You play a key role in ensuring high-quality results by choosing and maintaining the right Wave Soldering Flux. Your selection directly affects solder joint reliability, residue control, and equipment performance.

-

The chemical makeup of your flux influences wettability, residue formation, and corrosion resistance.

-

Low-solids and no-clean fluxes can boost process efficiency by reducing cleaning steps, but they may increase corrosion risk if residues attract moisture.

Careful flux management leads to better throughput and long-term reliability.

Key Takeaways

-

Choose the right flux type based on your assembly’s complexity, reliability needs, and cleaning capabilities to ensure strong, defect-free solder joints.

-

Apply flux carefully using methods like spray, foam, or manual application to achieve uniform coverage and prevent defects such as bridging or weak joints.

-

Store and handle flux properly by controlling temperature, humidity, and expiration dates to maintain its chemical activity and avoid soldering problems.

-

Regularly clean flux applicators and maintain equipment settings like foam and wave height to ensure consistent soldering quality and reduce defects.

-

Match flux selection and maintenance practices to industry standards and product requirements to improve throughput, reliability, and long-term manufacturing success.

Wave Soldering Flux Basics

What Is Flux

You use flux as a chemical agent in the wave soldering process. Wave Soldering Flux prepares metal surfaces for soldering by removing oxides and impurities. This cleaning action allows molten solder to flow smoothly and form strong, reliable joints. You typically apply flux to the printed circuit board (PCB) before it passes through the solder wave. The type of flux you choose determines whether you need to clean residues after soldering.

Tip: Always check the freshness and quality of your flux. Expired or contaminated flux loses its cleaning power and can cause soldering defects.

Why Flux Matters

Flux plays a critical role in the quality and reliability of your solder joints. When you use active and well-maintained Wave Soldering Flux, you achieve several key benefits:

-

It removes oxides and contaminants from PCB pads and component leads, ensuring proper solder wetting and adhesion.

-

It forms a protective barrier that prevents re-oxidation during soldering, which helps maintain strong connections.

-

It reduces the risk of defects such as bridging and non-wetting by promoting even solder flow.

If you use insufficient or degraded flux, you may face serious problems:

-

Poor cleaning leads to oxidation, which reduces solderability and causes incomplete or weak joints.

-

Inadequate flux activity can result in defects like solder leakage, tin bridging, and residue issues.

-

You may see voids, poor fillet formation, and even short circuits, all of which lower the reliability of your assemblies.

Remember: Proper flux selection and application are essential for preventing defects and ensuring high-quality results in wave soldering.

Types of Wave Soldering Flux

Rosin-Based

You often choose rosin-based fluxes for their chemical stability and protective properties. These fluxes come from natural pine resin and contain 30-50% solids by weight. When you use rosin-based Wave Soldering Flux, you notice an amber-colored residue that is hard, non-corrosive, and non-conductive. This residue protects copper surfaces from corrosion, even after aging. However, it can be difficult to remove and may require expensive solvents. The table below highlights key characteristics:

|

Property |

Description |

|---|---|

|

Origin |

Pine tree resin |

|

Residue |

|

|

Cleaning |

Requires solvent; can be costly and complex |

|

Activity Level |

Low to moderate |

|

Impact on Reliability |

Stable, protects joints, but residue may affect testing |

Note: Rosin-based fluxes leave more residue than other types, which can contaminate equipment and complicate cleaning.

No-Clean

No-clean fluxes help you streamline production by leaving minimal, non-corrosive residues. You can often skip cleaning steps, saving time and cost. These fluxes work well for high-volume manufacturing, but their residues may interfere with testing or coating in high-reliability applications. If you work in the aerospace or medical sectors, you may still need to clean these residues to ensure reliability.

-

No-clean residues are usually clear and hard.

Tip: Always verify that your no-clean Wave Soldering Flux is compatible with your assembly’s reliability requirements.

Water-Soluble

You select water-soluble fluxes when you need aggressive cleaning action. These fluxes have high solids content and remove oxides very effectively, making them ideal for dense or complex assemblies. After soldering, you must clean the residues thoroughly with water to prevent corrosion or electrical failures. Water-soluble fluxes offer excellent solder joint strength but demand careful post-soldering cleaning.

-

Residues are corrosive and hygroscopic.

-

Cleaning with water is mandatory for reliability.

