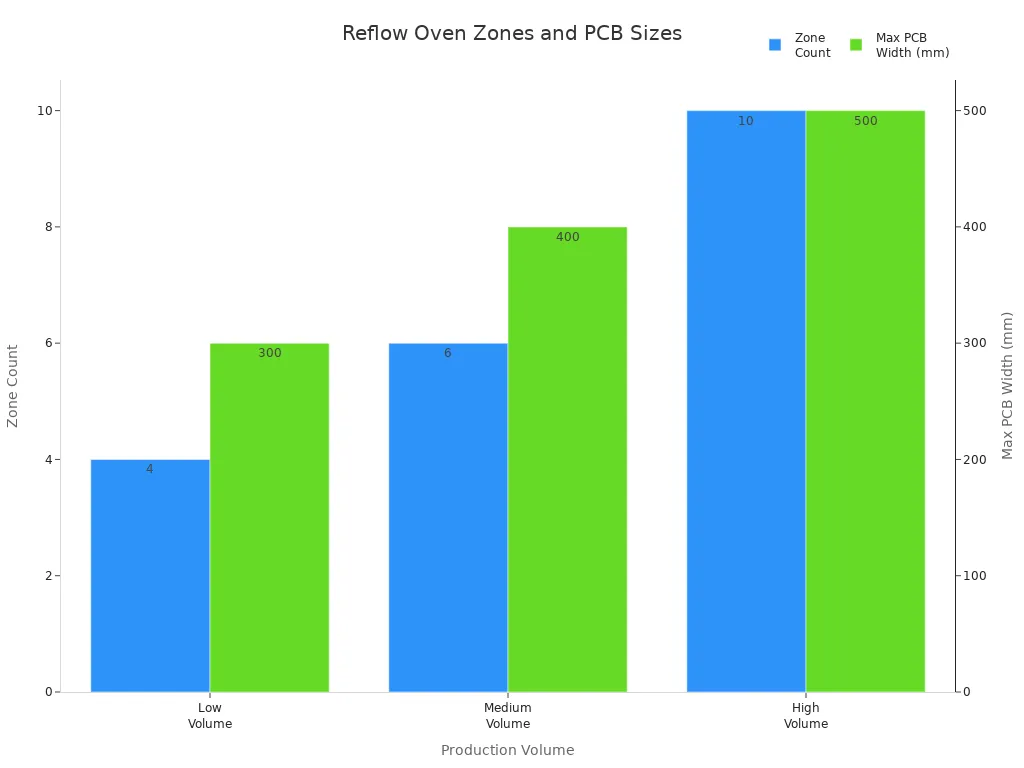

Choosing the right reflow oven depends on how many boards you plan to make. For low-volume or prototyping work, you’ll usually get the best results with a compact four-zone reflow oven that handles PCBs up to about 300 x 320 mm. If you plan for medium production, a 5 to 7-zone conveyorized reflow oven with a width near 400 mm fits most needs. High-volume lines often use big ovens with 8 to 12 zones and support for boards up to 500 x 457 mm. You want to match your reflow oven to your current workload, but don’t forget to think about future growth, board complexity, and your available space.

Tip: The right reflow oven balances speed, board size, and cost so you can run your process smoothly now and later.

Key Takeaways

-

Pick a reflow oven that works for your PCB amount now and lets you grow later. This helps you avoid spending more money on upgrades.

-

Make sure the oven is big enough for your largest board. Think about how many heating zones you need for good temperature control and soldering.

-

Being able to change the conveyor speed and oven length helps you work faster. It also helps you handle bigger or harder boards well.

-

If you make only a few boards, small ovens with fewer zones are good. If you make many boards, you need bigger ovens with more zones and automation.

-

Think about space, energy use, and cost when you pick your oven. This makes sure it fits where you work and does not cost too much. It also helps you save money over time.

Reflow Oven Size Factors

PCB Volume

When you pick a reflow oven, the first thing to think about is your production volume. This means how many boards you want to make each day or week. If you only build a few boards, you can use a small oven. If you need to make hundreds or thousands, you need a bigger oven that can keep up.

-

Production volume decides how fast your oven must work.

