You need to finish smt integration quickly and follow the rules by 2026. Is it possible to work fast and still obey all the laws? Manufacturers have problems like:

Following new laws as they change

Handling risks that can hurt their reputation

Reaching industry standards like ISO 9001 and IPC-A-610E

A clear plan and new ideas help you solve these problems. S&M is the leader and gives good solutions for your integration needs.

Key Takeaways

Make clear goals and KPIs to watch your SMT integration. This helps you stay on track and change things fast if needed.

Use smart tools like Automated Optical Inspection and X-ray Inspection to find mistakes early. This keeps quality high and makes your work faster.

Keep up with new rules so you do not have compliance problems. Train your team often so everyone knows the latest rules.

Use automation to make work better. Smart machines do less manual work, make more products, and keep quality good.

Care about the environment by using eco-friendly materials and ways of working. This follows the rules and also helps nature.

SMT Integration Challenges in 2026

Speed vs. Compliance

You want to finish projects fast, but you must follow rules. This is even harder with mixed technology pcb assembly. You have to check each step so you do not miss anything. Many manufacturers use Solder Paste Inspection and Automated Optical Inspection. They also use X-ray Inspection Systems. These tools help you find mistakes early. In mixed technology pcb assembly, you also use In-Circuit Testing and Functional Testing. These tests make sure everything works before you ship it. Reflow Profiling Tools and Inspection and Traceability Software help you keep records. They also help you make your process better. These steps let you work faster and still follow the rules.

Regulatory Shifts

New laws and rules change every year. In 2026, there will be more focus on data privacy and cybersecurity. This is very important for mixed technology pcb assembly in healthcare and other sensitive fields. You need to keep up with these changes to avoid trouble. Advanced systems like AI, IoT, and machine learning cost a lot. This makes smt integration harder for small companies. You also need to upgrade old machines and teach your team new technology. These changes take time and money, but they help you stay ahead.

Bottlenecks in SMT Lines

You might have delays during smt integration. Missing parts can stop your line, especially for medical or military products. Switching between assembly methods can make boards wait in line. If you work with partners in other time zones, talking to them can take longer. Supply chain problems from world events can make it hard to get parts. These bottlenecks slow you down and make it harder to reach your goals.

Planning for Seamless Integration

Setting Objectives and KPIs

You begin SMT integration by making clear goals. Goals help you see how you are doing. KPIs show if your process is good. You can check things like how fast you make products, how many mistakes happen, and how often machines work. When you set these targets, you make integration easier. You stop confusion and keep your team working together. If you miss a goal, you can change your plan fast.

Tip: Write your goals and KPIs down. Look at them often to see if you need to change anything.

Standards and Interoperability

Industry standards are important for smooth integration. Standards help your machines and systems work together. You follow rules like ISO 9001 and IPC-A-610E to keep quality high. Manufacturing Execution Systems (MES) connect machines and track production. IoT lets devices share information right away. Using these tools helps you talk better and avoid mistakes.

Industry standards help systems work together.

MES connects equipment for smooth integration.

IoT helps systems share information and work together.

You must check your systems meet these standards before you start. This step stops problems later.

Building the Right Team

You need a good team for smooth integration. Each person has special skills for the project. Technical skills help with machines and parts. Soft skills like teamwork and solving problems keep things running well. You also need people who notice details and manage projects.

Skill Type | Skills Description |

|---|---|

Technical Knowledge | |

Problem-Solving Skills | Finding issues and fixing them |

Project Management | Planning tasks and keeping track of time |

Communication Skills | Working together and teaching staff |

Attention to Detail | Checking quality and making processes better |

You avoid mistakes by planning well. For example, you pick the right air filtration system, design good airflow, and use ESD control from the start. These steps help you build a strong SMT line.

