Even small problems in your reflow oven can cause costly mistakes and slow down production. You may see issues like tombstoning, solder beading, residue discoloration, voids, graping, and head-in-pillow in Reflow Soldering. These problems happen more often in lead-free assembly. This is because it uses higher temperatures and smaller solder paste deposits.

Reliable ovens help you avoid cold solder joints, misaligned PCBs, and expensive fixes. Good process control, careful inspection, and smart design choices help lower these failures.

|

Fault Type |

Impact on Production |

|---|---|

|

Blower Fan Failure |

Uneven heating, rework |

|

Heater Failure |

Incomplete soldering |

|

Conveyor Drift |

Misalignment, defects |

Key Takeaways

-

Keep your reflow oven clean. Take care of it often. This helps stop uneven heating. It also helps prevent cold solder joints.

-

Check heaters, fans, and temperature sensors often. Make sure they work right. This helps keep heating steady and even.

-

Watch conveyor speed and alignment. This stops parts from moving wrong. It also helps avoid soldering problems.

-

Pick the right solder paste. Store it the right way. Check if it is still good. This helps stop weak joints and poor wetting.

-

Design PCBs with balanced pad sizes. Give pads enough space. This helps stop tombstoning and solder bridging.

-

Set the right temperature profile for your oven. Watch it closely. This helps make strong and reliable solder joints.

-

Check your boards with SPI, AOI, and X-ray tools. This helps find defects early. It also helps improve quality control.

-

Teach your staff about cleaning and calibration. Show them how to spot faults. This keeps your reflow process smooth and efficient.

Uneven Heating

Uneven heating is a problem that happens a lot in reflow ovens. If the oven does not heat every part the same, you can get defects like tombstoning or cold solder joints. Poor wetting can also happen. These problems make connections weak and PCBs unreliable. In Reflow Soldering, even a small change in temperature across the board can cause big trouble.

Causes

Heater Issues

Heater problems are a main reason for uneven heating. If one or more heaters stop working well, some parts of the oven will not get hot enough. You might see some zones heat up faster or slower than others. If the insulation, like glass wool, wears out, heat can escape. This makes some areas, especially near the edges or top, cooler than they should be.

Airflow Problems

Airflow is important for spreading heat inside the oven. Fans and blowers move hot air around the chamber. If a fan slows down, gets blocked, or stops, cold spots can form. Nozzle contamination can also block airflow and lower heating. The way your PCBs and components are shaped and placed changes how air moves. Boards with odd shapes or big parts, like BGAs, may not heat evenly. Edge effects on rectangular or disc-shaped boards can make this worse.

Tip: Careful design of circuit and component placement helps stop uneven heating. Try not to put big parts near the edges of your PCB.

Troubleshooting

Inspect Heaters

Start by checking each heater zone. Look for signs that a heater is not working right. Use thermocouples to check the temperature in different zones and compare them. If you find a problem, fix or replace the bad heater. Check the insulation for damage or wear. Good insulation keeps heat inside and helps keep the temperature steady.

Check Fans

Next, check all fans and blowers. Make sure they spin easily and do not have dust or residue. Clean any dirty nozzles to help airflow. Change fan speed or position if you need better air movement. Use a mesh belt or edge conveyor so air can flow around the PCB. This helps heat reach every part of the board.

-

Clean your oven often to get rid of flux and residue.

-

Watch the process with control charts or SPC to catch temperature changes early.

If you still have trouble after these steps, ask your oven maker for expert help.

Conveyor Issues

Problems with the conveyor in your reflow oven can cause big trouble. If the conveyor does not move well, boards may not heat right. Boards can also move out of place. This can cause soldering problems, parts that do not line up, or even broken pieces. These issues slow down work and make things cost more.

Here is a simple table showing common conveyor problems and what they do to PCB quality:

|

Conveyor Issue |

Impact on PCB Quality |

Prevention Measures |

|---|---|---|

|

Chain speed deviation |

– Bad heating can cause cold solder joints, cracked tin, or broken parts |

– Check conveyor speed often |

|

Mechanical wear of components |

– Boards move unevenly and get too much or too little heat |

– Check parts often and change old ones |

Causes

Belt Misalignment

Sometimes the conveyor belt moves the wrong way or pinches boards. This happens if rails are too tight or not straight. Bent rails, old bearings, and bad idlers can also cause this. If the belt sticks or shakes, boards may bend or move. Shaking from the floor or other machines can make it worse.

-

Rails that squeeze or bend boards

-

Bent or bumpy rails

-

Old bearings and idlers

-

Conveyor shaking or stopping

Motor Problems

Motor trouble can stop the conveyor or make it go too fast or too slow. If the motor loses power or a fuse blows, the belt may stop. Broken governors, bad wires, or a bad analog output can set off alarms or slow things down. A stuck chain or mesh belt can also stop movement.

-

Broken or bad governor contact

-

Motor damage or weak power

-

Blown fuse in the circuit

-

Drive chain off or stuck

-

The chain or mesh belt is blocked

Troubleshooting

Adjust Belt

To fix a belt that is not straight, check the rails and make them even. Clean the slide rail and keep it free of dust. If the belt is loose or shakes, move the tension roller to fix it. Oil the drive chain with special oil every two months. Check the moving parts for loose spots or weird noises.

Tip: Do not stop the conveyor belt when the oven is hot. Wait for it to cool down so the belt does not get old fast.

