can use ovens with lower heat (about 140°C) |

| Tin-Zinc | Varies (less common) | May change oven settings based on the alloy |

| Silver-Alloy Solders | 300–420 | Needs ovens that can go up to 420°C |

You must pick an oven that can reach these higher melting points. Chuxin’s ovens give the right heat range and control. This helps use many lead-free alloys and makes strong, mistake-free joints.

Throughput

Conveyor Types

Conveyor systems are very important in a reflow oven. The conveyor moves PCBs through each heating zone. This movement changes how many boards the oven can finish. It also affects how good the solder joints are.

- Conveyor belts move PCBs smoothly through the oven. This makes sure each board gets the same heat.

- Edge support conveyors help with double-sided soldering. They stop boards from bending. This is needed for complex assemblies.

- Some ovens can change width by themselves. This helps workers handle different board sizes fast. It also lowers the chance of mistakes.

- The conveyor design and heating method work together. They help keep the temperature even. This means fewer mistakes and less rework.

A good conveyor system helps make more boards faster. Advanced ovens, like Chuxin’s, use smart controllers and strong conveyors. These features automate the process. They lower human mistakes and keep quality high.

Speed

The conveyor speed decides how many boards the oven can finish in one hour. Workers must balance speed and quality. If the conveyor is too fast, soldering may not finish. If it is too slow, making boards takes longer.

| Oven Zone Count | Oven Width (mm) | Throughput (boards per hour) | Source / Expert |

|---|---|---|---|

| 4 zones | 300 | 60–70 | Steve Pollock, Essemtec USA |

| 5 zones | 400 | 110–120 | Steve Pollock, Essemtec USA |

Most lead-free nitrogen reflow ovens finish 60 to 120 boards each hour. This depends on the number of zones and oven width. Chuxin’s N2/Air Reflow Oven can handle high throughput. It has adjustable conveyor speeds and many heating zones. This helps factories meet different needs, from small jobs to big runs.

Energy Efficiency

Power Use

Reflow ovens use a lot of electricity. Lead-free soldering needs higher heat, so energy use goes up. A typical lead-free nitrogen hot air reflow oven uses about 100,000 kWh each year. This is about 334 kWh every day. That is around 22% more than ovens for tin-lead soldering.

Tip: Ovens with smart energy controls can save power when not in use. This saves money and keeps product quality high.

Chuxin’s ovens have strong insulation and energy-saving controls. These features help lower daily power use. They also support green manufacturing.

Cost

Energy efficiency changes how much it costs to run a reflow oven. Ovens that use less power cost less to run. This is important in places where electricity is expensive. Better insulation and smart heat controls stop heat from escaping. This also means less air conditioning is needed in the factory.

- Energy-efficient ovens lower power bills and total costs.

- Smart software controls power use and saves more energy.

- Better temperature control helps make more boards and fewer mistakes. This saves money on fixing or throwing away bad boards.

- Automatic energy-saving features and easy maintenance lower downtime and repair costs.

- Using less energy helps the planet and can make a company look better.

Chuxin’s N2/Air Reflow Oven uses these energy-saving features. This helps factories save money and work better.

Reliability

Maintenance

Reliability depends on regular care and maintenance. Common problems in reflow ovens are nitrogen supply issues, heater failures, conveyor speed problems, and airflow troubles. These problems can cause bad solder joints, weak connections, and more rework.

| Reliability Issue | Description | Impact on Production and Quality | Prevention Tips |

|---|---|---|---|

| Nitrogen Supply System Failure | Losing nitrogen gas causes oxidation during soldering. | Solder joints get oxidized, connections are weak, and more rework is needed. | Do regular maintenance and watch gas flow to stop supply problems. |

| Heater Failure | Broken heaters make temperature zones uneven. | Soldering is not finished, parts can burn, and solder quality drops. | Check heaters often, use test tools, and watch performance in real time. |

| Conveyor Calibration Drift | Conveyor speed is wrong, so PCBs do not heat right. | More mistakes like solder bridging and cracked parts happen. | Calibrate the conveyor often and watch speed in real time. |

| Airflow Inconsistencies | Dirty filters or fans make hot air spread unevenly. | Solder balls, open joints, and bad solder quality can happen. | Clean filters, check heat transfer, and watch fan speed. |

| Cooling System Failure | Cooling does not work right, so PCBs cool too fast or unevenly. | Cracks, broken solder joints, and more rework can happen. | Take care of the cooling system, check for water blocks, and watch temperature in real time. |

Workers should clean the oven chamber and conveyor often. They should also check temperature sensors and look at heating parts. Preventive maintenance helps find and fix problems early. This lowers downtime and helps the oven last longer.

Support

Good after-sales service and technical help are important for long-term reliability. Factories get many benefits:

- 24/7 customer support and fast help.

- Spare parts, repairs, and upgrades are easy to get.

- Training for workers and maintenance staff.

- Clear instructions and performance checks for fixing problems.

