When you buy SMT equipment, you make a big choice. This choice affects how much you spend and how good your products are. Good brands like S&M help you do less work by hand. They also help you make fewer mistakes. This means you can make more products and pay less for workers. You should pick SMT equipment that matches what you need as a small or medium business.

- Using the same parts with SMT equipment makes inventory easier.

- Making products easy to build helps SMT machines work better.

| Cost Category | Impact on Total SMT Assembly Cost |

| ——————————————————————————————————————————————— | ———————————— |

| Initial Equipment Purchase | Big effect, costs a lot at the start |

| Maintenance | Medium effect, keeps things running |

Key Takeaways

- First, know what you need and want before you buy SMT equipment. This helps you not make expensive mistakes. – Think about both new and used machines. New machines last longer but cost more. Used machines are cheaper but must be checked carefully. – Pick suppliers who give good help, teach you well, and have happy customers. This will help your SMT line work well. – Make sure your budget is fair. Look at ways to pay like loans, leasing, or renting. This helps you handle costs better. – Take care of your equipment often and teach your workers well. This lowers mistakes, makes machines last longer, and makes your products better.

SMT Equipment Needs

Production Goals

When you set up your smt line, think about your main goals first. Many companies want to make good pcbs fast and waste less. You might need to react quickly if the market changes. Sometimes you must build different printed circuit boards. Here are some goals that help you pick smt equipment:

- Use automation to work faster and better.

- Change between products quickly and stop less.

- Place parts with high accuracy every time.

- Choose green processes to help the environment.

- Add smart features to improve and share data.

If you keep these goals in mind, you can set up an smt line that fits your needs and gives good results.

New vs. Used

You have a big choice when buying smt machines: new or used? Both have good points and risks. The table below shows how new and used smt equipment compare:

| Aspect | New SMT Equipment | Used SMT Equipment |

| —————– | ————————————- | ————————————- |

| Cost | Costs more at first, but lasts longer | Cheaper, easier for small businesses |

| Availability | Takes longer to get | Usually ready to use soon |

| Reliability | Has the newest tech and works well | Might be worn, so check it carefully |

| Technical Support | Comes with full help and warranty | Less help, check its service record |

| Performance | Works best and is very accurate | Might not have the latest features |

| Investment | Good if you plan to use it for years | Good used machines can save you money |

Many small businesses pick used machines to save money. Used smt equipment helps you start faster and spend less. But you must check the machine’s quality and service history.

Budget Factors

Your budget decides what smt equipment you can buy. New machines usually cost $50,000 to $106,000. Used ones cost $18,000 to $61,000, based on age and brand. Many small businesses have trouble getting loans for smt machines. Banks think these machines are risky. Most small businesses use their own savings or find flexible payment plans. Renting or leasing can also help you use smt technology for less money. You should have good paperwork and a strong business plan to get funding. Always match your budget to your goals and focus on making good pcbs.

Buying SMT Equipment Process

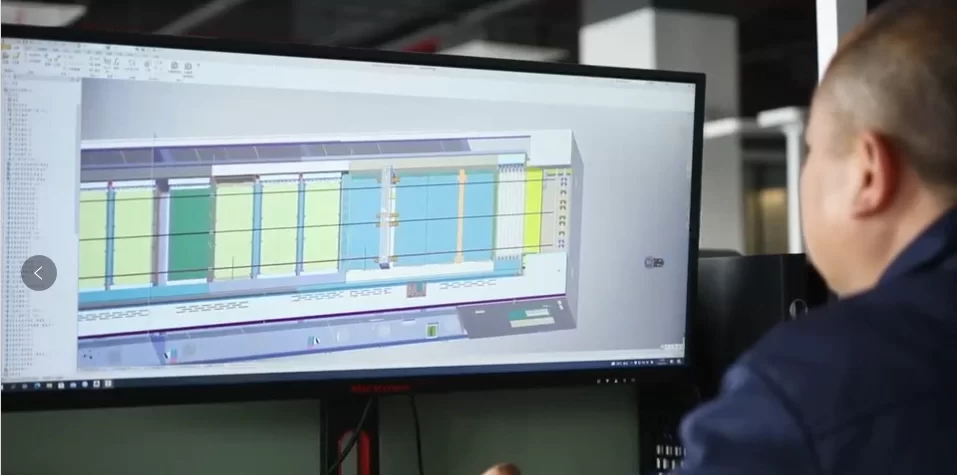

Image Source: pexels

Research Options

When you want to buy smt equipment, you need to look at your choices. Find machines that fit your work and follow safety rules. Here are the main steps you should take:

- Make sure each machine is safe to use. Train workers on how to use and fix the machines.

