Reflow soldering ovens play a critical role in electronics manufacturing. Over the past two decades, technological advances have transformed these ovens, making them smarter and more efficient. Advanced setup software and real-time monitoring allow manufacturers to adjust conveyor speeds and temperature profiles quickly, reducing changeover times and boosting throughput. Modern ovens now feature precise thermal control, predictive maintenance, and energy-efficient designs, supporting higher reliability and consistent soldering quality. This ongoing progress shapes the Development History of reflow ovens, driving innovation for industry professionals.

Key Takeaways

-

Reflow ovens revolutionized electronics manufacturing by enabling precise and efficient soldering of surface mount components.

-

Advances like convection heating and nitrogen atmospheres improved solder quality and increased production speed.

-

Lead-free soldering pushed the development of faster heating elements and better temperature control to meet stricter thermal needs.

-

Modern ovens use multi-zone heating and real-time monitoring to ensure uniform temperature and reduce defects.

-

Energy efficiency innovations, such as heat recovery and low-power designs, lower costs and support environmental goals.

-

Intelligent systems with AI and IoT enable smart process control, predictive maintenance, and higher product quality.

-

The automotive and consumer electronics sectors drive strong market growth, especially in the Asia-Pacific region.

-

Future trends focus on lead-free technology, advanced heat transfer methods, and Industry 4.0 integration for smarter, greener ovens.

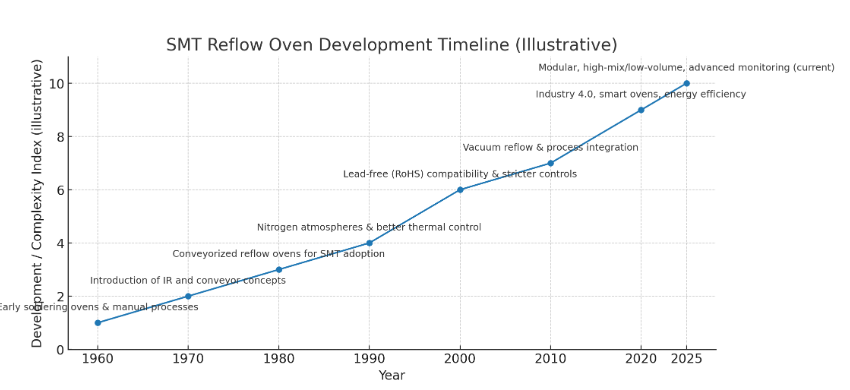

Development History

Early Methods

Before the introduction of reflow ovens, electronics manufacturers relied on traditional soldering techniques. The most common method was wave soldering, which worked well for multi-leaded through-hole components. Reflow ovens later became essential for surface mount technology, but could also adapt to some through-hole applications.

-

Wave soldering dominated early assembly lines.

-

Reflow ovens emerged with the rise of surface mount components.

-

Hand soldering remained in use for small-scale or specialized tasks.

Limitations

Early soldering methods presented several challenges that limited production speed and quality. Small-scale hand soldering often resulted in inadequate copper on joints and restricted solder flow due to small hole sizes. Insufficient heating capacity led to slow production and inconsistent results. Operators sometimes needed to preheat assemblies with heat guns and carefully manage heat-sunk joints, which increased assembly time and reduced throughput. These constraints made hand soldering inefficient and prone to quality problems in production environments.

|

Limitation Aspect |

Description |

Impact on Production Speed and Quality |

|---|---|---|

|

PCB Sagging |

Hot solder softened the PCB, causing sagging and inconsistent contact with the solder bath. |

Inconsistent solder connections, reduced quality. |

|

Entrapped Flux Globs |

Flux residues trapped in solder joints, causing defects like ‘rosin connections’. |

Unreliable solder joints, lower overall quality. |

|

Solder Oxides Formation |

Oxides formed webs across the soldered side of the PCB. |

Defects and poor solder flow negatively affect quality. |

|

Conveyor Speed and Solder Temp |

Slower conveyor speeds or higher solder temperatures are needed for complete fill. |

