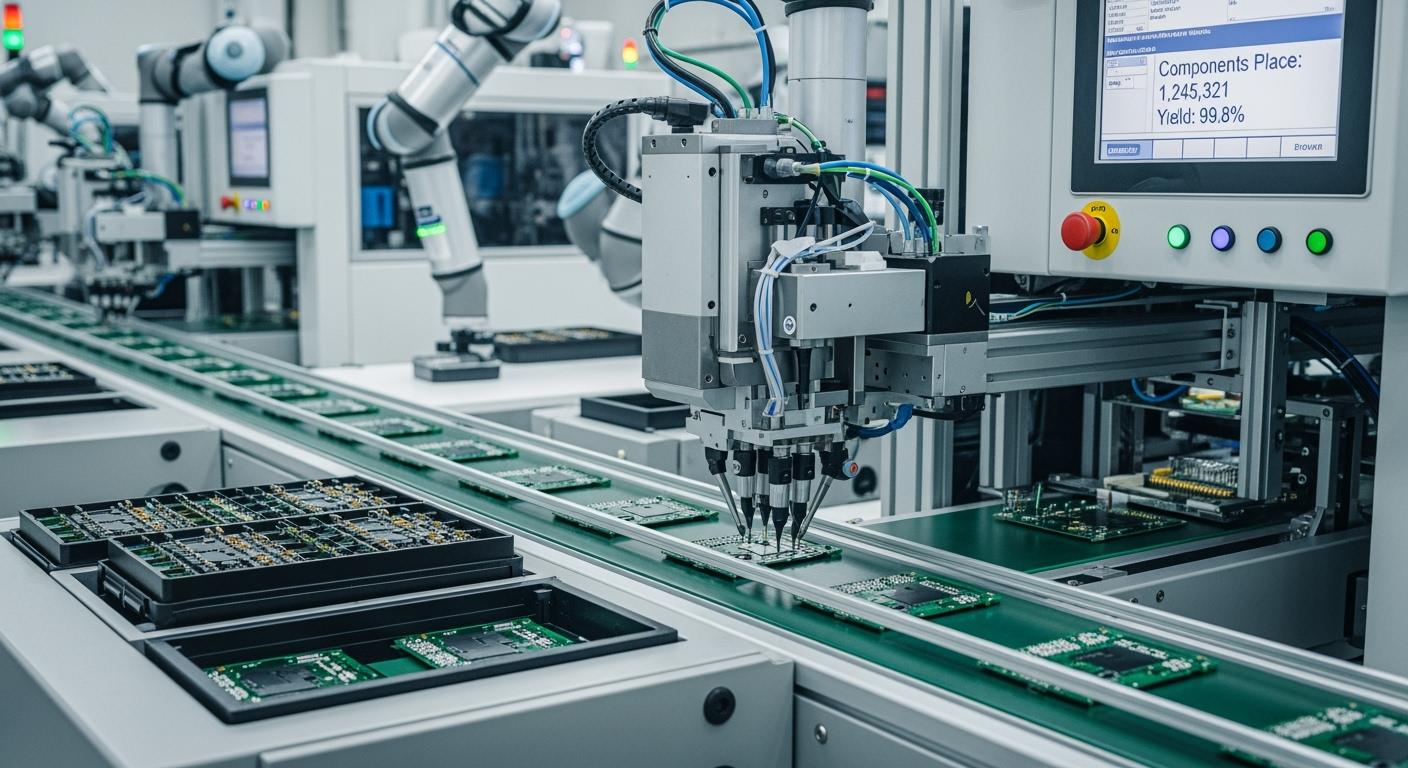

You want to get more good boards and make them faster. The right features help a lot. High-speed soldering and even solder use help you work better. Less manual work also makes things faster. AOI features check thousands of parts each minute. They find problems before they cause bad boards. Stencil printers and reflow ovens help you get the same good results over 95% of the time. S&M’s SMT Equipment has features that help you find more mistakes. These features also help you make more boards and keep quality steady. You get better results with features that help you be fast, careful, and steady.

