Solving cold joints in reflow soldering requires immediate action and precise technique. A cold joint forms when solder fails to bond properly, leading to weak electrical connections. This defect increases failure rates and peeling stresses, especially in temperature ranges from -10°C to 110°C, as shown below:

| Temperature Range (°C) | Solder Joint Failures | Peeling Stresses | Plastic Shear Strain |

| ———————- | ——————— | —————- | ——————– |

| -10 to 110 | High | High | Low |

Quick identification and effective solutions protect assembly reliability. Expert tips help prevent and repair these defects for lasting performance.

Key Takeaways

- Cold joints occur when solder fails to bond properly, leading to weak electrical connections. Identifying them early is crucial for device reliability.

- Ensure proper thermal profiling during reflow soldering. Set temperatures at least 15°C above the solder alloy’s melting point to prevent cold joints.

- Use high-quality solder paste and maintain clean surfaces. Contaminants can hinder solder flow, leading to defects.

- Regularly inspect solder joints visually and with a multimeter. Look for dull surfaces or high resistance to confirm joint integrity.

- Implement a structured checklist for both prevention and repair of cold joints. Consistent practices lead to better soldering outcomes.

Cold Joints Overview

Definition

Cold Joints represent a common defect in reflow soldering. Technicians identify these joints by their distorted, whitish, and sometimes bulging appearance. IPC standards describe several characteristics that help distinguish them from other soldering issues:

- The joint surface often looks dull or rough.

- Swelling or bulging may occur at the solder connection.

- Cold Joints can resemble disturbed joints, but they result from different causes.

A cold solder joint forms when the solder fails to melt completely and does not bond properly with the pad or component lead. This incomplete melting increases electrical resistance and reduces the reliability of the connection. Common causes include insufficient heat during reflow, improper temperature settings, or disturbances while the solder cools. Technicians can use visual inspection to spot dull, convex surfaces and multimeter testing to detect increased resistance.

Tip: Always set the reflow temperature at least 15°C above the solder alloy’s melting point to minimize the risk of cold joints.

Why They Matter

Cold Joints pose serious risks to electronic assemblies. These defects can lead to intermittent connectivity, causing devices to behave unpredictably or shut down without warning. Increased electrical resistance at the joint may result in overheating, which damages components and threatens device safety. Mechanical weakness also makes these joints prone to cracking or breaking under stress.

The table below summarizes the main consequences:

| Consequence | Description |

| ——————————- | —————————————————————————————————————- |

| Intermittent Connectivity | Devices may turn off or malfunction due to unreliable connections. |

| Increased Electrical Resistance | Voltage drops and overheating can occur, raising power consumption and damaging parts. |

| Signal Degradation | Sensitive circuits may experience noise, distortion, or signal loss. |

| Device Failures | Over time, cold joints can deteriorate, leading to complete device failure, especially in critical applications. |

Cold Joints also complicate troubleshooting. Intermittent faults make it difficult for engineers to pinpoint the source of problems. In safety-critical systems, these defects can shorten device lifespan and increase the risk of fire hazards.

Causes of Cold Joints

Insufficient Heat

Insufficient heat is a leading cause of cold joints in reflow soldering. When the soldering process does not reach the required temperature, the solder fails to melt completely. This incomplete melting prevents the formation of strong intermetallic bonds, which are essential for reliable electrical connections. Thermal analysis research indicates that inadequate heat application leads to weakened mechanical properties and increases the risk of joint failure during thermal cycling. Technicians often observe cold joints in assemblies where the reflow profile does not match the solder alloy’s specifications. In lead-free processes, higher temperatures can sometimes cause solder to solidify too quickly, reducing hole filling and increasing the likelihood of cold joints.

Tip: Always verify the thermal profile before starting production to ensure consistent heat distribution across the PCB.

