Selecting the right Selective Wave Soldering Machine for mixed PCB assembly can seem hard. You need to think about a few important things:

- PCB size and layout

- Production volume

- Types of components

- Automation level

- Solder alloy compatibility

Manufacturers often face problems like solder waste and thermal stress. They also see defects like solder balls or holes that do not fill well. Using both SMT and through-hole parts brings more process and heat control problems. Picking machine features that fit your needs helps you avoid these issues and lets you grow in the future.

Key Takeaways

- Think about your PCB size and layout before picking a soldering machine. Make sure the machine fits your biggest board. This helps you avoid delays in making products.

- Look at how many boards you need to make. Wave soldering works best for big groups of boards. Selective soldering is better for small batches or test boards.

- Make sure the solder alloys work with your machine. The right alloy stops problems and makes strong solder joints.

- Find machines with automation features. Automation helps stop mistakes and makes work faster. It also helps you finish more boards quickly.

- Choose machines with good technical support and maintenance. Good support helps you fix problems fast. It keeps your machine working well.

PCB & Production Needs

Board Size

When picking a Selective Wave Soldering Machine, look at your PCB size. The machine should fit your biggest board. If the board is too large, it might bend or move during soldering. Most machines can handle panels up to 300 mm by 400 mm. Automated machines can work with panels up to 350 mm by 450 mm. Smaller panels help lower thermal stress for lead-free soldering. SMT assembly can use panels up to 400 mm by 500 mm. Through-hole parts may need smaller boards.

Tip: Make sure your machine can handle your largest board. This helps you avoid delays in production.

Here is a quick chart showing common PCB sizes:

| PCB Size | Dimensions |

| —————- | —————————————————————————————– |

| Minimum PCB size | L50mm W50mm |

| Maximum PCB size | Up to 500x500mm |

Production Volume

How much you make affects your machine choice. If you build many boards, wave soldering is a fast and efficient process. For small batches or test boards, selective soldering is more exact.

- Wave soldering is best for big jobs.

- Selective soldering works well for small runs or samples.

Consider what you need now and in the future. If you plan to grow, pick a machine that can handle more work.

