Nitrogen usage in a reflow oven typically falls between 18 and 30 cubic meters per hour, maintaining oxygen concentrations from 300 to 800 ppm. This environment supports effective nitrogen reflow soldering and protects the soldering process from oxidation. Studies show nitrogen reduces solder beading, improves joint quality, and enhances wettability. The reflow oven creates a stable n2 atmosphere, which helps prevent defects and supports high joint quality throughout the reflow process.

|

Aspect |

Effect of Nitrogen Usage |

|---|---|

|

Oxidation Reduction |

Nitrogen displaces oxygen, reducing oxidation on solder surfaces. |

|

Solder Wettability |

Lower surface tension in nitrogen improves solder flow and joint quality. |

|

Defect Reduction |

Nitrogen reduces solder beading and head-in-pillow defects during reflow soldering. |

Key Takeaways

-

Nitrogen reduces oxygen in the reflow oven, preventing oxidation and improving solder joint quality.

-

Oven size, PCB type, and process settings affect how much nitrogen is needed during soldering.

-

Typical nitrogen flow rates range from 10 to 30 cubic meters per hour, depending on oven size and production needs.

-

Maintaining oxygen levels below 1000 ppm helps produce stronger, more reliable solder joints.

-

Regular monitoring and adjusting nitrogen flow saves costs and ensures consistent, high-quality soldering results.

Nitrogen Usage Factors

Oven Size

The size of a reflow oven directly impacts nitrogen usage. Larger ovens require more nitrogen to maintain a stable nitrogen environment and achieve the desired low oxygen levels. The volume of the oven determines the amount of inert gas environment needed to displace air and reduce oxidation during soldering. Operators must adjust nitrogen flow rates based on oven dimensions to ensure consistent N2 coverage throughout the process. Smaller ovens typically use less nitrogen, but even compact systems need precise control to prevent oxidation and maintain high-quality solder joints.

PCB Type

PCB type plays a significant role in nitrogen consumption. Certain PCBs demand higher nitrogen usage due to their design or application:

-

Thermally heavy PCBs, which have greater mass or use materials that retain heat, require more nitrogen because they take longer to reach reflow temperatures.

-

In air, extended heating can cause flux to burn off before solder melts, increasing the risk of oxidation and poor solder joints.

-

Nitrogen displaces oxygen, allowing longer reflow profiles and resulting in stronger, more reliable solder joints.

-

High-reliability PCBs used in aerospace, medical, military, industrial, and telecommunications sectors often require a nitrogen environment to meet strict quality standards.

-

Nitrogen reflow lowers oxygen levels below 500 ppm, which helps reduce oxidation and voiding, producing solder joints that withstand rigorous reliability testing.

Nitrogen also improves wetting by preventing further oxidation of the component leads and PCB pads. Flux agents perform better in nitrogen, and solder paste particles resist oxidation, reducing defects such as “graping.” Many defects related to oxidation can be minimized by switching from air to nitrogen reflow.

Process Settings

Process settings in the reflow oven, such as conveyor speed, temperature profile, and nitrogen flow rate, influence nitrogen usage. Higher conveyor speeds may require increased nitrogen flow to maintain the desired inert gas environments. Temperature profiles that involve longer or higher temperature zones can increase nitrogen consumption, as the oven must sustain a stable nitrogen environment for a longer period. Operators must balance these settings to optimize nitrogen usage while ensuring solder quality. Industry standards, such as IPC/JEDEC J-STD-020C, guide temperature profiles and highlight the importance of nitrogen in processes that require low oxygen levels for lead-free soldering. Certifications like ISO 9001:2015 and AS9100:2016 ensure that manufacturers maintain high-quality processes, including those involving nitrogen reflow soldering.

Tip: Regularly monitor oxygen levels and adjust process parameters to optimize nitrogen consumption without compromising solder joint quality.

Nitrogen Flow Rates in Reflow Oven

Typical Ranges

Industrial reflow ovens commonly operate with nitrogen flow rates between 20 and 30 cubic meters per hour. This range supports a stable inert atmosphere inside the reflow chamber, which is essential for high-quality soldering. Some ovens may use lower or higher rates depending on their size, production volume, and specific process requirements. Operators often measure flow rates in liters per minute (L/min) or cubic meters per hour (m³/hr), adjusting the settings to match the oven’s capacity and the complexity of the printed circuit boards.

|

Oven Size |

Typical Nitrogen Flow Rate |

|---|---|

|

Small/Benchtop |

10–18 m³/hr |

|

Medium/Standard |

18–25 m³/hr |

|

Large/Industrial |

25–30 m³/hr |

Adding nitrogen to the reflow oven at these rates ensures that the oxygen concentration remains low, which helps prevent oxidation and improves solder joint quality.