- Set up clear safety rules. Only trained people should use the machines. Always check air pressure and feeder setup. Keep the area clean before you start.

- Keep your work area tidy. Clean the machines, feeders, and trash bins often. This helps stop jams and mistakes.

- Hire skilled people to check and fix machines. Always turn off power before repairs. Use only approved parts for fixes.

- Control the room’s temperature and air pressure. Stop electromagnetic problems for steady smt work.

You should also do regular checks and adjustments. This keeps your smt line working well and stops long breaks. Good training helps you fix problems fast. Use good parts and feeders to stop jams and bad pcbs. Always follow the right steps when moving parts in and out. Keep making your process better for good results.

Evaluate Suppliers

Picking the right supplier is very important when buying smt machines. S&M is a top supplier. They sell many smt machines like reflow ovens, wave soldering machines, and conveyors. S&M has important certificates and is known for good quality and help.

When you look at suppliers, think about these things:

- Check what the machines can do. Look at how accurate they are, what parts they can use, and how fast they work. Make sure these fit your needs and future plans.

- See if the machine can handle different part sizes. It should be easy to set up and switch jobs.

- Plan how your machines will fit together. Think about the size and how it works with other machines. A good setup helps your smt line run well.

- Check if the supplier gives good help and training. A good supplier gives quick help, spare parts, and training. S&M is known for strong support and advice.

- Think about how the machine saves money and helps you grow. Do not just look at the first price.

- Ask others for reviews and advice. Talk to experts and read online comments. S&M gets good feedback for service and product quality.

Compare Features

You need to look at features before you buy smt equipment. For making lots of products, focus on these things:

- Make sure the machine fits all your part sizes.

- High accuracy is important. Look for machines that place parts very well.

- The machine should work the same way every time. This keeps your products good.

- Fast machines help you finish work on time. Check if the speed meets the right standards.

- The price should match what the machine can do and your budget.

Try the machines if you can. Using them helps you see if they are easy to use. Good setup and training from the supplier help a lot.

Tip: Always ask to see the machine work. This shows how it will work in your shop.

Financing

Paying for smt equipment can be hard. Many small businesses have trouble getting loans from banks. Banks think smt machines are risky, so they may say no. You might need to try many times or look for other ways.

Here is a table with some common ways to pay:

| Financing Provider | Key Features | Interest Rates | Terms | Eligibility & Limits |

| —————— | ———————————————————————————————————– | —————————- | ————— | ——————————————————– |

| Intech | No money needed up front, no extra fees, pay later, low fixed rates | Low fixed rates (can change) | Up to 7 years | Companies must be 2-3 years old; up to $750K per machine |

| Haas | Good rates for all terms, 0% interest deals | 0% interest for 2 years | Different terms | N/A |

You can also rent or lease machines. These ways let you use smt machines without paying a lot at first. Always check the rules, rates, and who can get the deal before you sign. Have your papers ready for loans. This means your business plan, money records, and details about the smt machine you want.

Documentation

Good paperwork is very important when you buy smt machines. You need to keep records for buying and setting up the machines. This helps you follow rules and keeps your work smooth.

- Watch part quality after you buy them. Store parts in sealed, dry boxes.

- Pick and store solder paste for your products.

- Check solder joints to make sure they are good.

- Protect parts from static electricity.

- Use tracking and checking systems in your work.

You also need these papers:

- PCB design files like Gerber, drill, and pick-and-place.

- Bill of Materials (BOM) with the right part numbers and amounts.

- Drawings that show where each part goes.

- Notes for any special steps in making.

- Test plans and steps.

For some industries, you need more records. These include logs for quality checks, solder paste, solder joints, static protection, and tracking. You must also keep training records and safety rules for chemicals and machines.

Note: Good paperwork helps you pass checks and keeps your smt line working well.