Solder Paste Issues

Solder paste quality and application play a critical role in preventing cold joints. If the solder paste contains insufficient flux or uses low-grade materials, the solder may not flow or wet the surfaces properly. This leads to lumpy, uneven joints instead of smooth, shiny connections. Inadequate cleaning of components and PCB pads can leave impurities that hinder solderability. Surface mount technology studies highlight that poor solder paste and flux can disrupt the chemical reactions needed for effective bonding. Technicians should select high-quality solder paste and ensure proper storage to maintain its effectiveness.

| Cause of Cold Joint Formation | Description |

| ————————————- | —————————————————————————— |

| Insufficient heat during soldering | Inadequate heat prevents proper reflow of solder, leading to poor wetting. |

| Inadequate cleaning of components/PCB | Impurities on surfaces hinder the solder’s ability to wet properly. |

| Quality of solder paste and flux | Poor materials fail to achieve the necessary chemical reactions for soldering. |

Process Disturbances

Process disturbances such as vibration, misalignment, or inadequate board support can also contribute to cold joints. During reflow soldering, small components may float on molten solder and shift away from their intended positions. Vibration or bouncing of the PCB often causes these misalignments, especially when the board lacks proper support. Incorrect reflow oven settings and human error further increase the risk. When components do not remain stationary during solder solidification, the resulting joints often lack strength and reliability.

- Small components may float and detach from target solder joints.

- Vibration or bounce can cause shifting or tilting of components.

- Insufficient support for the PCB increases the risk of misalignment.

Cold joints often result from a combination of these factors. Technicians must monitor each stage of the process to minimize defects and ensure robust solder connections.

Preventing Cold Joints

Thermal Profiling

Thermal profiling stands as a critical step in preventing soldering defects. Technicians use temperature profiling to control the reflow process, which directly impacts solder joint quality. A well-designed temperature profile activates the flux, ensures proper wetting, and manages cooling rates. These actions reduce the risk of defects.

Experts recommend several effective thermal profiling techniques:

- Ramp-Soak-Spike (RSS) profile

- Ramp-to-Spike (RTS) profile

- Controlled ramp rate between 1-5°C per second to avoid thermal stress

A precise thermal profile ensures each PCB reaches the correct temperature at the right time. If the temperature falls short, solder may not bond well, leading to weak joints. Excessive heat can damage components and degrade the product. By maintaining accurate thermal conditions, manufacturers achieve strong solder joints and significantly reduce the occurrence of cold joints.

Tip: Regularly monitor and adjust the thermal profile for each new assembly batch to maintain consistent results.

Solder Paste Quality

Solder paste quality plays a vital role in forming reliable joints. The type of flux in the paste affects joint quality. Water-soluble fluxes activate quickly but may cause re-oxidation during reflow. Finer solder particles improve stencil printing consistency, but they can increase surface oxidation, making soldering more challenging.

Key criteria for evaluating solder paste quality include:

- Consistent stencil printing, as most solder defects start at this stage

- Effective solder paste inspection (SPI) to check the deposit volume and placement

- Proper storage, such as refrigeration and airtight containers, to prevent oxidation

- Allowing paste to reach room temperature before use and minimizing air exposure

Poor handling or storage leads to degraded paste and weak joints. Technicians should always follow manufacturer guidelines for storage and handling. Consistent process monitoring and regular operator training further reduce the risk of defects.

Note: Over 60% of soldering defects originate from stencil printing errors. Careful inspection at this stage prevents many downstream issues.

PCB Preparation

Proper PCB preparation ensures optimal solder joint formation. Industry experts recommend several steps to prepare PCBs for reflow soldering:

| Step | Recommendation |

| —- | ————————————————————————————————– |

| 1 | Optimize PCB design to minimize shadowing and ensure even solder distribution. |

| 2 | Ensure clean surfaces to achieve an optimal wetting angle; use pre-fluxing to remove contaminants. |

| 3 | Control soldering temperature and duration to manage intermetallic compound formation. |

| 4 | Use flux to reduce surface tension and promote solder flow. |

| 5 | Implement effective inspection techniques to identify defects early. |

| 6 | Maintain consistency in process parameters, including solder bath composition. |

| 7 | Understand common defects and their causes for effective troubleshooting. |

Cleanliness of PCB surfaces is essential. Contaminants like dirt, oxidation, and oils prevent proper solder adhesion. Oxidation creates a barrier on metal surfaces, making soldering less effective. Technicians should always clean PCBs before assembly and use pre-fluxing to remove any remaining contaminants.