Technology and Surface Mount Solutions

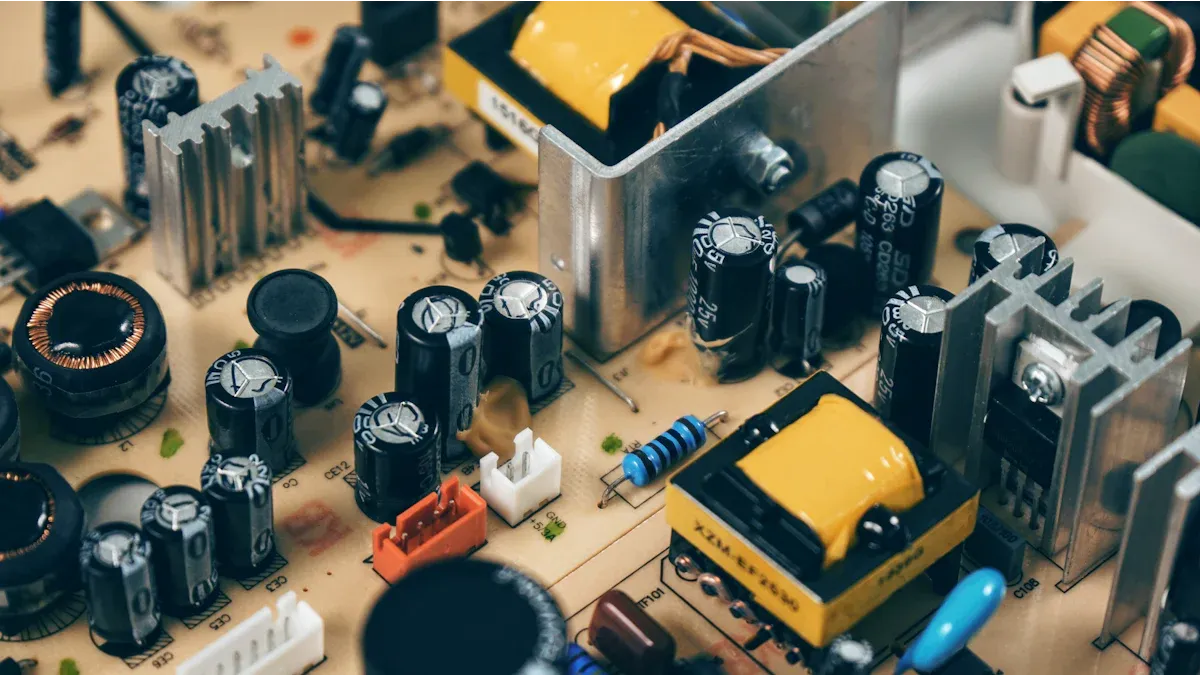

Surface Mount Technology Selection

You have to pick the best assembly method for your project. Each method is good for different things. The table below shows how the main options compare:

Criterion | SMT Assembly | THT Assembly | Mixed Assembly |

|---|---|---|---|

Component Density | Highest—both sides usable; parts down to 01005 and 0.3 mm BGA pitch | Lowest—hole diameter & keep-out zones limit routing | Medium—SMT for small parts, THT for bulky/high-stress parts |

Electrical Performance | Shorter interconnects → lower inductance/capacitance; ideal for RF & high-speed | Longer leads add parasitics; signal integrity harder above 100 MHz | Critical nets SMT; power/connector nets THT |

Mechanical Strength | Good for shock & vibration if board is well supported | Leads anchor parts through the board—best for pull/torque loads | Strategically uses THT where strain relief is needed |

Assembly Speed | > 60k CPH on modern pick-and-place; fully automated reflow | 3 k–4 k CPH; often manual insertion + wave or selective solder | Two passes (reflow + wave/selective) extend cycle time |

Tooling / NPI Cost | Low—no drilling for component leads; stencils inexpensive | Higher—drilling & wave pallets; hand-load labor | Highest initial setup; two soldering profiles, two inspection flows |

Board Real-Estate / Layer Count | Smaller boards or fewer layers → lower bare-board cost | Larger boards; extra layers (for power or routing) common | Board size reduction vs pure THT, but less compact than all-SMT |

Inspection & Test | Automated AOI, SPI, X-ray, ICT with pogo pins | Manual visual + ICT; AOI for wave solder less common | Dual inspection: AOI after reflow; wave solder joints manual or AOI-THT |

Thermal Cycling Reliability | Good when reflow profile optimized; small mass reduces ΔT stress | Excellent—leads act as stress relief during expansion | Depends on joint type; verify reflow + wave compatibility |

Typical Applications | Smartphones, IoT modules, wearables, high-frequency RF boards | Power supplies, automotive connectors, industrial relays, aerospace | Consumer appliances, LED lighting, EV chargers, medical devices |

Surface mount technology is best for small, fast, and packed products. It helps you finish work faster and spend less money.

S&M Equipment Integration

You want your SMT line to work well. S&M gives you smart machines for many jobs. You can use lead-free nitrogen hot air reflow ovens, selective wave soldering systems, and smart conveyors. These machines help you keep good quality and make fewer mistakes. S&M also helps with LED, new energy, and medical device work. You get strong machines that fit together. This makes your process faster and better.

Note: S&M’s solutions help you follow tough rules and keep your line ready for new changes.

IoT and Real-Time Monitoring

You can make your SMT line better with IoT and real-time checks. IoT tools gather data from your machines. This data helps you find problems early and fix them before things break. Real-time checks let you see how your line is doing all the time. You can fix problems quickly and keep things running. This way, you save energy, work more, and make better products. Good data from your SMT line also helps you follow rules and do better work. Many factories use IoT to make their work smarter and greener.

IoT helps you work more and save energy.

Real-time data helps you follow rules and make good products.

Process Optimization for SMT Integration

Component Placement and Soldering

You must work fast and make good quality when placing and soldering parts. Lead-free soldering is used because world rules say you have to. Lead-free alloys like tin-silver-copper (SAC) make joints stronger. Nitrogen-assisted reflow stops parts from rusting. Vapor-phase soldering heats parts evenly. These ways protect sensitive parts and make strong joints. This matters a lot for mixed technology pcb assembly.

New machines help you place parts quickly and correctly. Here are some new tools:

Multi-head, high-speed placement systems put many parts every hour.

High-precision visual systems help place tiny parts with accuracy of ±25μm.

Smart feeding systems work with MES to make things faster and cut mistakes.

Selective soldering is a smart way to use solder only where needed. This keeps delicate parts safe from too much heat. It also makes joints better. In mixed technology pcb assembly, you use both surface mount and through-hole ways. These new tools help you do both types of assembly well.

Tip: Always check your soldering profiles and machine settings before each batch. This stops defects and keeps your process steady.

Seamless Integration with Automation

Automation makes your SMT line faster and more steady. You can use MES to connect all machines and steps. MES lets you manage data and track everything in one place. This is important for mixed technology pcb assembly, where you handle many parts and steps.

Automation gives you many good things:

Benefit | Description |

|---|---|

Fewer people are needed, so there are fewer mistakes and faster work. | |

Higher Placement Speed | Machines work faster, which is good for big orders. |

Continuous Operation | Your line runs longer without stopping, so you get more done. |

You also get real-time checks and data analysis. This helps you find problems early and fix them fast. Automation keeps your SMT integration smooth, even with mixed technology pcb assembly. You can make more products and keep quality high.

Automation cuts down on manual work.

It helps you make more products.

Real-time data lets you make smart choices.

Inspection and Testing Advances

You must check your boards at every step to make sure they are good. Modern inspection and testing tools help you find problems early. This is very important for mixed technology pcb assembly, where you use both surface mount and through-hole parts.

Here are some top inspection and testing tools:

Technology | Description |

|---|---|

Checks for correct polarity, part direction, and solder quality at key spots. | |

X-Ray Inspection | Finds hidden problems in BGA parts, like solder gaps, by looking inside the board. |

In-Circuit Testing (ICT) | Checks that parts are in the right place and working, catching shorts and missing parts. |

Flying Probe Testing | Good for prototypes, uses moving probes to test the board. |

Thermal Imaging | Finds hot spots and bad solder joints by measuring heat during use. |

Boundary Scan Testing | Uses built-in chip features to test connections, great for complex boards. |

Functional Testing | Simulates real use to make sure the board works as it should. |

You should also check your SMT line often. These checks help you find weak spots and fix them. Use traceability tools like barcode scanners or MES to track every part and step. This helps you find where any problem started and fix it fast. In mixed technology pcb assembly, this control keeps your quality high.

Note: Always share quality feedback with your design and production teams. This helps you stop problems from happening again and keeps your process getting better.

Compliance and Quality Strategies

Meeting Global Standards

You must follow global standards to keep your SMT line compliant in 2026. These standards help you build trust with customers and avoid legal trouble. Many countries have new rules for electronics. You need to know what each rule means for your process. The table below shows the main standards you should follow:

Standard/Regulation | Description |

|---|---|

EU AI Act | High-risk AI obligations apply by August 2, 2026. You must manage risks, keep technical documents, use good data, provide human oversight, and monitor products after they reach the market. |

IPC Standards | New versions of IPC-A-610 and IPC J-STD-001 give you updated rules for good workmanship and soldering. |

Traceability | Customers want you to track every part and process. IPC-1782 guides you on how to do this. |

Sustainability | You must follow RoHS and REACH rules. These focus on recycling and saving energy as part of your quality checks. |

You should use smt pth assembly best practices to meet these standards. These practices help you keep your process strong and ready for audits. You also show your customers that you care about quality and safety.

Documentation and Traceability

You need good records to prove you follow the rules. Documentation and traceability help you track every material and step in your SMT line. This is important for meeting rules like REACH and RoHS. When you use smt pth assembly best practices, you make sure your records are clear and easy to check.

You track materials and processes in smt integration.

You meet legal rules by keeping good records.

You lower the risk of delays and fines with strong traceability systems.

Process traceability means you record what happens at each step. You write down machine settings and quality checks. This helps you find problems fast if something goes wrong. You can also use this information to improve your process. Good documentation supports your quality team and helps you pass audits.

You capture data about each operation and machine setting.

You use this data for reports and to solve quality problems.

You should use smt pth assembly best practices to set up your traceability system. This makes your SMT line safer and more reliable.

Regulatory Navigation

You face many rules in different countries. You must learn how to move through these rules without slowing down your work. Start by checking which laws apply to your products. Make a list of what you need to do for each rule. You can use checklists to stay organized.

You should train your team on new rules every year. This keeps everyone ready for changes. You can also use smart tools to watch for updates in the law. Many companies use software to track changes and send alerts.

Tip: Work with experts who know the rules in your industry. They can help you avoid mistakes and keep your SMT line running smoothly.

You should always use smt pth assembly best practices when you update your process. This helps you stay compliant and keep your quality high. When you follow these steps, you make your smt integration faster and safer.

Cost and Resource Efficiency

Reducing Integration Costs

You can save money on SMT integration by making smart choices early. Use standard pad sizes and pick common components. This helps you avoid special orders and keeps your parts simple. Try to use fewer PCB layers. Fewer layers make boards easier and cheaper to build. Make your PCB layout simple by using fewer vias and short traces. This makes your boards cost less and are easier to make.

Use standard pad sizes and common parts.

Use fewer PCB layers.

Make layouts simple and use fewer vias.

Pick board sizes that waste less material.

Buy new SMT machines for faster work.

Use machines to do jobs and pay less for labor.

Take care of your machines so they do not break.

Teach your team to check for problems early.

Recycle extra solder and keep track of your parts.

These steps help you get more value for your money and keep your SMT line working well.

Resource Optimization

You can use your resources better and still make good products. Focus on solder paste printing by picking the right stencil and paste. Set up your printer well so solder paste is even every time. Keep your placement machines programmed and checked. This helps you put parts in the right place and avoid mistakes. Make special reflow profiles for each PCB type. This gives you strong solder joints and fewer problems.

Use machines to check for problems early.

Watch your materials, especially parts that can get wet.

Write down what you do and check often.

These actions help you use your resources well and keep your line running smoothly.

S&M Case Examples

S&M helps you save money and use resources well with real solutions. For example, S&M’s lead-free nitrogen hot air reflow ovens use exact temperature control. This saves energy and makes better solder joints. The company’s selective wave soldering systems only use solder where needed. This saves solder and makes less waste. S&M’s smart conveyors and dual buffer stockers help you move materials and stop delays. Many customers in the LED and medical device fields use S&M’s machines to spend less and make more. You can trust S&M to help you build a good, efficient SMT line.

Future-Proofing SMT Integration

Adapting to New Technologies

Many new technologies will change SMT integration soon. If you keep learning, your production line stays strong. You will be ready for any changes. Some important trends are:

System-in-Package (SiP) puts many functions in a small space. This lets you make smaller and stronger devices.

Laser Direct Structuring (LDS) helps you put parts on curved or odd shapes. You get more ways to design things.

3D-Printed Electronics lets you make custom PCBs fast. You can try new ideas quickly.

Advanced Materials and Processes use new solder alloys. These make your boards work better and last longer.

Automation and Smart Manufacturing use robots and AI to speed up work. This also helps you spend less money.

Sustainability and Eco-Friendly Practices help you save energy and use safer materials.

Integration with 5G and IoT means you need faster and better connections.

Enhanced Testing and Quality Assurance uses new tools to find problems early.

You can use advanced SMD parts for high-speed devices. New ways to control heat help your boards stay cool. These changes get your SMT line ready for the future.

Building Agility

You must be flexible to keep up with new technology. Pick the right machines for your line. Good pick-and-place machines and solder paste printers help you work faster. They also help you make fewer mistakes. Reflow ovens with good heat control make strong solder joints. Automated optical inspection systems check your boards in real time.

SMT manufacturing helps you change fast when markets shift. You can use eco-friendly materials, like lead-free solder, without big changes. When devices get smaller and harder to build, you can use 3D printing and flexible PCBs to stay ahead.

Tip: Check your machines and steps often. This helps you see new trends and keep your SMT line ready for anything.

You can finish SMT integration fast and follow the rules if you use clear steps. Make your process new and use smart machines. Try to work faster, make better products, and help the planet. The table below shows the main ideas:

Description | |

|---|---|

Industrial modernization | Change your process to get better results. |

Smart and automated solutions | Use machines to make SMT work faster. |

Efficiency, quality, sustainability | Always try to be fast, do good work, and save resources. |

Government support | Use help from the government for your SMT line. |

Technological collaborations | Work with others to make new things. |

New ideas help you change when you need to. AI and machine learning help you make better choices and better products. S&M is a leader and helps you get ready for new changes in SMT integration.

FAQ

What is SMT integration?

SMT integration means you set up machines and processes to place and solder electronic parts on circuit boards. You use special tools to make this work fast and keep quality high.

How do you keep SMT lines compliant?

You follow global standards like IPC-A-610E and RoHS. You check your process often. You keep records and train your team. You use smart machines to help you meet rules.

Why should you choose S&M equipment?

S&M equipment gives you reliable performance. You get smart features, energy savings, and strong support. Many industries trust S&M for quality and efficiency.

What are the main benefits of automation in SMT?

Benefit | Result |

|---|---|

Faster Output | You finish jobs quickly |

Fewer Mistakes | You get better quality |

Less Labor | You save money |

How can you future-proof your SMT line?

You stay updated with new technology. You use flexible machines. You check trends and adapt your process. You work with experts and keep learning.