Reduced throughput; higher temperature caused PCB damage and machine wear. |

|

Complex Equipment for SMDs |

Glue dispensers and curing steps are required for SMDs. |

Increased processing time and maintenance reduce efficiency. |

|

Flux-related Issues |

High rosin flux caused solder skips and bridging. |

Frequent defects and rework, lowering quality, and slowing production. |

|

Heat Application Limitations |

Preheaters only under the conveyor led to slow speeds or high solder temperatures. |

PCB scorching, machine wear, and limited production speed due to thermal constraints. |

Heat Transfer Evolution

Infrared to Convection

The transition from infrared to convection heating marked a major milestone in the Development History of reflow ovens. Infrared ovens, popular in the 1980s, often produced uneven heating due to differences in component size, PCB thickness, and shadowing effects. These temperature gradients led to inconsistent soldering results. Convection ovens, introduced in the 1990s, used forced hot air to circulate heat evenly across the PCB. This advancement minimized temperature differences, eliminated shadowing, and allowed for shorter soak zones. As a result, manufacturers increased throughput by up to 40 seconds per board without sacrificing quality. Convection heating also improved flux activity and reduced thermal stress, enhancing process control and product reliability.

Note: Convection ovens require careful airflow management to prevent small parts from being displaced, but they offer lower operating costs and avoid overheating risks compared to infrared systems.

Nitrogen Atmosphere

Another significant development involved the use of nitrogen atmospheres in reflow ovens. By introducing nitrogen, manufacturers reduced oxidation during the soldering process. This improvement led to cleaner solder joints, fewer defects, and higher reliability, especially for fine-pitch and high-density assemblies. Nitrogen reflow ovens became standard in sectors demanding high-quality connections, such as automotive and telecommunications.

Lead-Free Adaptation

Heating Element Redesign

The shift to lead-free soldering brought new challenges to the Development History of reflow ovens. Lead-free processes require reflow temperatures about 30°C higher than traditional tin-lead soldering. Original heating elements, which heated at about 1 degree per second, could not meet these demands. Manufacturers replaced them with halogen heating elements and added ceramic insulation, increasing the heating rate to 6 degrees per second. This upgrade enabled faster and more precise heating, which is essential for maintaining the strict thermal profiles required by lead-free soldering. Programmable controllers, such as Arduino-based systems, allowed for fine-tuned temperature management, supporting both leaded and lead-free processes.

-

Faster heating rates support higher reflow temperatures.

-

Programmable controls enable precise thermal profiles.

-

Improved insulation reduces energy loss and enhances safety.

Temperature Uniformity

Maintaining temperature uniformity became critical as electronics grew more complex and miniaturized. Forced air convection ovens introduced precision air control and enhanced airflow management, achieving tighter temperature tolerances. Machine learning algorithms now optimize reflow profiles in real time, using sensor data to reduce thermal defects. These advancements support the reliable soldering of fine-pitch and high-density components, which are common in modern devices. Uniform temperature distribution reduces defects such as cold solder joints, voids, and misalignment, directly improving product reliability and performance. Advanced monitoring and control systems also enhance process traceability, supporting compliance with industry standards and high-reliability applications.