Oxygen PPM Levels

Maintaining low oxygen levels in the reflow oven is critical for effective soldering. Most manufacturers target oxygen concentrations between 300 and 1000 parts per million (ppm). Research shows that nitrogen with up to 1000 ppm oxygen is pure enough to improve soldering for most components. For processes using low-residue solder pastes, operators may aim for even lower oxygen levels, sometimes below 100 ppm. However, achieving ultra-low oxygen levels can be costly and may not provide significant quality improvements beyond the standard high-purity range.

Note: Lower oxygen levels reduce oxidation on component leads and solder particles, but extremely high-purity nitrogen does not always yield better results due to unavoidable mixing with ambient air inside the oven.

Advanced monitoring systems, such as the O2 Reflow Shuttle, now allow real-time mapping of oxygen ppm across all oven zones. These systems help manufacturers optimize nitrogen flow rates, minimize nitrogen consumption, and maintain consistent soldering quality.

Determining Flow Rates

Operators determine the correct nitrogen flow rate by considering several factors:

-

Oven Size and Design: Larger ovens require more nitrogen to fill the reflow chamber and maintain a stable N2 atmosphere.

-

Production Volume: Higher throughput demands more frequent nitrogen to the reflow oven, which increases nitrogen supply needs.

-

Target Oxygen Level: Lower target ppm requires higher flow rates or improved sealing to prevent air ingress.

-

Process Settings: Conveyor speed, temperature profile, and PCB type all influence the amount of nitrogen needed.

Modern reflow ovens often use sensors to monitor oxygen levels and automatically adjust nitrogen flow. This approach ensures efficient use of nitrogen supply while maintaining the desired soldering environment. On-site nitrogen generation systems, such as PSA or membrane generators, offer a cost-effective solution for continuous production. These systems provide high-purity nitrogen, eliminate delivery fees, and allow precise control over flow rates.

Tip: Regularly calibrate oxygen sensors and inspect oven seals to prevent nitrogen leakage. This practice helps maintain optimal flow rates and reduces unnecessary nitrogen consumption.

Adding nitrogen to the reflow oven not only protects solder joints from oxidation but also supports consistent production quality. Manufacturers who invest in advanced monitoring and on-site nitrogen supply systems often see rapid returns through reduced costs and improved process control.

