Comparing Wave and Selective Wave Soldering Methods

Explore key differences to choose the best PCB soldering method.

| Features | Wave Soldering | Selective Soldering |

|---|---|---|

| Process Control | The Conveyor moves the PCB through the solder wave. | Computer-controlled, precise joint targeting. |

| Component Compatibility | Best for through-hole and large parts. | Handles dense, mixed SMT and through-hole. |

| Production Volume | Ideal for high-volume mass production. | Better for small to medium runs. |

| Thermal Stress | Heats the entire board, higher stress. | Targets heat, reduces component stress. |

| Material Usage | Uses more solder and flux. | Applies solder and flux precisely. |

| Setup Complexity | Simple setup, less programming needed. | Requires detailed programming per board. |

| Defect Rate | Higher risk of bridging and balls. | Lower defects, better joint quality. |

| Flexibility | Less flexible for complex layouts. | Highly flexible for complex boards. |

| Cost Efficiency | Lower initial cost, higher material waste. | Higher equipment cost saves materials. |

| Maintenance | Modular design allows quick repairs. | Requires skilled maintenance and calibration. |

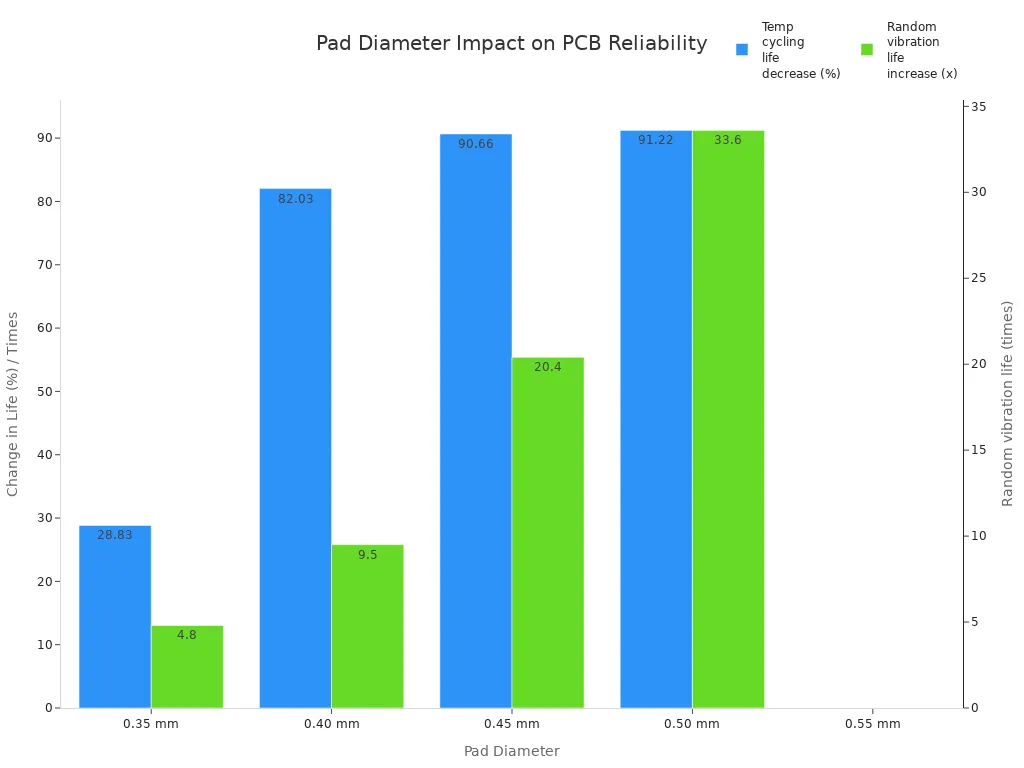

Choosing the right soldering method for your PCB depends on your goals for quality, efficiency, and reliability. Wave soldering leads in high-volume production, especially across Asia-Pacific, with a market size of about USD 500 million in 2023. Selective wave soldering adoption grows quickly as electronics become smaller and more complex. You should match technology to your Application Areas, production scale, and reliability needs. The soldering approach you select can impact temperature cycling life and vibration resistance, as shown in the chart below.

Key Takeaways

- Wave soldering suits high-volume production with mostly through-hole or larger components, offering speed and cost efficiency.

- Selective soldering excels in complex, mixed-technology boards needing precision, protecting sensitive parts with minimal heat exposure.

- Wave soldering heats the entire board, which can cause thermal stress; selective soldering targets only specific joints, reducing damage risk.

