Surface Mount Technology (SMT) reflow soldering and wave soldering differ in several critical aspects. SMT reflow soldering uses a reflow oven with multiple temperature zones and applies solder paste to mount components directly on the PCB surface. Wave soldering relies on a molten solder wave to attach through-hole components. The choice between these methods influences component compatibility, production speed, cost, and assembly quality.

|

Aspect |

SMT Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Application |

SMT components on complex, high-density PCBs |

Through-hole components on simpler PCBs |

|

Equipment |

Reflow oven with multiple zones |

Wave soldering machine with molten solder |

|

Production Speed |

Slower, precise process |

Faster, suited for high-volume runs |

|

Cost |

Higher initial equipment cost |

Lower cost for large volumes |

|

Quality |

Easier to control, trusted for high-quality assembly |

Stronger joints, but complex environmental control |

Selecting the right soldering method ensures better compatibility, efficient production, and optimal quality for every PCB assembly project.

Key Takeaways

-

SMT reflow soldering is best for surface-mount components on complex, high-density PCBs, while wave soldering suits through-hole components on simpler boards.

-

Reflow soldering uses controlled heating in ovens to melt solder paste precisely, supporting small, delicate parts and double-sided boards.

-

Wave soldering passes PCBs over a molten solder wave, creating strong joints quickly for large volumes of through-hole assemblies.

-

Reflow soldering offers higher precision and lower defect rates but requires expensive equipment and careful process control.

-

Wave soldering is faster and more cost-effective for mass production but involves higher energy use, environmental concerns, and less flexibility.

-

Choosing the right method depends on component type, board complexity, production volume, cost, and environmental regulations.

-

Many manufacturers combine both methods to handle mixed-technology boards, using reflow for SMT parts and wave soldering for through-hole components.

-

Proper process control, equipment matching, and understanding each method’s strengths help ensure high-quality, reliable PCB assemblies.

Soldering Methods

Modern electronics manufacturing relies on two main soldering techniques: SMT reflow soldering and wave soldering. Each method uses a different process and serves specific types of components. Understanding these differences helps engineers and manufacturers choose the best approach for their printed circuit board (PCB) assembly needs.

SMT Reflow Soldering

Definition

SMT reflow soldering is a process that attaches surface-mount components to the surface of a PCB. The process begins with the application of solder paste, which contains a mixture of flux and powdered metal alloy, onto the PCB pads using a stencil. Automated pick-and-place machines then position the components on the paste-covered pads. The board passes through a reflow oven, where controlled heating zones melt the solder paste, creating strong electrical and mechanical connections. The board then cools, solidifying the solder joints.

SMT reflow soldering uses precise temperature control and automation, making it ideal for high-density and complex PCB assemblies.

Applications

Manufacturers use SMT reflow soldering for a wide range of electronic products, especially those that require miniaturized or densely packed components. This method supports advanced packages such as Ball Grid Array (BGA), Chip Scale Package (CSP), and very small parts like 01005 resistors and capacitors. It works well for both single-sided and double-sided boards, allowing for flexible and efficient production.

Table: SMT Reflow Soldering Process Overview

|

Step |

Description |

|---|---|

|

Solder Paste |

Applied to PCB pads using a stencil |

|

Component Placement |

Surface-mount components are placed by pick-and-place machines |

|

Heating |

Reflow oven melts solder paste with controlled temperature zones |

|

Cooling |

Solder joints solidify as the board cools |

Wave Soldering

Definition

Wave soldering is a technique designed for through-hole technology (THT) components. In this process, operators or insertion robots place components with leads into holes on the PCB. The entire board receives a coating of flux, which prepares the surfaces for soldering. The PCB then travels over a wave of molten solder. The solder wave contacts the exposed metal leads and pads, forming electrical connections. The board cools after leaving the solder wave, solidifying the joints.

Wave soldering offers speed and efficiency for assembling boards with many through-hole components.

Applications

Wave soldering is best suited for PCBs that use through-hole components, such as connectors, large capacitors, and transformers. Manufacturers often choose this method for simpler or lower-density boards, where surface-mount technology is not required. It is common in power supplies, industrial controls, and consumer electronics that rely on robust mechanical connections.