Key Takeaways

High-speed soldering and automated inspection systems make work faster. They help find problems early. This means more good boards and less waste.

AI-powered placement and inspection tools cut down on mistakes. Factories can have up to 40% fewer errors. This saves money and makes better products.

Smart feeders move parts by themselves. This can make 30-40% more boards. They also help lower mistakes, so you can reach hard quality goals.

Real-time monitoring and predictive maintenance keep the SMT line working well. These tools help you find problems early. You can fix things before they break.

Flexible SMT line programming lets you change jobs fast. This helps keep good quality and speed, even with many board types.

Why Yield and Throughput Matter in SMT

Production Efficiency

You want your SMT assembly line to work well. Making more good boards in less time is important. High yield means you get more working boards from each batch. This helps you waste less and keeps things moving. When you work better, you save time and money. Many companies use real-time monitoring and data analytics now. These tools help you find problems fast and fix them quickly.

Here is a table that shows how companies improved yield and efficiency:

Case Study | Improvement Achieved | Yield Increase | Scrap Reduction |

|---|---|---|---|

Electronics Manufacturer | Optimized machine settings and quality controls | 20% | N/A |

Automotive Parts Supplier | Gained real-time visibility and process control | N/A | 25% |

You can see that better control and watching the process helps a lot. It leads to more good boards and less waste. That is why many companies buy high-speed SMT equipment. They want to make small devices and stay ahead of others.

Quality and Cost Impact

Good yield and high quality go together. If your SMT assembly line finds and fixes problems early, you save money. Automated inspection systems help you catch defects before they leave the line. This means you spend less on repairs and replacements.

Here are some key benefits you get from focusing on yield and quality:

Fewer defects escape (down by 85% in some cases)

First-pass yield can go from 92% to 98%

Rework costs can drop by up to 60%

100% traceability of defects to process steps

When you make better products, people trust you more. Customers know you give them good products. S&M helps you with advanced SMT solutions to reach these goals. The company uses smart manufacturing and automation to help you get the best yield and quality from your SMT assembly line.

AI-Powered SMT Equipment

Placement Accuracy

You want every part to land in the right spot on your board. AI-powered placement and inspection systems help you do this. These systems use smart cameras and algorithms to check each component as it moves. They spot mistakes before they become bigger problems. When you use AI-guided processes, you can see up to a 40% drop in placement errors compared to older methods.

Here is a table that shows how AI improves placement accuracy:

Findings | Description |

|---|---|

Error Reduction | Factories using AI-guided processes experienced a 40% decrease in mistakes. |

AI-powered placement and inspection tools also analyze live data. They adjust the process in real time. This means you get better results, even if your boards or parts change. If a part moves by just 0.05 mm, you could see 30% more soldering defects. Small mistakes can cost you a lot. Each 1 percent drop in yield can cost $70,000 a year for a machine that makes 7 million placements. You want to avoid these losses. S&M’s surface mount technology uses advanced AI to keep your smt line running with high accuracy.

Speed and Waste Reduction

You need your smt line to move fast and make less waste. AI-powered placement and inspection features help you reach this goal. These systems check for defects in milliseconds. You catch problems early and keep your line moving. Predictive maintenance tools use AI to watch for signs of trouble. They can cut downtime by up to 70%. You replace parts before they break, so you avoid costly stops.

AI-powered placement and inspection also help you use materials better. You throw away fewer boards and parts. This means you save money and boost throughput. S&M’s smt equipment gives you these smart tools. You get more good boards, faster, and with less waste.

Tip: Use AI-powered placement and inspection to spot trends and fix problems before they slow you down.

Smart Feeders in SMT Assembly Line

Automated Handling

You want your smt assembly line to work well and fast. Smart feeders help you do this. These feeders use machines to move parts quickly and correctly. When you use automated handling, you make more boards in less time. Many factories see output go up by 30-40% in just a few months. Defect rates drop to under 2%. This helps you reach tough quality goals. You also spend less on workers, sometimes saving over $100,000 each year in mid-size plants. Using machines means less waste and better energy use. Your smt process becomes kinder to the environment.