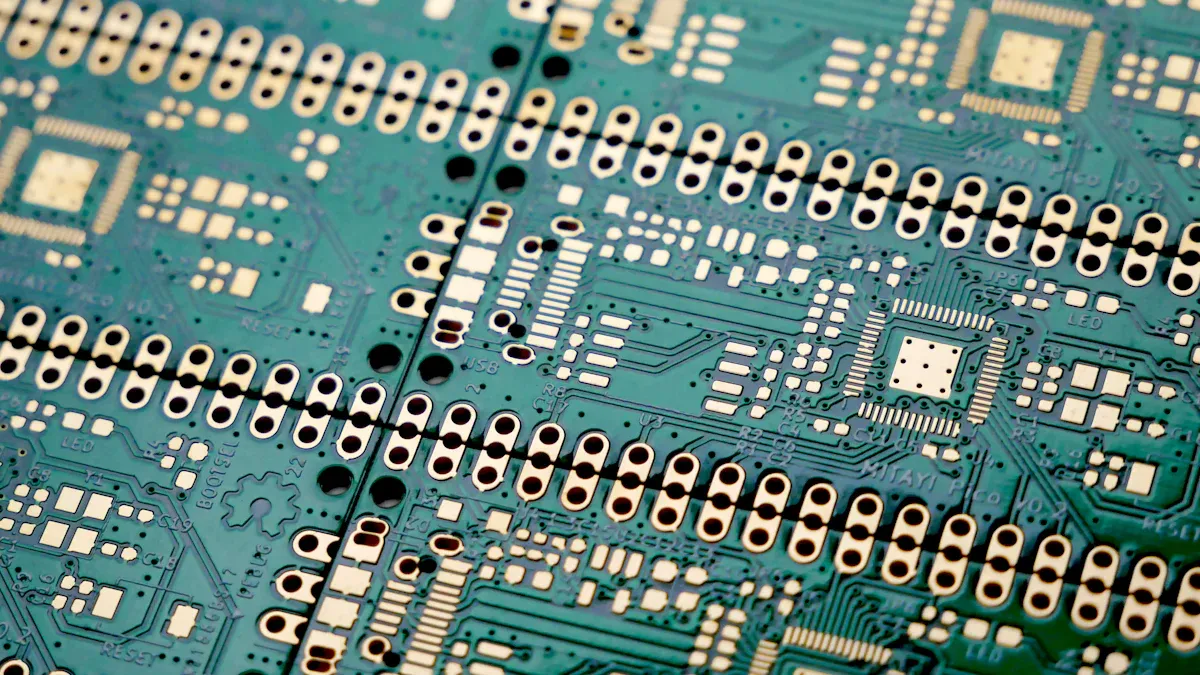

Component Types

Mixed PCB assemblies use both SMT and through-hole parts. First, SMT parts are soldered with reflow. Next, selective soldering is used for through-hole pieces. The machine must hit certain spots and not mess up other solder joints.

Note: Machines should be programmable and accurate for different PCB designs.

Managing heat is important. SMT and through-hole parts need different heat levels. If heat is not controlled, parts can break or wear out quickly. Selective soldering is good for boards with lots of parts. It can solder through-hole connectors at high heat and keep nearby SMT parts safe.

Soldering Process & Flexibility

Solder Alloy Compatibility

You should check what solder alloys your machine can use. Different alloys are good for different jobs. Some machines only work with lead-free solder. Others can use both lead-free and tin-lead solder. If you use both, you need to watch the temperature. Mixing lead and lead-free can make the flux turn into vapor. This can cause empty spaces in the solder joint. Some parts may break if the heat is too high. Using the wrong temperature can hurt your assembly.

Here is a table that shows common solder alloys and how they are used:

| Alloy Type | Composition | Common Use in Electronics |

| —————– | ———– | ———————————— |

| Tin-Copper | Sn-Cu | Cheap and makes strong solder joints |

| Tin-Silver-Copper | Sn-Ag-Cu | Used for high-performance jobs |

| Tin-Bismuth | Sn-Bi | Used for special jobs |

| Tin-Zinc | Sn-Zn | Not used much for special needs |

Lead-free solder melts at a higher temperature than tin-lead solder. SAC alloy (Tin-Silver-Copper) can melt at 217°C. Some solders need more than 230°C to melt. Pick a machine that works with your solder alloy. Make sure it keeps your parts safe.

Tip: Always check your parts’ temperature limits before you pick a solder alloy.

Nozzle & Preheating Options

Nozzle options help you solder boards with many parts. You can set the nozzle to hit only the spots you want. This keeps other parts safe and stops extra heat. If your board has tight spaces or mixed parts, nozzle flexibility is very important.

Preheating is also important. It helps the flux clean the metal and makes solder flow better. Preheating warms the board slowly. This stops thermal shock, which can hurt sensitive parts like BGAs and SMDs. Preheating lets gases in the solder paste escape slowly. This stops splatter and helps make strong solder joints.

- The machine slowly heats the board to a safe level.

- It keeps the board at this temperature so it heats evenly.

- Soldering starts, and the joints are better because of preheating.

Note: Good preheating and nozzle control help you stop defects and make your mixed PCB assemblies work better.