-

Higher volume means you need a faster conveyor and a larger oven.

-

The oven’s size and capacity must match your daily or weekly needs.

Note: Production volume is the main reason you might need a bigger reflow oven. Other things matter too, but volume comes first.

Board Size

You also need to check the size of your largest pcb. Your reflow oven must fit your biggest board with room to spare. Most ovens handle boards up to 400 mm wide, but some go up to 460 mm. You should also think about the height of your components. Some ovens give you 30 mm above and 25 mm below the pcb for tall parts.

-

Make sure your largest pcb fits comfortably in the oven.

-

Adjustable conveyor rails help with different board sizes.

-

Always check the oven’s chamber size before you buy.

Soldering Complexity

If you work with complex pcb assemblies, like multi-layer boards or fine-pitch parts, you need more from your reflow oven. Complex boards need even heating and careful temperature control to make strong solder joints.

-

More heating zones help control temperature for tricky soldering jobs.

-

Good ovens use top and bottom heat, infrared lamps, and air jets for even heat.

-

Precise cooling keeps your components safe and your solder joints strong.

Tip: Always match your reflow oven to your pcb volume, board size, and soldering needs. This helps you get the best results and avoid problems later.

Key Reflow Oven Features

Heating Zones

When you look at a reflow oven, you will notice it has different zones. Each zone controls the temperature for a part of the process. More heating zones give you better control over how your boards heat up and cool down. If you work with simple boards, you might only need a few zones. For complex boards, like those with lots of layers or special chips, you need more zones to keep the temperature just right.

Having more zones lets you match the time and temperature curve to what your board needs. This helps you avoid problems like cracked solder or weak joints. You can set each zone to a different temperature, so your boards heat up slowly, stay hot just long enough, and then cool down safely. This is key for high-quality soldering, especially when you build many different types of boards.

Tip: More heating zones mean you can fine-tune your process and get better results, even with tricky boards.

Oven Length

Oven length matters when you want to boost your production or handle bigger boards. Longer ovens give you more space for preheating and heating. This helps when your boards are large or have heavy parts. You can run the conveyor faster and still give each board enough time in the right temperature zones.

-

Longer ovens support higher throughput.

-

They help manage the heat for big or thick boards.

-

You get more control over the temperature profile.

You need to balance oven length with your available space. A longer reflow oven can handle more boards at once, but it takes up more room in your shop.

Belt Speed

Belt speed is another important feature. You can adjust how fast the conveyor moves through the reflow oven. This lets you control how long each board stays in each zone. If you need to make more boards, you can speed up the belt. If your boards need more time to heat up, you slow it down.

Changing the belt speed helps you match the process to different boards and solder pastes. You can avoid problems like bad solder joints or parts moving out of place. Some ovens use special motors to keep the speed steady and move boards smoothly. This makes sure every board gets the same temperature treatment.

Note: Adjustable belt speed gives you the flexibility to handle many types of PCB assemblies and improve your yield.