Chuxin is known for great after-sales service. They have standard service steps, train their technicians, and use a customer scoring system. This helps solve problems fast and keeps production going. Good support and maintenance help factories work better and protect their investment in reflow ovens.

Key Features

Control Systems

Interface

Modern reflow ovens have smart control systems. These systems make using the oven easy and accurate. Most top ovens have touchscreens that are simple to use. Workers can set temperatures and watch data in real time. They can also change how fast the conveyor moves with a few taps. Passwords keep the settings safe, so only trained people can change them. Chuxin’s N2/Air Reflow Oven has a plug-and-play interface. This helps new users start working fast. The oven can be checked from far away using RS-232 or WiFi. Engineers can see how the oven is doing from anywhere in the building.

| Feature | Description |

|---|---|

| User-friendly interface | Touchscreen controls, easy loading/unloading |

| Password access | Secures settings for engineers and operators |

| Remote connectivity | WiFi for monitoring and control |

| Profile management | Store and recall multiple soldering profiles |

Data Logging

Good data logging is needed for quality and tracking. Modern ovens save temperature, conveyor speed, and nitrogen level for every job. The oven can keep up to 500 profile graphs. Workers can look at these graphs to make things better. If something goes wrong, alarms tell the workers right away. The oven can print or download reports for checks. Chuxin gives full inspection reports and shipping papers with each oven. This helps with tracking and following rules.

| Data Logging Feature | Benefit |

|---|---|

| Real-time profiling | Monitors temperature with multiple thermocouples |

| Alarm and event logging | Tracks faults and process deviations |

| Profile storage | Saves and compares up to 500 profiles |

| Download/print reports | Supports audits and quality checks |

Zone Configuration

Heating Zones

Having many heating zones is important in lead-free nitrogen reflow ovens. Ovens with 7 or 8 zones give better control at each step. Each zone can have its own temperature. This lets the oven make special heat patterns. It helps stop mistakes and makes strong solder joints. This works even if the board has different parts or sizes.

- Multi-zone ovens help control how fast the board heats up.

- More zones mean more boards can be made and the oven is ready for harder jobs.

- Experts say at least 7 zones are good for lead-free soldering. Eight zones are even better for more choices.

Flexibility

Zone flexibility lets factories work with many PCB types. Workers can change zone heat and air for different boards. Flexible PCBs need less heat. Double-sided boards need careful control so the other side does not melt. Chuxin’s ovens have a wide process window. This helps make many good boards for all kinds of SMT work.

Zone flexibility helps make good profiles, high yields, and better soldering for any board.

Safety

Protection

Safety features keep people and machines safe. New ovens have emergency stop buttons and main power switches. They also have lights that show the oven’s status. Covers and control boxes stop people from touching hot or moving parts. The oven only works if all safety parts are on. Workers must wear safety clothes and turn off power before fixing the oven. Chuxin’s ovens have many layers of over-temperature protection. They also have alarms and easy ways to do maintenance.

- Emergency stop and main power switches

- Over-temperature and fault alarms

- Board drop detection and warning lights

- Safe cover operation with electric struts

Certifications

Reflow ovens must follow strict safety and quality rules. Certifications show the oven is safe and works well for making electronics.

| Certification | Purpose/Description | Region/Scope |

|---|---|---|

| CE Marking | Health, safety, and environmental compliance | European Union |

| UL Certification | Product safety testing | United States, Canada |

| RoHS Compliance | Restricts hazardous materials | Global |

| FCC Certification | Limits electromagnetic interference | United States |

| ISO 9001 | Quality management system standard | Global |

Chuxin’s ovens come with full reports and papers. This helps with tracking and meeting these certifications. Their focus on quality and safety helps factories meet world standards and customer needs.

Best Reflow Oven for SMT

Brand Comparison

Chuxin N2/Air Series

Chuxin’s N2/Air Series is known for its advanced technology and high quality. These ovens use full convection and work with both nitrogen and air. Factories use them for small jobs and big production runs. The N2/Air Series keeps the temperature steady and controls nitrogen well. It also works great for lead-free soldering. Chuxin gives detailed inspection reports for every oven. They track each oven from start to finish. Their after-sales service is always available. They answer quickly and have skilled workers to help. Many electronics makers pick Chuxin for steady results and good support.

Other Brands

Other brands also make SMT reflow ovens. Some big names are Heller, Rehm, and BTU. These brands have ovens with many heating zones and energy-saving features. They also have easy-to-use controls. Heller ovens save energy and are built strong. Rehm ovens control the process well and have flexible zones. BTU ovens are good for making lots of boards fast. Each brand has its own strengths. But not all brands give as much service or tracking as Chuxin. When people pick a reflow oven, they look at how well it works, how reliable it is, and the support they get.

Model Pros and Cons

Chuxin VS/DS Series

The Chuxin VS Series and DS Series are made for lead-free soldering. They work with nitrogen or air. The VS Series controls nitrogen very well. This is good for parts that need less oxygen. The DS Series is made for fast work and has flexible zones. Both series keep the temperature even and are easy to use. Chuxin gives full quality checks with each oven. They include inspection reports and shipping papers. Users get fast help with repairs and clear training guides.