Environmental factors also play a role. High humidity can cause solder paste to absorb moisture, reducing its effectiveness. Temperature fluctuations disrupt the melting and solidification of solder, increasing the risk of defects. Manufacturers should control environmental conditions in the assembly area to maintain consistent results.

Tip: Regular operator training equips staff with the skills needed to apply correct soldering techniques and spot potential issues early.

By focusing on thermal profiling, solder paste quality, and PCB preparation, technicians can prevent most cold joints before they occur. Consistent cleaning, careful solder application, and ongoing process monitoring form the foundation of reliable soldering practices.

Identifying Cold Joints

Visual Inspection

Technicians rely on visual inspection as the first step in identifying cold joints on assembled PCBs. They look for specific indicators that signal poor soldering quality. The most reliable criteria include surface appearance, physical defects, and component alignment. A cold joint often displays a dull, grainy surface instead of the shiny finish seen in well-formed solder connections. Cracks or gaps between the component and pad suggest incomplete bonding. Solder that forms a ball-like shape rather than flowing smoothly points to insufficient heat or poor wetting. Lifting leads, where the component appears raised or off the pad, may hide a cold joint underneath.

| Indicator | Description |

| ————————————————————————————————————————————— | —————————————————————————- |

| Dull, Grainy Appearance | Indicates insufficient heat during soldering, leading to poor conductivity. |

| Cracks or Gaps | Visible separations between the component and pad signal a cold joint. |

| Ball-Like Shape | Solder that beads up instead of flowing smoothly suggests a lack of bonding. |

| Lifting Leads | Components that appear off the pad may indicate a cold joint underneath. |

Technicians also use a checklist to speed up the inspection process:

- Dull, grainy appearance instead of shiny and smooth

- Visible cracks or gaps between the component and pad

- Ball-like shape of solder that does not flow smoothly

- Lifting leads indicating components are not properly bonded

Tip: Use magnification tools to enhance visibility and catch subtle defects during inspection.