Common Pitfalls

Image Source: pexels

Needs Assessment

You need to start with a clear needs assessment before buying smt equipment. Many buyers skip this step and end up with machines that do not fit their production goals. If you do not know your production scale, product types, or technical needs, you may pick the wrong equipment. This can lead to high defect rates, extra rework, and higher costs. Always check your design rules, component choices, and material standards. Make sure you match your smt process to your products and use quality components for better results.

Tip: Write down your needs and review them with an expert before you buy.

After-Sales Support

After-sales support is very important when you choose an smt supplier. If you ignore this, you may face long downtimes and higher repair costs. Good support gives you training, spare parts, and fast help when problems happen. Without it, your equipment may stop working, and your production quality will drop. Always check the supplier’s reputation for service and ask about their support plans.

Equipment Condition

If you buy used smt equipment, always check its condition. Poorly maintained machines can break down often and cost more to fix. Look for signs of rust, broken parts, or old software. Ask for service logs and maintenance records. Well-kept equipment runs better, lasts longer, and keeps your product quality high.

Installation & Training

Proper installation and training help you get the most from your smt machines. Work with your supplier during setup. Make sure your team learns how to use and care for the equipment. Good training covers both how to run the machine and how to keep it in top shape. This reduces mistakes and keeps your line running smoothly.

Scalability

Think about scalability when you plan for the future. Choose smt equipment that can grow with your business. Machines with smart features and automation help you handle more work without more errors. Real-time data and machine vision systems keep your quality high as you expand.

Tips to Buy SMT Machines

Maintenance

You must take care of your SMT machines to make good pcbs and save money. Always follow the maker’s plan for maintenance. Clean your machines every day. Do a deep clean often. Check for broken parts, loose belts, or wires each week. Calibrate your machines often to keep them working right. Change air filters and update software to stop problems. Keep your work area clean. Control the room’s temperature and humidity. These steps help stop defects and make your machines last longer. S&M gives strong help after the warranty ends. Their experts help you fix problems fast and keep your line working.

Tip: Calibrating pick-and-place machines often helps you put parts in the right spot and lowers mistakes in your work.

Operator Training

Operators who know what to do help your smt line a lot. Give your team training on how to use and care for the machines. Training helps workers find problems early and handle alarms the right way. When your team can program and fix the machines, you get fewer mistakes and less downtime. S&M’s tech team can help with training and fixing problems. They make sure your team learns the newest skills.

User Feedback

Listening to other users gives you helpful tips that work in real life. Many people say S&M’s machines help them set up faster and need fewer workers. Some users finished hard setups in 45 minutes instead of 7 hours. Good reviews show S&M’s machines save money and are easy to use. Customers also like the company’s quick service and helpful support. You can use these stories to help pick the best machines for your needs.

Process Improvement

You can make your smt line better by changing small things over time. Use automation and smart tools to work faster and make fewer mistakes. Make your setup steps the same and train your team often. Make your PCB design better by using common part sizes and clear labels. This helps machines place parts easier and makes good pcbs faster. Try new ideas, watch your results, and keep making your process better. S&M gives expert advice and flexible help so you can get better quality and work faster.

You can make a smart choice when you buy smt equipment. Start with a clear plan for your needs. Many smes succeed by checking suppliers, asking for user feedback, and focusing on after-sales support. Top brands like S&M help smes grow with reliable machines and strong training. Experts say you should plan your budget, compare features, and follow setup steps. Many smes use loans to manage costs. You can also use loans for upgrades or repairs. When you learn from other smes and use loans wisely, you build a strong smt line for your business.

FAQ

What is the most important thing to check before buying SMT equipment?

You should always check if the machine matches your production needs. Look at speed, accuracy, and part size. Ask for a demo if possible.

How do you know if a supplier is reliable?

Read customer reviews and ask for references. Check if the supplier offers training and fast support. S&M, for example, has strong customer feedback and technical help.

Can you upgrade SMT machines later?

Many SMT machines let you add new features or software. Ask the supplier about future upgrades. This helps your business grow without buying new machines.

What should you do if your SMT machine breaks down?

Contact your supplier’s support team right away. Follow their troubleshooting steps. S&M offers quick help and expert advice to get you back to work fast.