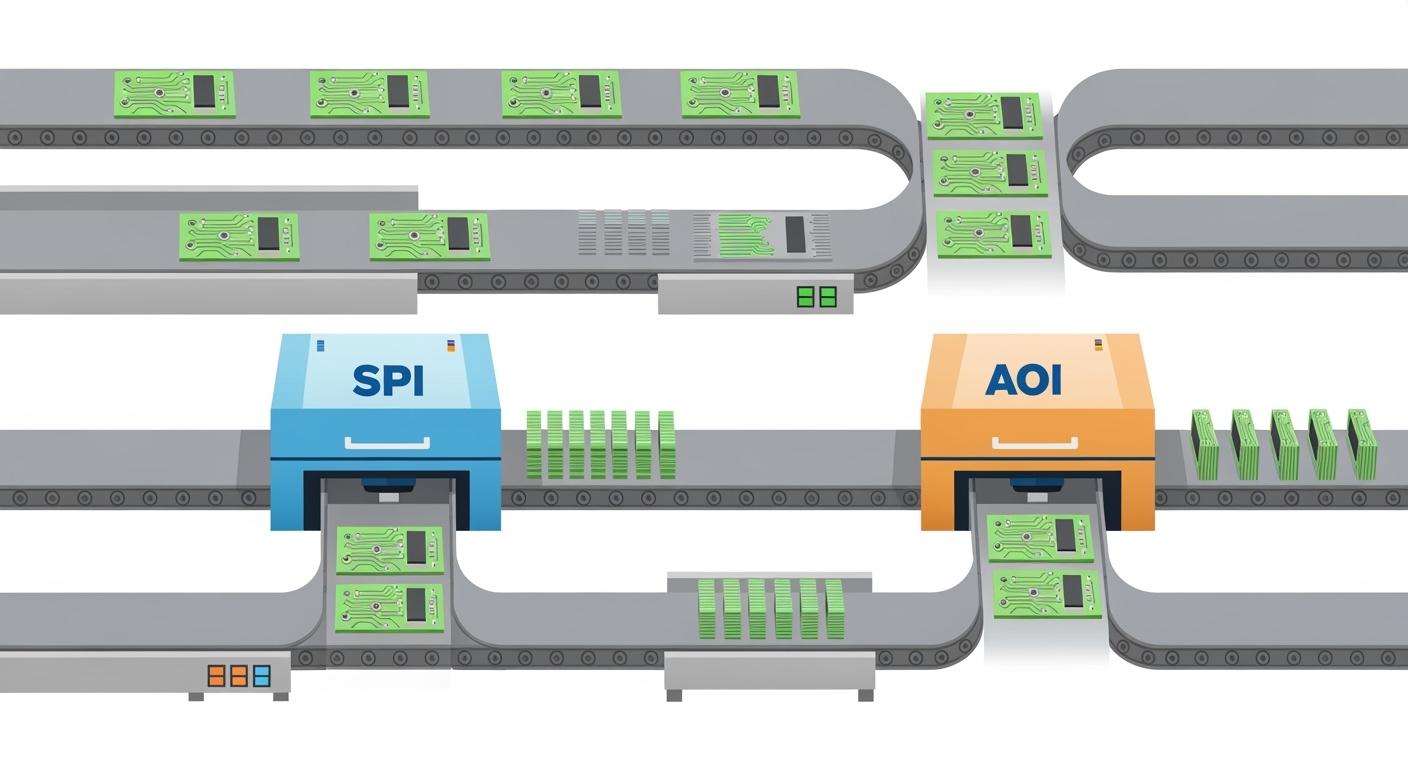

You can find the right buffer conveyor capacity for AOI and SPI bottlenecks by looking at how things move at inspection stations. If you make the buffer conveyor the right size, you stop production from stopping and keep your SMT line working well. Buffer conveyors hold printed circuit boards when inspection gets slow, so the line keeps going and works better. S&M gives good SMT solutions, like the advanced Nitrogen reflow oven, to help you get steady and high-quality results.