Table: Component Compatibility and Board Suitability

|

Aspect |

SMT Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Component Types |

Surface-mount, fine pitch, BGA, CSP, small packages |

Through-hole only |

|

Board Density |

High-density, multi-layer |

Low to medium density |

|

Flexibility |

Double-sided, various board sizes |

Typically single-sided, less flexible |

Tip: Choose SMT reflow soldering for complex, high-density boards with small components. Use wave soldering for traditional through-hole assemblies and simpler designs.

SMT Reflow Soldering Process

Process

Solder Paste

The SMT reflow soldering process begins with careful preparation of the printed circuit board. Technicians clean the PCB to remove dust, oils, and other contaminants. This step ensures that the solder paste will adhere properly to the pads. Next, a stencil printer applies solder paste to the designated pads on the PCB. The stencil’s thickness and aperture size control the amount and placement of solder paste. Proper application prevents defects such as bridging or insufficient solder, which can affect the quality of the final joints.

Placement

After solder paste application, automated pick-and-place machines position surface-mount components onto the paste-covered pads. These machines use vision systems and robotic arms to achieve high accuracy and repeatability. Precise placement is essential. It prevents misalignment and common issues like tombstoning, where one end of a component lifts off the pad. Accurate placement also ensures that each component forms a reliable connection during the next stage.

Heating

The assembled PCB enters a reflow oven, which features multiple temperature zones. The heating process follows a controlled temperature profile with four main phases: preheating, soaking, reflow, and cooling. During preheating, the board gradually warms up to avoid thermal shock. The soaking phase activates the flux in the solder paste, cleaning the metal surfaces. In the reflow phase, the temperature rises above the solder’s melting point, allowing the solder to flow and form strong metallurgical bonds. Proper temperature control in the oven prevents defects such as cold joints or thermal damage to sensitive components.

Cooling

After the solder has melted and formed connections, the PCB moves into the cooling zone. Controlled cooling solidifies the solder joints, locking components in place. Rapid or uneven cooling can cause stress or cracks in the joints, so manufacturers carefully manage this step. The result is a board with reliable electrical and mechanical connections.

Tip: Each step in the SMT reflow soldering process plays a critical role in achieving high-quality, defect-free solder joints.

Equipment

|

Equipment Type |

Typical Specifications / Capabilities |

|---|---|

|

Reflow Soldering Oven |

Industrial convection ovens with 8-10 temperature zones; adjustable profiles for Sn/Pb and lead-free solders |

|

Temperature Zones |

8 zones for basic ovens, 10 zones for advanced ovens (suitable for lead-free soldering) |

|

Temperature Profiles |

Sn/Pb solder peak: 215-245°C; Lead-free solder peak: up to 260°C |

|

Production Line Matching |

Oven size and speed align with pick-and-place machine throughput |

|

Advanced Features |

Nitrogen atmosphere to prevent oxidation; support for lead-free boards |

|

Additional Equipment |

Pick-and-place machines, solder paste stencils, inspection tools (X-ray, AOI, 3DSPI) |

Modern SMT reflow soldering lines often use advanced ovens from manufacturers like Panasonic and Yamaha. These lines integrate inspection tools such as automated optical inspection (AOI) and X-ray systems to detect defects early. Nitrogen reflow ovens help prevent oxidation, improving joint quality. Matching the oven’s throughput with the rest of the production line ensures efficient operation.

Advantages

-

SMT reflow soldering achieves precise control over temperature and process parameters, resulting in consistent, high-quality solder joints.

-

The method supports high-density and double-sided PCB assemblies, making it ideal for modern electronics.

-

Energy savings of up to 20-40% are possible when using low-temperature solder alloys, reducing manufacturing costs.

-

Lower soldering temperatures minimize component warpage and thermal stress, which enhances product reliability.

-

Process optimizations, such as improved temperature profiling and pressure-based monitoring, can increase yield by 15-20% and reduce cycle times.

-

Integration with inspection systems allows for early detection of defects, further improving product quality and reducing rework.

Note: SMT reflow soldering stands out for its efficiency, precision, and suitability for complex PCB designs.

Disadvantages

While SMT reflow soldering offers many benefits, it also presents several disadvantages that engineers and manufacturers must consider. These limitations can impact cost, component compatibility, repairability, and process reliability.

-

High Initial Investment: SMT reflow soldering requires expensive equipment, such as reflow ovens, pick-and-place machines, and solder paste printers. The capital needed for these machines often exceeds that of traditional through-hole assembly lines. Companies must also invest in training operators to handle the advanced machinery and processes.