Service Motor

If the belt does not move, look at the motor and wires first. Change any blown fuses and check the circuit. See if the drive chain is off or stuck. If you see a slow speed alarm, check the governor and analog output. If the speed is not steady or the belt shakes, oil the chain and drive parts. Change any broken encoders or couplings. Fix or change the governor if you need to.

-

Clean the outside of the machine and take away trash every day.

-

Watch the conveyor speed and shaking all the time.

-

Check parts often and change old ones.

You can stop most conveyor problems by keeping your oven clean and in good shape. Checking and watching things often helps you find problems early. This keeps your PCB assembly working well and without trouble.

Temperature Profile

A correct temperature profile is very important for good reflow soldering. If you use the wrong profile or your sensors are not right, you can get problems like cold solder joints, tombstoning, and solder balling. Each part of the reflow process needs careful watching. You have to check the temperature at every step to make sure your solder joints stay strong and work well.

Causes

Sensor Errors

Sensors check the temperature inside your oven. If a sensor breaks or gives wrong numbers, your oven can get too hot or too cold. This can make the PCB heat up unevenly. You might see parts move out of place, solder bridging, or not enough solder. Sometimes, old solder or bad thermocouple attachment gives wrong data. Kapton tape by itself does not hold thermocouples well when it gets hot. You need high-temp solder or conductive epoxy to get good readings.

Profile Settings

Profile settings control how fast and how much your oven heats and cools the boards. If you set the ramp rate too high or the soak time too short, you can get thermal shock and cold joints. Too much heat can hurt parts or make more voids. Not enough heat leaves solder unmelted. Things like oven load, exhaust, or mistakes can also change your profile.

Here is a table that shows how each part of the temperature profile changes solder joint quality:

|

Reflow Stage |

Temperature Range & Ramp Rate |

Impact of Deviations on Solder Joint Quality & Defects |

|---|---|---|

|

Preheat |

50–150°C, ramp rate 1–3°C/sec |

Controls solvent evaporation and flux activation; improper ramping can cause solder balling |

|

Soak |

150–180°C, duration 60–120s |

Ensures uniform heating and oxide removal; poor soak leads to cold joints and voids |

|

Reflow |

217–245°C, time above liquidus 30–90s |

Critical for solder melting and joint consolidation; 10°C deviation increases void rate by 15% |

|

Cooling |

245–50°C, cooling rate -2 to -4°C/sec |

Controls solder solidification and grain structure; improper cooling increases IMC thickness by 30%, reducing reliability |

Note: Good thermal control can lower defects by up to 80% and help you get a first-pass yield of 99.5%.

Troubleshooting

Calibrate Sensors

You should check your sensors often. Use thermocouples or profiling tools to measure the real temperature on your PCB. Take off old solder before using high-temp solder or conductive epoxy. This helps you get the right numbers. Use Kapton tape only to hold wires after you attach the thermocouple. Clean flux from the oven and pipes. This stops wrong readings and keeps your oven working well.

Adjust Profile

Change your profile to fit your board and solder paste. Set ramp rates and soak times for your parts. For tricky boards, use a ramp-soak-spike profile. This helps heat spread out and lowers voids. For BGAs, a ramp-to-spike profile may help stop head-on-pillow defects. Watch the time above the liquidus and peak temperature closely. Use AOI and X-ray to look for defects. Change your profile if you find problems.

Follow these steps to keep your temperature profile right:

-

Measure PCB temperatures with profiling tools, not just oven settings.

-

Adjust soak and preheat zones for even heating.

-

Set time above liquidus and peak temperature for your solder paste.

-

Think about your PCB’s thermal mass when setting times.

-

Test and change profiles based on what you see.

-

Control cooling rates for strong solder joints.

-

Follow the maker’s rules for temperature limits.

Tip: Check your oven profile at least once a week or after you fix it. Watching in real time helps you spot problems early.

Solder Bridging

Solder bridging happens when solder joins pads that should not touch. This makes a short circuit and can hurt your PCB. You often see this after reflow soldering with fine-pitch parts.

Causes

Excess Paste

Using too much solder paste is a main reason for bridging. If you put on extra paste, it can spread and join pads. This happens if the stencil is thick or the holes are too big. Bad control of the paste amount or using old paste can also cause problems.

Stencil Thickness

Stencil thickness decides how much solder paste goes on each pad. A thick stencil puts down too much paste. Big or crooked stencil holes let paste go where it should not. Thin stencils, about 0.1–0.15 mm, help stop bridging for small parts.

Pad Design

Pad design is important for stopping solder bridging. Pads that are too close or shaped wrong can trap solder. Vias on pads or missing solder mask between pads let solder flow and make bridges. Dirty or rusty pads also keep solder from sticking right.

Tip: Always clean your PCB and check for dust, oil, or old flux before you print solder paste.

The main causes of solder bridging include:

-

Bad PCB pad design (pads too close, uneven, or vias on pads)

-

Wrong or crooked stencil design

-

Too much or too little solder paste

-

Bad or old solder paste

-

Dirty PCB (dust, water, oil, or flux left over)

Troubleshooting

Control Paste Volume

You can stop bridging by using the right amount of solder paste. Pick a stencil that is the right thickness for your parts. For fine-pitch parts, use a stencil that is 0.1–0.15 mm thick. Make sure the stencil holes are about 80–90% the size of the pad. Use inspection tools to check the paste amount and where it goes.