Key Takeaways

Pick the right buffer conveyor size to stop production from pausing and keep the SMT line running well.

Watch inspection cycle times to make sure your buffer conveyor can move PCBs without slowing down.

Use live data to change buffer sizes when production needs change, so things stay fast and good.

Match the speeds before and after to help PCBs move better and lower mistakes in inspection.

Use buffer systems that can change for new inspection needs and different production speeds.

Buffer conveyor impact on spi and solder paste inspection

Effects of insufficient buffer conveyor capacity

You need the right buffer conveyor so your spi and solder paste inspection stations work well. If your buffer conveyor is too small, your smt line will have problems. The process can stop if spi or solder paste inspection gets slow. This makes pcb placement stop, and you lose time making products. If the buffer conveyor cannot hold enough pcbs, the machines before it must stop. This causes a bottleneck in your surface mount technology process. You might see more defects because the inspection gets rushed. It becomes harder to find problems, and you might miss them.

Tip: Always check how long spi and solder paste inspection takes so your buffer conveyor is the right size.

Impact of Buffer Conveyor Sizing | Description |

|---|---|

Absorption of Short Stops | Buffers stop small problems from spreading through the line and help prevent bottlenecks. |

Prevention of Material Backup | The right size stops material from piling up, which can block machines before and after. |

Recovery from Interruptions | Good buffer size helps the line start again quickly after a stop and keeps things moving. |

Effects of excessive buffer conveyor capacity

If your buffer conveyor is too big, you waste space in your smt line. Too much buffer conveyor space makes it harder to control pcb flow. You might see pcbs waiting longer at spi and solder paste inspection. This can slow down placement and make production less efficient. Big buffers can also hide problems, so you may not see defects early. You need to balance buffer conveyor size for the best smt line.

Benefit | Explanation |

|---|---|

Accumulation systems let work keep going during slow times, so you make more products. | |

Maximized Line Uptime | These systems keep things running, so you have less downtime and better efficiency. |

Lower Maintenance Expenses | Good systems break less and need less fixing, so you save money and have fewer stops. |

Production efficiency at inspection stations

The right buffer conveyor helps spi and solder paste inspection stations work better. The buffer conveyor keeps the placement process moving, even if inspection slows down. This keeps your pcb line balanced. You can use advanced spi systems to get real-time data and change your process. S&M’s Nitrogen reflow oven works with buffer conveyors for high-volume production and fewer defects. You find more defects and have fewer stops. This means better quality and more reliable pcb placement. When you make your buffer conveyor the right size, you improve every part of your smt process.

Calculating buffer conveyor capacity for inspection

Identifying spi cycle times and throughput

You need to know how fast your spi station works before you size your buffer conveyor. The cycle time tells you how long spi takes to inspect each pcb. You can measure print time and clean time for solder paste inspection. For example, a print time of 10 seconds and a clean time of 30 seconds gives you a total of 50 seconds for 2 pcbs. This means your line rate is 25 seconds per pcb. If you clean the stencil after 4 pcbs, your rate improves to 17.5 seconds per pcb. You get a throughput increase of 30 percent. You must track these times to understand how many pcbs move through spi and solder paste inspection. You can use advanced spi systems to collect real-time data and see how your process changes. This helps you spot defects and improve production efficiency.

Tip: Write down your spi cycle times for each shift. You can see if your process slows down and fix problems early.

Assessing upstream and downstream speeds

You must check how fast machines before and after spi work. The upstream speed shows how quickly placement machines send pcbs to spi. The downstream speed tells you how fast the next station takes pcbs after inspection. If upstream placement speed is faster than spi, you need a buffer conveyor to hold pcbs. If downstream machines run slower, you must adjust your buffer size. You can use offline spi to inspect pcbs away from the main line. This helps you balance speeds and avoid bottlenecks. You must look at placement speed, solder paste inspection time, and how many pcbs each station handles. You can use real-time data to track these speeds and make changes for process optimization.