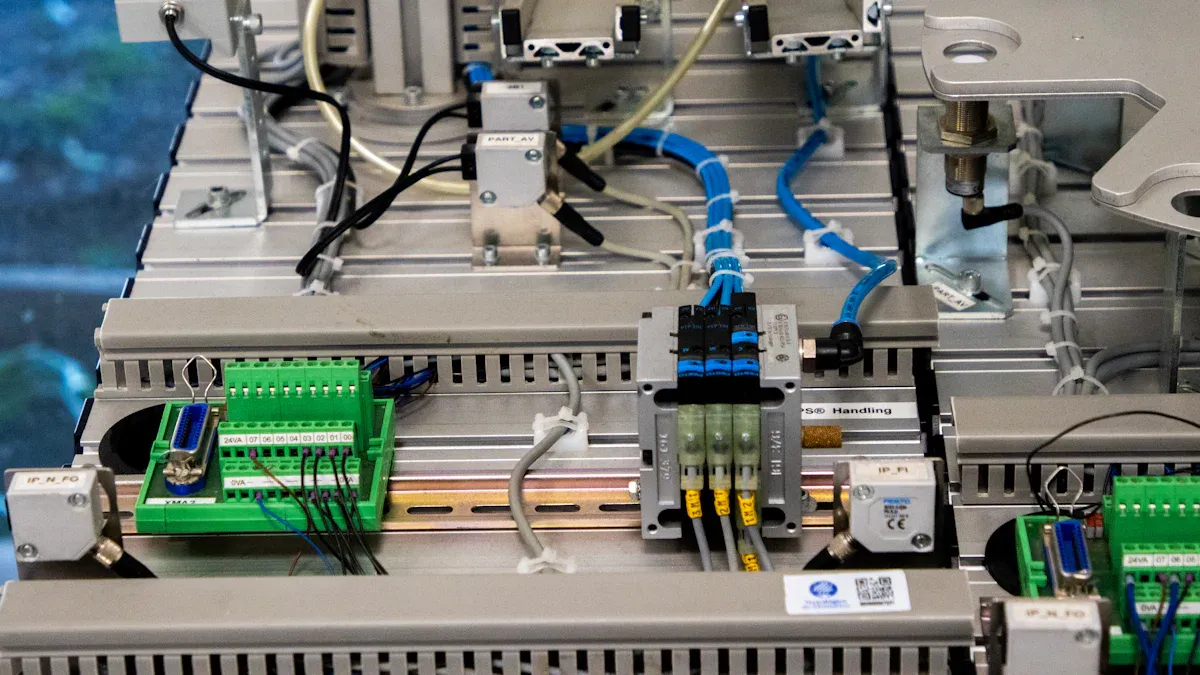

Selective Wave Soldering Machine Features

Automation & Control

Automation makes building electronics easier and faster. When you use a Selective Wave Soldering Machine with smart automation, you get better results. The machine only sells the spots that need it. This keeps other parts safe and stops waste. You can set up the machine using Gerber data. This helps you get accurate soldering every time.

- Automation lets you set the time and heat for each joint.

- You do not have to change the machine by hand as much. This means fewer mistakes.

- Mini-wave or laser soldering heads are very precise. They can reach small spaces and tricky designs.

- Real-time monitoring helps you find problems quickly. The machine can stay accurate within ±0.05 mm.

Tip: Automated control helps you make more boards faster. You also get fewer mistakes and less fixing.

New machines are getting smarter. Many use IoT and keep records of what happens. You can check solder temperature and flux levels. This helps you spot problems fast and keep track of quality checks. The table below shows how watching the process and saving data helps you:

| Feature | Impact on Quality Assurance |

| —————— | ———————————————————————————————————————————————————————————————————- |

| Process Monitoring | Gives you real-time feedback on solder temperature and flux levels. Helps you spot defects. |

| Data Logging | Saves process details for traceability and compliance. Important for regulated industries. |

If you want to follow new rules and be eco-friendly, pick machines that work with lead-free solder and have flexible settings. Custom systems let you change jobs quickly. This saves you time and money.

Safety & Integration

Safety is important in every factory. You need a Selective Wave Soldering Machine that keeps workers and boards safe. New machines protect electronics from dust and water. This helps your boards last longer.

- Always wear goggles and gloves near soldering machines.

- Keep your work area neat and clean. This helps stop accidents.

- Use machines that meet safety rules. Check them often to make sure they work well.

Note: Good safety features keep your team and products safe. They also help you follow factory rules.

Integration means your machine fits with your other equipment. You want your Selective Wave Soldering Machine to work with your current line. Many machines can handle both SMT and through-hole parts at the same time. This is good for complex boards.

| Key Benefits | Description |

| ————————— | ————————————————————————————— |

| High-speed soldering | Let’s you build more boards faster. |

| Uniform solder application | Make sure every joint looks and works the same. |

| Reduces manual intervention | Less handwork means fewer mistakes. |

You might have problems when you add a new machine. Sometimes, it does not work with your old equipment. You need trained workers to use new machines. Adding new systems can be hard, but it helps you make more boards.

| Integration Challenge | Description |

| ————————————————————————————————— | ————————————————- |

| Compatibility Issues | It may not work well with older equipment. |

| Need for Skilled Operators | Workers must learn new skills to run the machine. |

| Complexity of Integration | Adding new systems can be hard and take time. |

Tip: Plan your upgrades and train your team. This makes adding new machines easier and helps you get the best results.

When you pick a Selective Wave Soldering Machine, look for features that help you now and later. Automation, safety, and easy integration help you build better boards and keep your line working well.

