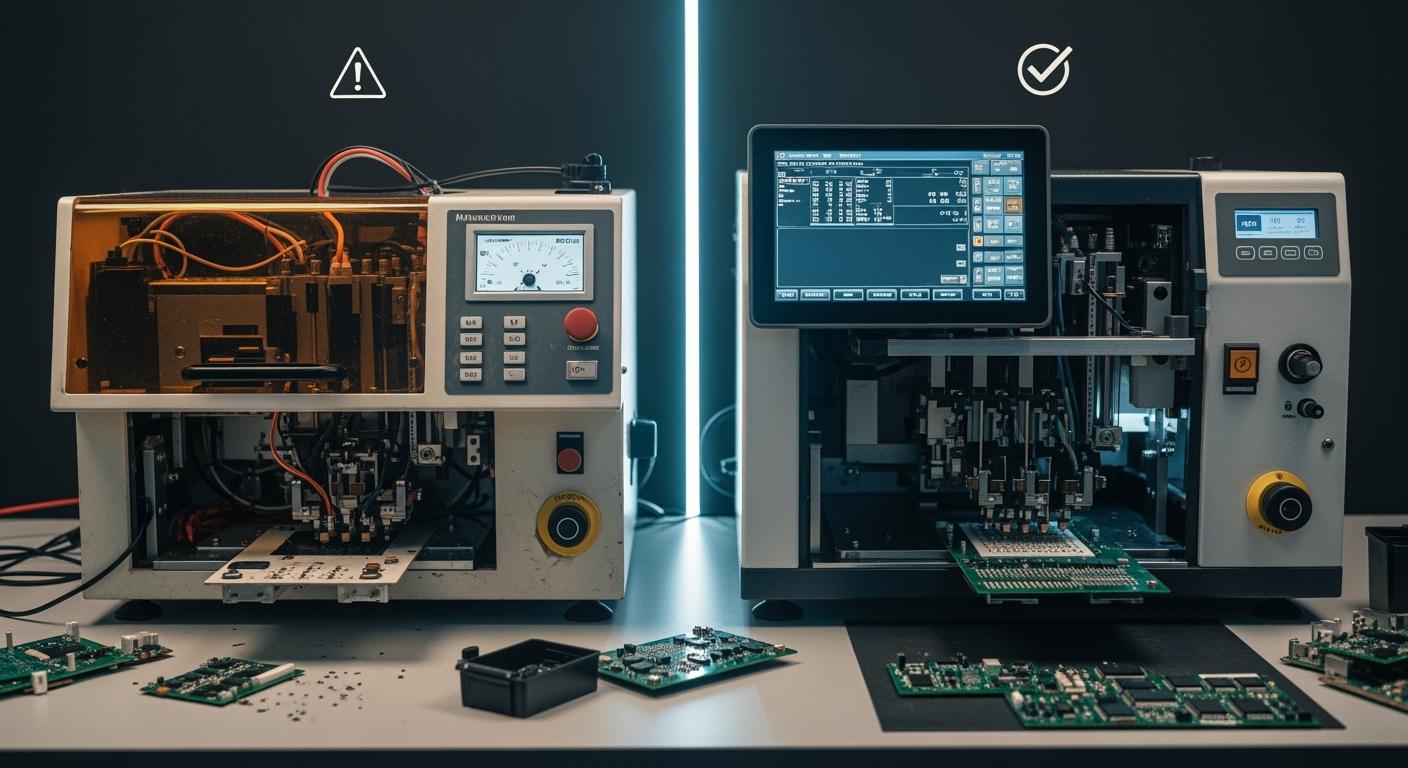

You can see big differences when you look at low-cost and high-quality SMT equipment. High-quality machines work better and are more reliable. For example, advanced SMT automation can make thousands of boards every day. It needs less labor, so it saves time and money. Cheaper options may not do as much work. Picking the right SMT solution helps your production meet demand. It also makes sure the quality stays the same. S&M cares about new ideas and good quality. They help your business now and as it grows in the future.

Key Takeaways

High-quality SMT equipment works faster and is more accurate, so production gets done quicker. – Good machines make fewer mistakes, which means customers are happier. – Think about long-term costs, because better machines need less fixing and cost less to keep working. – New SMT equipment has automation that helps people work faster and keeps up with new needs. – Picking the right equipment now helps your business grow and lets you make different PCB designs later.

SMT Equipment Performance

Speed And Production Efficiency

SMT equipment should match your production needs. Fast machines help you make more circuit boards each day. Low-cost SMT machines are good for small jobs. They run at medium speeds, under 20,000 CPH. High-quality SMT equipment can go 30,000 CPH or higher. These machines finish big orders quickly and make work easier.

Here is a simple table that shows the difference in speed:

Type of Machine | Speed Range (CPH) | Description |

|---|---|---|

Medium-Speed Machines | Below 20,000 | Good for small manufacturers and general-purpose production. |

High-Speed Machines | 30,000 or more | Best for mass production and high throughput. |

S&M’s SMT equipment uses new technology for better results. You get faster speeds and more efficient production. This helps you save time and meet what customers want.

Placement Accuracy And Quality

Accuracy matters in SMT production. Every part should go in the right place. Low-cost SMT equipment may miss sometimes. You might see small mistakes. High-quality SMT equipment from S&M uses smart features to improve accuracy. These machines can handle tiny parts and place them very precisely. This helps make smaller and smarter electronics.

High-quality SMT equipment gives you better boards. S&M’s machines check placement and fix errors. Your finished boards work better and last longer.

Tip: Accurate placement means fewer mistakes and happier customers.

Error Rates And Reliability

Error rates change your production results. Low-cost SMT equipment may make more mistakes. You might need to fix more boards, which slows you down. High-quality SMT equipment from S&M uses smart tools to lower error rates. The machines check each step and find problems early. This makes your production more reliable.

S&M’s SMT equipment uses technology to cut down human mistakes. You get steady performance and better results. Reliable machines help you avoid delays and keep customers happy.

Smart systems lower mistakes and make machines more reliable.

You get more good boards and spend less fixing problems.

Picking high-quality SMT equipment from S&M gives you better results, higher efficiency, and steady production. You can trust your SMT line to do a great job every time.

Cost And ROI

Upfront Investment

When you look at smt equipment, you notice a big price difference. Low-cost machines look good because they cost less at first. Some placement machines can be as cheap as USD 9,000. Stencil printers might cost between USD 8,000 and USD 14,000. If you want advanced inspection, a 3D AOI system can cost $89,000. AXI units can cost over $145,000. High-quality machines cost more money, but you get better technology. You also get more accurate results and stronger quality control. Spending more at the start helps you avoid problems later.

Note: Paying more at first often means better quality and fewer problems during production.

Maintenance And Long-Term Savings

You should think about more than just the first payment. Maintenance and other costs are important too. Low-cost machines may break down more often. You might need more repairs and spare parts. They can use more energy and may not get software updates. These extra costs add up over time. High-quality smt equipment from S&M uses new technology to lower maintenance needs. You spend less money on repairs and downtime. S&M’s machines save energy and get easy software updates. This helps you save money every year.

Here are some things that change your total costs:

How often you need repairs or spare parts

How much energy your machines use

The cost of software updates and licenses

Downtime and product rejection rates

S&M’s focus on quality control helps you avoid hidden costs. You get reliable machines that keep your line working well.

Value In High-Volume Production

If you make a lot of products, the right equipment matters a lot. High-quality smt machines help you work faster and fill big orders. Advanced pick-and-place machines can handle up to 200,000 components per hour. This means you finish jobs faster and launch products sooner. Automated systems can make your line four to five times more productive than manual work. You also get better accuracy and stronger quality control. This lowers your rejection rate.

When you use S&M’s solutions, you save real money. You spend less time fixing mistakes and more time making good products. Your roi gets better because you get more value from your investment. High-quality equipment is not just a cost. It is a smart choice for long-term growth.

Tip: For high-volume production, the cheapest machine is not always the best. The best value comes from strong quality control, high efficiency, and reliable technology.

You should look at both the first cost and the long-term benefits. S&M’s smt equipment gives you strong quality, low costs over time, and a better roi. This helps your business grow and do well in a tough market.

Technology In New SMT Equipment

Automation Features

When you use new smt equipment with automation, things change a lot. Automated component placement makes your line faster and smarter. You can see real-time data about how many parts you place. You also see how well your line works. Dashboards help you find problems and make things better. Predictive maintenance alerts tell you before something breaks. This means your machines stop less often. Advanced technology lets your machines talk to MES and ERP systems. Automated replenishment requests keep your inventory low. They also help you respond quickly. You get better traceability, so you can follow strict industry rules.

Automated component placement makes things faster and more accurate.

Real-time defect detection finds problems early.

Automation features help you make more with less work.

Inspection Systems

Inspection accuracy is important for every smt line. New smt equipment uses advanced vision systems to check small parts. These systems find tiny errors in pad alignment. They make sure every board meets quality standards. Automated component placement works with inspection systems to lower mistakes. You get real-time defect detection at line speed. This means you do not slow down production.

Metric | Before AOI | After AOI | Improvement |

|---|---|---|---|

5% | <1% | Reduction of 4% | |

Production Efficiency Increase | N/A | 30% | Boost in efficiency |

Daily Output Increase | N/A | 20-25% | Increase in output |

AOI systems in new smt equipment can find defects as small as 0.025 mm. Smart software lowers false alarms and checks every board. You get better quality and fewer boards are rejected.

Upgrade Potential

You want your smt equipment to last and stay up to date. New smt equipment from S&M gives you many ways to upgrade. You can clean nozzles and feeders every day. This keeps automated component placement working well. Regular calibration keeps your vision system sharp. It also keeps your accuracy high. Lubrication and nozzle replacement help your machines run smoothly. Data backup protects your settings. Certified technicians check your line every six months. This keeps your line reliable.

Upgrade options help you keep your technology new.

You get long-term use and strong performance.

New smt equipment from S&M gives you advanced technology, automation, and good inspection accuracy. You get real-time defect detection, less downtime, and ways to upgrade for the future.

Scalability And Flexibility

Adapting To Production Changes

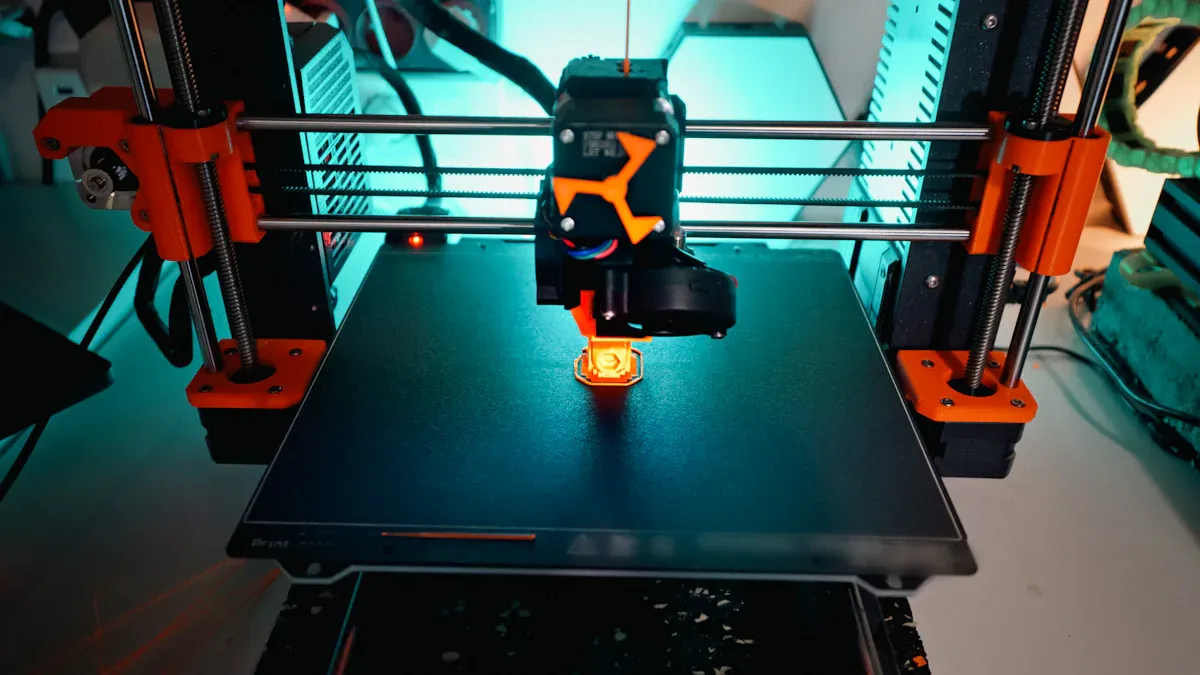

You want your production line to handle new needs. High-quality smt equipment helps you do this. You can start small and add more machines later. This saves money and space. You can make small or big orders with the same system. You do not need to change everything. More automation helps you spend less and work faster. Your line can keep up as your needs change.

Here is a table that shows how high-quality equipment helps you grow:

Feature | Description |

|---|---|

Scalability | |

Compliance | Meeting current and upcoming environmental and safety standards. |

Innovation | Incorporation of the latest technological advancements by the vendor. |

Supporting Diverse PCB Designs

Your customers might want many types of circuit boards. You need a flexible smt line for different shapes and sizes. High-quality smt equipment uses modular designs. You can switch jobs and make changes fast. Smart feeder management and automatic nozzle replacement help you finish changeovers quickly. This means you can meet different needs without slowing down.

SMT equipment puts parts on PCBs fast and accurately.

Modular design lets you upgrade or join machines for new projects.

Advanced features help you change jobs quickly for many PCB designs.

Expansion Options

You can grow your line step by step. Start with one placement machine. Add another machine when you need more. Keep adding as your business gets bigger. This way, you use your resources well and avoid big risks.

Add one or two more machines as orders grow.

Expand your line as your production needs change.

Tip: Flexible expansion keeps your business ready for new challenges.

High-quality smt equipment from S&M gives you tools to adapt, support many designs, and expand easily. You can meet today’s needs and get ready for tomorrow’s growth.

Suitability For Different Users

Startups And Small Businesses

If you have a small business or startup, you need the right smt equipment. Think about how fast the machine works and how accurate it is. You also want a machine that does the same job well every time. Here is a simple table to help you compare what is important:

Consideration | Description |

|---|---|

Placement Speed | Pick a speed that fits your work and money plan. Use IPC 9850 standards to check machines. |

Placement Accuracy | Try to get a machine that puts parts in the right spot. |

Machine Repeatability | A good machine does the same thing every time. |

Component Size Capability | Make sure your machine can use different part sizes. |

Overemphasis on Price | Do not just pick the cheapest. Sometimes a middle-priced machine is best. |

After-Sales Service | Choose a company that helps you if something breaks. |

Blindly Pursuing High Performance | Start with what you need now. You can get better machines later. |

Tip: Do not only think about price or the best machine. Pick one that fits your needs now and lets you grow later.

Established Manufacturers

If you work at a big company, you need high-quality smt machines. These machines help you make more products faster. You will save money because you fix fewer mistakes. The machines can also change as your company gets bigger. Here is a table that shows the main good points:

Benefit | Description |

|---|---|

Increased Production Efficiency | Fast machines help you make more and keep quality high. |

Cost Savings | You pay more at first, but you save money by doing less work by hand and making fewer mistakes. |

Future-Proofing | New machines let you change your line when you need to. |

Note: Buying good machines helps you stay ahead when things change.

Industry-Specific Solutions

Some jobs need special smt machines. For example, you might work with LED, New Energy, or Medical Devices. Each job has its own needs. Here are some examples:

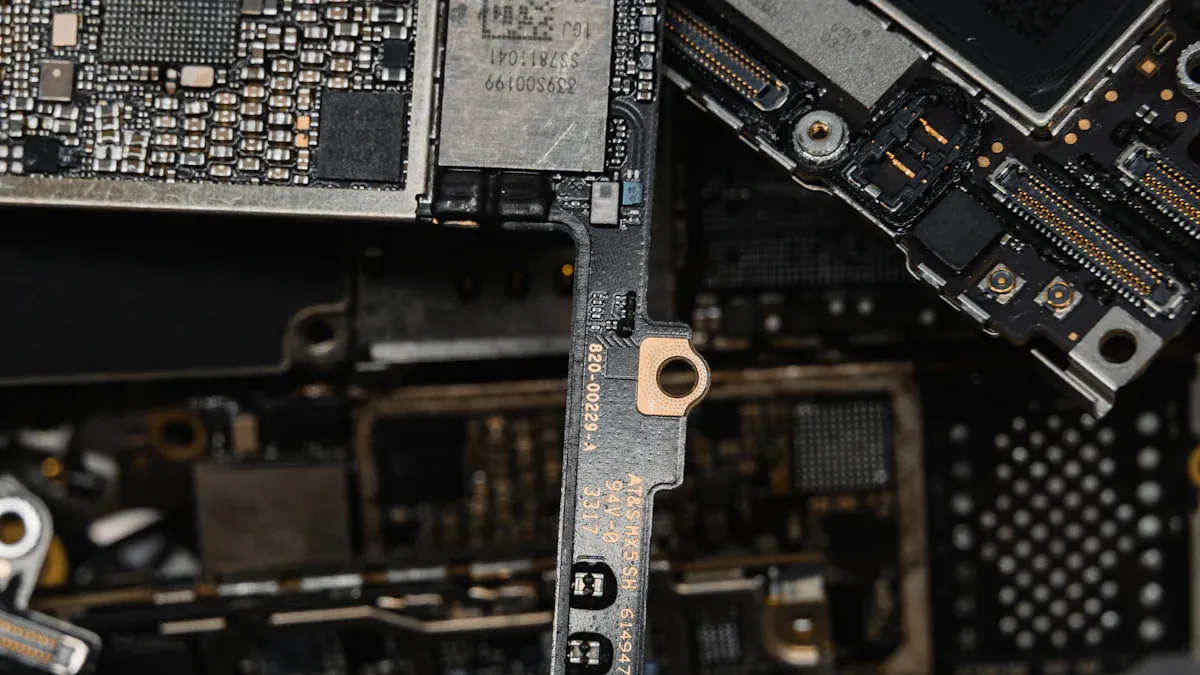

Medical tools need small and exact parts.