Benefit | Description |

|---|---|

Productivity Increase | Output goes up by 30-40% in the first months. |

Defect Rate Reduction | Defect rates drop below 2%. |

Annual Labor Savings | Plants can save over $100,000 each year. |

Improved Environmental Footprint | Less waste and lower energy use. |

Error Reduction

Smart feeders do more than just move parts around. They use sensors and watch things in real time to stop mistakes. You always know how many parts you have with real-time counting. The system tells you when it is time to refill. Batch and model checks stop mix-ups with materials. MES system uploads feeding data so you can track everything. These features cut errors by up to 30%. You spend less time fixing problems and more time making good boards.

Smart feeders with sensors help you change parts faster and get better first-pass yield.

Studies show smart feeders help you track parts and cut mistakes in smt assembly lines.

When you use S&M’s smart feeders, you get more good boards and work faster. Advanced THT AOI systems check every board to make sure it is good. This means less rework and your smt line keeps running well.

High-Resolution Vision Systems

Defect Detection

You want your smt line to find problems early. High-resolution vision systems help you spot defects fast and accurately. These systems use advanced cameras to check each board as it moves. You can see tiny mistakes that might cause short circuits or bad connections. This helps you avoid expensive repairs and keeps your products working well.

Vision systems in smt assembly can place parts within ±10 micrometers.

You lower the chance of defects like short circuits or connection problems.

Automated optical inspection helps you find issues right away and makes production faster.

The quality of your printed circuit boards is important for product reliability.

Finding defects quickly and accurately helps you stop failures.

When you use high-resolution vision systems, every board meets your standards. You can trust your smt process to give good results each time.

Solder Inspection

Solder inspection is an important step in smt production. You need to check every joint to make sure it is strong and clean. High-resolution vision systems let you see even tiny problems. These systems use special lenses and sensors to scan each solder joint.

Feature | Specification |

|---|---|

Minimum Resolution | 4 μm |

Repeatability (Height) | 0.4 μm |

Repeatability (Width) | 0.5 μm |

Each lead gets checked by itself, so you get clear results even on shiny surfaces. The system removes noise but keeps important data. You can inspect boards quickly, which works for hybrid assemblies and fast smt lines. Fast programming and easy setup help you keep your smt production moving.

You want to catch all defects and keep your inspection process strong. High-resolution vision systems help you do this. You get better yield, less waste, and more trust in your smt products.

Real-Time Analytics for SMT

Process Optimization

You want your smt line to work well every day. Real-time monitoring lets you see what is happening right now. You can find problems early and fix them fast. If there is a placement issue, you get an alert right away. You can act quickly and keep things moving.

A manager saw more placement errors on the dashboard. He fixed the issue fast and kept downtime short.

The dashboard showed a sudden change in the reflow oven. Quick action stopped the production from slowing down.

Real-time monitoring helps you see your smt process clearly. You can watch each step and make smart choices. Data analytics helps you find patterns and make your workflow better. When you pay close attention, you get more good boards and less waste. Your machines also work their best.

Predictive Maintenance

You want your smt equipment to last longer and work well. Predictive maintenance uses real-time monitoring and smart sensors to help you. You can see signs of trouble before machines break. If you notice placement quality drops, you know to check your equipment. You can plan repairs before bigger problems stop your line.

Machines working alone cannot spot failures early.

If placement quality gets worse, a problem may be coming.

When you connect data from different vendors, you can fix things before downtime.

IoT devices gather data for predictive maintenance in factories.

Analytics algorithms study old and new data to find problems early.

You use this information to plan repairs before breakdowns, so you avoid stops.

Real-time monitoring saves you money and time. You keep your smt line running strong. You get better results and fewer surprises.

Industry 4.0 and SMT Integration

Machine Communication

You want your smt assembly line to be smarter and faster. Industry 4.0 helps by letting machines and systems connect. When machines share information, you get updates right away. This gives you better control over your process. You can watch every step as it happens. This helps you spot problems early and keep things running well.

Industry 4.0 lets you control and check machines from far away. You can see your devices and make changes fast. Smart settings change to fit what you need. This makes your job easier and safer. Using data helps you make good choices. You can improve your work and stay ahead of others.