- Selective soldering reduces material waste and rework by applying solder and flux only where needed, saving costs in small to medium runs.

- Wave soldering machines provide fast throughput and easy maintenance, ideal for simple layouts and large-scale manufacturing.

- Selective soldering requires careful programming and setup, but delivers higher reliability and quality for demanding industries like aerospace and medical.

- Choosing the right method depends on PCB design, component density, production volume, budget, and quality requirements.

- Many manufacturers use both methods in one facility to balance speed, cost, and precision across different product needs.

Quick Guide

Decision Overview

Choosing between wave soldering and selective soldering depends on your PCB’s design, production needs, and cost targets. The table below compares the main decision criteria for each method:

| Decision Criteria | Wave Soldering | Selective Soldering |

|---|---|---|

| Component Type | Best for through-hole and larger surface mount components | Handles densely populated boards, tall parts, and tight spacing |

| Production Volume | Ideal for high-volume production | Better for small to medium runs or unique boards |

| Cost Considerations | Higher operating costs, more solder and flux used | Lower operating costs, less material waste, no masking or glue needed |

| Technical Requirements | Needs preheating and full-board soldering | Allows custom settings per component, manages thick boards, and uneven heating |

| Process Advantages | Fast for large batches, proven process | High reproducibility, optimized joints, no expensive pallets |

| Limitations | High energy use, cleaning, and rework are often needed | Needs unique programming per board, slower for mass production |

| Special Use Cases | Through-hole and large SMT components | Boards with tall parts, dense pins, or tight layouts |

Tip: Review your Application Areas and production goals before making a final decision.

When to Use Wave Soldering

You should choose wave soldering in these situations:

- You assemble PCBs with mostly through-hole technology (THT) or dual-in-line package (DIP) components.

- Your products use large connectors, power devices, or simple layouts where surface-mount technology (SMT) is not enough.

- You need to produce large quantities quickly and cost-effectively.

- Your industry requires robust solder joints, such as in automotive, industrial automation, or lighting.

- Your boards can handle higher heat and do not include many temperature-sensitive parts.

Wave soldering works best for high-volume, straightforward assemblies. It saves time and reduces costs in these Application Areas.

When to Use Selective Soldering

Selective soldering fits best when you face these challenges:

- Your PCB has a mix of through-hole and SMT components, especially on both sides of the board.

- Tall or large components block access for wave soldering, or you have connectors on both sides.

- You need precise control over soldering temperature, timing, and location to protect sensitive parts.

- You want to avoid heating the entire board, which helps with thermal management and reduces stress.

- Your production runs are medium-sized, or you need to handle many unique board designs.

- You want to save on flux and solder, and you do not want to use glue or masking.

Selective soldering gives you flexibility and precision for complex or high-density boards. It is the preferred method when quality and reliability matter most.