Optimize Stencil

Check your stencil design and make sure it lines up right. The holes should match the pad size and shape. Rounded holes help stop solder from building up in corners. Line up the stencil before printing. Clean the stencil often so the paste does not pile up.

Review Design

Look at your PCB layout and try to make more space between pads. Add solder mask between pads to stop solder from running across. Use pad shapes that help solder go to the right spot. Pick finishes like ENIG or Immersion Tin for better solder wetting.

|

Troubleshooting Area |

What You Should Do |

|---|---|

|

Solder Paste Volume |

Use the right stencil thickness and hole size; check paste spots |

|

Stencil Design |

Line up the stencil; use rounded holes; clean the stencil often |

|

Pad & Circuit Layout |

Make pads farther apart; add solder mask; use good pad shapes |

|

Reflow Profile |

Heat slowly; do not use too high peak heat |

|

Inspection |

Note: AOI and X-ray systems help you find solder bridges fast. Finding them early saves time and cuts down on fixing.

If you do these things, you can stop most solder bridging. Good control, smart design, and checking often keep your PCBs safe and working well.

Tombstoning

Tombstoning is a problem you might see during Reflow Soldering. It happens a lot with small parts like chips, resistors, and capacitors. One end of the part lifts up and stands straight, like a tombstone. This can break the circuit and make your PCB not work well.

Causes

Uneven Heating

Uneven heating is the main reason for tombstoning. If both pads do not get the same heat, one pad melts solder first. This pulls the part up on one side. You may see this if your oven heats unevenly or your PCB design makes one pad hotter. Heat sinks near a pad or different trace widths can also cause this.

-

Wetting forces are not balanced on both sides.

-

Pads heat up at different times and temperatures.

-

Fast heating or bad thermal control can make it worse.

If you see tombstoning a lot, check your oven’s temperature profile. Make sure both pads heat up at the same speed.

Pad Size

Pad design is important for tombstoning. If pads are not the same size or shape, solder melts at different times. Big or uneven pads make it easier for the part to tip up. If solder paste is not put on evenly, this can also cause problems. Small or odd-shaped parts are more likely to be tombstoned.

-

Pads are too big or not the same size.

-

Pad layout is not even on both sides.

-

Stencil holes are not designed well.

Troubleshooting

Balance Heating

You can stop tombstoning by heating both pads in the same way. Set your reflow profile to heat up slowly and keep it steady. Use thermal tools to look for hot or cold spots. Clean your oven and PCBs to stop oxidation, which can slow melting on one side. Pick solder alloys like SAC305 that melt over a wider range.

|

Troubleshooting Step |

What You Should Do |

|---|---|

|

Profile Adjustment |

Heat up slowly and soak evenly |

|

Oven Calibration |

Use tools to check the oven temperature |

|

Alloy Selection |

Use solder that melts over a wide range |

|

PCB Cleaning |

Clean off dirt and oxidation |

Tip: Calibrate your oven often and use SPC to watch temperature and solder paste amount.

Adjust Pad Design

Check your PCB pad design and make both pads the same size and shape. Follow IPC rules for pad sizes. Make sure your stencil puts the same amount of paste on both pads. Use good solder paste that spreads well. Place parts carefully and use the right pressure.

-

Make the pad size and space the same on both sides.

-

Print solder paste evenly with a good stencil.

-

Use solder paste that is not too thick or too thin.

-

Clean PCBs and parts before you start.

You can use AOI and X-ray to find tombstoning early. Teach your team to spot and fix problems fast. If tombstoning keeps happening, try glue like Chipbonder to hold parts down during reflow.

Note: Tombstoning happens most with small passive parts. When you use tiny parts, watch pad design and heating even more closely.

Cold Solder Joints

Cold solder joints happen when the solder does not melt all the way. These joints look rough, gray, and not shiny. They break easily and do not hold parts well. If you do not control your process, cold solder joints can happen a lot. These weak spots can make your PCB stop working if it shakes or gets hot, or gets cold. You need to watch the temperature and settings to stop this problem.

Causes

Low Heat

Low heat is the main cause of cold solder joints. If the oven is not hot enough, the solder gets soft but does not flow. Big parts or pads can take away heat and keep things too cool. This stops the solder from making a strong hold. You might see joints that are bumpy or not smooth. Sometimes, the oven skips preheating or does not heat evenly. If the equipment is not set right, the temperature can change too much.

-

Parts and pads do not get hot enough for solder to melt

-

Bad heating steps, like missing preheat or uneven heat

-

Equipment problems or wrong settings can cause the temperature to be wrong

Poor Wetting

Poor wetting means the solder does not stick to the pads or leads. Dirt, oil, or rust can stop solder from sticking. Old solder paste does not flow or stick well. If the flux does not work because of low heat or it is old, it cannot clean off rust. Too much water in the air or dust can also cause cold solder joints.

-

Rusty pads or leads stop solder from sticking

-

Flux does not work because of not enough heat, or it is old

-

Old or bad solder paste

-

Solder paste gets too thick or too thin from wet air

Troubleshooting

Raise Temperature

You can fix cold solder joints by making the oven hotter. Set the top temperature at least 15°C higher than the solder melting point. Keep this heat for more than 45 seconds so the solder melts all the way. Check the oven to make sure it is set right. Do not use too much preheat or too high heat, or the flux will not work. Watch how fast the board cools so it does not cool too slowly.