Note: You must match the speeds of all stations. If one station is slower, your buffer conveyor must hold enough pcbs to keep production moving.

Optimal buffer size formulas

You can use formulas to find the best buffer conveyor size for your inspection stations. You must know the capacity, speed, and size of your pcbs. You can use the throughput calculation formula:

Where:

Q is the capacity

ρ is the average density of the conveyed material

A is the cross-sectional area of the item

v is the belt speed

You can also use the conveyor speed formula:

Where:

S is the speed

LP is the length of product

ZL is the length of zone (gap between products)

PPM is products per minute

Variable | Description | Units |

|---|---|---|

Q | Capacity | kg/s or lb/s |

ρ | Average density of the conveyed material | kg/m³ or lb/ft³ |

A | Cross-sectional area of the item | m² or ft² |

v | Belt speed | m/s or ft/s |

Variable | Description | Units |

|---|---|---|

S | Speed | fpm |

LP | Length of product | ft |

ZL | Length of zone (gap between products) | ft |

PPM | Products per minute | – |

You must use these formulas to set your buffer conveyor for spi and solder paste inspection. You can adjust the buffer size if you change your pcb or placement speed. You can use defect classification to see how many defects you find at each station. You must check your buffer conveyor often to keep your smt line balanced. S&M’s Nitrogen reflow oven works with your buffer conveyor for high-volume production. You get better defect detection and process integration. You can optimize your production process and improve efficiency. You must use process optimization to keep your surface mount technology line running well.

Tip: Use these formulas to check your buffer size every month. You can spot problems before they cause stops in pcb manufacturing.

Real-world examples with S&M solutions

High-mix production line buffer sizing

In a high-mix SMT line, you see many pcb types. You change products often. You need to make sure your buffer conveyor fits different inspection times. You write down each pcb and how long inspection takes. You see that placement speed is not always the same. You set your buffer conveyor to hold enough pcbs when inspection is slow. You use real-time data to count waiting pcbs at inspection. You change the buffer conveyor if you find defects or things slow down. You make production better by keeping placement and inspection balanced. You use S&M’s buffer conveyor and Nitrogen reflow oven to help your line stay flexible. You find problems early and stop the line from stopping too much.

Tip: Make a table to list pcb types, inspection times, and placement speed. This helps you find bottlenecks and make your process better.

PCB Type | Inspection Time (sec) | Placement Speed (PPM) | Buffer Capacity |

|---|---|---|---|

A | 15 | 4 | 8 |

B | 20 | 3 | 10 |

C | 12 | 5 | 6 |

High-volume line buffer sizing

In a high-volume line, you see lots of pcbs move fast. You need to size your buffer conveyor for quick work. You check how fast placement and inspection go. You set your buffer conveyor to hold enough pcbs during short stops. You use S&M’s Nitrogen reflow oven for big jobs. You look at real-time data to see if defects go up. You change buffer conveyor size to keep things moving. You get better at finding defects and making the process work well. You keep your SMT line running smoothly and stop it from being down too long.

Note: Always check buffer conveyor size after you change your process. This keeps your SMT line working well and helps production.

Avoiding common buffer conveyor mistakes

Process variability and line balancing

SMT production has many challenges. One big mistake is not thinking about process changes. Machines and people work at different speeds. This makes pcb boards move faster or slower. If you do not plan for this, your buffer conveyor can get too full or empty. Then, inspection cannot keep up and defects may go up. You need to make sure each part of the line works together. Watch real-time data to see how many pcb boards wait at inspection. Change your buffer conveyor if you see slow spots or backups. This keeps production running well and helps you find defects early. S&M’s tools help you handle changes fast. Their equipment lets you adjust quickly and keeps your smt line balanced.

Tip: Write down placement speed and inspection times every day. This helps you find problems before they stop your line.

