The Induction of Buffer Stocker

Buffer stocker is also called cache equipment, this equipment is used for automatic production line temporary storage of products role, mainly used in the production line at a certain moment of a certain equipment production cycle becomes longer, resulting in front-end equipment suspension, in order to solve this problem, the introduction of buffer stocker, or front-end and back-end production efficiency is inconsistent and front-end engineering efficiency is high, the introduction of buffer stocker can allow the front-end engineering to process the product in advance into the cache machine to meet the continuous production

operation of the post-engineering project, widely used in various electronic factories SMT production line.

Functional Application

Enter the automatic interface to operate, and select the equipment function selection interface required for production before the equipment enters the automatic operation.

1. First-in-first-out function:

According to the first-in-first-out order stored in the cache machine, the PCB board is sent according to the board finding signal of the post-engineering.

2. First-in-last-out function:

According to the order of last in and first out stored in the cache machine, the PCB board is sent out according to the board finding signal of the post-project.

3. Pass-through production function:

When you choose to use the pass-through function, the cache has a dock function and no longer caches the PCB board.

4. Cooling function:

Turn on this function to allow the PCB board to stay in the temporary machine, and the residence time can be set.

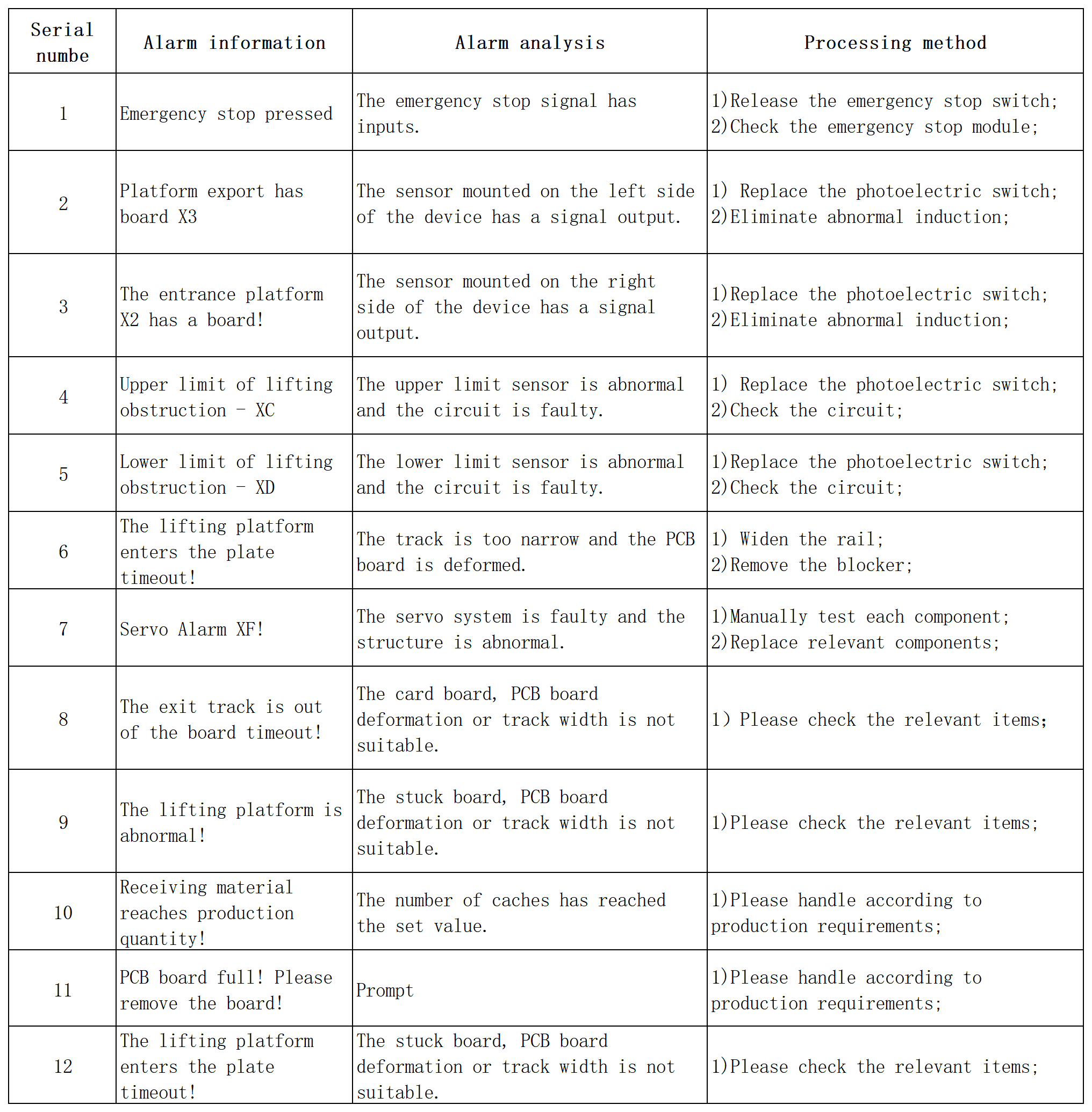

Common Faults and Treatment

Equipment Repair and Maintenance

1. Rail conveyor belt: Adjust the tension of the pulley and check the wear.

2. Inspection of each photoelectric sensor: Dust cleaning, sensitivity check.

3. Upper limit bit check: Check whether the origin location is normal.

4. Lift screw refueling: 2 times/month.

5. Transmission components: Check whether there is any abnormal noise, screw tightening.

6. Inspection in the electric control box: Dust cleaning.

Equipment Considerations

1. It is strictly forbidden to put hands and heads into the machine during the operation of the equipment, which may cause accidents or injuries.

2. In the automatic state of the equipment, it is strictly forbidden to maintain, manually pick up and repair the equipment, which may cause accidents or injuries and product damage; Must be completed in a shutdown or power-off state.

3. It is strictly forbidden to touch the moving parts of the equipment under working conditions, which may cause pinching.

4. It is strictly forbidden to change the electric control box of the equipment, which may cause electric shock and malfunction.

5. Equipment repair and maintenance must be completed by professionals or qualified personnel.

6. The equipment is strictly forbidden to hit, causing damage at your own risk.

7. The equipment should be installed in an environment with low vibration, no dust, no electromagnetic wave interference,and no corrosive objects, with a temperature of less than 55 degrees and a humidity of less than 90%.

8. Please do not use sharp materials or vigorously to operate the touch screen, (such as screwdrivers, nails, etc.) otherwise it will cause damage to the surface protective film of the touch screen, which may cause damage to the touch screen.