Market Growth and Industry Trends

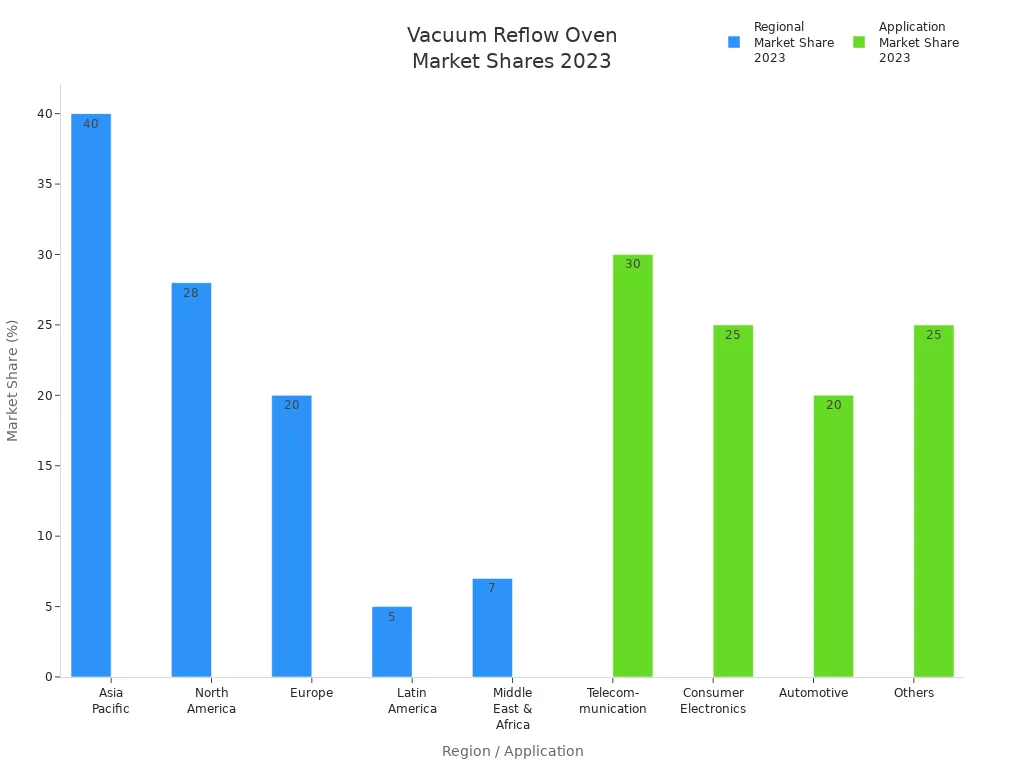

The Development History of reflow ovens closely aligns with the expansion of the electronics manufacturing industry. Demand for advanced electronic devices, miniaturization, and innovations in soldering technology drive market growth. The automotive industry’s shift to electric and autonomous vehicles has increased the need for precise soldering solutions. Asia-Pacific leads the market, holding about 45% share in 2023, with a projected CAGR of 5.0%. North America and Europe also show steady growth, supported by the automotive, aerospace, and industrial sectors. Major companies invest heavily in research and automation to meet evolving manufacturing needs.

|

Attribute |

Description |

|---|---|

|

Estimated Global Reflow Oven Market Size (2025E) |

|

|

Projected Global Reflow Oven Market Value (2035F) |

USD 1,641.5 million |

|

CAGR (2025 to 2035) |

Approximately 4.4% |

The Development History of reflow ovens demonstrates a clear link between technological innovation and the demands of modern electronics manufacturing. As the industry continues to evolve, reflow ovens will remain central to achieving high-quality, reliable, and efficient assembly processes.

Advancements

Temperature Control

Multi-Zone Heating

Multi-zone heating stands as a cornerstone of modern reflow oven design. Manufacturers use this technology to divide the oven into several independently controlled zones. Each zone targets a specific stage of the soldering process: preheat, soak, reflow, and cooling.

-

The preheat zone removes moisture and prepares components.

-

The soak zone activates flux and ensures even solder paste melting.

-

The reflow zone reaches peak temperature to form secure solder joints.

-

The cooling zone solidifies the joints and minimizes thermal stress.

This precise control allows gradual, uniform heating and cooling, which prevents component damage and ensures reliable solder connections. Multi-zone heating also supports the higher temperatures required for lead-free soldering, reducing the risk of overheating and thermal stress. As electronic assemblies become more complex, this approach ensures consistent results and high product quality.

Real-Time Monitoring

Modern reflow ovens now feature advanced real-time monitoring systems. These systems use sensors and software to track critical parameters such as zone temperature, conveyor speed, and process window index (PWI).

-

Continuous monitoring detects process drift or variations instantly, triggering alarms before defects occur.

-

Systems like OvenSENTINEL™ provide live measurements, automated data collection, and powerful reporting tools.

-

Real-time feedback loops help maintain process stability, reduce defects, and improve yield.

Automated statistical process control (SPC) charts and Cpk calculations support traceability and compliance. By eliminating manual profiling and enabling proactive adjustments, real-time monitoring ensures high reliability and consistent quality in every production run.