Estimating Nitrogen Usage

Calculation Methods

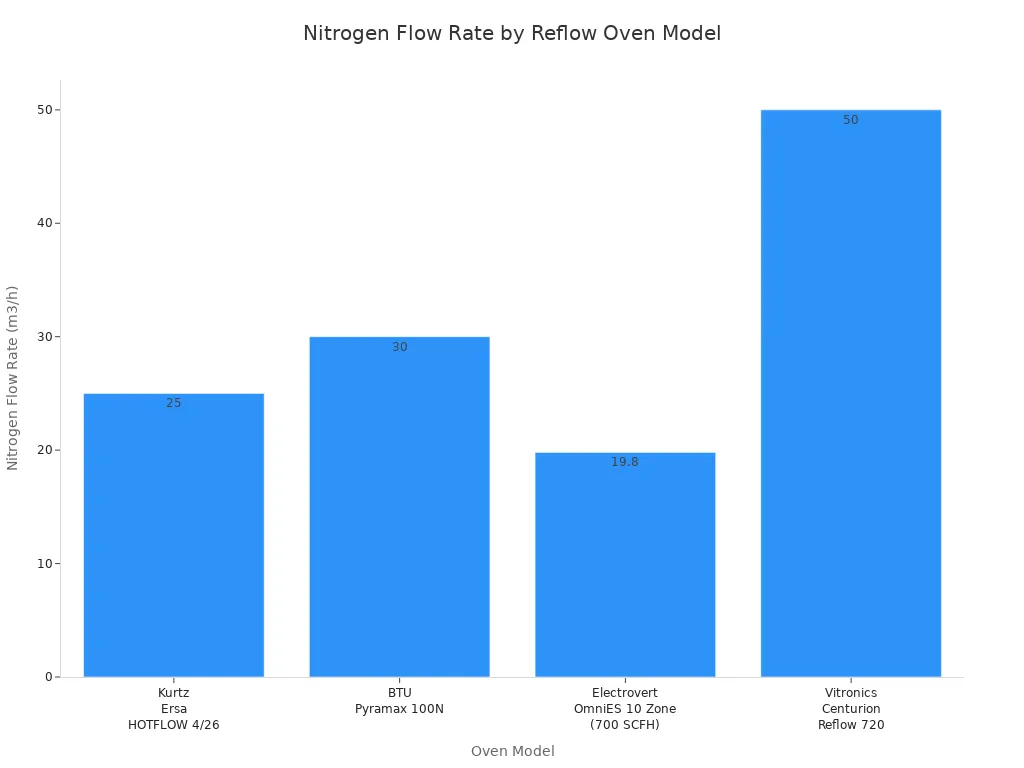

Manufacturers estimate nitrogen usage by considering equipment specifications and operational needs. Each reflow oven model lists a recommended nitrogen flow rate, pressure, and purity. Operators should check these values before setting up the process. The following table compares nitrogen flow rates for several popular reflow oven models:

|

Manufacturer |

Model |

Nitrogen Flow Rate |

Nitrogen Pressure |

Purity |

Notes |

|---|---|---|---|---|---|

|

Kurtz Ersa |

HOTFLOW 4/26 |

25 m³/h |

4.5-10 bar |

99.999% |

Factory-specified flow rate |

|

BTU |

Pyramax 100N |

30 m³/h |

4 bar |

99.99% |

– |

|

Electrovert |

OmniES 10 Zone |

700-1200 SCFH |

80-100 PSI |

99.99%+ |

2000 SCFH supply recommended |

|

Vitronics |

Centurion Reflow 720 |

50 m³/h |

70 PSI |

99.99% |

– |

To estimate total nitrogen consumption, multiply the flow rate by the hours of operation. For example, a reflow oven running at 25 m³/h for 8 hours will use 200 m³ of nitrogen. Operators should also consider the number of zones and ppm targets, as more zones or lower oxygen levels require higher nitrogen flow. Cooling system design and circulation methods can further influence nitrogen usage and efficiency.

Tip: Review manufacturer specifications and adjust nitrogen flow based on actual production needs to maximize efficiency and reduce waste.

Production Volume Impact

Production volume directly affects nitrogen usage. When the oven runs continuously, nitrogen must flow at a steady rate to maintain low oxygen levels. Higher production volumes mean longer operational hours and increased nitrogen consumption. The following table shows typical flow rates and how operational conditions impact nitrogen usage:

|

Nitrogen Flow Rate to Maintain 1000 ppm O2 |

Approximate Range (slpm) |

|---|---|

|

Typical flow rates reported |

< 300 to 400 |

|

Operational Condition |

Impact on Nitrogen Usage |

|---|---|

|

Continuous production (active) |

Requires continuous nitrogen flow to maintain O2 levels |

|

Production stops or idle mode (manual control) |

Nitrogen consumption reduces due to lower fan speed or reduced nitrogen introduction |

Operators can improve efficiency by reducing nitrogen flow during idle periods or using automated controls. Monitoring production schedules and adjusting nitrogen supply helps balance quality and efficiency. By matching nitrogen usage to actual production needs, manufacturers can lower costs and maintain optimal soldering conditions.

Optimizing Nitrogen Reflow Soldering

Adjusting Flow Rates

Manufacturers can optimize nitrogen reflow soldering by carefully adjusting flow rates. Dynamic flow engineering, such as serpentine and recirculation patterns, minimizes nitrogen consumption while maintaining an inert atmosphere. Operators inject nitrogen at multiple points and recirculate it within heating zones, which reduces the need for additional gas. Controlling gas composition, pressure, and flow rate prevents oxidation and promotes wetting during the soldering process. Adjusting nitrogen flow rates creates an environment that displaces oxygen, which helps reduce voiding and enhances solderability. This approach leads to cleaner, shinier solder joints and better quality joints. On-site nitrogen generation also improves efficiency and provides full control over supply and purity, reducing operational costs and disruptions.