Low-Solids

Low-solids fluxes contain only 1.5% to 8% solids, much less than traditional fluxes. When you use low-solids Wave Soldering Flux, you reduce residue and often eliminate the need for post-soldering cleaning. These fluxes support no-clean processes and help you lower costs and environmental impact. The residues are electrically benign, which improves long-term reliability.

|

Flux Type |

Typical Solids Content (%) |

|---|---|

|

Low-solids/no-clean |

1.5 to 8 |

|

Full-rosin fluxes |

15 to 45 |

|

Water-soluble fluxes |

11 to 35 |

Using low-solids fluxes allows you to simplify your process and reduce solvent use, making your operation more efficient and environmentally friendly.

Flux Selection Factors

End Use and Reliability

You must consider the final application of your assembly when selecting Wave Soldering Flux. If you build mission-critical electronics, such as aerospace, medical, or military devices, you need to meet the highest reliability standards. IPC Class 3 sets strict requirements for these assemblies. You must achieve zero-defect manufacturing, perform detailed inspections, and maintain full traceability. You also need to use fluxes that pass the J-STD-004B SIR test, which ensures high electrical resistance under harsh environmental conditions. This test exposes flux to high temperature and humidity for extended periods, confirming that it will not degrade or cause failures over time.

-

You must use certified suppliers and trained personnel for Class 3 manufacturing.

-

You need to document every step and track each lot for regulatory compliance.

-

You often apply cleaning and conformal coating to prevent corrosion and protect flux residues.

If you work with consumer or industrial electronics, you may have more flexibility. However, you still need to match the flux type to the reliability needs of your product. Always check if your flux supports long-term performance in the intended environment.

Tip: For assemblies exposed to vibration, thermal cycling, or humidity, choose fluxes with proven reliability under stress.

Assembly Complexity

The complexity of your PCB assembly directly affects your choice of Wave Soldering Flux. High-density boards with many components require fluxes that offer strong wetting and oxidation protection. You need flux that provides tackiness to hold components in place and promotes even heat distribution. Tailored formulations help you optimize performance for specific metals and finishes.

|

Flux Type |

Assembly Complexity |

Key Characteristics and Suitability |

|---|---|---|

|

High-density, complex PCBs |

Highly active, excellent wetting; residues are conductive and corrosive but easily cleaned with DI water; ideal for a spotless finish. Requires cleaning. |

|

|

Low-Residue / No-Clean |

High-reliability applications |

Minimal residue, reduces interference with testing or coatings; often no cleaning required; may need cleaner surfaces or preheating. Suitable for telecom, military electronics. |

|

Rosin-Based Flux |

Simpler assemblies |

Excellent wetting but leaves sticky residues; requires cleaning; suitable where cleaning is feasible and high wetting is needed. |

You must balance wetting performance, residue management, and cleaning feasibility. Complex assemblies often need highly active fluxes, but these can leave sticky or corrosive residues. You may need to use aqueous or solvent-based cleaning systems to remove these residues. Always consider the compatibility of your flux with lead-free processes and the materials used in your assembly.

Note: For high-density boards, select fluxes that support precise alignment and prevent shifting during soldering.

Residue and Cosmetics

Residue levels from different fluxes impact both the reliability and the cosmetic appearance of your assemblies. If you use rosin-based or resin-containing fluxes, you may notice sticky residues that attract dust and impurities. This stickiness can make your assembly look dirty or contaminated, especially in humid or hot environments. Visible residues can also contaminate connectors, increasing contact resistance and causing functional failures.

You must decide if visible residues are acceptable for your product. Some customers demand spotless assemblies for aesthetic reasons. In contrast, invisible ionic residues do not affect appearance but can cause corrosion and reliability issues. You need to choose a Wave Soldering Flux that balances cosmetic requirements with electrical safety.

-

Visible solid residues mainly affect appearance and may protect against moisture.

-

Ionic residues pose reliability risks but remain unseen.

Tip: If you need a clean, professional look, select low-residue or no-clean fluxes and verify that they do not compromise reliability.