-

Limited Compatibility with Through-Hole Components: SMT reflow soldering works best for surface-mount devices. Boards that include many through-hole components need additional steps, such as selective soldering, which increases both complexity and cost. Selective soldering machines also operate more slowly than wave soldering systems when handling large numbers of through-hole parts. Some components, especially those that are large or require strong mechanical support, are only available in through-hole packages. This limitation makes SMT reflow soldering less suitable for assemblies that demand robust mechanical connections.

-

Challenging Manual Assembly and Repair: The small size and fine pitch of SMT components make manual soldering, inspection, and repair more difficult. Technicians often struggle to identify and replace tiny parts, which increases the risk of damage during rework. Through-hole technology remains easier to handle for manual assembly and repair tasks.

-

Process Sensitivity and Defect Risks: SMT reflow soldering introduces several process-related challenges. The table below highlights common defects, their causes, and typical solutions:

|

Challenge |

Common Causes |

Typical Solutions |

|---|---|---|

|

Tombstoning |

Unequal heating, pad design issues |

Improve pad design, optimize reflow profile |

|

Insufficient/Excessive Solder |

Poor stencil design, printing errors |

Control paste volume, refine printing parameters |

|

Head-in-Pillow |

Thermal mismatch, low flux activity |

Adjust the reflow profile, select the proper flux |

|

Non-Wetting/De-Wetting |

Poor PCB finish, insufficient heat |

Use better finishes, optimize profiling |

|

Solder Balling |

Moisture, improper reflow, and poor printing |

Control moisture, clean stencils, and adjust profile |

|

Cold Solder Joints |

Low heat, contamination, and movement during reflow |

Increase temperature, avoid movement, and check the alloy |

|

Shadowing |

Large parts block the solder flow |

Place small parts before large ones |

-

Reliability Concerns for Certain Applications: SMT solder joints use less solder than through-hole joints. This can raise concerns about joint strength and long-term reliability, especially in environments with vibration or mechanical stress. SMT reflow soldering is also less suitable for circuits that generate significant heat, as the smaller joints may not dissipate heat as effectively.

Manufacturers must weigh these disadvantages against the benefits when choosing SMT reflow soldering for their projects. Careful process control, equipment investment, and design choices help address many of these challenges, but some limitations remain inherent to the technology.

Wave Soldering Process

Process

Wave soldering uses a series of carefully controlled steps to create strong and reliable solder joints for through-hole components. Each stage plays a key role in the final quality of the assembly.

Flux

Technicians start by applying flux to the underside of the PCB. The flux sprayer coats the board, cleaning and activating the metal surfaces. This step removes oxides and helps the molten solder flow smoothly during the next stages. Proper flux application reduces the risk of defects such as solder balling and poor wetting.

Preheat

After fluxing, the PCB moves into the preheat zone. Preheating pads gradually raise the board’s temperature. This step prevents thermal shock when the board contacts the hot solder wave. Preheating also activates the flux, which improves solder flow and helps remove impurities. A well-controlled preheat stage ensures that components do not lift and that solder fills the holes completely.