Tip: Use advanced temperature control systems and real-time oxygen sensors to maintain consistent profiles and optimize nitrogen usage.

Maintenance Tips

Regular maintenance ensures efficient nitrogen usage in reflow welding processes. Operators should monitor and control oxygen levels, keeping them below 100 ppm to reduce oxidation and corrosion. Maintaining a nonfluctuating static air pressure inside the oven prevents air intrusion, preserving the nitrogen atmosphere. Cleaning filters, inspecting blower fans, and calibrating conveyors help avoid uneven heating and soldering defects. Removing flux contaminants before cooling enhances performance and extends equipment life. These practices support high solderability and reduce the frequency of repairs, which boosts overall efficiency in the soldering process.

-

Check oven seals and baffles for leaks.

-

Clean gas-to-gas heat exchangers to prevent clogging.

-

Monitor oxygen analyzers and recalibrate as needed.

Recovery Systems

Modern recovery systems further reduce nitrogen consumption in nitrogen-filled reflow welding. Closed-loop convection control and sealed oven designs maintain low oxygen levels, sometimes as low as 2 ppm above the source. Software-driven systems, such as EnergyPilot, automatically lower nitrogen use during idle times without sacrificing performance. Standby, sleep, and hibernate modes reduce energy and nitrogen use, enabling quick recovery and stable process conditions. Two-stage flux recovery systems also improve nitrogen conservation by efficiently removing contaminants. These innovations help manufacturers reduce voiding rate, enhance solderability, and achieve high efficiency in the soldering process.

Nitrogen reflow soldering offers clear benefits. It creates an inert atmosphere that minimizes oxidation, improves wetting, and reduces defects such as bridging and tombstoning. Soldering in a nitrogen environment enables lower peak temperatures, protecting sensitive components and enhancing solderability. These effects lead to higher joint quality, longer component lifespan, and better overall performance in reflow welding processes.

Nitrogen plays a vital role in reflow oven processes by reducing oxidation and improving solder joint quality. Operators who monitor nitrogen flow and oxygen levels achieve better process consistency and cost savings. The following table highlights key industry standards for nitrogen usage:

|

Aspect |

Key Takeaways |

|---|---|

|

Role of Nitrogen |

Displaces oxygen, resulting in cleaner solder joints and improved wetting. |

|

Oxygen Levels |

Target below 1000 ppm; high-reliability products may require less than 100 ppm. |

|

Nitrogen Purity |

At least 99.99% purity ensures process stability and quality. |

|

Benefits |

Fewer defects, reduced flux residue, and improved first-pass yield. |

Operators who apply nitrogen estimation and optimization strategies see reduced waste and enhanced reliability. Monitoring nitrogen usage supports immediate adjustments, protects equipment, and extends lifespan. Manufacturers in the automotive, medical, and military sectors rely on nitrogen for regulatory compliance and high reliability.

Regular nitrogen monitoring leads to lower production costs, improved solder joint adhesion, and consistent product quality.

-

Monitoring nitrogen flow reduces unnecessary consumption and waste.

-

Stable nitrogen environments protect equipment and ensure reliable manufacturing.

Readers should implement nitrogen management practices to maximize efficiency and maintain high-quality soldering results.

FAQ

How does nitrogen purity affect soldering quality?

Nitrogen purity directly impacts solder joint quality. High-purity nitrogen (99.99% or higher) reduces oxidation, resulting in cleaner and stronger solder joints. Lower purity may allow more oxygen, increasing the risk of defects.

Can operators reduce nitrogen usage without sacrificing quality?

Yes. Operators can optimize flow rates, maintain oven seals, and use real-time oxygen monitoring. These steps help minimize nitrogen consumption while preserving soldering quality.

What is the recommended oxygen ppm level for most reflow ovens?

Most manufacturers recommend maintaining oxygen levels below 1000 ppm. High-reliability applications may require levels under 500 ppm. Lower oxygen levels help prevent oxidation and improve solder joint reliability.

Are on-site nitrogen generators cost-effective for small manufacturers?

On-site nitrogen generators often provide cost savings over bottled gas, especially for continuous production. Small manufacturers benefit from reduced delivery fees, consistent supply, and better control over nitrogen purity.