Wave Soldering

Process

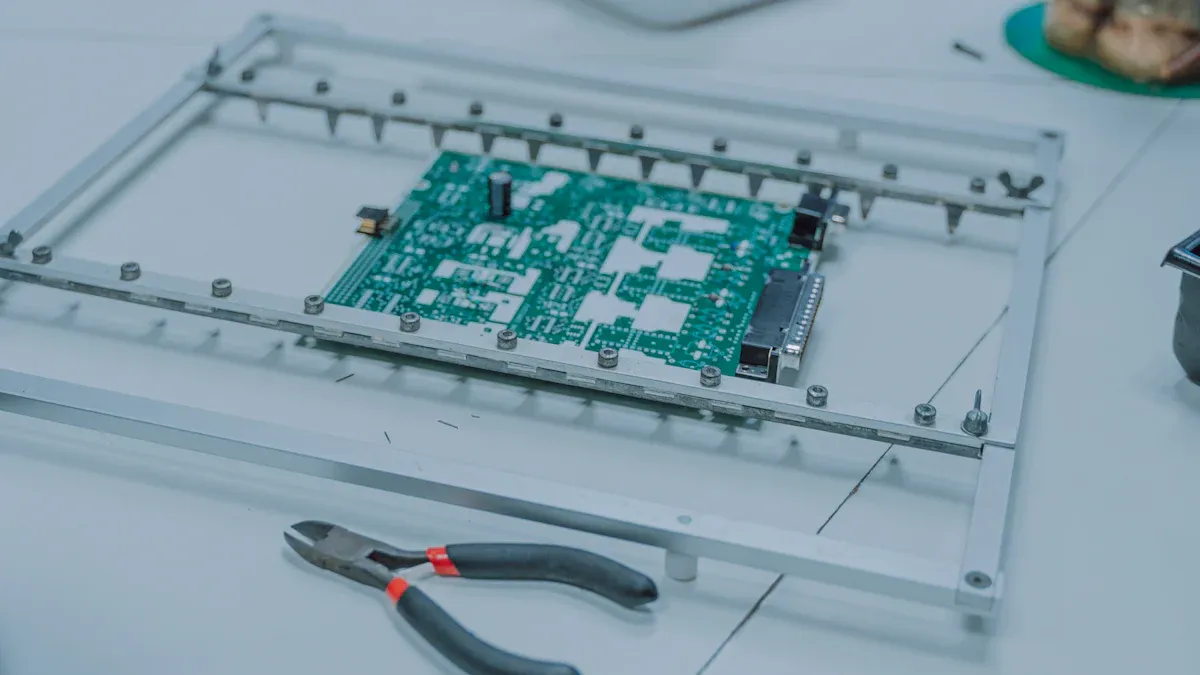

Wave soldering uses a conveyor to move your PCB through several key stages. First, the board passes through a fluxing station, where flux is applied to clean and prepare the metal surfaces. Next, the PCB enters a preheating zone. S&M’s advanced wave soldering machines feature a four-stage independent hot air preheating system. This design ensures uniform heating, reduces thermal stress, and improves solder joint reliability. The modular structure of these machines allows for quick maintenance and stable operation.

After preheating, your board moves over a molten solder wave. The solder pot, with precise temperature control up to 300°C, creates a standing wave that contacts the exposed metal leads and pads. This process forms strong, consistent solder joints across all through-hole components in a single pass. Automated systems control conveyor speed, solder wave height, and flux application, ensuring repeatable results and reducing manual labor.

Safety features, such as secondary heating monitoring and multiple alarms, protect both your operators and your boards. The enclosed preheating structure and constant-pressure flux system maintain energy efficiency and process stability. These technical advancements make wave soldering a reliable choice for high-volume PCB production.

Pros

Wave soldering offers several advantages, especially when you need to produce large quantities of simple or through-hole PCBs:

- High Throughput: You can solder hundreds of boards per hour. Fast conveyor speeds and simultaneous soldering of many components maximize your output.

- Cost Efficiency: Equipment investment is lower than with selective soldering. Consumable costs remain minimal because solder and flux are efficiently contained and used.

- Process Automation: Automated controls reduce labor costs and ensure consistent quality. You spend less time on manual soldering and rework.

- Uniform Solder Joints: Precise control of wave patterns and preheating zones leads to fewer defects and more reliable connections.

- Energy Efficiency: Modern machines, like those from S&M, use insulated preheating zones and modular designs to reduce heat loss and operating costs.

- Easy Maintenance: Modular construction allows for quick repairs and minimal downtime, keeping your production line running smoothly.

Note: Wave soldering excels in high-volume environments where speed and cost matter most.

Cons

While wave soldering brings many benefits, you should also consider its limitations compared to selective soldering:

- Defect Risks: Common issues include solder bridging, insufficient solder, solder balling, and incomplete hole fill. These defects often result from improper temperature control, flux application, or PCB design.

- Limited Flexibility: Wave soldering works best for simple, through-hole assemblies. Complex boards with mixed technologies or tight layouts may require masking or additional steps.

- Thermal Stress: The entire board heats up during the process, which can damage sensitive components or cause warping if not managed carefully.

- Cleaning Needs: Flux residues and solder splashes may require extra cleaning, adding to your post-soldering workload.

| Limitation | Description |

|---|---|

| Solder Bridging | Unintended connections between pads, causing shorts |

| Insufficient Solder | Weak joints due to a lack of solder on leads or pads |

| Solder Balling | Small solder beads that can cause shorts |

| Incomplete Hole Fill | Poor solder penetration through holes |

FAQ:

Q: Can wave soldering handle lead-free requirements?

A: Yes, modern systems support lead-free soldering with precise temperature control and oxidation prevention features.

Q: Is wave soldering suitable for double-sided or high-density boards?

A: It is less ideal for these applications. Selective soldering offers better results for complex layouts.

Best Uses

When you select a soldering method for your PCB assembly, you want to match the process to your board’s design and production needs. Wave soldering stands out in several key scenarios, especially when you need speed, reliability, and cost efficiency for large-scale manufacturing.