Tip: Use a profiling tool to check the real board temperature, not just the oven number.

Check Paste Quality

Always use new solder paste. Throw away old or bad paste and use fresh paste. Keep paste in a cool, dry place so it stays good. Make sure the stencil puts the right amount of paste on the board. Clean pads and leads before you start to get rid of dirt and rust. Use enough flux to help the solder stick. Watch the air for too much water to keep the paste from going bad.

Recommended troubleshooting steps:

-

Change the oven settings to match what the maker says.

-

Set the top heat at least 15°C above the solder melting point and keep it for 45 seconds.

-

Use new solder paste and throw away old paste.

-

Do not use too much preheat, or the flux will stop working.

-

Make sure the board cools at the right speed.

|

Troubleshooting Step |

What You Should Do |

|---|---|

|

Oven Profile Adjustment |

Set the right top heat and hold time |

|

Solder Paste Quality |

Use the new paste and store it in a cool, dry place |

|

Cleaning and Preparation |

Clean pads and leads before you start |

|

Flux Usage |

Use enough flux and do not overheat |

|

Environmental Control |

Watch for too much water and dust in the air |

Cold solder joints make your PCB weak and can cause it to break. You can stop them by using the right heat, good materials, and keeping things clean. Check your process often and make changes to build strong boards every time.

Blowholes and Voids

Blowholes and voids are problems you might see in reflow soldering. These look like tiny holes or empty spots inside solder joints. You often find them in BGA parts and crowded boards. If you do not fix these, your PCB can get weak and not work well.

Causes

Trapped Gas

Gas can get stuck inside the solder joint during reflow. When solder paste gets hot, it lets out gas from flux and other stuff. If the oven does not let this gas out, bubbles form. These bubbles turn into voids or blowholes. You may see more trapped gas if you use solder paste with too much flux or heat up too fast.

Moisture

Moisture is another big reason for blowholes. If your PCB or parts have water inside, it turns to steam when heated. Steam pushes through the solder and makes holes. You can get moisture from bad storage or boards that are not dry. If you skip pre-baking, you may get more blowholes.

Tip: Always keep your PCBs and parts in a dry place. Use sealed bags or dry cabinets to keep out water.

Here is a table that shows common causes and fixes for blowholes and voids:

|

Defect Type |

Common Causes |

Recommended Fixes |

|---|---|---|

|

Blowholes (Pinhole Voids) |

– Moisture in PCB or parts |

– Pre-bake boards/parts |

|

Voids |

– Gas trapped by flux |

– Use vacuum reflow |

Troubleshooting

Dry PCBs

You can lower blowholes by drying your PCBs before soldering. Pre-bake your boards and parts at the right heat. This step takes out water and helps stop steam from forming. Keep solder paste in a cool, dry place and use it before it goes bad.

Optimize Profile

Set the oven profile carefully. Use a slow preheat to start the flux and let the gas out. Adjust soak time so solder paste melts evenly. Do not heat too fast or you will trap more gas. For tricky boards, use vacuum reflow ovens. These ovens pull out trapped gas and cut voids to less than 10%.

Here are steps you can follow to lower blowholes and voids:

-

Preheat the PCB long enough to start the flux and let the gas out.

-

Store solder paste and boards in dry places to prevent water.

-

Use X-ray and AOI to find hidden voids and check quality.

-

Keep solder paste and oven settings steady for every batch.

X-ray inspection helps you find voids inside solder joints. You can use this tool to check the size and number of voids without hurting the board.

You can also try these troubleshooting tips:

|

Troubleshooting Step |

Description |

|---|---|

|

Change the stencil to control the paste amount and use less paste. |

|

|

Use low-voiding solder paste |

Pick solder pastes that trap less gas and make fewer voids. |

|

Control reflow thermal profile |

Change preheat and soak times to help flux work and let the gas out. |

|

Employ vacuum reflow ovens |

Use a vacuum during reflow to pull out trapped gas and lower voids. |

Blowholes and voids can show up in 30–40% of solder joints, mostly in BGAs. These problems make your PCB weaker and hurt how it works. Industry rules say you should keep voids under 25% for good boards. If you use vacuum reflow, you can cut voids to under 10%. Always check your boards with X-ray to find and fix these problems early. Good solder joints help your PCBs last longer and work better.

Flux Residue

Flux residue is a problem you often see after reflow soldering. Even if you use “no-clean” flux, some residue can stay under the parts. This leftover flux can hurt your PCB, especially if it gets stuck in small spaces.

Causes

Incompatible Flux

Sometimes, you pick a flux that does not fit your PCB or parts. Some fluxes spread out more, which helps with warping but leaves more residue. Others do not spread much, which can make bad solder joints. The chemicals in flux, like organic acids, amines, and halides, can make sticky or harmful films. These films can pull in water and make thin wet layers under parts. When this happens, you might get more leakage current and less reliability, even if the air is dry.

Tip: The way you design your parts matters. Short standoff heights and close pins trap more flux residue, which can cause more leaks.

Incomplete Reflow

If your oven does not get hot enough, the flux cannot fully burn off or go away. This leaves more residue behind. Short standoff heights and big metal pads can block gas from escaping, trapping flux under parts. The resin or rosin in the flux can also break down with heat and water, making more ionic residue. These residues can cause rust and make your PCB not last as long.

Here is a table that shows how flux residue can hurt your PCB:

|

Aspect |

What Happens |

Impact on PCB Reliability |

|---|---|---|

|

Frequency |

Flux residue is common, even with no-clean flux. |

Residue under parts is normal in most jobs. |

|

Chemical Behavior |

Acids in flux can make films when it is wet. |

These films can cause more leaks and less reliability. |

|

Component Design |

Short standoff height traps more residue. |

More trapped residue means more risk of problems. |

|

Flux Choice |

Flux that spreads a lot leaves more residue. |

More residue can mean more leaks and worse performance. |

Troubleshooting

Use Proper Flux

You can lower flux residue by picking the right flux for your board and parts. Use low-residue or no-clean flux that works with your process. Always check that your flux matches your solder paste and PCB. Change your oven settings to make sure the flux burns off and goes away. Set the right heat and time for your oven. This helps the flux break down and leave less residue.

-

Pick a flux that fits your PCB and parts.

-

Set oven heat and time to match the flux needs.

-

Test new flux before using it in real jobs.

Clean Boards

If you still see residue, you need to clean your boards. Use cleaners that work with your flux. Isopropyl alcohol or special cleaners help with rosin-based flux. For water-soluble flux, rinse with clean water and dry the board well. Ultrasonic cleaning helps with hard spots. Always check your boards after cleaning. Use AOI, x-ray, or a microscope to look for leftover residue.

Here are the steps you can follow to get rid of flux residue:

-

Find out what kind of flux residue is on your board.

-

Pick the right way to clean it (solvent, water, or ultrasonic).

-

Gently scrub tough spots with a soft brush.

-

Rinse and dry the board all the way.

-

Check and test the board to make sure it is clean.

Cleaning and checking your boards often keeps them working well and stops problems from flux residue. Teaching your team how to clean and handle boards the right way also helps you get better results.

Component Misalignment

Component misalignment happens a lot in reflow soldering. Sometimes, parts move, turn, or stand up on one end. These problems can break circuits or make weak connections. If you want your PCBs to work well, you need to know why misalignment happens and how to fix it.

Causes

Placement Error

Placement errors happen when the pick-and-place machine puts parts in the wrong spot. Sometimes, the machine drops parts off-center or does not push them deep enough into the solder paste. If the nozzle is dirty or the vision system is not working right, mistakes happen more often. You can also get problems if the stencil puts too much or too little paste on the pads. When the solder melts, surface tension pulls the part. If the part is not pressed in well, it can float or move.

Some main reasons for placement errors are:

-

The pick-and-place machine does not push the part deep enough.

-

The nozzle or vision system is dirty or not lined up.

-

The stencil puts down too much or too little solder paste.

-

Parts are placed too close together, especially small ones next to big ones.

If you see lots of parts out of place, check your machine settings and paste printing first.

Conveyor Vibration

Conveyor vibration is another big reason for misalignment. If the conveyor shakes or moves too fast, parts can slide or twist before the solder gets hard. High blower speeds or uneven airflow in the oven can also push parts out of place. If the oven has blocked nozzles or the fan speed is too high, you may see more shifting. Sometimes, boards bump into oven parts or curtains as they move through.

Here is a table that shows common causes and fixes for misalignment:

|

Cause Category |

Description |

Root Cause |

Suggested Remedy |

|---|---|---|---|

|

Conveyor vibration |

Parts move during transport |

Too much shaking or speed changes |

Lower conveyor speed, handle gently |

|

Placement errors |

Parts not centered or pressed in |

Pick-and-place mistakes |

Calibrate machine, clean nozzles |

|

Solder paste issues |

Wrong amount of paste |

Stencil or printing mistake |

Adjust stencil, control paste amount |

|

PCB design |

Small parts near big ones |

Layout problems |

Add space, change PCB design |

|

Airflow imbalance |

Parts move from the oven air |

High blower speed, blocked nozzles |

Adjust airflow, clean oven |

Troubleshooting

Calibrate Placement

You can fix most placement errors by checking your pick-and-place machine. Make sure each part is pushed halfway into the solder paste. Clean the nozzles and check the vision system for dust or problems. Change the machine program to match the pad and part sizes. Use a stencil that puts down the right amount of paste. Check the pad design and spacing to keep surface tension even when solder melts.

Stabilize Conveyor

To stop vibration problems, keep the conveyor running smoothly. Lower the speed if parts move around. Check for loose parts or old bearings in the conveyor. Clean oven nozzles and set the fan speed to a safe level. Make sure nothing touches the boards as they move through the oven. For tricky parts, use small glue dots to hold them in place before reflow.

Here are steps you can follow to lower misalignment:

-

Calibrate the pick-and-place machine and check the placement force.

-

Clean nozzles and vision systems.

-

Adjust stencil design and solder paste amount.

-

Keep the conveyor smooth and lower vibration.

-

Balance oven airflow and clean nozzles.

-

Use glue for parts that move easily.

-

Change your PCB layout and add more space if needed.

-

Check boards after reflow with AOI or X-ray.

Regular checks and small changes help keep your parts in the right place. This makes your PCBs stronger and more reliable every time.

Solder Paste Issues

Solder paste plays a big role in how your PCB assembly turns out. If you use paste that is old or stored incorrectly, you can get defects like poor wetting, cold solder joints, or even missing connections. You need to know what causes solder paste problems and how to fix them.