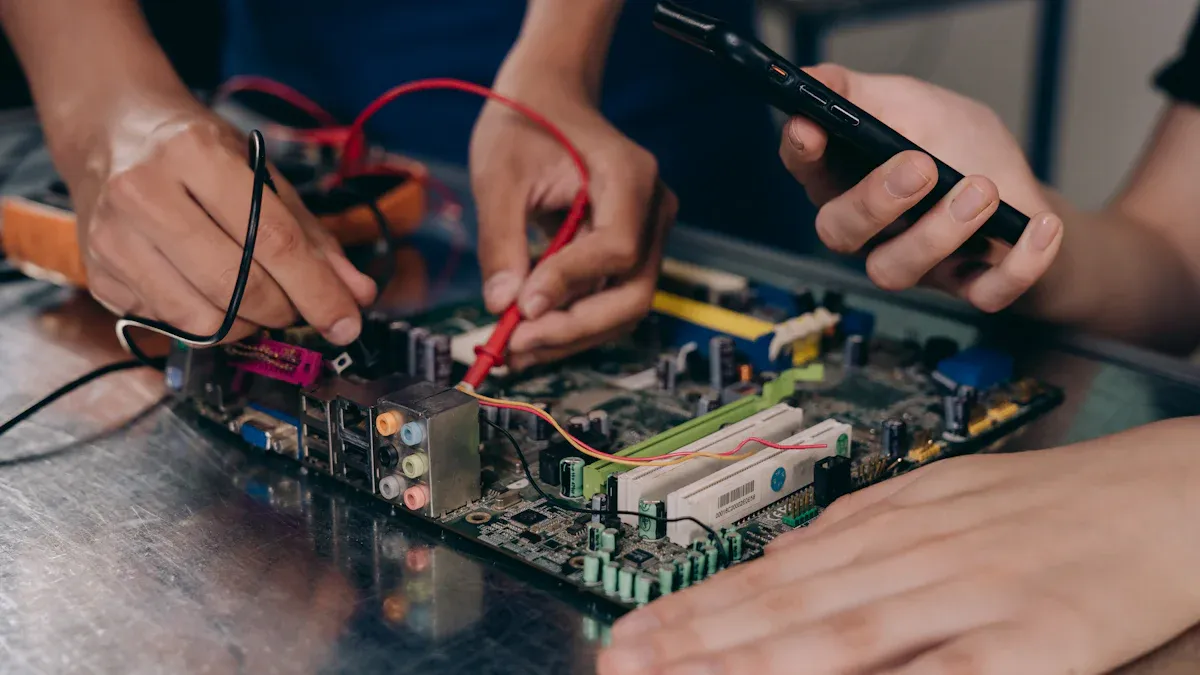

Multimeter Testing

Multimeter testing provides a reliable method for confirming cold joints after visual inspection. Technicians set the multimeter to measure resistance and place the probes on the component leads and PCB pads. A properly soldered joint shows low resistance and stable continuity. In contrast, a cold joint often displays higher resistance or fails to register a reading, indicating a poor electrical connection. This approach allows technicians to pinpoint faulty joints that may not be obvious to the naked eye.

Multimeter testing stands out for its effectiveness compared to other diagnostic methods. It measures both resistance and continuity, helping identify weak or intermittent connections. When a joint exhibits high resistance, technicians know the bond is unreliable and needs repair. This technique ensures that every connection meets the required standards for conductivity and reliability.

Note: Always test multiple points on the PCB to ensure comprehensive coverage and avoid missing hidden defects.

Fixing Cold Joints

Hot Air Rework

Hot air rework offers a precise method for repairing defective solder joints, especially on complex assemblies like BGAs. Technicians follow a systematic approach to ensure reliable results:

- Prepare the Workspace: Secure the PCB and arrange all necessary tools.

- Preheat the PCB: Use a preheater set between 100°C and 150°C for 1–2 minutes. This step reduces thermal shock and helps distribute heat evenly.

- Remove the Old Component: Heat the target area to 220–250°C. Use a vacuum tool to lift the component gently.

- Clean the Pads: Remove residual solder with a wick and clean the area using isopropyl alcohol.

- Apply Flux: Spread a thin, even layer of flux on the pads to promote solder flow.

- Place the New Component: Align the replacement part carefully. Attach new solder balls if needed.

- Reflow with Hot Air: Follow the recommended temperature profile to form robust connections.

- Cool and Inspect: Allow the board to cool naturally. Inspect the joints for quality.

Tip: Always let the board cool gradually to prevent thermal stress and microcracks.

Safety remains a top priority during hot air rework. The following table summarizes essential precautions:

| Safety Precaution | Description |

| —————————————————————————————————————— | —————————————————————– |

| Avoid Excessive Temperature | Set temperatures based on component heat tolerance. |

| Gradual Heating | Increase temperature slowly to avoid thermal shock. |

| Appropriate Airflow | Adjust airflow to prevent displacement of small parts. |

| Even Heating | Move the hot air tool continuously for uniform heat distribution. |

| Anti-static Measures | Use anti-static wrist straps and mats. |

| Protective Measures | Wear safety glasses to guard against solder splashes. |

| Ventilated Environment | Work in a well-ventilated area to reduce fume exposure. |

| Equipment Inspection | Check the rework station for faults before use. |

| Cleaning and Maintenance | Clean tools after each session to maintain performance. |

Technicians also wear heat-resistant gloves and masks, inspect equipment before use, and monitor temperature settings closely. These steps help prevent accidental damage to sensitive components.