Choosing the Right Reflow Oven

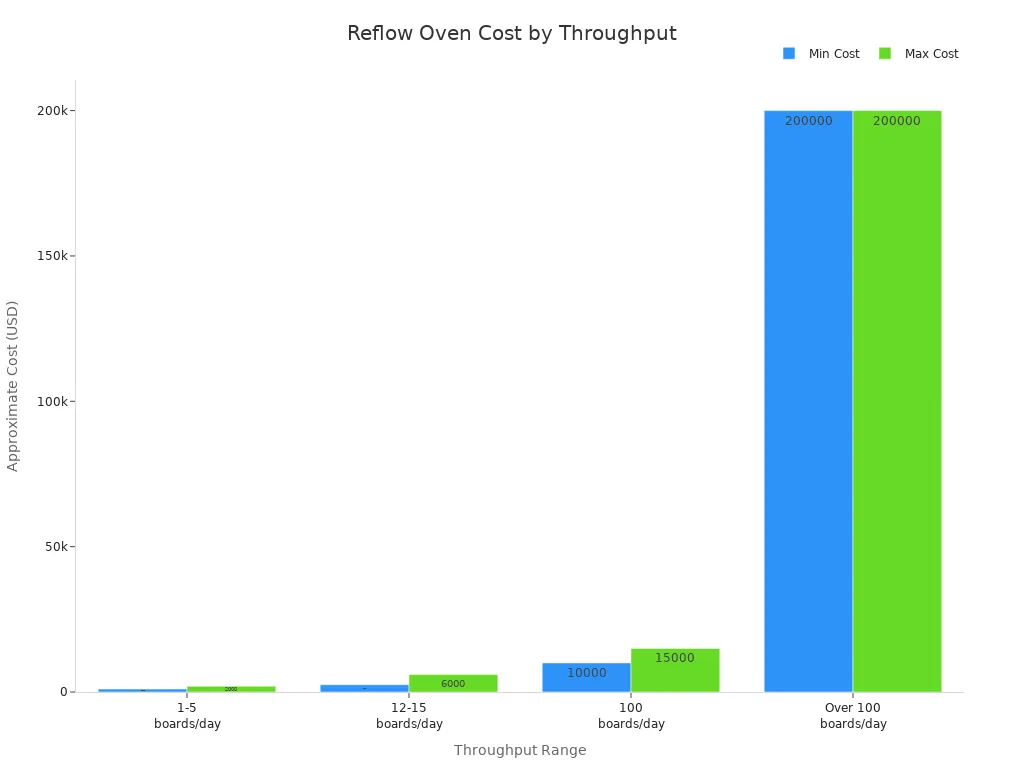

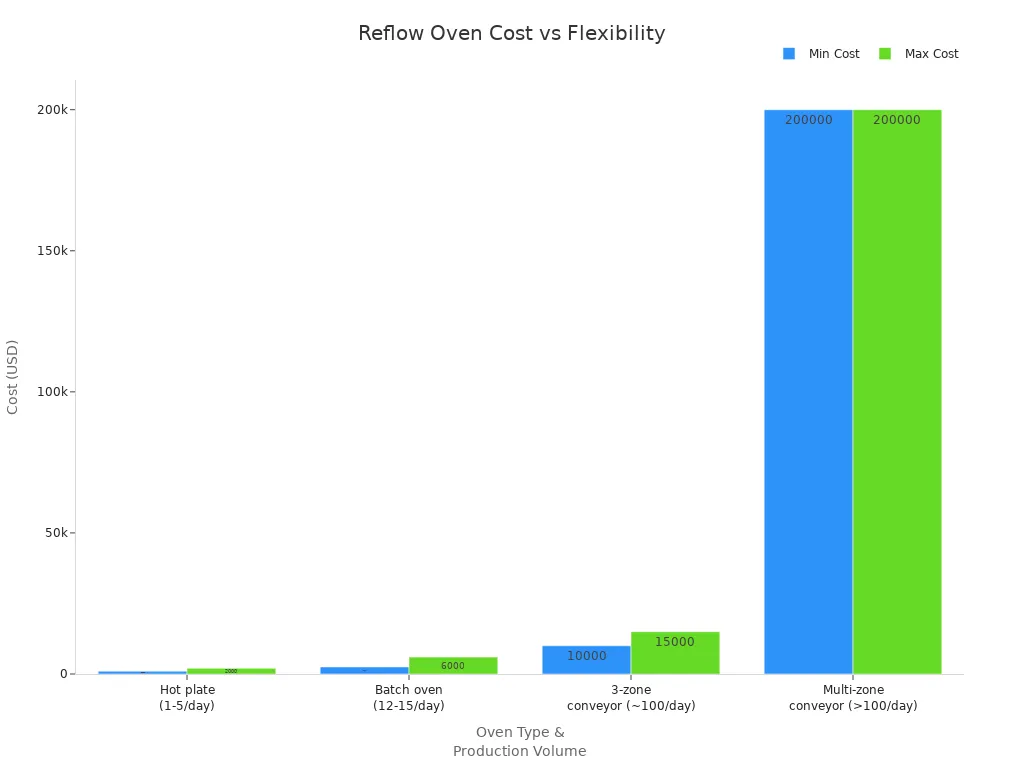

Low Volume

If you only make a few boards each day, you have many choices. You could use a hot plate or a small batch oven. These are cheap and do not need much space. But they do not let you control the temperature well. This can cause problems with your soldering. You might get weak joints or parts that do not stick.