Causes

Storage

You must store solder paste the right way. If you leave paste out in the open, it can dry out or pick up moisture. High temperatures make the paste separate or thicken. If you keep pasting in a fridge, you slow down chemical changes. You should always keep paste in sealed containers. If you let air or water get in, the paste can go bad fast.

Tip: Store solder paste at 2–10°C in a dry place. Use sealed jars or tubes to keep out air and moisture.

Expiry

Solder paste has a shelf life. If you use paste that is too old, the flux inside may not work well. Old paste can get lumpy or dry. You might see poor printing, bad spreading, or weak solder joints. Always check the expiry date before you use any paste. If you see paste that looks dry, separated, or smells strange, do not use it.

|

Paste Condition |

What You See |

What Can Go Wrong |

|---|---|---|

|

Fresh |

Smooth, shiny, spreads |

Good wetting, strong joints |

|

Expired |

Dry, lumpy, separates |

Poor wetting, weak joints |

|

Bad Storage |

Thick, crusty, watery |

Voids, cold joints, defects |

Troubleshooting

Inspect Paste

You should always check solder paste before you use it. Look at the color and texture. Fresh paste looks smooth and shiny. If you see lumps or dry spots, throw it away. Smell the paste. If it smells sour or strange, it may be bad. Use a spatula to stir the paste. If it does not mix well, do not use it.

-

Check the expiry date on every jar or tube.

-

Look for signs of drying, separation, or lumps.

-

Stir the paste and see if it spreads easily.

Alert: Using bad paste can cause soldering defects that are hard to fix later.

Control Environment

You need to control the environment where you store and use solder paste. Keep the room cool and dry. High humidity makes paste absorb water, which leads to voids and poor joints. Do not leave paste out for too long. Only take out what you need for the job. Put unused paste back in the fridge right away.

|

Environment Factor |

What You Should Do |

Why It Matters |

|---|---|---|

|

Temperature |

Keep at 2–10°C |

Stops paste from drying |

|

Humidity |

Keep below 60% |

Prevents water uptake |

|

Air Exposure |

Use sealed containers |

Stops oxidation |

You can use a logbook to track when you open and use each jar of paste. This helps you avoid using old or bad paste. Teach your team to check paste every time before printing.

Good solder paste makes strong, reliable joints. If you control storage and check paste often, you lower the risk of defects and keep your PCB assembly running smoothly.

Wicking and Insufficient Solder

Wicking and insufficient solder are two problems that can make your PCB assembly weak or unreliable. If you see thin, stretched solder joints or spots where there is not enough solder, you might have these issues. You need to know why they happen and how to fix them to keep your boards strong and safe.

Causes

Pad Design

Pad design plays a big role in solder wicking. If you use pads that are too small or have long traces connected, solder can flow away from the joint. This is called “wicking.” The solder moves along the copper trace instead of staying on the pad. You might see this more with fine-pitch parts or when you use narrow pads. Sometimes, exposed copper or long thermal reliefs can pull solder away from where you need it.

Tip: Always check your pad size and shape before you start assembly. Good pad design helps solder stay in the right place.

Low Paste Volume

Low paste volume means you do not have enough solder paste on the pad. If you use a stencil with small or blocked apertures, less paste gets printed. Old or dry solder paste can also cause this. When you do not have enough paste, the joint looks thin or incomplete after reflow. You might see open joints or weak connections. This problem often happens with small pads or when the stencil is not cleaned well.

Common signs of low paste volume:

-

Solder joints look flat or thin

-

Some pads have no solder at all

-

Components lift or move during reflow

Troubleshooting

Adjust Design

You can fix wicking by changing your pad design. Make pads wide enough to hold the right amount of solder. Use solder mask between pads and traces to stop solder from flowing away. Shorten thermal reliefs or use smaller copper areas to keep solder on the pad. If you design your PCB with the right pad size and spacing, you lower the risk of wicking.

|

Design Change |

How It Helps |

|---|---|

|

Wider pads |

Hold more solder |

|

Solder mask between pads |

Stops solder from wicking |

|

Shorter thermal reliefs |

Keep the solder near the joint |

Note: Follow IPC standards for pad sizes. This helps you get strong, reliable solder joints.

Increase Paste

If you see insufficient solder, you need to increase the paste volume. Check your stencil for blocked or worn apertures. Clean the stencil often to keep paste flowing well. Use a thicker stencil if your parts need more solder. Make sure you use fresh solder paste and store it in a cool, dry place. Inspect the paste print before reflow to catch problems early.

Steps to increase paste volume:

-

Use a stencil with the right thickness for your parts.

-

Clean the stencil after every few prints.

-

Check solder paste expiry and storage conditions.

-

Inspect paste deposits with SPI (Solder Paste Inspection) tools.

Good solder joints start with the right design and enough paste. If you watch these steps, you can stop wicking and insufficient solder from hurting your PCB quality.

Reflow Soldering Defects

When you use Reflow Soldering, you might see some rare defects. These problems do not happen all the time, but they can cause big trouble. You should learn about these issues so you can find them early. If you spot them fast, you can fix them before your PCB gets damaged.

Common Defects

Solder Beading

Solder beading means you see tiny balls of solder near a part. These beads are usually close to chip resistors or capacitors. Solder beads show up when too much solder paste gets pushed out. If the oven heats up too quickly, the paste can pop and make beads. Solder beading can cause short circuits or make your board look messy.