Energy Efficiency

Heat Recovery

Heat recovery technology has become essential for reducing operational costs and environmental impact. Reflow ovens now capture and reuse waste heat, lowering the demand on primary heating systems. This approach stabilizes energy use and reduces reliance on fossil fuels, cutting both expenses and carbon emissions.

BTU’s Energy Pilot system, for example, uses standby, sleep, and hibernate modes to save up to 40% of energy during idle times. These modes also reduce nitrogen consumption and emissions, supporting sustainable manufacturing.

Low-Power Design

Low-power design further enhances energy efficiency. Manufacturers achieve energy savings of up to 10-15% by using double insulation and advanced gas management systems.

-

Nitrogen consumption drops by as much as 40% with uniform gas flow.

-

Lower electrical usage reduces operating costs and environmental impact.

-

Maintenance intervals extend due to improved flux management systems.

Some ovens now feature energy management software and low-temperature catalyst systems that decompose flux without extra power or cooling. These innovations make reflow ovens more cost-effective and environmentally friendly.

Intelligent Systems

Process Optimization

Intelligent systems have transformed process optimization in reflow soldering. Advanced inspection and smart control technologies provide real-time feedback, enabling continuous adjustments that reduce rework and enhance product quality.

-

Data-driven diagnosis and computational intelligence adapt to changing manufacturing conditions.

-

Neurofuzzy systems extract rules from process data, optimizing thermal profiles and improving stability.

A systems engineering approach combines materials science, thermal dynamics, and precision control, ensuring optimal results even as products become smaller and more complex.

Stability and Quality

Intelligent control systems directly improve process stability and yield rates. Automated profiling tools and real-time monitoring detect temperature drifts immediately, virtually eliminating thermal process-related defects.

-

The Process Window Index (PWI) serves as a statistical tool to compare and rank thermal profile performance.

-

Automated management reduces setup and changeover times, increasing uptime and profitability.

-

Continuous monitoring and data analytics support quality assurance and compliance.

These advancements ensure that reflow ovens deliver consistent, high-quality results, meeting the demands of modern electronics manufacturing.

Market Trends

Growth Drivers

Automotive Electronics

Automotive electronics continue to drive the reflow oven market. Manufacturers in this sector require precise and reliable soldering for advanced vehicle systems. Electric vehicles and autonomous driving technologies demand highly integrated circuits in compact spaces. Reflow ovens support these needs by providing accurate temperature control and consistent soldering quality. The automotive industry’s push for new energy vehicles and smart car electronics has led to innovations such as lead-free soldering and nitrogen protection systems. Companies invest in intelligent automation and IoT integration to enhance operational efficiency and meet strict regulatory standards. Environmental policies encourage adoption of energy-efficient ovens with emission control features.

-

Automotive electronics require high reliability and precision.

-

Industry 4.0 integration boosts efficiency and energy savings.

Consumer Electronics

Consumer electronics represent another major growth driver. The demand for smaller, multifunctional devices continues to rise. Smartphones, wearables, and miniaturized gadgets require advanced soldering solutions. Reflow ovens enable manufacturers to produce high-density printed circuit boards with minimal defects. The proliferation of smart devices and the need for reliable connections fuel market expansion. Companies focus on process optimization and energy efficiency to stay competitive.

Note: The consumer electronics industry expands rapidly due to the proliferation of smartphones and miniaturized devices, requiring advanced soldering solutions.

|

Market Driver Category |

Description |

|---|---|

|

Consumer Electronics Industry |

|

|

Automotive Sector |

Increasing electronic integration, especially with electric vehicles and autonomous technologies, is boosting demand. |

|

Industrial Automation & Industry 4.0 |

Adoption of automation to improve efficiency, with reflow ovens integral to automated assembly lines. |

|

Regional Growth (Asia Pacific) |

Government initiatives and investments support strong electronics manufacturing hubs in China, Japan, and South Korea. |

Regional Expansion

Asia-Pacific

Asia-Pacific leads global electronics production, accounting for over 60% of output. Countries such as China, Japan, South Korea, and Taiwan serve as major hubs for semiconductor and SMT assembly. Manufacturers in this region adopt reflow ovens to meet growing demand for compact and high-density PCBs. Automation in electronics assembly increases as labor costs rise and quality requirements become more stringent. Emerging markets like India and Vietnam benefit from government incentives and foreign investment. Technological advancements in SMT processes and the shift toward Industry 4.0 drive demand for energy-efficient, high-throughput ovens.