A conveyorized reflow oven with 3 to 5 zones works better. It lets you control each step of the process. You can set different temperatures for preheat, soak, and reflow. Most people who make a few boards like a 5- or 6-zone oven best. It gives you more options for different boards. It also helps you keep your process steady as you grow.

Tip: If you want to make more boards later, buy the biggest oven you can afford now. This will save you money and trouble in the future.

Here is a quick look at the trade-offs for low-volume ovens:

|

Oven Type |

Zones |

Cost Range |

Flexibility |

Best For |

|---|---|---|---|---|

|

Hot Plate |

0 |

$1,000-$2,000 |

Very Low |

Hobbyists, very low volume |

|

Batch Oven |

1 |

$2,500-$6,000 |

Low |

Small boards, prototypes |

|

Conveyorized Reflow Oven |

3-6 |

$10,000-$15,000 |

Good |

Growing low-volume shops |

More zones give you better soldering and more options, but cost more. Batch ovens are okay for simple jobs. Conveyorized ovens help with harder boards and bigger jobs.

Medium Volume

If you start making over 100 boards each day, you need a faster oven. Conveyor ovens with 4 to 6 zones are the best choice for this. These ovens let you control the temperature at every step. This means your boards heat evenly and you get fewer mistakes.

Medium volume ovens fit boards up to 12″ x 12″. They work for most electronics, from small to big. You can change the conveyor speed and save settings for different boards. This helps you switch jobs fast and keep things running well.

-

Conveyor ovens handle more boards and bigger sizes.

-

Ovens with 4-6 zones give you better control and quality.

-

Touchscreen controls and energy-saving modes make work easier.

Medium volume ovens cost more, but you make boards faster and with fewer errors. You also get more options for different board designs. If you want your business to grow, a 6-zone oven is a good idea.

Note: The right oven for medium volume should balance speed, options, and price. You can make more boards each hour and keep your soldering strong.

High Volume

If you run a big assembly line, you need a fast and accurate oven. High-volume work uses conveyor ovens with 8 to 12 zones. These ovens move boards through many steps—preheat, soak, reflow, and cooling. Each zone has its own temperature, so you can set the heat just right.

High-volume ovens have special features like real-time checks, automatic recipe changes, and nitrogen for cleaner solder. You can make thousands of boards every day. Automation keeps things steady and cuts down on mistakes. These ovens cost more, but they save money by making fewer bad boards.

-

Conveyor ovens with 8-12 zones are for high-volume work.

-

Real-time checks and automation make quality better and save work.

-

Nitrogen ovens help make stronger and cleaner solder joints.

Here is what you get with a big reflow oven:

-

Faster work and more boards made.

-

Better control at every step of soldering.

-

Fewer mistakes and better product quality.

-

Can handle advanced and tiny electronics.

Tip: High-volume ovens cost more at first, but they help you make more boards and keep your quality high.

Additional Considerations

Energy Use

You might notice that bigger reflow ovens use more energy, but the story does not end there. The size of your oven depends on how many boards you want to process and how fast you need them done. Longer ovens can handle more boards at once, but they may use more electricity unless you optimize them. For example, some ovens use multi-lane systems. These let you move more boards without making the oven longer, which can help lower energy use.

Insulation makes a huge difference. When you add a thermal jacket to your oven, you can cut your yearly electricity use by half. That means you save money and reduce waste. The way you set the temperature in each zone also matters. If you run your oven at the right temperature and adjust the conveyor speed, you can keep your process efficient and avoid wasting energy.

Tip: Good insulation and smart temperature control can save you a lot on your power bill.

Space Needs

You need to think about where you will put your reflow oven. Small ovens fit on a workbench or a small table. Medium and large ovens need more room. Some high-volume ovens can be over 10 feet long. You also need space for loading boards, unloading them, and doing maintenance.

-

Measure your workspace before you buy.

-

Leave room for airflow and safety.

-

Plan for future growth if you think your needs will change.