Pros of Chuxin VS/DS Series:

- Keeps temperature even for all board sizes

- Controls nitrogen well for clean solder joints

- Zones can be changed for different PCBs

- Touchscreen is easy to use

- Good service and fast technical help

Cons of Chuxin VS/DS Series:

- New users may need some training at first

- Nitrogen systems can cost more to run

Note: Chuxin’s focus on quality and customer care helps users fix problems fast.

Market Alternatives

Other brands have models with similar features. Heller’s 1809 MK5, Rehm’s VisionXP+, and BTU’s Pyramax are popular choices. These ovens have many heating zones and save energy. They also control the process well. Heller ovens use less energy and are easy to fix. Rehm ovens have flexible settings and are very reliable. BTU’s Pyramax is good for fast production lines.

Pros of Market Alternatives:

- Many models for different factory needs

- Work well in big factories

- Good process control and data tracking

Cons of Market Alternatives:

- Some brands take longer to send parts or help

- Not all models have the same tracking or inspection papers

- Service quality can change in different places

When picking a reflow oven, buyers should check more than just the features. Service, support speed, and paperwork are important for long-term use. Chuxin stands out because of its strong service and focus on quality.

Tip: Always ask for inspection reports, how fast service is, and customer reviews before you buy.

Selection Checklist

Step-by-Step Guide

Define Needs

- Figure out what your factory needs. Pick the oven type, size, and how many heating zones you want for your SMT line.

- Make clear goals for even heat, nitrogen use, and if it works with lead-free solder alloys.

- Decide how many boards you need to make each hour.

- Plan your budget. Think about the price to buy the oven and the money you will spend to run it.

Evaluate Options

- Look for suppliers online, at trade shows, or in magazines.

- Check supplier websites and catalogs. See if they have CE, UL, or RoHS certifications.

- Read what other customers say and look at case studies to see how the ovens work in real factories.

- Talk to suppliers. Ask for details, choices to change the oven, and prices.

- Ask to see the oven work or get a sample. Test if it heats evenly, works fast, and is easy to control.

- Make sure the supplier checks quality and helps after you buy.

- Talk about the warranty, service, and when the oven will arrive.

- Try to make a good relationship with the supplier. This helps you get help and better ovens in the future.

Tip: Always check if the oven can use nitrogen, has more than one heating zone, and lets you change conveyor speed. These things help you get the right heat and good solder joints.

Mistakes to Avoid

Overlooking Service

- Some buyers only look at features and price. They forget to check if the supplier helps after you buy.

- If you do not have good support, the oven may break and cost more to fix.

- Pick a supplier who answers fast, has spare parts, and teaches you how to use the oven.

Ignoring Costs

- Some people only think about the price to buy the oven. They do not think about the money needed for power, nitrogen, and fixing the oven.

- High running costs can make a good oven too expensive later.

- Look at all costs, like energy, supplies, and service plans.

Note: If you choose carefully, you will not waste money and your SMT line will work well for a long time.

Picking the right reflow oven for lead-free SMT work takes careful thought. You need steady temperature control and good nitrogen use for strong solder joints. High build quality, good exhaust, and accurate profiles help keep things safe and working well. Good after-sales service, like Chuxin gives, helps keep the oven running and makes sure boards are good.

The next steps are to talk to oven makers, set up demos, and ask SMT experts for advice. This helps you pick the best oven and set up your process the right way.

FAQ

What is the main benefit of using a nitrogen reflow oven for lead-free soldering?

Nitrogen stops too much oxygen from touching the solder. This keeps the joints clean and strong. Factories get fewer mistakes and better products. Nitrogen also helps companies follow strict rules for electronics.

How often should operators perform maintenance on a reflow oven?

Operators need to check and clean the oven every week. They should look at filters, conveyors, and sensors. Doing this often stops problems and keeps the oven working well.

Can Chuxin’s N2/Air Reflow Oven handle both prototyping and mass production?

Yes. Chuxin’s N2/Air Reflow Oven works for small and big jobs. It has zones you can change and a conveyor that goes faster or slower. This makes it good for many kinds of work.

What certifications do Chuxin reflow ovens carry?

Chuxin ovens have CE, UL, and RoHS certifications. These show the ovens are safe, good for the environment, and can be sold in many places.

How does data logging help with quality control?

Data logging saves the temperature, speed, and nitrogen for each batch. Workers can look at this information to make things better and keep results the same.

What should buyers consider when comparing reflow oven brands?

Buyers should look at temperature control, nitrogen use, speed, energy use, and support. Good service and clear papers are important too.

Does Chuxin provide after-sales support and training?

Chuxin gives help all day and night and answers quickly. They train workers and give clear guides and reports. Customers get help whenever they need it.

How can users reduce nitrogen consumption in reflow ovens?

Users can set the nitrogen flow just right and keep the oven sealed tight. Checking for leaks and using the best settings helps save gas.