Scalability and future-proofing

Think about the future when you set up your buffer conveyor. Many people forget to plan for changes in smt production. If you add new pcb types or make more boards, your buffer conveyor must hold more. If you do not plan, you might see more defects or slower inspection. Pick buffer conveyors that you can make bigger or change. S&M has modular systems that grow with your needs. Their conveyors work with advanced inspection and placement machines. This helps you keep up with new jobs and keep pcb manufacturing working well. You protect your money and keep your line ready for new things.

Common Mistake | How to Avoid It |

|---|---|

Ignoring process variability | Watch real-time data and change buffers |

Not planning for scalability | Use modular conveyors from S&M |

Overlooking line balancing | Match placement and inspection speeds |

Remember: Good planning and the right tools help you stop defects and keep your smt line running well.

Adjusting buffer conveyor capacity in dynamic environments

Scaling buffer conveyors for changing needs

You need your smt line to stay flexible. Production changes a lot. You see new pcb types and different speeds. Buffer conveyors must grow with your process. S&M’s modular systems help you change buffer size fast. You can add or take away units as production gets bigger. Automation helps keep production moving without stopping. Buffers go in important spots to stop jams and help more pcbs move. Flexible scheduling lets you handle rush orders. You keep production working well and save money.

Method | Description |

|---|---|

Automation | Automated buffering systems help avoid downtime and maintain continuous production cycles. |

Flexible Scheduling | Buffers allow for adjustments in production schedules, accommodating rush orders without halting the line. |

Buffer Placement | Strategic placement of buffers at key points prevents jams and supports higher throughput. |

You make processes work better and get more done.

You spend less time looking for materials.

You help production stay smooth and reliable.

Tip: Use real-time data to watch placement speed and pcb flow. Change buffer conveyors when production changes.

Adapting to new inspection requirements

You must change buffer conveyors when inspection needs change. Inline spi and advanced inspection systems need different buffer sizes. S&M’s modular pcb buffer system lets you make storage bigger easily. You change buffer units to hold more or fewer pcbs as needed. You change the speed and store boards to stop production from stopping. You make things work better and help find defects. You keep your smt line ready for new inspection tools and ways. You find fewer defects and make pcb manufacturing better.

Modular buffer units make expansion easy.

Adjustable storage holds different numbers of pcbs.

Buffers change speed and store boards to stop stoppages.

Note: Check buffer conveyor size often. Change it when you add new inspection systems or see more defects. This keeps your smt line balanced and helps production work better.

You can make your smt line better by using simple steps for buffer conveyor size at inspection spots. First, look closely at your pcb process. Use real numbers from your work to pick the right buffer size for inspection and placement. S&M’s Nitrogen reflow oven helps your smt process stay steady and work well. Always check your smt line when production changes. Try these easy steps:

Look at your smt line to find the best places for pcb to wait.

Pick buffer sizes using real inspection and production numbers.

Teach your team about the smt system and how to place parts.

Watch how your smt line and inspection are doing.

Take care of your pcb systems so production and placement stay smooth.

This way, your inspection, smt, pcb, process, production, and placement all work together for better results.

FAQ

How do you decide the right buffer conveyor size for AOI/SPI?

You check the inspection cycle times and the speed of machines before and after the inspection station. Use real numbers from your line to set the buffer size.

What happens if you use a buffer conveyor that is too small?

You see production stops and bottlenecks. Machines before the inspection station must wait. You may miss defects because inspection gets rushed.

Can you change buffer conveyor size as your production grows?

Yes. You use modular buffer conveyors from S&M. Add or remove units to match new PCB types or higher production rates.

Why does S&M recommend real-time data for buffer sizing?

Real-time data helps you spot slow spots and backups. You adjust buffer size quickly. This keeps your SMT line balanced and efficient.

How does the Nitrogen reflow oven help with buffer conveyor integration?

The Nitrogen reflow oven from S&M works with buffer conveyors for steady production. You get fewer defects and better quality. The oven supports high-volume and high-mix lines.