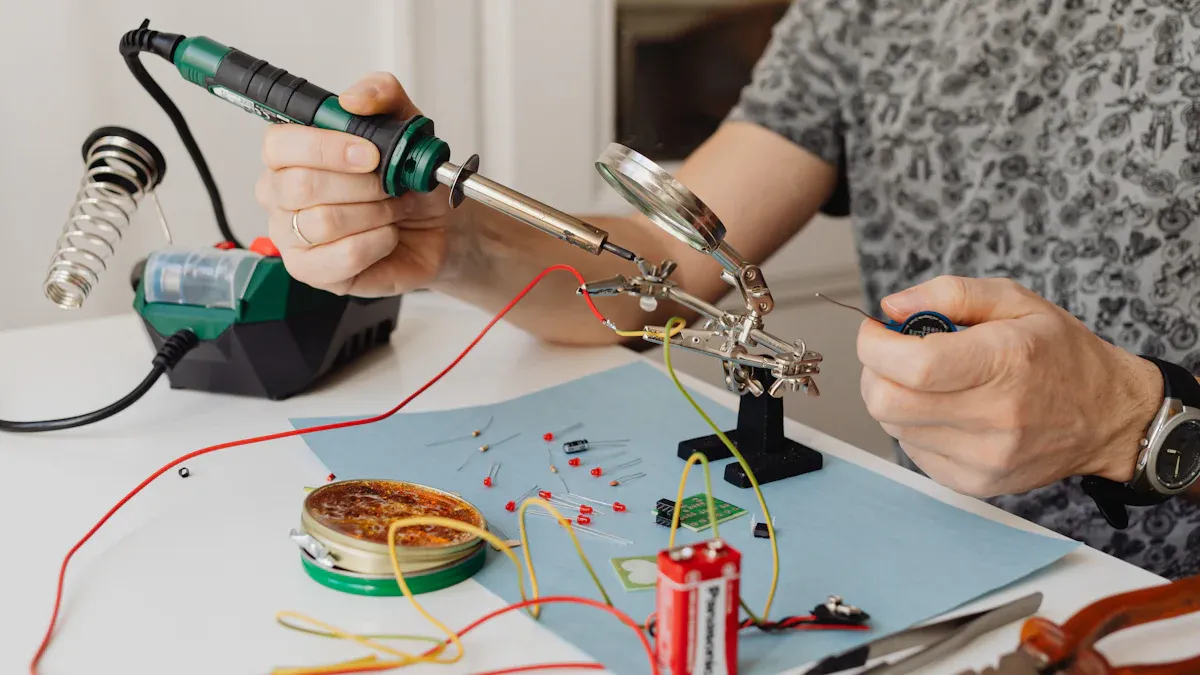

Soldering Iron Technique

A soldering iron provides a direct and controlled way to repair individual joints. Technicians use this method for through-hole and surface-mount components. The following best practices ensure effective repairs without damaging PCB pads:

- Set the soldering iron to the recommended temperature for the solder alloy.

- Heat the joint directly, allowing both the pad and component lead to reach soldering temperature.

- Apply fresh solder as the joint heats, ensuring it flows smoothly and covers the pad.

- Use high-quality solder and flux to improve heat transfer and wetting.

- Maintain sufficient contact time between the iron and the joint, but avoid prolonged heating to prevent pad lifting.

- Clean the tip regularly to ensure efficient heat delivery.

Note: Proper technique minimizes the risk of damaging delicate traces or pads during rework.

After repairing, technicians inspect the joint visually for a shiny, smooth finish. They also check for proper alignment and absence of excess solder.

Using Flux

Flux plays a critical role in successful cold joint repairs. Its application improves solderability and increases the likelihood of forming strong, reliable connections. Technicians benefit from flux in several ways:

- Flux removes oxides from the surfaces of pads and component leads, which is essential for proper wetting and adhesion.

- It prevents new oxides from forming before solder application, maintaining surface solderability.

- During the soaking stage of reflow, flux activation ensures uniform temperature distribution and maximizes solder paste effectiveness.

A drop of just 10°C in the soak stage (180–200°C) can increase the occurrence of cold joints by 25%. Applying flux before rework helps avoid this risk and ensures consistent results.

Tip: Always use the correct type and amount of flux for the specific soldering process to avoid residue and ensure optimal performance.

Post-Repair Testing

Verifying the integrity of repaired joints is essential for long-term reliability. Technicians use a combination of inspection and testing methods:

- Microscopic Examination: Use a loupe or microscope to check for patchy wetting or small bubbles.