-

Asia-Pacific dominates due to manufacturing scale and government support.

-

Rapid automation and regulatory compliance fuel adoption.

-

Strong exports and R&D investments support market growth.

North America, Europe

North America and Europe focus on high-end, specialized applications. Automotive, aerospace, and medical sectors require advanced reflow ovens for reliability and safety. Manufacturers invest in energy-efficient technologies and emission control systems to meet environmental regulations. The adoption of vacuum ovens grows in these regions, driven by stringent quality standards and the need for high-performance solder joints.

Tip: North America and Europe show steady growth, supported by automotive, aerospace, and industrial sectors.

Oven Types

Convection Ovens

Convection ovens remain the most widely adopted type in electronics manufacturing. Their cost-effectiveness and energy efficiency make them suitable for high-volume PCB production. Forced convection variants improve heat transfer and speed, supporting complex and densely populated boards. Asia-Pacific leads in convection oven usage due to its large manufacturing ecosystem.

|

Factor |

Convection Ovens |

Vacuum Ovens |

|---|---|---|

|

Easier to operate with fewer specialized skills required. |

Requires skilled personnel for operation and maintenance; complexity limits adoption. |

|

|

Cost Barrier |

Lower cost encourages widespread use, especially among SMEs. |

High upfront and operational costs restrict penetration in emerging markets and SMEs. |

|

Market Opportunities |

Broad applicability in automotive, aerospace, medical, and renewable energy sectors. |

Growing demand in high-reliability sectors and advanced electronics manufacturing. |

|

Technology Segments |

Dominated by forced convection ovens with precise temperature control. |

Includes convection vacuum, vapor phase, and laser vacuum ovens; vapor phase growing, but niche. |

|

Regional Market Share |

The Asia-Pacific region leads due to its large electronics manufacturing ecosystem. |

North America and Europe focus on high-end, specialized applications. |

Vacuum Ovens

Vacuum ovens gain traction in sectors demanding high reliability, such as aerospace and medical electronics. These ovens operate under vacuum to reduce oxidation and solder defects, producing superior solder joints by minimizing voids and contamination. Despite their advantages, higher costs and operational complexity limit adoption among small and medium enterprises. North America and Europe see greater use of vacuum ovens for high-end applications, while Asia-Pacific continues to dominate convection oven usage.

Vacuum reflow ovens enhance solder joint reliability and support advanced electronics manufacturing, but require skilled operators and significant investment.

Future Trends

Lead-Free Technology

Manufacturers continue to prioritize lead-free technology in reflow ovens. Regulatory frameworks such as RoHS enforce strict standards, pushing companies to adopt lead-free soldering processes. Environmental sustainability has become a major concern for both producers and consumers. Companies respond by investing in greener manufacturing solutions.

-

Stringent environmental regulations drive the adoption of lead-free ovens.

-

Consumer awareness encourages sustainable production practices.

-

Miniaturization and complex PCB designs require precise soldering equipment.

-

The rise of IoT and smart devices increases demand for advanced electronic assemblies.

Asia-Pacific leads the market due to robust electronics manufacturing in China, Japan, and South Korea. North America and Europe also experience growth, supported by technological innovation and regulatory compliance. Convection reflow ovens dominate because they deliver efficient heat transfer and uniform temperature distribution. Vapor phase ovens are gaining popularity in the automotive and aerospace sectors, where temperature control is critical. Infrared ovens offer energy efficiency and rapid heating, making them suitable for small-scale production.