Here is a table that shows how machine communication helps your smt line:

Mechanism | Impact on User Experience and Operational Efficiency |

|---|---|

Predictive Models | Predicts defects with over 82% accuracy |

Proactive Maintenance | Increases uptime and reduces costs |

Automation | Minimizes errors and waste, improves speed |

Machines share data without stopping. This means you waste less time and make fewer mistakes. Your smt process gets more reliable and works better.

Adaptive Scheduling

You need your smt line to change fast when needed. Adaptive scheduling in industry 4.0 helps you do this. The system picks the best order for making products. This means you spend less time switching parts. It helps you avoid stops and keeps your line moving.

Smart scheduling uses lean ideas to cut waste. It helps you change reels less often and makes the process smooth. You can make more boards in less time. The system also helps you change fewer unique parts. This matches new smart manufacturing trends.

Here is a table that shows the benefits of adaptive scheduling:

Key Outcomes | Description |

|---|---|

Changeover Time | Only 1014 min for optimal product sequence |

Operational Efficiency | Less waste and better alignment with lean principles |

Part Change Minimization | Reduces downtime and supports smart manufacturing |

Industry 4.0 makes your smt line flexible and easy to change. You can handle new products and needs quickly. Machines work together, and you get the same good quality every time.

Tip: Use adaptive scheduling to keep your smt line fast and avoid stops.

Advanced Board Handling by S&M

Material Flow

You want your SMT line to move boards smoothly from one station to the next. S&M’s advanced board handling systems help you do this. These systems use smart conveyors and buffer units. You can keep your boards moving without stops or jams. This keeps your line running at top speed.

You get better results when you control material flow. Smart conveyors adjust speed to match each process. Dual buffer stockers hold boards when one machine needs more time. This means you avoid bottlenecks and downtime. You can handle high-mix or high-volume jobs with less effort.

Here are some ways advanced board handling improves your SMT line:

You reduce waiting time between machines.

You keep boards safe from damage during transfer.

You can change production speed quickly.

You handle different board sizes with one system.

Tip: Use smart conveyors and buffer units to keep your SMT line flexible and fast.

Board Protection

You want every board to reach the end of the line in perfect shape. S&M’s board handling equipment protects your boards at every step. These systems use gentle grips and smooth surfaces. You avoid scratches, warping, and static damage.

Automated Optical Inspection (AOI) systems check each board for defects. High-resolution cameras and advanced algorithms find up to 95% of assembly problems before final testing. You catch issues early and improve product reliability. AOI works well for high-density layouts because it uses multi-angle cameras and 3D modeling.

Solder Paste Inspection (SPI) checks every solder pad for correct volume and alignment. This step lowers defect rates before you place components. You get fewer bad boards and higher yield.

AOI and SPI systems help you spot problems early.

You protect your boards from handling errors.

You improve yield and reduce waste.

When you use S&M’s advanced board handling, you get strong material flow and top-level board protection. Your SMT line becomes more reliable and efficient.

AOI Enhancements in SMT Equipment

Fast Inspection

You want your SMT line to work fast. AOI uses smart tools to check boards quickly. AI and machine learning help AOI find defects right away. These systems learn from lots of pictures. They spot problems that old machines might miss. You do not need much time to set up new checks. The system changes and starts working fast.

High-resolution cameras show clear pictures of each part. You can see tiny defects that may cause trouble later. Automated inspection connects with your MES. This gives you full inspection and saves time.

Here is a table that shows how new AOI helps you inspect faster:

Advancement Type | Description |

|---|---|

AI and Machine Learning | Finds defects in real time and helps fix problems before they happen. |

High-Resolution Cameras | Makes it easier to spot mistakes and lowers wrong alerts. |

Automated Inspection Solutions | Works with MES for full inspection, saving time and making things run better. |

You also get helpful data from IoT devices. This data helps you make your SMT process better.

Tip: Use AI-powered AOI to set up faster and keep your line moving.

Fault Coverage

You want to find every defect before boards leave your line. Better AOI fault coverage helps you do this. New AOI uses smart optics and algorithms. They find defects people might not see. You get more good boards the first time because every solder paste and part placement meets your standards.