- Electrical Checking: Measure resistance and continuity with a multimeter to confirm solid electrical connections.

- X-ray Inspection: For hidden joints, such as those under BGAs, use X-ray imaging to detect cracks or incomplete wetting.

These steps confirm that repairs have restored both mechanical strength and electrical performance. Consistent post-repair testing ensures that cold joints do not compromise the overall quality of the assembly.

Quick Checklist

Prevention Steps

Technicians can prevent cold joints by following a structured approach. A quick checklist helps maintain high standards and reduces the risk of defects:

- Verify thermal profile settings before each production run.

- Select high-quality solder paste and store it in airtight containers.

- Clean PCB surfaces thoroughly to remove contaminants.

- Inspect stencil printing for consistent solder paste deposits.

- Monitor environmental conditions such as humidity and temperature.

- Train staff regularly to recognize and avoid common soldering errors.

- Use flux appropriately to promote proper wetting and adhesion.

🛡️ Tip: Regular training sessions help technicians identify cold joints early and apply best practices during assembly.

Repair Steps

A standardized repair checklist improves consistency and reliability in cold joint fixes. Technicians should follow these steps for effective repairs:

- Prepare the workspace with all necessary tools and safety equipment.

- Preheat the PCB to minimize thermal shock.

- Remove the defective component using hot air or a soldering iron.

- Clean the pads with a solder wick and isopropyl alcohol.

- Apply flux to enhance solder flow and adhesion.

- Install the new component and align it precisely.

- Reflow or resolder the joint using the correct temperature profile.

- Inspect the repaired joint visually and with a multimeter.

The following table highlights practices that support consistent cold joint repairs:

| Practice | Description |

| ——————————- | ————————————————————————– |

| Use proper soldering techniques | Ensures strong and reliable connections, reducing the risk of cold joints. |

| Train technicians | Helps in quickly identifying and fixing soldering defects. |

| Inspect PCBs post-soldering | Ensures quality control and compliance, preventing defects. |

🔍 Note: Post-repair inspection with magnification and electrical testing confirms the integrity of each joint.

Industry experts recommend several strategies to prevent cold joints:

- Calibrate spreaders for temperature control using infrared sensors.

- Optimize spreader speed and alignment through operator training.

- Apply correct paving techniques, including hot joints and tack coats.

- Conduct regular inspections for thermal segregation and joint quality.

- Utilize automated control systems and thermal imaging cameras.

Process control and inspection play a vital role in reducing defects:

| Method | Contribution to Defect Reduction |

| ——————————————————————————————————————————– | ——————————————————————— |

| Statistical Process Control | Monitors solder paste volume and reflow temperatures for consistency. |

| Reflow Profiles | Optimizes temperatures to avoid common soldering defects. |

| Stencil Cleaning and Alignment | Prevents paste build-up and misalignment. |

| Automated Optical Inspection | Detects misalignment and solder bridges early. |

| X-ray Inspection | Finds hidden defects in complex packages. |

Technicians achieve reliable results by following the checklist and maintaining strict process control. Regular inspection ensures strong solder joints and long-term assembly performance.

FAQ

What causes cold joints in reflow soldering?

Cold joints often result from insufficient heat, poor solder paste quality, or disturbances during the soldering process. Technicians must monitor temperature profiles and ensure clean surfaces to prevent these defects.

How can technicians identify a cold joint?

Technicians spot cold joints by looking for dull, grainy surfaces or cracks around the solder. They also use a multimeter to check for high resistance or intermittent connections.

Can cold joints be repaired without removing the component?

Yes. Technicians can use a soldering iron and flux to reheat the joint and apply fresh solder. This method restores electrical and mechanical integrity without removing the component.

What tools help prevent cold joints during assembly?

Key tools include thermal profilers, solder paste inspection systems, and automated optical inspection equipment. These tools help maintain process control and ensure consistent solder quality.

Why is flux important in cold joint repair?

Flux removes oxides and improves solder flow. It helps the solder bond properly to the pad and component lead, reducing the risk of another cold joint.