How to spot solder beading:

-

Tiny round solder balls near the sides of parts

-

Beads show up after reflow, mostly with small parts

-

Boards with extra paste or fast heating have more beads

Component Cracking

Component cracking happens when parts break during Reflow Soldering. You might see cracks in ceramic capacitors or other weak parts. Cracks can form if the oven heats or cools too fast. Quick temperature changes put stress on the parts. If you use the wrong parts or ones with hidden problems, cracking gets worse.

Signs of component cracking:

-

You see cracks or chips on the outside of parts

-

Capacitors or resistors break after reflow

-

Parts do not pass electrical tests, or leak too much

Troubleshooting

Optimize Profile

You can stop many defects by setting the oven right. Heat and cool the oven slowly. Make sure the temperature goes up gently and does not shock the parts. Use a ramp-soak-spike profile for boards with sensitive parts. Check the time above the liquidus and the highest temperature for every batch. Use profiling tools to check the real temperature on your PCB.

Tip: Always test your oven settings with a sample board before you run a big batch.

Review Materials

Pick parts that can handle the heat of Reflow Soldering. Use components that are rated for the highest temperature you use. Check datasheets for heat limits and pick strong parts. Store parts in a dry place to keep out water. Look at the parts before you use them to find cracks or chips early.

|

Troubleshooting Step |

What You Should Do |

|---|---|

|

Profile Adjustment |

Heat and cool slowly, test with samples |

|

Material Selection |

Use heat-safe parts, check datasheets |

|

Inspection |

Look for cracks before and after reflow |

|

Storage |

Keep parts dry and away from water |

You can lower the chance of soldering and cracking by controlling your process and picking the right parts. Careful checks and good heat control help you build strong, reliable PCBs.

Inspection and Quality Control

Quality control helps you catch problems before they reach your customers. You need to check every step in your process to make sure your PCBs work well. Good inspection and monitoring help you avoid costly mistakes and keep your assembly line running smoothly.

Solder Paste Inspection

Solder paste inspection (SPI) checks the amount and placement of solder paste on your boards. You use SPI machines to scan each pad after printing. These machines measure the height, area, and shape of the paste. If you find too much or too little paste, you can fix it before moving to the next step.

Why SPI matters:

-

You catch printing errors early.

-

You lower the risk of solder bridging or open joints.

-

You save time and money by fixing problems right away.

Tip: Always check your SPI results before starting Reflow Soldering. This step helps you avoid many common defects.

AOI and X-ray

Automated Optical Inspection (AOI) uses cameras to look for defects after soldering. AOI checks for missing parts, wrong placements, and bad solder joints. You can set up AOI to scan every board or just a sample from each batch.

X-ray inspection lets you see inside solder joints. You use X-rays to find hidden problems like voids, head-in-pillow, or poor connections under BGAs. X-rays are very helpful for complex boards where you cannot see every joint.

|

Inspection Method |

What It Finds |

When To Use It |

|---|---|---|

|

AOI |

Missing parts, misalignment, solder bridges |

After soldering |

|

X-ray |

Voids, hidden defects, BGA issues |

For complex or hidden joints |

AOI and X-ray help you catch problems that you might miss with your eyes alone.

Process Monitoring

You need to watch your process all the time. Use sensors and software to track oven temperature, conveyor speed, and humidity. Set up alarms to warn you if something goes wrong. Keep records of your process data so you can spot trends and fix issues before they get worse.

Key things to monitor:

-

Oven temperature profile

-

Conveyor speed and vibration

-

Solder paste storage conditions

You can use control charts to track changes over time. If you see a problem, stop the line and fix it right away. Regular monitoring helps you keep your Reflow Soldering process stable and your boards reliable.

Good inspection and process control help you build strong, high-quality PCBs every time.

Maintenance and Prevention

Keeping your reflow oven in good shape helps you avoid many problems. You can prevent most faults by following a simple routine. You should focus on cleaning, calibration, and staff training. These steps help you keep your process stable and your PCBs reliable.

Regular Cleaning

Dust, flux, and solder paste can build up inside your oven. If you let dirt stay, it can block airflow and cause uneven heating. You should clean the oven chamber, fans, and conveyor often. Use a soft brush or vacuum to remove loose particles. Wipe down surfaces with a lint-free cloth. Clean nozzles and filters to keep air moving well.

Tip: Set a cleaning schedule for your team. Clean the oven at the end of each shift or at least once a week.

A clean oven helps you get better results in Reflow Soldering. You lower the risk of cold solder joints and other defects. You also make your equipment last longer.

Calibration

Oven calibration makes sure your temperature readings stay accurate. You should check thermocouples and sensors every month. Use a profiling tool to measure the real temperature on your PCB. Compare these numbers to the oven display. If you see a difference, adjust the settings or replace faulty sensors.

Here is a simple calibration checklist:

-

Check all temperature zones with a profiling tool.

-

Compare readings to oven controls.

-

Adjust settings if needed.

-

Replace sensors that do not match.

-

Record calibration results in a logbook.

Note: Regular calibration helps you keep a stable process. You catch problems early and avoid costly rework.

Staff Training

Your team needs to know how to use and care for the oven. Train staff to spot common faults and follow cleaning routines. Teach them how to run calibration checks and use inspection tools. Show them how to handle solder paste and set up the oven for each job.

|

Training Topic |

Why It Matters |

|---|---|

|

Cleaning procedures |

Prevents dirt and defects |

|

Calibration steps |

Keeps temperature accurate |

|

Fault recognition |

Stops problems early |

|

Safe handling |

Protects equipment and boards |

You should hold training sessions every few months. Give your team clear instructions and check their skills. Well-trained staff help you keep your Reflow Soldering process smooth and reliable.