Support & Scalability

Technical Support

You need good technical support when using a Selective Wave Soldering Machine. Fast help lets you fix problems quickly and keeps your work going. Top companies give strong support, quick fixes, and easy care. They help with setup, repairs, and training. Many companies give a one-year warranty for parts and labor if there are defects. If something breaks, you get repairs or new parts for free.

| Warranty Duration | Coverage | Support Provided |

| ————————————————- | —————————————– | ———————————————– |

| 1 year | Parts and labor for manufacturing defects | Repair services or replacement parts at no cost |

You also get after-sales service, all-day technical help, and expert training. These services help you avoid mistakes and keep your machine running well.

| Service Type | Description |

| ———————— | ———————————————————– |

| After-Sales Service | Experts help set up and keep your machine working its best. |

| Technical Support | You can get help any time, day or night. |

| Parts and Repair Service | You get fast help with spare parts and repairs. |

| User Training | Training helps workers learn and make fewer mistakes. |

Tip: Getting spare parts and help fast keeps your line working and stops long delays.

Maintenance & Upgrades

Doing regular maintenance keeps your machine working well and your boards free from problems. You should check settings, adjust conveyors and nozzles, and watch heat levels. New software tools help you track important settings and keep your process strong.

| Maintenance Requirement | Description |

| ——————————————————————————————————————————————————————— | ———————————————————— |

| Regular Preventive Maintenance | Stops problems before they start and keeps machines working. |

| Monitoring of Machine Parameters | Helps keep the process steady and stops mistakes. |

| Calibration of Conveyor and Nozzles | Make sure everything lines up, and soldering is always good. |

| Control of Thermal and Mechanical Parameters | Keeps heat and movement in safe ranges for better soldering. |

| Use of Advanced Software Tools | Let’s you watch key settings and keep the process strong. |

You should think about growing in the future. Modular machines let you add new parts or make more boards by buying extra modules. Upgrades help you meet new needs and make your machine last longer. New automation makes work faster and more exact. Machines that can handle more boards and change easily help you grow as your business gets bigger.

| Feature | Benefit |

| ————————————————————————————————————————————- | ——————————————— |

| Modular Design | Lets you add new parts to make more boards. |

| Adaptability | Let’s you change how you build boards easily. |

| Lifespan Extension | New designs help machines last longer. |

- Selective wave soldering machines can work for small or big jobs.

- Automated soldering helps stop mistakes and keeps quality high.

- Fast machines help you finish more boards and handle hard jobs.

Note: Planning for upgrades and doing regular checks helps you get ready for new jobs and keeps your work strong.

Picking the right Selective Wave Soldering Machine helps you reach your goals. It also helps you avoid problems during assembly. You should pay attention to some important things:

| Criteria | Description |

| ———————————————————————————————————- | ——————————————————————- |

| Production volume | Choose if you want in-line or batch processing. |

| Board complexity | Look at board sizes and mixed-technology needs. |

| Process flexibility | Make sure the system works with different alloys and nozzle setups. |

| Automation level | Search for automatic cleaning and monitoring features. |

| Software capabilities | Pick controls that are easy to use and allow offline programming. |

| Maintenance and support | Check if spare parts and help are easy to get. |

| Future scalability | Choose a system that can grow as your business grows. |

Using these criteria helps you think about more than just price. You can look at technical needs, environmental needs, and support needs. This helps you get good value and strong results for a long time.

FAQ

What is the main benefit of selective wave soldering for mixed PCB assembly?

You can solder through-hole parts very accurately. This does not hurt the SMT components nearby. The process helps you make fewer mistakes. Your boards will be better and last longer.

How do you choose the right nozzle size for your boards?

Pick a nozzle that fits your pad and part layout. Small nozzles are good for tight spots. Big nozzles work for large joints. Always look at your board design before you pick.

Can you use both lead-free and tin-lead solder in one machine?

Some machines let you use both types of solder. You need to clean the machine when you switch alloys. This stops the soldiers from mixing. Always check what your machine can do before you start.

What maintenance tasks keep your selective soldering machine running well?

Clean your machine often and check the nozzles for problems. Update the software when needed. Make sure the conveyor is straight. Watch the temperature settings to keep things safe.

How does automation improve your soldering process?

Automation lets you set up soldering paths and control heat. This saves time and cuts down on mistakes. You get the same good results every time with less handwork.