Why Foxconn Vietnam Chose S&M VS-1003-N: A 2026 Reflow Oven Case Study on Lead Time and Thermal Control

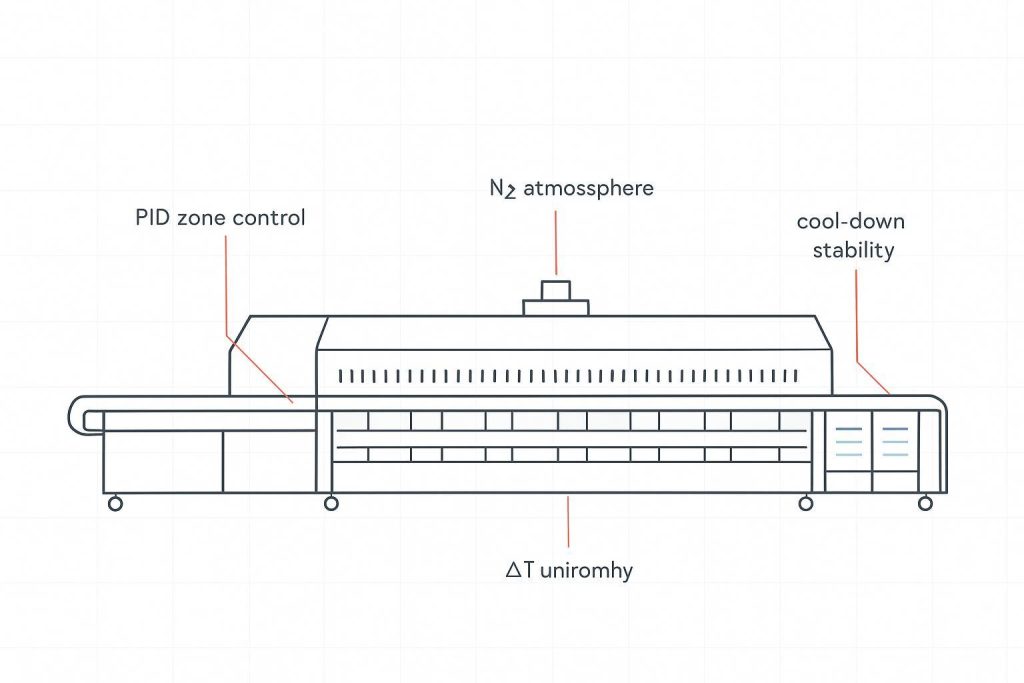

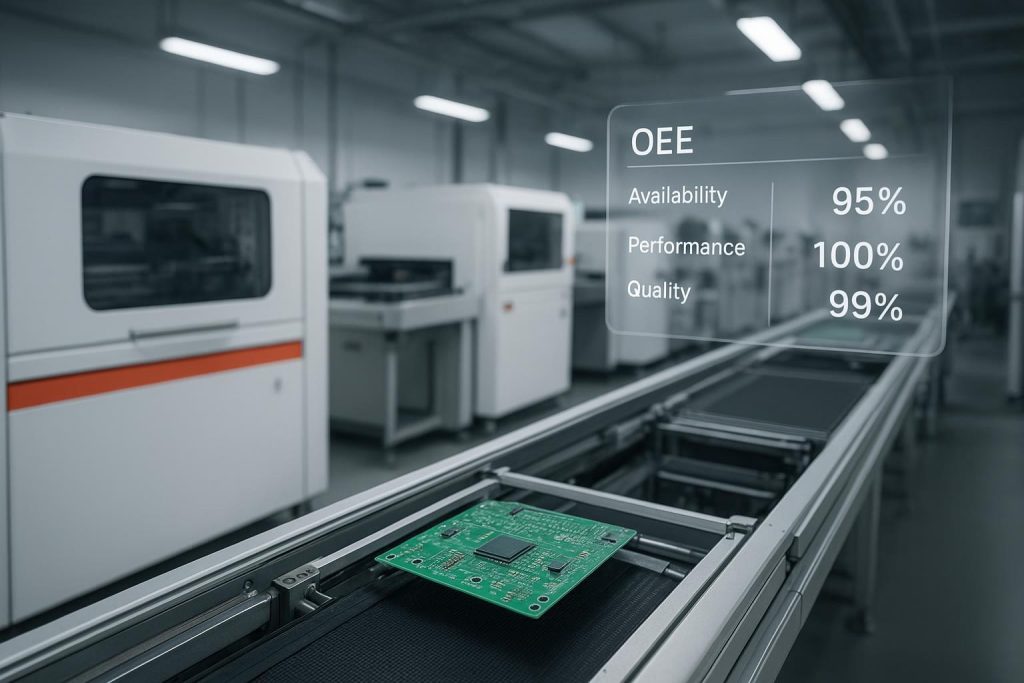

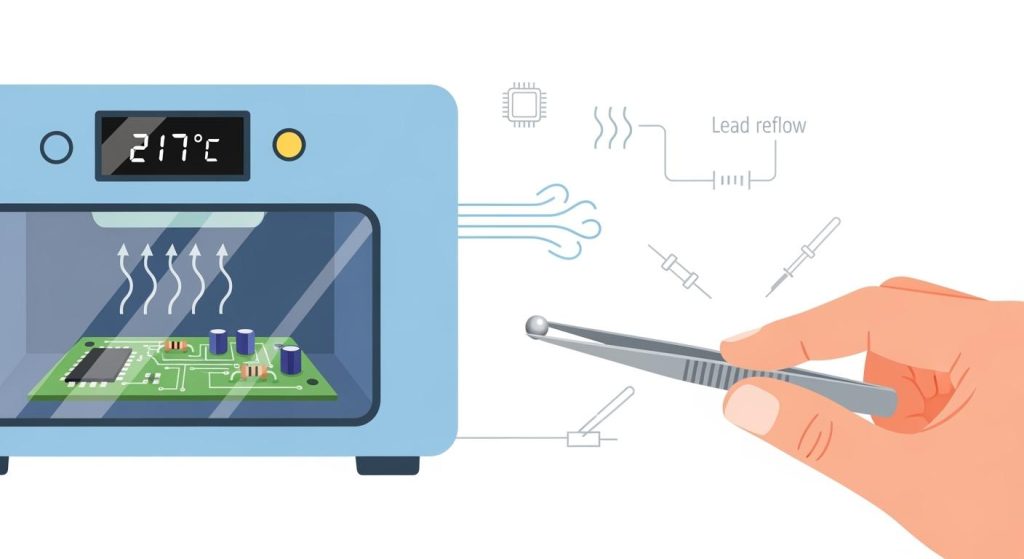

Reflow oven case study: How the S&M VS-1003-N nitrogen reflow oven tightened thermal control to shorten line lead time and streamline changeovers.