If you squeeze a big oven into a small area, you might have trouble with heat or safety. Always check the oven’s size and make sure it fits your shop.

Cost

Buying a reflow oven is a big investment. Entry-level ovens cost between $5,000 and $20,000. These work well for small jobs or prototypes. Mid-range ovens cost $20,000 to $50,000 and give you better control and more features. High-end ovens can cost $50,000 or more, but they offer automation and handle large batches.

|

Oven Type |

Average Cost (USD) |

What You Get |

|---|---|---|

|

Entry-Level |

$5,000 – $20,000 |

Basic features, higher energy use |

|

Mid-Range |

$20,000 – $50,000 |

Better control, lower defects |

|

High-End |

$50,000+ |

Automation, high throughput |

You also need to think about operating costs. Electricity is a big part of this. If you use nitrogen gas, that adds to your bill. Maintenance matters, too. Smaller ovens with smart designs can lower your costs by using less nitrogen and needing fewer repairs. Larger ovens, if run at lower temperatures, can last longer and need less maintenance.

-

Plan for both the price tag and the long-term costs.

-

Regular maintenance and training help you avoid expensive repairs.

-

The right oven size and features can save you money over time.

Note: Picking the right oven now helps you avoid surprise costs later.

Quick Comparison Table

Choosing the right reflow oven can feel tricky. You want something that fits your needs today but also helps you grow. This table gives you a quick look at how low, medium, and high-volume ovens stack up. Use it to compare the main features side by side.

|

Feature |

Low Volume 🟢 |

Medium Volume 🟡 |

High Volume 🔴 |

|---|---|---|---|

|

Typical Zones |

3 – 5 |

4 – 7 |

8 – 12 |

|

Max PCB Size |

300 x 320 mm |

400 x 400 mm |

500 x 457 mm |

|

Oven Length |

0.5 – 1.5 meters |

1.5 – 3 meters |

3 – 6 meters |

|

Throughput |

10–50 boards/hour |

50–200 boards/hour |

200+ boards/hour |

|

Best For |

Prototyping, small runs |

Growing businesses |

Mass production |

|

Energy Use |

Low |

Medium |

High |

|

Cost Range |

$5k – $15k |

$20k – $50k |

$50k+ |

|

Footprint |

Small (tabletop/floor) |

Medium (floor) |

Large (floor/line) |

|

Flexibility |

High |

Medium |

Lower |

Tip:

If you’re not sure which size to pick, think about your biggest board and your busiest day. Always leave some room to grow. You don’t want to outgrow your oven too soon!

Quick pointers to help you decide:

-

Go with a low-volume oven if you build prototypes or small batches.

-

Medium-volume ovens work well for steady, growing production.

-

High-volume ovens shine when you need speed and automation for big orders.

You can use this table as a checklist. Match your needs to the features. This way, you’ll find the oven that fits your shop and your goals.

Choosing the right reflow oven starts with knowing your PCB volume and board size. Think about how many boards you make now and how much you want to grow. Most users do best with an oven that fits their largest board and has enough zones for good temperature control. If you have special needs or complex boards, you should:

-

Pick an oven that matches your biggest PCB and expected volume.

-

Choose a model from a trusted brand with good support.

If you’re not sure, talk to an expert. The right oven today can save you time and money as your business grows.

FAQ

What happens if my reflow oven is too small for my boards?

You can’t fit your largest PCB inside. This causes uneven heating or even damage. Always check the oven’s max board size before you buy.

How many heating zones do I really need?

For simple boards, 3 to 5 zones work well. If you build complex or multilayer boards, go for 6 or more zones. More zones give you better control.

Can I use a large oven for small batches?

Yes, you can. Just remember, bigger ovens use more energy. If you only make a few boards, a smaller oven saves money and space.

Do I need nitrogen for my reflow oven?

You don’t always need it. Nitrogen helps make cleaner solder joints, but it costs more. Most shops use air unless they need extra-clean results.

How do I know when to upgrade my oven?

Watch your production speed. If you can’t keep up with orders or your boards get defects, it’s time to upgrade. Plan ahead so you don’t fall behind.