Manufacturers introduce compact and modular ovens for flexible production. Advanced software optimizes heating profiles for various lead-free solder alloys. Integration of AI, machine learning, and IoT enables predictive maintenance and remote diagnostics. Companies focus on energy efficiency and sustainability, aiming to reduce carbon footprints. OEMs and EMS providers adopt these technologies to meet quality, reliability, and regulatory standards. The market continues to evolve, with innovation supporting miniaturization and higher reliability.

Enhanced Intelligence

Intelligent process control shapes the next generation of reflow ovens. Companies invest in AI-powered systems to enhance precision and optimize production. Smart desktop ovens offer improved accuracy and process control for small-scale manufacturing. Energy-efficient models and IoT-enabled monitoring systems support sustainability and operational efficiency.

-

AI and data analytics enable real-time adjustments and predictive maintenance.

-

IoT integration allows remote monitoring and smart factory connectivity.

-

Advanced analytics support quality assurance and reduce downtime.

-

Touchscreen interfaces and modular designs improve usability and productivity.

Industry 4.0 capabilities become standard, with smart sensors and automated solutions optimizing production efficiency. Strategic collaborations between OEMs and software providers accelerate the development of integrated reflow solutions. Regulatory emphasis on sustainability drives the adoption of low-emission, energy-saving ovens. Companies respond to market drivers such as digital transformation, demand from electric vehicles, 5G, and IoT sectors, and the push for automation and traceability.

Machine learning integration supports process optimization and quality control. Manufacturers use advanced thermal profiling, nitrogen reflow systems, and real-time monitoring to improve precision and consistency. Conveyor system innovations and zoned heating technologies reduce operational costs and defects. The market moves toward flexible, intelligent, and sustainable manufacturing solutions.

Advanced Heat Transfer

Emerging heat transfer technologies set new standards for reflow ovens. Hybrid heating solutions combine convection, radiation, conduction, and vapor phase methods. These systems reduce temperature differentials between small and large components, preventing overheating and improving solder joint quality. Vacuum ovens offer improved throughput, reduced size, and lower maintenance, minimizing voids and enhancing reliability.

|

Emerging Heat Transfer Technology |

Purpose / Benefit |

Development Status / Notes |

|---|---|---|

|

Hybrid heating (convection, radiation, conduction, vapor phase) |

Reduces temperature differentials, prevents overheating |

Technology readiness is progressing rapidly |

|

Vacuum ovens |

Reduces voiding, improves throughput, and reliability |

Increasing adoption, especially in high-reliability sectors |

|

Multi-zone heating/cooling |

Better thermal control, higher throughput |

Ovens with up to 18 heating zones and 6 cooling zones available |

|

Industry 4.0 integration (IoT, AI, machine learning) |

Enhances automation, predictive maintenance, and quality assurance |

Emerging trend in smart ovens |

|

Sustainability-driven innovations |

Lowers carbon footprint, reduces operational costs |

Ongoing improvements in atmosphere control and energy efficiency |

Manufacturers focus on multi-zone heating and cooling, with ovens featuring up to 18 heating zones and 6 cooling zones. Multi-lane ovens help reduce floor space and increase throughput. Integration of Industry 4.0 technologies supports process automation, predictive maintenance, and quality assurance. Sustainability-driven innovations aim to lower nitrogen use and power consumption, reducing environmental impact.

Vacuum reflow ovens see strong market growth. The market is projected to expand from USD 250 million in 2024 to USD 372.1 million by 2032, with a CAGR of 5.1%. Growth is driven by demand in the automotive, telecommunications, consumer electronics, and semiconductor sectors. Asia-Pacific leads with the highest share and fastest growth, supported by concentrated electronics manufacturing.

Technological advances such as automation, smart sensors, and Industry 4.0 integration improve process control, reduce defects, and enhance production yield. Manufacturers overcome challenges like high initial investment and technical complexity by focusing on energy-efficient and eco-friendly technologies. The market outlook remains positive, with increasing adoption expected through 2032.

Energy Efficiency

Energy efficiency stands at the forefront of innovation in reflow oven technology. Manufacturers face increasing pressure from environmental regulations and rising operational costs. They respond by investing in advanced solutions that reduce energy consumption and emissions while maintaining high-quality soldering results.