Flux Application and Maintenance

Application Methods

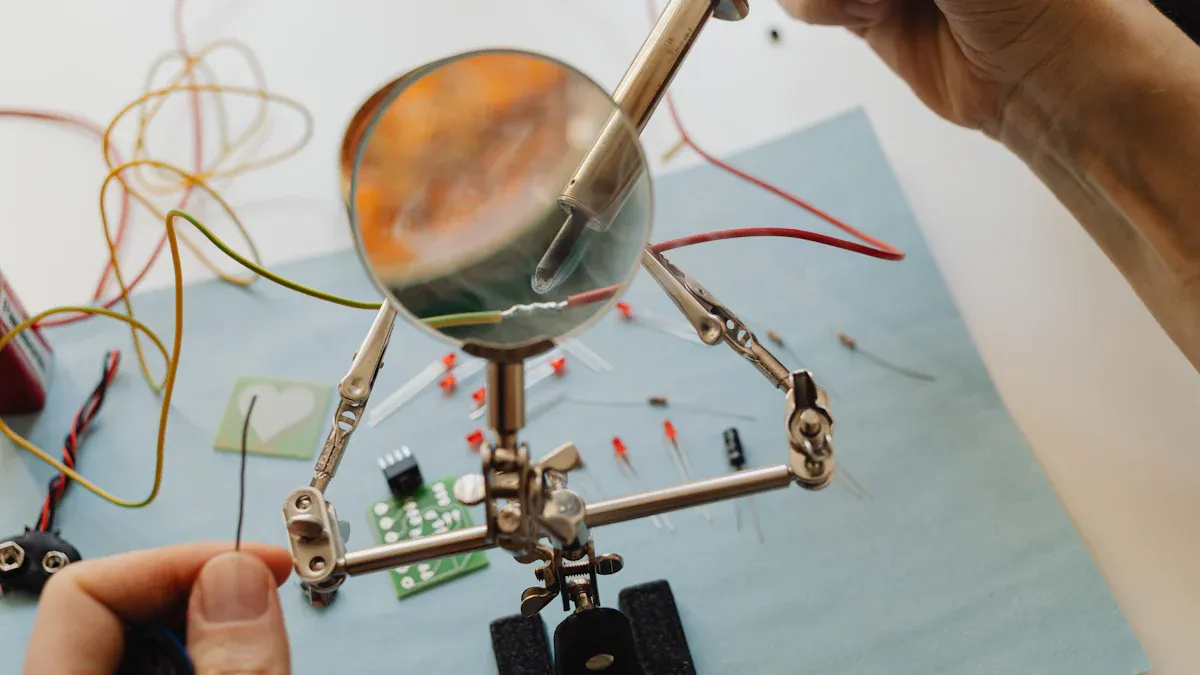

You have several options for applying flux in wave soldering. The method you choose affects both the efficiency of your process and the quality of your solder joints. The most common application methods include spray fluxing, foam fluxing, and manual application.

|

Method |

Description |

Advantages |

Typical Use Case |

|---|---|---|---|

|

Spray Fluxing |

Fine mist of flux is sprayed onto the PCB bottom as it passes over the fluxing unit. |

Consistent application, adjustable volume, suitable for high-speed production. |

High-volume, modern wave soldering |

|

Foam Fluxing |

Air bubbled through flux to create foam that contacts the PCB. |

Simple setup, cost-effective for low-to-medium volume production. |

Low-to-medium volume production |

|

Brush/Manual |

Flux is applied manually using a brush or dropper. |

Precise control for small areas, no equipment needed. |

Small-scale, rework, prototypes |

Spray fluxing gives you the most consistent and uniform coverage. You can adjust spray speed, flux volume, and air knife pressure to fine-tune the process. For example, increasing spray speed and volume while lowering air knife pressure improves flux coverage. This method works best for high-volume production lines. Foam fluxing uses air to create a foam that coats the PCB. This method is simple and cost-effective for smaller batches. Manual application works well for prototypes or repairs, where you need precise control.

The way you apply flux directly impacts solder joint quality. Uniform coverage prevents oxidation and ensures strong joints. If you use too much flux, you risk solder bridging and residue buildup. Too little flux can cause poor wetting and weak joints. You should always match the flux type and amount to your soldering process.

Tip: Train your operators on proper flux application techniques and equipment settings. Well-trained staff reduce errors and improve consistency.

Foam Height and Control

Maintaining the correct foam height is critical when you use foam fluxing. The foam must contact the entire underside of the PCB without overflowing. If you set the foam height too high, you may see excess flux, which leads to solder bridging and residue problems. Too low, and you risk incomplete coverage, resulting in poor solder joints.

Modern wave soldering machines often use dual-wave systems. You should keep the solder wave height about 2-3 mm above the PCB surface. Small adjustments—within 0.5 mm—help you maintain uniform solder joints across all boards. Turbulent solder waves can splash solder droplets, causing solder balling and defects. You can prevent this by adjusting the wave for smooth, laminar flow.

-

Regularly check and adjust foam and wave heights.

-

Clean and maintain flux applicators to avoid uneven application.

-

Monitor conveyor speed and temperature to ensure consistent results.

Thermal profiling helps you spot cold spots that could weaken solder joints. Consistent foam application and wave height reduce defects and improve process reliability.

Note: Schedule routine maintenance for your wave soldering equipment. