You need selective wave soldering solutions that deliver high-precision welding, flexibility, and compactness for small-batch electronics production. The market for these systems continues to grow, driven by automation and miniaturization in industries like medical devices and aerospace.

|

Assembly Technique |

Impact on Manufacturing Efficiency |

|---|---|

|

SMT |

Enables compact designs, increases density, and improves efficiency |

|

Through-Hole Technology |

Ensures durability, maintains compactness |

Offline selective soldering systems offer lower investment costs and are well-suited for specialized applications; however, technical complexity and skilled labor requirements must be considered. Rapid prototyping and standardized packaging further enhance efficiency and adaptability.

Key Takeaways

-

Selective wave soldering provides precise soldering that protects sensitive components and minimizes waste, making it an ideal solution for small-batch and complex electronics.

-

Compact and flexible soldering systems save space, lower costs, and adapt quickly to changing production needs, improving efficiency and quality.

-

Automation and advanced process control ensure consistent solder quality, reduce defects, and speed up production even with complex boards.

-

Choosing the right system depends on your board types, production volume, and need for flexibility; supplier support and training are key to success.

-

Lead-free soldering and software integration help meet environmental standards and boost production reliability with smart monitoring and control.

Why Selective Soldering

Flexibility for Small Batches

You need a soldering process that adapts quickly to changing production demands. Selective soldering gives you this flexibility, especially for small-batch and prototype runs. Unlike traditional wave soldering, you do not need expensive jigs or masks. You can program the machine to target only the required solder points, which saves time and reduces setup costs.

Selective soldering automates the process, so even operators without deep technical knowledge can set up new jobs quickly. This approach prevents overheating and protects sensitive components, making it ideal for mixed-technology boards and complex assemblies.

Here’s how selective soldering compares to traditional wave soldering for small-batch production:

|

Aspect |

Selective Wave Soldering |

Traditional Wave Soldering |

|---|---|---|

|

Precision |

Higher precision |

Lower precision |

|

Protection of Sensitive Components |

Better protection |

Higher risk of damage |

|

Solder Waste |

Reduced waste |

Increased waste |

|

Control and Accuracy |

Greater control |

Limited control |

|

Cost-effectiveness for Small Batches |

Ideal |

Suited for large batches |

|

Reliability and Consistency |

Consistent quality |

Inconsistent quality |

You benefit from process reproducibility and quick optimization. Selective soldering reduces inefficiencies common in mass production, while maintaining quality and flexibility.

Precision for Complex Boards

Modern electronics often require high-precision welding, especially when you work with dense or mixed-technology PCBs. Selective soldering applies solder only where you need it, which minimizes the risk of solder bridging and protects sensitive components from heat damage.

-

You can handle advanced components like BGAs and QFNs that cannot tolerate wave soldering.

-

Automated, programmable equipment controls temperature, atmosphere, and timing for consistent, high-quality joints.

-

Nitrogen-assisted selective soldering prevents oxidation, resulting in clean, shiny solder joints.

-

The process supports high-density interconnects and complex layouts, reducing defects and improving reliability.

Selective soldering enables you to meet the demands of industries such as automotive, medical, and power electronics, where precision and reliability are critical. You gain the ability to solder mixed SMT and through-hole assemblies with minimal defects and high repeatability.

High-Precision Welding Needs

Protecting Sensitive Components

You face increasing challenges when assembling modern electronics with sensitive components. High-Precision Welding methods help you avoid thermal damage and ensure the integrity of your assemblies. Selective soldering stands out because it targets only the necessary joints, reducing heat exposure for delicate parts. You can rely on this process for PCBs with complex layouts and temperature-sensitive devices.

Selective soldering applies solder with pinpoint accuracy, combining the efficiency of wave soldering with the control of hand soldering. Nitrogen atmospheres further improve joint quality and lower defect rates, which is especially important for heat-sensitive parts.

Here is a comparison of common High-Precision Welding processes and their suitability for small-batch electronics manufacturing:

|

Welding Process |

Key High-Precision Requirements and Features |

Suitability for Small-Batch Electronics Manufacturing |

|---|---|---|

|

Manual Soldering |

High flexibility; low technical requirements; quick adjustment and modification capability |

Ideal for small-batch and sample production due to adaptability and cost |

|

Reflection Welding |

Fast welding speed; minimal thermal and electrostatic impact; protects temperature-sensitive components |

Suitable for delicate, temperature-sensitive parts requiring precision |

|

Lead-Free Soldering |

Precise control of process parameters; environmental compliance; stable welding quality |

Meets environmental standards and ensures reliable, high-quality joints |

|

High precision; non-contact; low thermal stress; ability to weld tiny components; requires control of laser power, spot size, speed |

Widely used for advanced electronics with tiny, complex parts |

|

|

SMT (Surface Mount Technology) |

High integration; precise temperature control; suitable for small-sized designs |

Suitable for small-batch production with high precision demands |

You can see that High-Precision Welding methods like laser welding and selective soldering protect sensitive components by minimizing unnecessary heat and providing exact control over the process.

