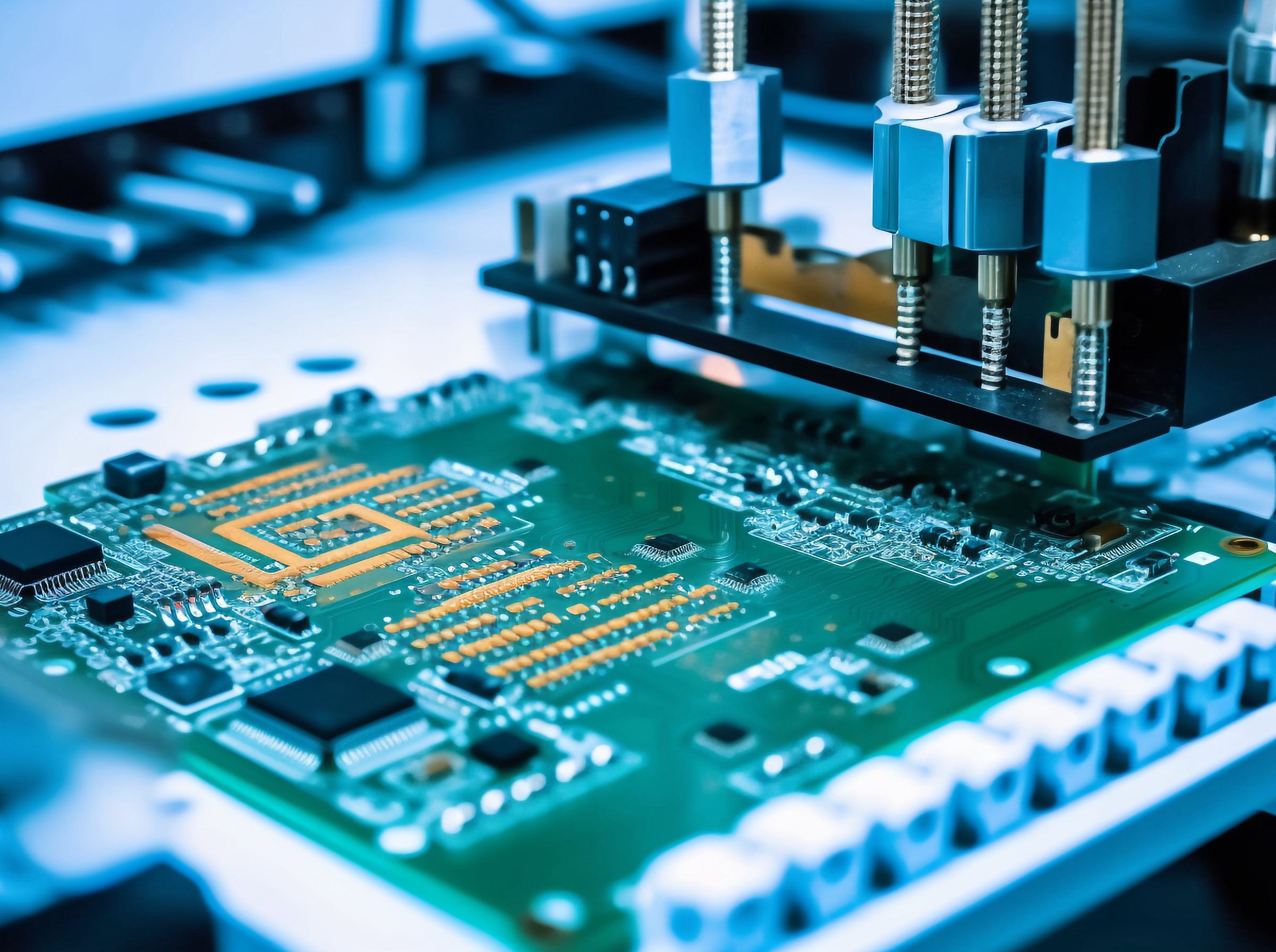

In the highly automated SMT production line, the AGV vacuum PCB suction machine, as the core equipment for PCB handling, has become a key equipment for improving production efficiency and flexibility with its high efficiency, precision, and stability.

1. Core technology: three pillars of precision, efficiency, and reliability

Intelligent navigation and seamless docking

Supports automatic docking with AGV carts, without manual intervention, to achieve unmanned operation throughout the process.

Standard SMEMA signal communication ensures efficient coordination with equipment such as placement machines and reflow soldering, and the beat matching can reach 8-15 seconds/board.

Vacuum adsorption system

Adopts multiple independent vacuum generation systems, with stable and reliable adsorption force, suitable for PCBs with a thickness of 0.6 mm~6 mm (maximum load 30kg), to avoid warping or damage.

Gas source requirements: 4~6 bar, flow rate 30L/min, to meet the needs of high-speed continuous operation.

Automated control and safety protection

PLC control + color human-machine interface, intuitive operation, supports flexible adjustment of parameters (such as board loading time and transmission direction can be customized).

Multiple electrical protection circuits and sound and light alarm systems meet industrial safety standards to ensure the safety of human-machine collaboration.

2. Application advantages: Why choose the S&M Vacuum Bare Board Loader?

Efficient production

The double-stack cycle loading design can put in 2 stacks of PCBs at a time (maximum capacity of 200 pieces), reducing waiting time and improving production line utilization.

The transmission speed reaches 9m/min, the board placement platform automatically rises and falls, and the board loading time is only 8 seconds (customizable), perfectly matching the high-speed placement machine.

Flexible adaptation

Compatible with a wide range of PCB sizes: 80×50mm ~ 510×460mm, supporting left→right or right→left transmission directions, adapting to diversified production line layouts.

Optional semi-automatic mode, flexible response to small batch or line change needs.

Stability and reliability

Independent vacuum system + multiple circuit protection, low failure rate, easy maintenance (abnormal information text prompt).

Transmission height 900±20mm, precise docking SMT equipment to avoid misalignment risks.

3. Industry adaptability and innovative highlights

High-density electronic manufacturing

It can stably handle both thin and heavy-weight plates (0.6mm) (30kg), suitable for high-precision fields such as consumer and automotive electronics.

Intelligent upgrade potential

MES/ERP interface is reserved to support future expansion of AI dynamic scheduling or 5G remote monitoring, and help build digital factories.

Green design

The motor power is only 25W, with low energy consumption, which is in line with the trend of sustainable manufacturing.

4. Technical Parameters Overview (Key Indicators)

Item Parameters

Maximum PCB capacity 200 pieces (0.6mm thick)

Upper limit of single board weight 30kg

Transmission speed 9m/min

Power requirement 220V AC, single phase, maximum 300VA

Dimensions (L×W×H) 750×1500×1750mm

Cycle time 8-15 seconds

S&M AGV vacuum bare board loader provides SMT production lines with a full-process automation solution from “loading → mounting → reflow” through intelligent handling, high compatibility design, and industrial-grade reliability. Its modular structure and scalability reserve space for the upgrade of future smart factories.

Choosing an S&M AGV vacuum bare board loader means selecting not just a piece of equipment, but also committing to efficiency, precision, and future productivity!

(Note: The above data is based on standard configuration and can be customized and upgraded according to customer needs.)