Emoji: 🛠️ Regular care and training build strong, high-quality PCBs.

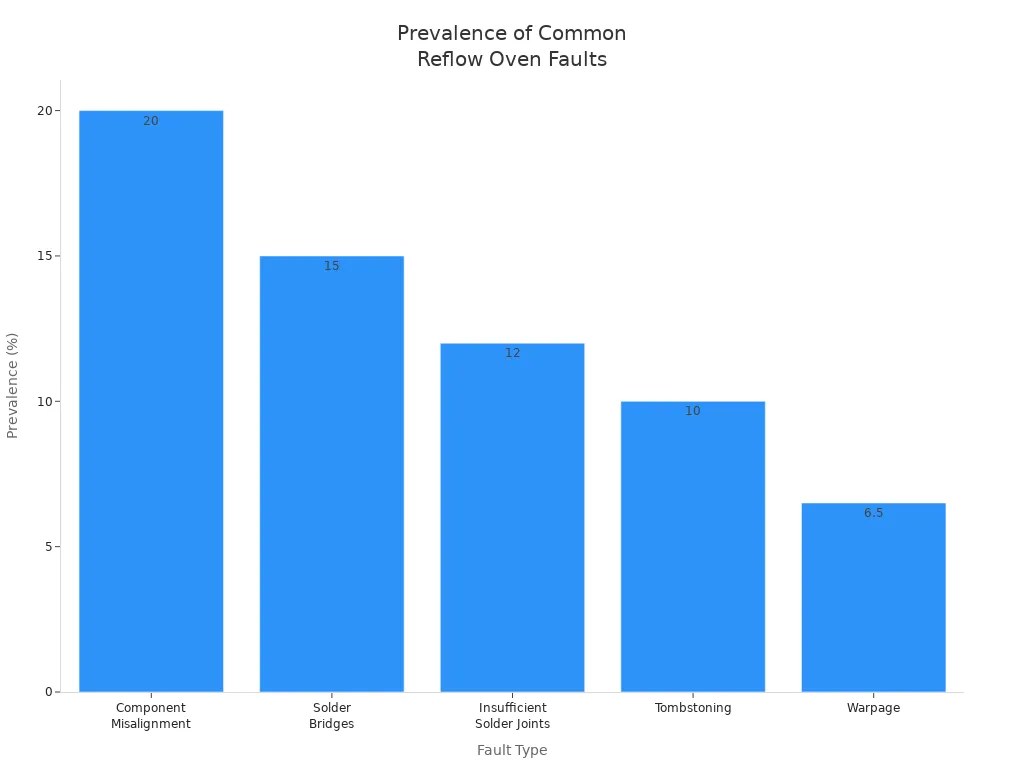

You can see many problems in reflow ovens. Some common faults are solder bridges, tombstoning, misalignment, and not enough solder joints. These issues slow down your work and make PCBs worse. The table below shows how often these problems happen and what they do:

|

Common Faults |

Description |

Industry Prevalence |

Impact on Assembly |

|---|---|---|---|

|

Solder Bridges |

Unintended solder connections are causing shorts |

~15% |

Short circuits, failures |

|

Tombstoning |

Component lifts during reflow |

~10% |

Poor electrical contact |

|

Component Misalignment |

Parts shifted during placement or reflow |

~20% |

Weak or failed connections |

|

Insufficient Solder Joints |

Too little solder applied |

~12% |

Weak joints |

|

Warpage |

PCB or component deformation |

5-8% |

Misalignment, cracked joints |

You can stop most faults if you follow simple steps. Clean the oven and fans every week. Calibrate the temperature zones once a month. Check the solder paste and parts before you use them. Watch the conveyor speed and shaking. Teach your team how to spot problems.

-

Clean oven chambers and fans every week

-

Calibrate temperature zones every month

-

Check the solder paste and parts before using

-

Watch conveyor speed and vibration

-

Train staff to spot faults

Good Reflow Soldering makes PCBs better and keeps work fast. Using data helps you fix problems before they get worse.

FAQ

What is the most common reflow oven fault?

You often see uneven heating. This problem causes weak solder joints and defects. You should check heaters and fans often to keep the oven working well.

How can you prevent solder bridging?

You can use the right stencil thickness and control solder paste volume. Clean your PCB before printing. AOI helps you catch bridges early.

Why does tombstoning happen during reflow?

Tombstoning happens when pads heat unevenly. One side melts first and lifts the part. You can fix this by balancing the pad design and oven temperature.

What should you do if you find cold solder joints?

Raise the oven temperature. Use fresh solder paste. Clean pads before assembly. These steps help you get strong, shiny solder joints.

How often should you calibrate your reflow oven?

You should calibrate your oven every month. Use a profiling tool to check temperature zones. Record results in a logbook for better process control.

Can you use expired solder paste?

No, you should not use expired solder paste. Old paste causes weak joints and defects. Always check the expiry date before use.

What tools help you inspect solder joints?

You can use AOI for surface checks and X-ray for hidden defects. SPI machines help you measure solder paste before reflow.

How does cleaning affect oven performance?

Regular cleaning removes dust and flux. Clean ovens heat evenly and last longer. Set a cleaning schedule for your team to keep quality high.