You should consider wave soldering in these situations:

- Through-Hole Assemblies: If your PCB uses mostly through-hole components (THT), wave soldering delivers strong, reliable joints. This method handles large connectors, power devices, and components that require robust mechanical support.

- Mixed Technology Boards: For boards that combine through-hole and some surface mount components, wave soldering can process both types efficiently. You often see this in consumer electronics, where cost and speed matter.

- High-Volume Production: When you need to produce thousands of units, wave soldering offers unmatched throughput. The conveyor system and automated controls from S&M’s machines keep your line moving with minimal downtime.

- Larger or High-Power Components: Devices like transformers, relays, and large capacitors benefit from the deep solder penetration and strong electrical connections that wave soldering provides.

- Simple or Medium-Complexity Layouts: If your board layout is straightforward, with enough spacing between components, wave soldering ensures consistent results without the need for masking or extra steps.

Industry Examples:

Many manufacturers use wave soldering for televisions, home audio-visual equipment, and digital set-top boxes. These products rely on strong joints and high reliability, which wave soldering delivers.

| Application Area | Why Wave Soldering Excels |

|---|---|

| Consumer Electronics | Fast, cost-effective for large batches |

| Industrial Automation | Handles robust, high-power components |

| Automotive Electronics | Delivers strong joints for vibration resistance |

| Lighting Systems | Supports large connectors and power devices |

| Power Supplies | Ensures deep solder penetration for high-current circuits |

S&M’s wave soldering machines enhance these advantages with modular design, advanced preheating zones, and safety systems. You get stable operation, easy maintenance, and precise control over every stage of the process.

Tip:

If your board features high-density SMT parts, tight layouts, or sensitive components, you may want to compare wave soldering with selective soldering. Selective soldering offers more precision for complex assemblies, but wave soldering remains the best choice for high-volume, through-hole, and mixed-technology boards with larger components.

FAQ

Q: Can I use wave soldering for boards with both through-hole and surface mount components?

Yes, you can. Wave soldering works well for mixed-technology boards, especially when most components are through-hole. For boards with many SMT parts or tight layouts, selective soldering may be more suitable.

Q: What industries benefit most from wave soldering?

Industries like consumer electronics, automotive, industrial automation, and lighting systems rely on wave soldering for its speed, reliability, and ability to handle large or high-power components.

Q: How do S&M’s wave soldering machines improve production?

S&M’s machines offer modular design, advanced preheating, and robust safety features. These improvements reduce downtime, ensure consistent quality, and make maintenance easier for your team.