Consistent Solder Quality

You need consistent solder joints to guarantee product reliability, especially in small-batch production. High-Precision Welding delivers this consistency by automating critical parameters such as solder application time, temperature, and nozzle position. Selective soldering uses a solder reservoir and programmable controls to apply molten solder exactly where needed.

-

You reduce the need for manual soldering, which often introduces variability and excessive heat.

-

Automated selective soldering completes complex tasks quickly and with repeatable quality.

-

The process minimizes thermal aging, which extends the lifespan of your PCBs and components.

-

You benefit from programmable settings based on your board design, ensuring each batch meets the same high standards.

High-Precision Welding fills the gap between manual and wave soldering, making it ideal for complex or mixed-technology boards. You achieve reliable, high-quality joints with less risk of defects, even as you scale up your small-batch production.

Top Solutions

Compact Systems

When you work in small-batch or prototype production, compact selective wave soldering systems offer clear advantages. These machines save valuable floor space and fit easily into facilities with limited space. You can move them as needed, which makes your production line more flexible. Compact systems also reduce your initial investment and ongoing operational costs.

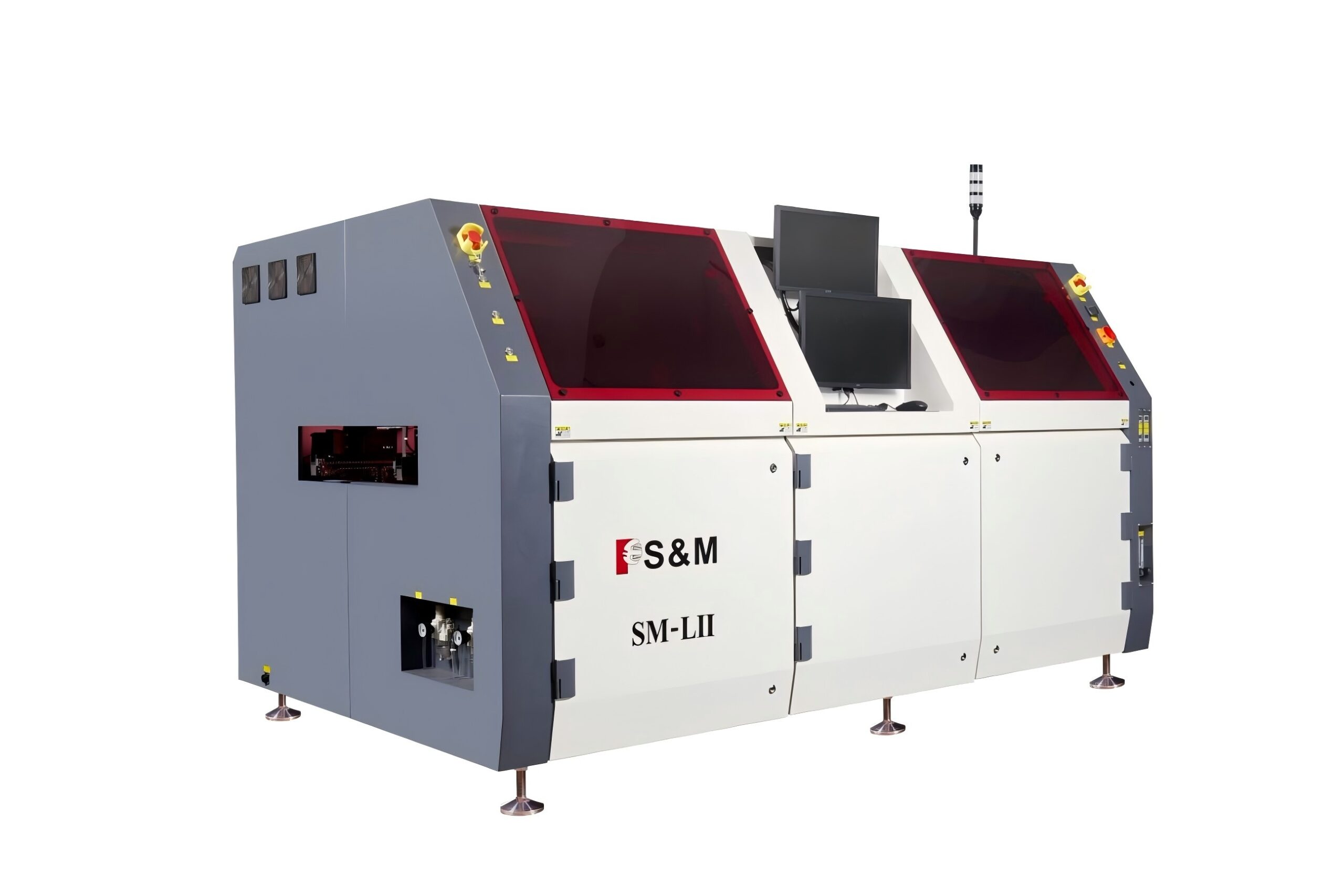

Here are some of the most recommended compact selective wave soldering machines for high-precision, small-batch production:

|

Model |

Soldering Area |

Positioning Accuracy |

Key Features |

Best For |

|---|---|---|---|---|

|

ECOSELECT 4 |

Up to 500 x 500 mm |

±0.1 mm |

Compact footprint, modular design, energy-efficient, easy programming |

Small to medium batches, flexible layouts |

|

GoWave |

400 x 300 mm |

±0.1 mm |

Entry-level, cost-effective, simple operation, fast changeover |

Prototyping, low-volume runs |

|

VERSAFLOW |

Customizable |

±0.05 mm |

High automation, advanced process control, multi-wave capability |

Complex, high-density PCBs |

|

CUBE.460 |

460 x 460 mm |

±0.1 mm |

Tabletop design, minimal footprint, quick setup, low maintenance |

Small-batch, R&D labs |

|

DEZ-H3600A |

400 x 300 mm |

±0.05 mm |

Closed-loop servo control, halogen preheating, full computer control |

High-density, complex PCBs |

|

H3600A |

Up to 300 x 300 mm |

±0.1 mm |

Programmable paths, IR/hot air preheating, eco-friendly, flexible for sizes |

Mixed technology, sensitive components |

Tip: Compact systems like these allow you to solder only the required points on each board. You avoid unnecessary solder waste and reduce the risk of thermal damage to sensitive components.

You benefit from features such as programmable soldering paths, real-time monitoring, and automatic nozzle adjustments. These systems support High-Precision Welding, ensuring consistent results even with fine-pitch or heat-sensitive parts. Their energy-efficient operation and reduced material consumption help you control costs while maintaining quality.