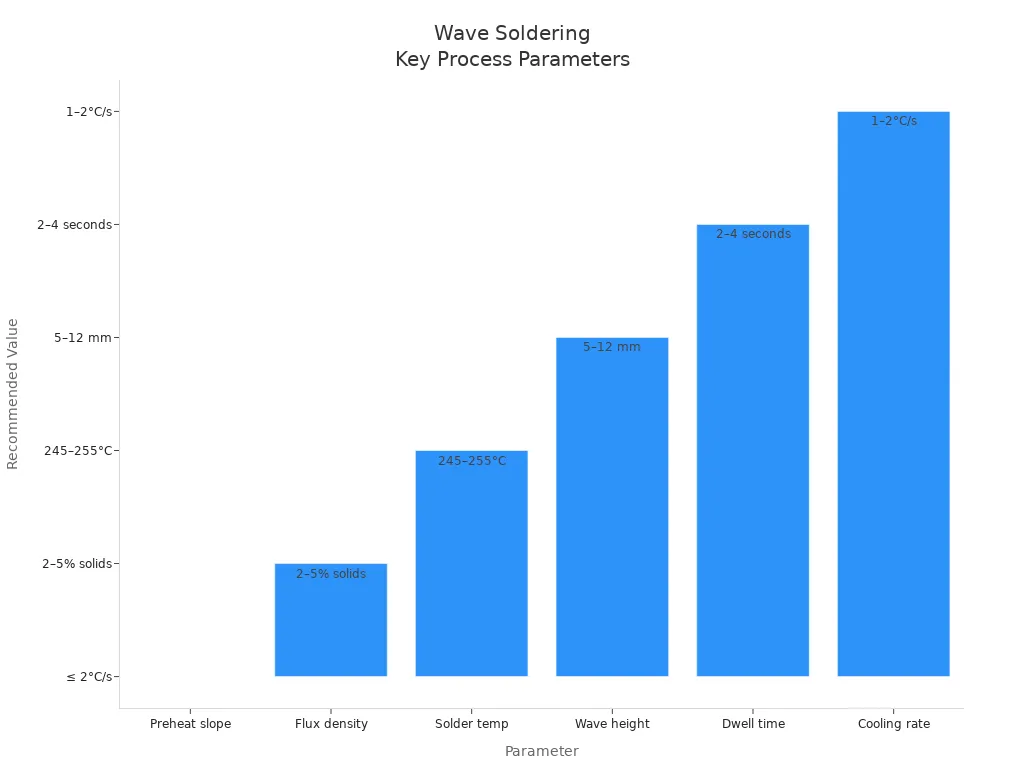

Solder Wave

The heart of the process is the solder wave. The PCB travels over a wave of molten solder created by a pump in the solder pot. The wave touches the exposed leads and pads, forming electrical and mechanical connections. Many modern machines use dual-wave systems. The first, a turbulent wave, ensures solder penetrates tight spaces. The second, a laminar wave, provides a smooth finish and reduces bridging. Technicians adjust conveyor speed and wave height to control how much solder contacts each joint. Maintaining a wetting angle below 30 degrees helps create strong, reliable connections.

Cooling

Once the board leaves the solder wave, it enters the cooling zone. Controlled cooling solidifies the solder joints and locks the components in place. If cooling happens too quickly or unevenly, joints may crack or become weak. Careful temperature management during this stage preserves joint integrity and prevents defects.

Tip: Each step in the wave soldering process directly affects the quality and reliability of the finished PCB. Fine-tuning parameters like preheat temperature, conveyor speed, and wave design helps prevent common defects such as bridging, skips, and voids.

Equipment

Wave soldering requires several specialized machines and tools:

-

Conveyor System: Moves PCBs through each process stage at a controlled speed.

-

Flux Sprayer: Applies flux evenly to the PCB underside.

-

Preheating Pads: Gradually warm the board before soldering.

-

Solder Pot and Pump: Hold and circulate molten solder to create the solder wave.

-

Wave Soldering Machine: Integrates all steps, often with features like dual-wave systems and nitrogen tunnels for better solder quality.

-

Inspection Tools: Visual and automated systems check for defects after soldering.

Popular machines include the Electrovert Electra™ and Vitronics Soltec Delta X. These models offer features such as programmable wave shapes, nitrogen soldering, and closed-loop process control. Many support both traditional leaded and modern lead-free solder alloys, meeting environmental standards like RoHS.

Advantages

Wave soldering offers several key benefits for PCB assembly:

-

High efficiency enables rapid processing of large volumes, making it ideal for mass production.

-

Automation reduces labor costs and human error, increasing consistency and throughput.

-

The process creates strong, reliable joints by fully surrounding leads with molten solder.

-

Adjustable parameters allow technicians to optimize each joint, reducing defect rates.

-

Preheating and fluxing improve cleanliness and solder quality, supporting near zero-defect production.

Wave soldering remains a cost-effective and reliable choice for assembling through-hole PCBs, especially in high-volume manufacturing environments.

Disadvantages

Wave soldering, while efficient for many through-hole assemblies, presents several notable disadvantages that engineers and manufacturers must consider. These drawbacks affect not only the production process but also the environment and long-term reliability of electronic products.

-

Environmental Sensitivity

Wave soldering often uses lead-based solders, which pose environmental and health risks. The process generates fumes that require proper ventilation and filtration to protect workers and the surrounding area. When manufacturers switch to lead-free solders, they face new challenges. Lead-free alloys have higher melting points, which increases thermal stress on both components and PCBs. These alloys also behave differently during soldering, so technicians must adjust flux formulations and process parameters to achieve reliable joints. -

High Material and Energy Consumption

Maintaining a pot of molten solder demands significant energy. The equipment must keep solder at high temperatures throughout production, which increases operational costs and carbon footprint. The process also consumes large amounts of solder and flux. Lead-free soldering, in particular, leads to more dross formation—waste material that must be disposed of properly. This not only raises material costs but also creates additional environmental concerns. -

Cleaning and Waste Management

After soldering, flux residues often remain on the PCB. These residues can be corrosive or conductive, so manufacturers must clean the boards thoroughly. Cleaning processes generate wastewater and chemical byproducts, which can pollute water sources if not managed correctly. Solid waste, such as solder dross and PCB trimmings, also requires careful disposal to prevent environmental harm. -

Equipment and Process Limitations

Wave soldering machines involve a high initial investment. The equipment can cause thermal stress to heat-sensitive components, sometimes leading to defects or reduced product lifespan. The process is less flexible than SMT reflow soldering, especially for double-sided or high-density boards. Adjusting the process for different board designs or component types can be complex and time-consuming. -

Health and Safety Concerns

Emissions from soldering, including volatile organic compounds (VOCs) and micro-particles, can affect air quality and worker health. Proper air purification systems and safety protocols are essential in any facility using wave soldering.

Manufacturers must weigh these disadvantages against the benefits of wave soldering. Careful process control, investment in modern equipment, and adherence to environmental standards can help reduce many of these risks. However, the inherent challenges of material consumption, environmental impact, and process complexity remain important factors in the decision-making process.

Table: Environmental Impact Comparison

|

Aspect |

Wave Soldering Impact |

|---|---|

|

Energy Consumption |

High, due to the continuous heating of the solder pot |

|

Waste Generation |

Solder dross, flux residues, wastewater |

|

Air Emissions |

Fumes, VOCs, heavy metal particles |

|

Material Use |

High solder and flux consumption, especially lead-free |

|

Equipment Wear |

Increased with lead-free alloys and dross formation |

Wave soldering remains a valuable technique for many applications, but its disadvantages highlight the need for ongoing improvements in process control, waste management, and environmental protection.

Comparison

Component Compatibility

Choosing the right soldering method depends on the types of components used in the assembly. SMT reflow soldering and wave soldering each support different component families. The table below highlights their compatibility:

|

Aspect |

SMT Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Exclusively for surface-mount components (SMT), including small, high-density, and high-precision parts like BGAs and QFNs |

Exclusively for through-hole components, typically larger parts such as power transistors, capacitors, resistors, and connectors |

|

|

Applications |

Ideal for compact, high-precision devices like smartphones and laptops |

Suited for motherboards, power supplies, and large PCBs with through-hole components |

|

Flexibility |

Handles various PCB designs and component types, including complex ICs |

Limited to traditional through-hole technology, less adaptable to complex designs |

|

Reliability & Quality |

High reliability for small components due to precise temperature control |

Reliable for larger components, less risk of overheating |

Surface-mount technology allows engineers to design smaller, more complex devices. SMT reflow soldering supports these needs by working with fine-pitch and high-density parts. Wave soldering, on the other hand, remains the best choice for larger, through-hole components that require strong mechanical connections. Each method is exclusive to its compatible component types, so the choice directly affects the design and function of the final product.

Tip: For high-density, miniaturized electronics, SMT reflow soldering is essential. For robust, traditional assemblies, wave soldering is preferred.

Process Steps

The process steps for each soldering method differ in both sequence and complexity. These differences impact production speed, efficiency, and the types of boards that can be assembled.

|

Aspect |

SMT Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Process Steps |

1. Apply solder paste via stencil and screen printing |

1. Apply flux to the PCB |

|

Core Mechanism |

Uses hot air in a multi-zone oven to melt solder paste |

Uses a wave of molten solder to mass-solder through-hole components |

|

Production Efficiency |

More flexible and easier to monitor; better for SMT assembly; less wasteful |

Faster and more affordable for mass production of through-hole PCBs; requires careful temperature control and is more complex |

|

Suitability |

Preferred for small to medium volumes and high-density SMT boards |

Preferred for large-scale through-hole PCB assembly |

|

Cost and Complexity |

Generally slower and more costly for large volumes |

More complex environment; small temperature changes can cause defects, but quicker and cheaper for mass production |

SMT reflow soldering uses a step-by-step approach. It starts with solder paste application, followed by precise component placement, and finishes with controlled heating in a reflow oven. This method allows for careful monitoring and adjustment at each stage. Wave soldering, in contrast, uses a more streamlined process. After applying flux and preheating, the board passes over a wave of molten solder, which connects all through-hole components at once. This approach increases speed and suits high-volume production, but it requires strict control of temperature and timing to avoid defects.

Note: SMT reflow soldering offers more flexibility for complex boards, while wave soldering delivers speed for simpler, high-volume assemblies.

Equipment

The equipment used in each soldering method varies in cost, complexity, and maintenance needs. These differences influence both the initial investment and ongoing production costs.

-

Reflow soldering machines feature advanced temperature control and intelligent monitoring systems. These features make them more expensive at the start. The equipment is highly integrated and complex, which leads to more frequent and specialized maintenance. Operators must regularly replace costly solder paste, adding to ongoing expenses.

-

Wave soldering equipment generally requires a lower initial investment. The machines have a simpler design, which makes them easier and less costly to maintain. Operating costs remain lower, especially for large production runs. However, wave soldering is less flexible and best suited for simpler, high-volume boards.

Manufacturers should consider both the upfront and long-term costs when choosing between these two methods. SMT reflow soldering provides flexibility and quality for advanced assemblies, but wave soldering remains cost-effective for traditional, large-scale production.

Quality

Quality in PCB soldering depends on defect rates, reliability, and the ability to handle sensitive components. Both reflow and wave soldering offer unique strengths and challenges.

|

Aspect |

SMT Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Defect Rates |

Typically less than 1% due to precise solder paste application and controlled heating profiles. |

Higher defect rates (2-5%) for bridging or solder skips if parameters are not optimized. |

|

Thermal Impact |

Lower thermal stress with controlled heating (peak 220-260°C), suitable for heat-sensitive components. |

Higher thermal stress from direct contact with molten solder (250-260°C), risk of PCB warpage, and component damage. |

|

Reliability |

Higher reliability due to lower defect rates and reduced thermal shock. |

Robust mechanical joints but increased risk of thermal damage and defects if not carefully controlled. |

|

Application |

Ideal for fine-pitch, high-density SMT components and sensitive parts. |

Best for THT components and mixed-technology boards requiring strong mechanical bonds. |

-

Reflow soldering achieves high quality for surface-mount assemblies. The process uses precise temperature control, which reduces the risk of defects like tombstoning and bridging. Defect rates often stay below 1% when the process is well managed.

-

Wave soldering creates strong mechanical joints for through-hole components. However, it can show higher defect rates, especially if technicians do not optimize parameters. Defects such as bridging or solder skips may reach 2-5%.

-

Modern wave soldering machines use advanced quality control systems. These systems help detect and correct issues early, improving yields and reducing defects in high-volume production.

-

Reflow soldering works best for heat-sensitive and fine-pitch components. Wave soldering handles large, robust parts but may cause thermal stress if not carefully controlled.

Note: For assemblies that require high reliability and low defect rates, reflow soldering stands out. For products that need strong mechanical joints, wave soldering remains a solid choice.

Cost

Cost considerations play a major role in selecting a soldering method. Each process involves different equipment, materials, and operational expenses.

|

Cost Factor |

Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Equipment Investment |

High initial cost (reflow oven, pick-and-place, stencils) |

Moderate initial cost (wave soldering machine, conveyor) |

|

Material Consumption |

Lower solder and flux use per board |

Higher solder and flux use, especially for lead-free |

|

Maintenance |

Specialized maintenance, higher cost |

Simpler maintenance, lower cost |

|

Labor |

Lower labor costs due to automation |

Moderate labor, especially for setup |

|

Cleaning/Waste |

Less cleaning needed, lower waste |

More cleaning and waste management are required |

-

Reflow soldering requires a larger upfront investment. The process uses advanced ovens and automated placement machines. These machines cost more to purchase and maintain.

-

Wave soldering equipment costs less at the start. However, it uses more solder and flux, especially with lead-free alloys. This increases ongoing material costs.

-

Cleaning and waste management add to the cost of wave soldering. Flux residues and solder dross require special handling and disposal.

-

Automation in reflow soldering reduces labor costs. Wave soldering may need more manual setup, especially for complex boards.

Tip: For high-volume, through-hole assemblies, wave soldering offers lower per-unit costs. For complex, SMT-heavy boards, reflow soldering justifies its higher initial investment with better quality and lower long-term waste.

Production Volume

Production volume affects the efficiency and cost-effectiveness of each soldering method. Manufacturers must match the process to their batch size and product type.

|

Production Volume |

Reflow Soldering |

Wave Soldering |

Selective Soldering |

|---|---|---|---|

|

Less cost-effective due to setup costs; best for SMT-heavy boards |

Not ideal; masking/protection needed for SMT |

Suitable for precision and flexibility; slower |

|

|

Medium Volume |

Scales well with automation; cost-effective for SMT-heavy designs |

Efficient for through-hole; less flexible for SMT |

Good for complex or mixed boards; slower throughput |

|

High Volume |

Highly automated and efficient; ideal for fine-pitch SMT |

Very fast and cost-effective for through-hole |

Not suitable; slower speed and higher costs |

-

Reflow soldering scales well from medium to high production volumes. Automation makes it efficient for large batches of SMT boards.

-

Wave soldering excels in high-volume production of through-hole assemblies. The process can handle hundreds of boards per hour, making it a top choice for mass manufacturing.

-

For low-volume or prototype runs, selective soldering or pin-in-paste reflow can offer flexibility. These methods avoid the high setup costs of wave soldering lines and work well for mixed-technology boards.

-

Wave soldering remains a mainstream process for large-scale, lower-level electronic products. Its speed and low cost make it ideal for high-volume runs where SMT performance is not critical.

Manufacturers should consider both the type of components and the expected production volume when choosing a soldering method. The right match improves efficiency and reduces costs.

Choosing a Method

Factors

Selecting the right soldering method for a PCB assembly project involves several important factors. Engineers and manufacturers must evaluate the type of components, board design, production volume, and budget. The table below summarizes key considerations:

|

Factor |

Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Component Type |

Best for surface mount components (SMT) |

Best for through-hole components (THT) |

|

Board Complexity |

Suitable for small, complex, and delicate parts |

Better for simpler boards or mixed technology |

|

Production Volume |

Faster and more cost-effective for high volume |

|

|

Precision |

High precision and control reduce solder bridges |

Less precise, may cause solder bridging |

|

Thermal Stress |

Less thermal stress on components |

More aggressive heating, risk to delicate parts |

|

Cost |

Higher initial equipment cost, efficient for prototypes |

Lower equipment cost, cheaper for mass production |

|

Environmental Impact |

Requires solder paste handling and oven profiling |

Generates more waste and power consumption |

|

Equipment Maintenance |

More complex equipment, frequent maintenance |

Simpler equipment, easier maintenance |

|

Mixed Technology |

Often combined with wave soldering for THT parts |

Used for through-hole parts in mixed assemblies |

Note: Lead-free requirements can influence the choice. Lead-free soldering needs higher temperatures, which may damage sensitive components. Regions with strict environmental laws, such as the EU, require lead-free processes for both methods. Manufacturers must adjust equipment and materials to meet these standards.

Scenarios

Engineers often face real-world situations that guide their choice between reflow and wave soldering. Here are some common scenarios:

-

A company designs a smartphone with fine-pitch surface mount devices and a complex multilayer board. They select reflow soldering for its precision and ability to handle small, sensitive parts.

-

An automotive electronics manufacturer produces control modules with many through-hole connectors and large components. They use wave soldering to achieve strong joints and fast, high-volume output.

-

A medical device project requires both SMT and through-hole parts. The team combines reflow soldering for the surface mount chips and wave soldering for the connectors, ensuring reliability and compliance with strict quality standards.

-

An industrial control system uses a simple, single-sided PCB with mostly through-hole parts. Wave soldering provides a cost-effective and efficient solution.

-

A prototype run for a new wearable device involves small batches and delicate components. Reflow soldering offers the accuracy and control needed for early-stage development.

Tip: In regions with strict environmental regulations, such as the EU, manufacturers must use lead-free soldering. This requirement affects both process choice and equipment settings. Lead-free wave soldering demands higher temperatures and stricter control, increasing complexity and cost.

Manufacturers should always match the soldering method to the specific needs of the project. They must consider component types, board design, production scale, budget, and regulatory requirements. This approach ensures reliable, high-quality assemblies and efficient production.

Summary

Quick Reference

-

Component Type:

-

Wave soldering works best for through-hole (THT) components.

-

Reflow soldering is ideal for surface-mount (SMT) components.

-

-

Process Speed:

-

Wave soldering processes many boards quickly, making it suitable for high-volume production.

-

Reflow soldering offers more precision but operates at a slower pace.

-

-

Heat Source:

-

Wave soldering uses direct contact with molten solder.

-

Reflow soldering uses controlled hot air or infrared ovens.

-

-

Typical Applications:

-

Wave soldering is common in power supplies, industrial controls, and products needing strong mechanical joints.

-

Reflow soldering is used in smartphones, laptops, and compact electronics.

-

-

Cost and Efficiency:

-

Wave soldering is cost-effective for large batches of similar boards.

-

Reflow soldering has higher setup costs but excels in automated, high-density assembly.

-

-

Common Defects:

-

Wave soldering may cause bridging or leave flux residues if not controlled.

-

Reflow soldering can result in tombstoning or solder balls.

-

Workshops and industry guides often provide detailed bullet lists and troubleshooting manuals for both methods, making these points easy to reference during production and maintenance.

Key Differences

|

Feature |

Wave Soldering |

Reflow Soldering |

|---|---|---|

|

Component type |

Through-hole (THT) |

Surface-mount (SMT) |

|

Heat source |

Molten solder wave |

Hot air / infrared oven |

|

Temperature range |

245–260°C |

220–250°C |

|

Speed |

High for THT boards |

Moderate, higher precision |

|

Suitability |

Mechanical strength, high current |

High-density, compact layouts |

|

Cost |

Lower for bulk THT |

Higher for setup and materials |

|

Common defects |

Bridging, flux residue |

Tombstoning, solder balls |

-

Wave soldering stands out for speed and cost efficiency in the mass production of through-hole boards. It achieves high throughput and strong joints but requires careful control to avoid defects.

-

Reflow soldering provides the precision needed for modern, high-density electronics. It supports automation and fine-pitch components, making it the top choice for SMT assemblies.

-

Many manufacturers combine both methods for mixed-technology boards, using reflow soldering for SMT parts and wave soldering for through-hole connectors.

-

Process optimization, such as controlling temperature profiles and flux application, is essential for both methods to ensure reliable, defect-free soldering.

For high-volume, robust assemblies, wave soldering is the practical choice. For compact, complex devices, reflow soldering delivers the best results. Understanding these differences helps engineers select the right process for each project.

Selecting the right soldering method shapes PCB assembly quality and efficiency. The table below highlights essential differences:

|

Aspect |

SMT Reflow Soldering |

Wave Soldering |

|---|---|---|

|

Process Control |

Easier, precise |

More complex, less precise |

|

Component Types |

Surface-mount |

Through-hole |

|

Speed & Cost |

Slower, higher cost |

Faster, cost-effective |

Industry experts recommend these steps for choosing the best method:

-

Match component types and board complexity.

-

Consider environmental and mechanical demands.

-

Consult experienced assembly providers for tailored solutions.

Careful evaluation ensures reliable, cost-effective PCB assemblies.

FAQ

What is the main difference between SMT reflow and wave soldering?

SMT reflow soldering attaches surface-mount components using solder paste and a reflow oven. Wave soldering connects through-hole components by passing the board over a wave of molten solder. Each method suits different component types and assembly needs.

Can one PCB use both SMT reflow and wave soldering?

Yes, many manufacturers combine both methods for mixed-technology boards. They use reflow soldering for surface-mount parts and wave soldering for through-hole components. This approach ensures strong joints and reliable performance.

Which method is better for high-volume production?

Wave soldering works best for high-volume production of through-hole assemblies. It processes many boards quickly and efficiently. SMT reflow soldering also supports automation but suits high-density, surface-mount designs.

Are lead-free solders compatible with both methods?

Both SMT reflow and wave soldering can use lead-free solders. However, lead-free alloys require higher temperatures and stricter process control. Manufacturers must adjust equipment settings to prevent defects and meet environmental standards.

What common defects occur in SMT reflow soldering?

Common defects include tombstoning, solder balls, and insufficient solder. These issues often result from improper paste application, incorrect temperature profiles, or poor component placement. Careful process control helps reduce these problems.

How does wave soldering impact the environment?

Wave soldering consumes more energy and materials. It produces solder dross, flux residues, and fumes. Proper waste management and ventilation systems help reduce environmental impact and protect worker health.

Can technicians repair boards after SMT reflow or wave soldering?

Technicians can repair both types of boards, but SMT assemblies are harder to fix due to smaller components and tighter spacing. Through-hole boards from wave soldering are easier to rework and inspect.

What factors should engineers consider when choosing a soldering method?

Engineers should evaluate component types, board complexity, production volume, cost, and environmental requirements. Matching the soldering method to project needs ensures reliable, high-quality assemblies.