Selective Soldering

Process

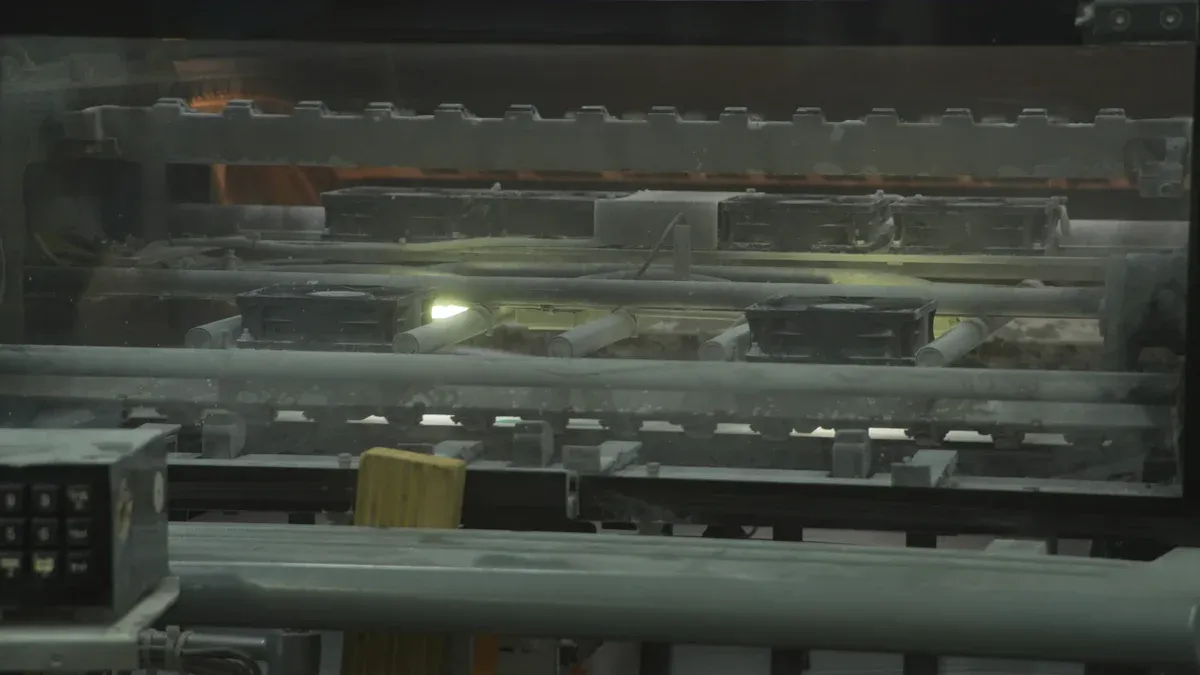

Selective soldering uses advanced automation to deliver precise, repeatable results for complex PCB assemblies. You start by loading your board onto a dual-platform system. S&M’s selective soldering machines use an industrial computer and multi-axis motion control to guide the process. You can import PCB images or GERBER files, then program the exact soldering path, speed, and height for each joint. This level of control lets you target only the areas that need solder, protecting sensitive components from unnecessary heat.

The process begins with flux application. A high-precision XY platform, driven by servo motors, moves the flux nozzle to each joint. Next, the board enters a preheating zone, which uses both hot air and infrared heating to ensure even temperature distribution. This step reduces thermal shock and prepares the board for soldering.

During soldering, the machine uses dual solder stations and precision nozzles to apply solder only where needed. Real-time cameras monitor the process, allowing you to capture photos and videos for quality control. The system tracks key parameters—such as air pressure, conveyor speed, and solder pot temperature—so you can maintain consistent results. Automated alarms and process monitoring help you quickly identify and correct any issues.

Tip:

Selective soldering gives you full control over each solder joint, making it ideal for boards with mixed technologies or tight layouts.

Pros

Selective soldering offers several advantages over traditional wave soldering, especially for modern, high-density PCB designs:

- High Precision and Flexibility: You can program the machine to solder only specific joints, which is essential for boards with both SMT and through-hole components.

- Minimal Thermal Stress: Only targeted areas receive heat, so sensitive parts stay protected. This reduces the risk of damage and warping.

- Consistent Quality: Automation and process monitoring ensure each joint meets strict standards. You get fewer defects and higher first-pass yields.

- Reduced Material Waste: The system applies solder and flux only where needed, saving on consumables and lowering operating costs.

- Easy Rework and Traceability: You can resolder individual joints without affecting the rest of the board. Camera integration and process logs make quality control simple.

- Supports Multiple Alloys: Some systems allow you to use different solder alloys on a single board, increasing your manufacturing flexibility.

| Advanced Feature | Description |

|---|---|

| Dual Fluxers & Solder Pots | Solder two different joints or alloys at once for greater efficiency. |

| Parallel Processing | Solder two PCBs simultaneously, doubling productivity. |

| Closed-loop Process Control | Ensures stable, repeatable, high-yield results with real-time monitoring. |

Note:

Selective soldering is the preferred method for automotive, medical, aerospace, and consumer electronics where reliability and precision matter most.

Cons

While selective soldering brings many benefits, you should consider some challenges compared to wave soldering:

- The process requires careful programming and setup for each board type. You may need specialized training to optimize production.

- Boards with thick copper layers or heavy components can experience uneven heating, which may affect solder quality.

- Tight component spacing or tall parts can complicate fixture design and solder nozzle access.

- Maintaining consistent process parameters—such as temperature, soldering time, and flux application—is critical to avoid defects.

- Selective soldering typically operates at a slower pace than wave soldering for large batches, making it less suitable for very high-volume, simple assemblies.

FAQ:

Q: Is selective soldering suitable for all PCB types?

A: Selective soldering works best for complex, mixed-technology, or high-density boards. For simple, high-volume through-hole assemblies, wave soldering may be more efficient.

Q: How does selective soldering improve quality control?

A: Automated process monitoring, real-time cameras, and precise control over each joint help you achieve consistent, defect-free results.

Best Uses

Selective soldering stands out when you need precision and reliability for your PCB assemblies. You should consider this method if your boards feature a mix of through-hole and surface-mount components, especially when these parts appear on both sides. S&M’s selective soldering machines give you advanced control with dual platforms and multi-axis motion systems. This technology lets you program exact soldering paths, speeds, and heights for each joint. You can target only the areas that need solder, which protects sensitive components from unnecessary heat.