Inline and Offline Options

You can choose between inline and offline selective wave soldering systems based on your production needs. Inline systems integrate directly into your automated assembly line. They handle higher throughput and support continuous production. Offline systems operate as standalone units. They suit smaller batches, prototyping, or specialized jobs where flexibility is key.

Inline Systems:

-

Integrate with conveyors and automated handling.

-

Offer high throughput and minimal manual intervention.

-

Provide advanced process control and traceability.

-

Ideal for medium to large-scale production with consistent product flow.

Offline Systems:

-

Operate independently from the main line.

-

Allow manual board loading and unloading.

-

Enable quick changeovers for different products.

-

Best for small-batch, prototype, or repair work.

You find that leading brands like VERSAFLOW and ECOSELECT 4 offer both online and offline configurations. This flexibility lets you scale your production as your business grows. Machines such as the DEZ-H3600A and H3600A provide manual board placement, which gives you more control over specialized or low-volume jobs.

Note: Compactness, flexibility, and cost efficiency remain critical in both inline and offline systems. You can adapt quickly to changing customer requirements and keep your production costs under control.

When you select a system, consider the following:

-

Floor space available in your facility.

-

Volume and variety of your production.

-

Need for automation versus manual control.

-

Support and maintenance options from the supplier.

You gain superior accuracy, consistent solder quality, and reduced defects with these solutions. Many users report defect reductions of up to 50% and improved production efficiency. Reliable after-sales support and easy maintenance further increase user satisfaction.

Key Features

Automation

You gain a significant advantage with automation in selective wave soldering systems. Modern machines streamline your workflow and reduce manual intervention. You can program soldering paths using picture programming, Gerber files, or visual teaching. Automated chain-driven conveyance moves your PCBs efficiently through each stage. Real-time monitoring keeps you informed about every step.

|

Feature Category |

Details |

|---|---|

|

Conveyance |

Automated chain-driven conveyance for PCB transport |

|

Programming Methods |

Picture programming, Gerber document, visual teaching programming |

|

Monitoring |

Real-time soldering process monitoring (standard) |

|

Operating Mode |

PCB board guided transportation; XYZ axis movement of the solder furnace |

|

Space Efficiency |

Compact design minimizing floor space |

|

Manual Operation |

Designed to facilitate manual operation despite automation |

You can combine flux spraying and soldering in one process. PC-based control systems let you set, save, and recall parameters for different jobs. Many systems offer digital N2 flow control and customizable preheating. These features help you adapt quickly to new products and maintain consistent quality.

Process Control

You need precise process control to achieve reliable results in small-batch production. Selective soldering equipment gives you high positioning and welding accuracy. This precision reduces defects such as miswelding and leaking solder. You see fewer reworks and higher production efficiency.

Advanced process control lets you fine-tune heat and flux application. AI-driven optimization and real-time defect detection improve solder joint integrity. IoT-enabled systems provide predictive maintenance and adaptive flux application. These technologies ensure consistent quality and reduce variability. You benefit from higher production speed, better quality, and fewer failures, especially with complex PCB assemblies.

Tip: High-Precision Welding processes with advanced control help you maintain strict standards and reduce scrap, even as your product mix changes.

Cost Efficiency

You want to optimize costs without sacrificing quality. Selective wave soldering delivers strong cost savings, especially for small-batch, high-precision electronics assembly.

-

You can choose manual or automatic element installation based on order size.

-

Selective wave soldering suits both small and large batches, supporting cost and quality optimization.

-

Wave soldering can reduce costs by up to 60% compared to manual soldering in mass production.

-

Gas costs remain low, averaging about 0.3 RMB per board.

You avoid expensive jigs and reduce solder waste. Automated systems lower labor costs and minimize rework. These savings make selective wave soldering a smart investment for small-batch production with demanding quality requirements.

Technology Trends

Lead-Free Soldering

You see a major shift toward lead-free soldering in selective wave soldering systems. This change responds to strict environmental regulations such as RoHS and REACH. Manufacturers now use advanced solder alloys like Sn-Ag-Cu and develop new flux formulations to handle higher melting temperatures. You benefit from improved mechanical properties and reliability in solder joints, but you must optimize your process to avoid thermal stress and ensure proper hole fill.

-

Lead-free soldering increases the thermal demands on your equipment.

-

You need precise control over solder deposition and temperature profiles.

-

Optimized hole dimensions and flux chemistry help you achieve strong, reliable joints.

Lead-free selective wave soldering supports your compliance with global standards and reduces environmental impact. You can minimize soldering defects and maintain high-quality output, even with complex, high-density PCBs.

You also notice that sustainability trends drive the adoption of eco-friendly processes. Reduced flux consumption and lower soldering waste help you control costs and meet green manufacturing goals.

Software Integration

Modern selective wave soldering systems rely on advanced software integration to boost your production efficiency and quality. You use programmable soldering patterns, automatic calibration, and real-time monitoring to maintain consistent results. Software features help you reduce human error and improve machine functionality.

|

Feature/System |

Software Integration Role |

Benefits |

|---|---|---|

|

Data logging and trending |

Precise flux control, reduced bridging, improved hole penetration |

|

|

ServoSonic Fluxing |

Ultrasonic atomized spray, selective fluxing |

Reduced flux consumption, self-cleaning |

|

ExactaWave Wave Height |

Closed-loop feedback sensor |

Automatic wave height control compensates for the solder level changes |

|

MES Integration |

Supports Manufacturing Execution System (MES) |

Better process control and traceability |

You can connect your soldering equipment to Industry 4.0 platforms. IoT connectivity, predictive maintenance, and remote diagnostics help you reduce downtime and improve process control. AI-powered defect detection and digital twins allow you to optimize soldering parameters before production starts. These innovations give you greater flexibility and reliability, especially for small-batch, high-precision electronics manufacturing.

Tip: Software integration lets you adapt quickly to new product requirements and maintain strict quality standards across every batch.

User Insights

Case Studies

You can see the real value of selective wave soldering through user experiences in industries like automotive electronics and LED lighting. Many manufacturers choose selective soldering for high-density and mixed-technology PCB assemblies because it allows you to set soldering parameters for each joint. You apply flux only where needed, which reduces waste and keeps your boards cleaner.

-

Automotive electronics companies report a 30% increase in throughput and a 50% drop in solder bridging defects after switching to selective wave soldering with nitrogen inerting. Production costs also decrease by 20%.

-

Selective soldering helps you handle complex boards with many SMD and through-hole components. You avoid the high energy use and solder defects common with traditional wave soldering.

-

Modular and flexible machine designs let you adapt to different PCB shapes and sizes. You can scale your production as your needs change.