Key trends shaping energy efficiency in reflow ovens include:

-

Stricter environmental regulations, such as those from the US Environmental Protection Agency (EPA), push companies to design ovens that consume less energy and emit fewer pollutants.

-

Manufacturers invest in advanced thermal profiling and energy-efficient components. These upgrades ensure compliance and improve operational efficiency.

-

Energy Star certification encourages the development of smarter, more sustainable oven designs.

-

IoT-enabled monitoring systems allow real-time tracking of emissions and energy use. These systems also support predictive maintenance, which reduces downtime and optimizes energy consumption.

-

Industry 4.0 technologies, including machine learning and real-time analytics, help optimize thermal profiles and minimize energy waste.

-

Smart, connected ovens integrated into smart factories lower labor costs and emissions. This approach aligns with global sustainability goals.

-

Early adopters of these innovations gain a competitive edge through improved brand reputation and operational savings.

Technological advancements also play a significant role in boosting energy efficiency. Improved temperature uniformity and faster heating cycles reduce the time and energy required for each production run. IoT-enabled monitoring provides real-time data analysis, enabling predictive maintenance and minimizing unplanned downtime. Enhanced thermal management and emission controls further contribute to lower energy usage.

Manufacturers increasingly adopt modular oven designs and automation. These features improve process repeatability and consistency, which leads to more efficient energy use. Industry 4.0 trends, such as smart factories, drive robust growth in energy efficiency across the sector. Companies invest heavily in research and development to enhance oven capabilities and accelerate global adoption of energy-saving technologies.

Eco-friendly, energy-saving, and low-emission infrared (IR) reflow ovens are gaining popularity. Regulatory and environmental awareness fuel this trend. The IR reflow oven market is projected to reach approximately $3.5 billion by 2027, reflecting steady growth driven by these technological advancements.

Note: Energy efficiency improvements not only reduce operational costs but also support environmental sustainability. Companies that prioritize these innovations position themselves as leaders in responsible manufacturing.

Reflow ovens have evolved from basic heating systems to advanced, intelligent equipment. Ongoing innovation drives competitiveness in electronics manufacturing through:

-

Integration of Industry 4.0 technologies like IoT and AI

-

Adaptation for lead-free and miniaturized assemblies

-

Customizable solutions for diverse industry needs

Manufacturers who embrace these advancements meet regulatory standards and market demands. Reflow ovens will continue to shape the future of electronics production, supporting quality, sustainability, and technological progress.

FAQ

What is a reflow oven used for in electronics manufacturing?

A reflow oven melts solder paste to attach electronic components to printed circuit boards. Manufacturers rely on this equipment for surface mount technology assembly. The oven ensures consistent solder joints and high product reliability.

How do convection and vacuum reflow ovens differ?

Convection ovens use forced hot air for even heating. Vacuum ovens operate under reduced pressure to minimize solder voids and oxidation. Vacuum ovens produce higher reliability joints, especially for aerospace and medical electronics.

Why is lead-free soldering important?

Lead-free soldering meets environmental regulations such as RoHS. Manufacturers protect workers and end-users from toxic exposure. Lead-free processes also support global sustainability goals and improve product safety.

What role does Industry 4.0 play in reflow oven technology?

Industry 4.0 introduces smart sensors, IoT connectivity, and AI-driven process control. These technologies enable predictive maintenance, real-time monitoring, and automated adjustments. Manufacturers achieve higher efficiency and traceability.

How do manufacturers improve energy efficiency in reflow ovens?

Manufacturers use heat recovery systems, double insulation, and low-power designs. IoT-enabled monitoring tracks energy use and emissions. These innovations reduce operational costs and support environmental compliance.

Which industries drive demand for advanced reflow ovens?

Automotive, consumer electronics, aerospace, and medical sectors require precise soldering and high reliability. Electric vehicles, smart devices, and miniaturized electronics increase demand for advanced oven technology.

What future trends will shape reflow oven development?

Manufacturers focus on lead-free technology, enhanced intelligence, advanced heat transfer, and energy efficiency. Automation and Industry 4.0 integration will drive innovation. The market expects growth in vacuum and modular oven types.