You will find selective soldering most valuable in industries where quality and consistency matter most. Aerospace, medical, and military electronics often require PCBs that meet strict standards. In these fields, even a single solder defect can cause critical failures. Selective soldering helps you avoid these risks by applying solder only where needed and by using real-time process monitoring. This approach reduces thermal stress and prevents damage that sometimes occurs with traditional wave soldering.

Tip:

If your project involves high-reliability electronics or complex layouts, selective soldering offers the control and quality you need.

Here are some scenarios where selective soldering outperforms wave soldering:

- Complex, Mixed-Technology Boards: You can handle PCBs with both through-hole and SMT components, even when they are densely packed or located on both sides.

- High-Reliability Applications: You meet IPC-A-610 Class 2 and Class 3 standards, which are essential for aerospace, medical, and military products.

- Sensitive Components: You avoid exposing delicate parts to unnecessary heat, reducing the risk of damage.

- Innovative Designs: You support smaller, more powerful devices by removing traditional soldering constraints.

- Telecommunications and Industrial Controls: You achieve precise, repeatable joints for boards that require long-term durability.

| Application Area | Why Selective Soldering Excels |

|---|---|

| Aerospace & Defense | Meets strict reliability and quality standards |

| Medical Devices | Protects sensitive components, ensures consistent joints |

| Telecommunications | Handles dense, mixed-technology layouts |

| Industrial Automation | Supports complex, high-density boards |

| Advanced Consumer Tech | Enables innovative, compact designs |

Selective soldering also helps you reduce material waste. The system applies solder and flux only where needed, which lowers your operating costs. You can easily rework individual joints without affecting the rest of the board. Real-time cameras and process logs make quality control straightforward.

FAQ:

Q: When should I choose selective soldering over wave soldering?

You should choose selective soldering when your PCB design is complex, includes sensitive components, or must meet high-reliability standards.

Q: Can selective soldering handle both small and large production runs?

Yes, selective soldering works well for small to medium runs and for boards that require unique programming or frequent design changes.

Application Areas

Application Areas Comparison

You need to match your soldering method to the right Application Areas for the best results. Wave soldering and selective soldering each serve different needs in the electronics industry. You will find wave soldering most effective in high-volume production, especially for PCBs with through-hole or larger surface mount components. This method works well for products that do not require pinpoint accuracy or have simple layouts.

Selective soldering, on the other hand, gives you the precision needed for complex boards. You can use it for densely populated PCBs, boards with tall components, or those with tight spacing. Selective soldering is essential when you need to protect sensitive parts or meet strict quality standards.

Here are some common Application Areas for both methods:

- Power supply electronics

- Medical electronics

- Computer motherboards

- Automotive electronics (engine control units, EV charging systems)

- LED industry (lights, lenses)

- Communication devices (routers, modems)

- Smart home appliances (smart TVs)

- Industrial control systems (power switches)

- Consumer electronics (phones, set-top boxes, power banks)

- New energy (solar panel manufacturing)

- Security industry (cameras, monitoring equipment)

- Semiconductor industry

- Aerospace and defense (aircraft power control boards)

- Electrical power systems (smart meters)

- EMS/ODM manufacturing

You will see wave soldering used more often in consumer electronics, such as computer motherboards and smart TVs. Selective soldering is preferred in industrial electronics, including automotive, medical, and power supply products, where reliability and precision matter most.

Tip:

Choose wave soldering for simple, high-volume boards. Use selective soldering for complex, high-reliability assemblies.

Production Scale

Production scale plays a key role in your decision. Wave soldering shines in large-scale manufacturing. You can process hundreds or thousands of boards per hour, making it ideal for mass production. This method keeps your line moving and your costs low when you need to deliver big orders.

Selective soldering fits best with small to medium production runs. You get the flexibility to handle frequent design changes and the precision to meet strict standards. If you work with prototypes, custom boards, or products that require careful attention to detail, selective soldering gives you the control you need.

- Wave soldering: Best for high-volume, large-scale production.

- Selective soldering: Ideal for small to medium runs, or when you need flexibility and accuracy.

Some high-end selective soldering machines can support larger volumes, but they require a higher investment and more programming. For most manufacturers, wave soldering remains the top choice for speed and throughput at scale.

Cost Factors

Cost is a major factor when you choose between wave soldering and selective soldering. You need to consider both the initial investment and the ongoing expenses.

| Production Run Size | Wave Soldering Cost Characteristics | Selective Soldering Cost Characteristics |

|---|---|---|

| Small | High material and rework costs | More cost-efficient, less waste |

| Medium | Higher material use, less efficient | Lower waste, higher equipment cost |

| Large | Most cost-effective, high-speed | Less efficient, more time-consuming |

Wave soldering uses more solder, flux, and energy. This increases your material costs, especially for small or medium runs. Selective soldering requires a higher upfront investment, but you save on materials because the machine targets only the joints that need solder. You also reduce waste and rework.