-

Real-time monitoring and nitrogen use improve solder joint quality, meeting strict standards in automotive, medical, and LED lighting applications.

Selective wave soldering gives you precise control, reduces resource consumption, and ensures high reliability—even for the most demanding assemblies.

Common Challenges

You may face several challenges when you implement selective wave soldering for small to medium batch production. The most common issues include speed, cost, and operational complexity.

|

Challenge Category |

Description |

|---|---|

|

Speed and Throughput |

Selective soldering works more slowly than traditional wave soldering, usually handling 10-20 PCBs per hour. |

|

Operational Costs |

Equipment costs more and often requires nitrogen, raising running expenses. |

|

Operator Training |

You need skilled operators and extra training for precise programming and setup. |

|

Process Complexity |

Programming soldering heads and maintaining the system adds complexity and setup time. |

|

Efficiency and Cost-Effectiveness |

Slower speed and higher costs can challenge efficiency, but you save on solder and maintenance. |

You balance these challenges with the benefits of reduced solder waste, lower maintenance, and better quality for small-batch, high-mix production. Selective soldering lets you meet strict industry standards while keeping your process flexible and efficient.

Choosing the Right Solution

Assessing Needs

You must evaluate your production requirements before selecting a selective wave soldering solution. Start by identifying the types of boards you assemble. Mixed technology boards with both SMT and through-hole components demand machines that use mini waves or solder jets. These features allow you to solder specific areas without damaging sensitive components.

Consider the following criteria when assessing suitability:

-

Ability to solder only targeted areas, protecting sensitive parts.

-

Precision in soldering for high-density and complex layouts.

-

Fast setup time and low changeover costs for frequent product switches.

-

Compatibility with your component types, especially through-hole and mixed SMT/PTH boards.

-

Advanced process control, including temperature management, flux application, preheating, and solder wave height.

-

Ease of maintenance and reliability for consistent quality.

You should also look at production volume. Small-batch runs benefit from systems that minimize setup complexity and maximize flexibility. Machines with programmable paths and quick-change features help you adapt to new jobs efficiently.

Tip: Preheating stabilizes your boards and reduces thermal shock. Proper flux application ensures strong, reliable solder joints.

Supplier Support

Supplier support plays a crucial role in your long-term success. You need a partner who offers more than just equipment. Reliable suppliers provide training, technical assistance, and fast access to spare parts. They help you optimize process parameters and troubleshoot issues quickly.

|

Supplier Service |

Benefit to You |

|---|---|

|

Training |

Reduces operator errors |

|

Technical Support |

Minimizes downtime |

|

Spare Parts Access |

Ensures smooth operation |

|

Process Optimization |

Improves solder quality |

Choose suppliers with a proven track record in small-batch, high-precision production. Ask for references and case studies. Request demonstrations to see how the machine performs with your specific boards. Strong supplier support helps you maintain high standards and adapt to changing production needs.

Note: A knowledgeable supplier guides you through setup, maintenance, and process optimization, ensuring your investment delivers consistent results.

Selecting the right selective wave soldering solution for small-batch, high-precision production requires careful evaluation. You should focus on:

-

Ease of use and application range for complex boards

-

Safety features and operator training needs

-

Flexibility for frequent changeovers and intricate designs

|

Factor |

Influence on Your Decision |

|---|---|

|

Production Needs |

Match system capabilities to PCB complexity and precision requirements |

|

Budget Constraints |

Balance equipment investment and operational costs with process efficiency |

|

Supplier Reliability |

Choose partners with proven expertise and strong technical support |

For best results, request a demo or consult with experts to ensure your solution meets your unique requirements. Reach out for tailored advice and maximize your production success.

FAQ

What is the main advantage of selective wave soldering for small-batch production?

You gain precise control over solder application. Selective wave soldering targets only the required joints. This process reduces waste, protects sensitive components, and improves quality. You can quickly switch between different board designs.

How do you maintain consistent solder quality?

You use programmable controls to set temperature, timing, and solder flow. Automated monitoring ensures each joint meets your standards. Regular calibration and maintenance keep your system reliable.

Can you use selective wave soldering with lead-free alloys?

Yes. Most modern selective wave soldering systems support lead-free alloys. You must adjust temperature profiles and use compatible flux. This approach helps you meet environmental regulations.

What training do operators need?

Operators should learn machine setup, programming, and basic troubleshooting. Many suppliers offer training sessions. You benefit from hands-on practice and clear documentation.

How do you choose between online and offline systems?

You select inline systems for higher throughput and automation. Offline systems work best for prototypes or small batches. Consider your production volume, available space, and need for flexibility.