AOI checks thousands of parts each minute. This fast inspection is great for busy lines. Early detection lets you fix problems before they get worse. You save money and avoid fixing boards later.

Here is a table that shows the benefits of better AOI fault coverage:

Benefit | Description |

|---|---|

Makes sure solder paste and parts are placed right. | |

Reduced Post-Reflow Failures | Finds defects early so problems do not get bigger. |

High-Speed Inspection | Checks thousands of parts each minute for busy lines. |

Advanced Detection | Uses smart optics and algorithms to find defects people may miss. |

Better AOI means fewer wrong alerts.

Early fixes help you stop problems at the start.

You save money by needing fewer manual checks and getting more good boards.

You get more good boards and fewer problems when you use advanced AOI in your SMT line.

Flexible SMT Line Programming

Rapid Setup

You want your line to start fast. Flexible SMT line programming helps you set up jobs quickly. You load recipes and settings with just a few clicks. You use past data to make smart choices. This means fewer mistakes and better first-pass yield. You save time when you switch products. Your process keeps moving without long stops.

You track every step with data. You know which settings work best for each board. Alerts tell you if something changes. You fix problems before they slow you down. Smart programming tools help you work better. You get more good boards and less waste. You reach your first-pass yield goals faster.

Tip: Use flexible programming to make SMT assembly better and keep your line ready for any job.

High-Mix Support

You work with many board types and mixes. Flexible SMT line programming helps you handle high-mix jobs. You use data to manage different SKUs and changeovers. You keep quality steady for every unit. First-pass yield stays high even when you switch jobs often.

Here is how flexible programming helps high-mix environments:

Evidence Type | Description |

|---|---|

Lines switch jobs quickly, so downtime stays low. | |

Efficient Component Management | Teams work together to handle many SKUs easily. |

Quality Consistency | Every unit follows the same quality rules for good results. |

You use data to plan each run. You know which parts to load and when. Your line keeps running without delays. You track quality for every board. You see which settings work best. You use data to make your process better every day.

Smart scheduling helps you work faster.

You reach high first-pass yield with many board types.

Data helps you keep your process strong.

Flexible SMT line programming helps you meet customer needs. You handle new jobs fast. Your line stays ready for any challenge.

Picking smt equipment with the right features really helps your process. You get more good boards, make them faster, and improve quality. S&M’s solutions help you reach these goals. The table below explains why these choices are important:

Driving Forces | Description |

|---|---|

Miniaturization of Electronics | Need for precise smt equipment in every process |

Automation & Productivity | Automated smt equipment boosts process improvement |

Technological Advancements | AI and vision systems drive process efficiency |

Industry Growth | More demand for advanced smt equipment and process control |

To keep your process strong, do these things: Review your process to see what can be better. Work with S&M to pick the best smt equipment for your needs. Keep learning about new smt equipment and process trends.

You can join webinars, read market reports, or go to trade shows to learn about new ways to improve your process. Learning all the time helps you stay ahead and ready for anything.

FAQ

What are the main benefits of using advanced SMT systems?

You get faster production, fewer errors, and better quality. Advanced SMT systems help you spot problems early. These systems also let you handle more board types and keep your line running smoothly.

How do SMT systems improve yield and throughput?

SMT systems use smart sensors and real-time data. These systems catch defects before they cause waste. You can adjust settings quickly. This helps you make more good boards in less time.

Why should you choose S&M SMT systems for your assembly line?

S&M SMT systems offer strong automation and high accuracy. These systems use AI, vision, and smart feeders. You get reliable results and easy setup. S&M systems also support many industries and board types.

Can SMT systems handle high-mix production?

Yes, SMT systems can switch between jobs fast. These systems use flexible programming and smart scheduling. You can manage many board types and keep quality high. SMT systems help you meet changing customer needs.

How do SMT systems support predictive maintenance?

SMT systems use sensors and analytics to watch machine health. These systems alert you before a problem stops your line. You plan repairs early. This keeps your systems running and reduces downtime.