Wearable health devices use tiny and light pieces.

Implantable devices must be very accurate and safe.

S&M makes smt machines for these jobs. Their machines meet ISO 13485 rules and help with FDA needs. Good tracking systems let you see every part and test. S&M looks at your parts, builds machines for you, and adds checks to test your products right away.

S&M makes special machines for your job, so your products work their best.

Decision Guide For SMT Equipment

Key Factors To Consider

You should think about a few important things before you pick smt equipment. The right choice helps your business grow. It also keeps your line working well. Here is a table that shows what to look for:

Factor | Description |

|---|---|

Production Capacity | Make sure the equipment fits your current and future production needs. |

Product Characteristics | Check if the machine can handle different types of PCBs and components. |

Enterprise Capital Conditions | Look at your budget and find the best value for your money. |

Equipment Operation and Maintenance | Pick machines that are easy to use and maintain. This reduces downtime. |

Technical Support and Service | Choose suppliers who offer strong technical support and clear service options. |

Tip: Good support and easy maintenance help you fix problems fast and keep your line running.

Matching Equipment To Needs

You need to pick smt equipment that matches your goals. Think about how fast you want to place parts. Also, think about what kinds of parts you use. The table below can help you choose:

Criteria | Description |

|---|---|

Placement Rate | Fast placement means higher output. |

Component Mix | Machines should handle all the parts you use. |

Equipment Maintenance | Reliable machines keep your line moving. |

Training and Support | Make sure your team knows how to use the equipment and gets help when needed. |

Note: Training your team and picking good machines help you reach your quality goals.

Common Mistakes To Avoid

People sometimes make mistakes when they pick smt equipment. You can avoid these problems by doing a few simple things:

Clean your machines often so dirt does not build up.

Lubricate parts as the manual says to stop them from wearing out.

Set up your machines the right way and check the settings often.

Do regular maintenance to find small problems before they get big.

Train your team so they know how to use and care for the machines.

Some problems you might see are bridging between pads, de-wetting solder, poor wetting with lead-free solder, and parts moving out of place. You can stop these by using the right solder paste, keeping the temperature steady, and checking the surface finish.

Tip: Cleaning, oiling, and training your team help your smt line work better.

If you want help, you can talk to S&M. Their team helps you pick the best smt equipment for your business. You get support, training, and good machines for every part of your work.

If you pick high-quality smt equipment, your production gets better. You will have fewer mistakes and spend less money over time. Your machines work faster and stop less often. This makes your customers happier.

Good parts help you work faster and fix less.

When your products are always good, your business can grow.

Long-term Benefits | |

|---|---|

Higher | Faster ROI, more efficiency, and easy scaling |

You can count on S&M for smt solutions you can trust. Their machines are reliable, easy to grow with, and use new ideas. They help you reach your goals in the future.

FAQ

What is used smt equipment?

Used smt equipment means you buy machines that someone else owned before. You can save money when you choose used smt equipment. These machines still help you make circuit boards. You need to check if the equipment works well before you buy it.

How do I know if used smt equipment is right for my business?

You should look at your production needs. Used smt equipment can help you start with less money. If you need machines for small jobs, used smt equipment may fit. You must check the equipment for quality and reliability before you decide.

What are the main benefits of high-quality equipment compared to used smt equipment?

High-quality equipment gives you better speed and accuracy. You get less downtime and more reliable machines. Used smt equipment may cost less, but new equipment often lasts longer. You can trust new machines to keep your line running well.

Tip: New equipment helps you avoid problems and keeps your production strong.

How can I reduce downtime with my machines?

You can clean your machines often. You should follow the equipment manual for care. Regular checks help you find problems early. Used smt equipment may need more care. Good equipment and trained workers help you lower downtime.

Can used smt equipment support different types of circuit boards?

Used smt equipment can work with many board types. You need to check if the machines have the right features. Some equipment can change for new jobs. You should ask the seller about the machines’ abilities before you buy.

Equipment Type | Supports Many PCB Types | Needs Upgrade? |

|---|---|---|

Used SMT Equipment | Sometimes | Maybe |

New Equipment | Yes | No |