Other factors that influence your total cost include:

- Machine size and capacity

- Solder and flux consumption

- Type of fluxing and preheat systems

- Automation level and board handling

- Maintenance and support services

- Integration with your existing systems

- Training and skill requirements

- Environmental and safety compliance

Note:

For large-scale production, wave soldering offers the lowest cost per board. For small and medium runs, selective soldering helps you save on materials and rework, even with a higher initial investment.

FAQ

Q: Can I use both wave soldering and selective soldering in the same factory?

Yes, many manufacturers use both methods to handle different Application Areas and production needs.

Q: How do I decide which method is best for my product?

Consider your board complexity, production volume, quality requirements, and budget. Wave soldering works best for simple, high-volume boards. Selective soldering is better for complex, high-reliability products.

Q: Does selective soldering always cost more?

Not always. While the equipment costs more, you save on materials and reduce rework, especially for small and medium runs.

Reliability

When you choose a soldering method, reliability often becomes your top priority. Both wave soldering and selective soldering can produce strong, dependable joints, but each method offers different strengths depending on your board design and production needs.

Comparing Reliability: Wave Soldering vs Selective Soldering

- Wave soldering works well for high-volume production and simple boards. You get fast results and consistent joints when your layout is straightforward. However, because the entire board passes through a molten solder wave, you may see defects like solder bridges, solder balls, or incomplete hole fill. These issues can affect reliability, especially on complex or densely packed boards.

- Selective soldering gives you greater control. The machine targets only the areas that need solder, which reduces thermal stress on sensitive components. This precision leads to fewer defects and higher joint reliability, especially for mixed-technology or high-density PCBs. You avoid overheating parts, and you can reproduce the same results across many boards.

- Selective soldering also eliminates the need for masks or pallets, which you often need with wave soldering for complex layouts. This not only saves time but also improves process consistency.

| Reliability Factor | Wave Soldering | Selective Soldering |

|---|---|---|

| Thermal Stress | Higher (entire board heated) | Lower (only targeted areas heated) |

| Defect Rate | Higher on complex boards | Lower, especially for dense layouts |

| Reproducibility | Good for simple boards | Excellent, even for complex assemblies |

| Suitability for Sensitive Components | Limited | Excellent |

| Need for Masking/Pallets | Often required for complex boards | Not required |

Tip:

If your Application Areas include medical, aerospace, or automotive electronics, you should prioritize selective soldering for its superior reliability and process control.

Why Reliability Matters in Your Application

You want your products to last and perform under stress. In industries like automotive, medical, or industrial controls, a single bad solder joint can lead to costly failures. Selective soldering helps you meet strict quality standards by minimizing defects and ensuring every joint meets your requirements. Wave soldering remains a solid choice for less complex boards where speed and cost matter most, but selective soldering stands out when you need the highest reliability.

FAQ

Q: Can wave soldering deliver reliable joints for all board types?

Wave soldering is reliable for simple, through-hole boards. For complex or high-density layouts, selective soldering provides better results.

Q: Does selective soldering always guarantee zero defects?

No process can guarantee zero defects, but selective soldering greatly reduces the risk, especially for sensitive or complex assemblies.

Q: Which method should I choose for high-reliability Application Areas?

Selective soldering is the preferred choice for high-reliability needs, such as aerospace, medical, and automotive electronics.

Choosing a Method

Key Factors

When you choose between wave soldering and selective soldering, you need to consider several key factors. Each factor affects your final product’s quality, cost, and reliability.

PCB Design

Your PCB design plays a major role in your decision. If your board uses mostly through-hole components and has a simple layout, wave soldering from S&M offers speed and efficiency. For complex, mixed-technology boards—especially double-sided PCBs—selective soldering provides the precision you need. Selective soldering minimizes heat exposure, which protects sensitive components and reduces thermal stress. You should avoid placing surface mount parts too close to through-hole pins, as this can block solder wave access and cause defects.

Component Density

Dense layouts with many small or closely spaced parts challenge traditional wave soldering. Selective soldering adapts well to these situations. It targets only the required joints, preventing solder bridges and shadowing. For boards with large connectors or power devices, wave soldering remains effective, but you must ensure proper spacing and orientation to avoid poor joints.

Volume

Production volume often determines your best method. Wave soldering excels in high-volume runs. You can process hundreds of boards per hour, making it ideal for mass production. Selective soldering suits small to medium batches, prototypes, or frequent design changes. It offers flexibility but operates at a slower pace.

Budget

Budget impacts your choice. Wave soldering equipment costs less upfront and works best for large runs. However, you may spend more on materials and rework for complex boards. Selective soldering requires a higher initial investment, but you save on solder and flux by targeting only specific joints. For small or medium runs, selective soldering can lower your total cost.

Quality

Quality requirements guide your method. If you need robust, reliable joints for simple boards, wave soldering delivers. For high-reliability applications—such as medical, aerospace, or automotive electronics—selective soldering ensures consistent, defect-free results. It meets strict industry standards and supports advanced process monitoring.

Checklist

Use this checklist to help you decide:

- Is your PCB simple, with mostly through-hole parts? → Choose wave soldering.

- Does your board have mixed SMT and through-hole components? → Consider selective soldering.

- Do you need high-volume, fast production? → Wave soldering is best.

- Are your boards complex, dense, or double-sided? → Selective soldering offers better control.

- Is your budget limited to equipment costs? → Wave soldering may fit.

- Do you require the highest reliability and minimal defects? → Selective soldering is preferred.

Tip: Always review your PCB layout and production goals before making a final decision.

Mistakes to Avoid

You can avoid common pitfalls by following industry best practices:

- Do not place small components behind larger ones; this prevents shadowing and poor solder joints.

- Avoid placing SMT parts too close to through-hole pins.

- Do not ignore pad size and shape; follow IPC standards to prevent solder bridging.

- Never skip proper flux selection and preheat profiling.

- Do not overlook the need for skilled programming in selective soldering.

- Avoid using wave soldering for dense, complex boards where precision is critical.

⚠️ Careful planning and adherence to best practices ensure reliable, high-quality assemblies.

FAQ

Q: Can I use both wave and selective soldering in one facility?

Yes, many manufacturers combine both methods to handle different board types and production needs.

Q: Which method is better for double-sided, mixed-technology boards?

Selective soldering provides the precision and control needed for these complex assemblies.

Q: How do I ensure the best solder joint quality?

Follow IPC standards, use proper heat profiles, and select the right method for your board’s design and volume.

You face a critical choice between wave soldering and selective soldering. Wave soldering delivers speed and cost efficiency for large-scale, less complex boards. Selective soldering offers precision and reliability for intricate or sensitive assemblies. Always match your soldering method to your PCB design and production goals. Consult with S&M experts to optimize solder mask openings, assembly requirements, and process parameters. You gain better manufacturability and compliance by leveraging their experience. For complex decisions, expert guidance ensures you select the right technology for your needs.

Tip: Reach out to technical support or assembly partners for tailored advice on soldering methods and process optimization.

FAQ

What is the main difference between wave soldering and selective soldering?

Wave soldering covers the entire board with solder in one pass. Selective soldering targets specific joints with precision. You should choose wave soldering for simple, high-volume boards and selective soldering for complex or sensitive assemblies.

Which method gives you better results for mixed-technology PCBs?

You get better results with selective soldering for mixed-technology PCBs. This method allows you to program soldering paths for both through-hole and SMT components, ensuring precise joints and protecting sensitive parts.

How do production volumes affect your choice?

You should use wave soldering for large-scale production. This method processes hundreds of boards per hour. Selective soldering fits small to medium runs, prototypes, or frequent design changes, offering flexibility and accuracy.

Can you use both methods in one facility?

Yes, you can combine both methods in your facility. Many manufacturers use wave soldering for simple, high-volume boards and selective soldering for complex or high-reliability products. This approach maximizes efficiency and quality.

Which method is more cost-effective for small batches?

Selective soldering is more cost-effective for small batches. You save on solder and flux because the machine targets only specific joints. Wave soldering uses more materials and may require extra rework for complex boards.

How does S&M ensure quality and reliability in both methods?

S&M integrates advanced process monitoring, modular designs, and real-time alarms in both wave and selective soldering machines. You benefit from stable operation, precise control, and consistent results, meeting strict industry standards.

What industries benefit most from each method?

You see wave soldering excels in consumer electronics, lighting, and industrial automation. Selective soldering stands out in automotive, medical, aerospace, and telecommunications, where reliability and precision are critical.

Tip: Always match your soldering method to your PCB’s complexity, production scale, and reliability needs for the best results.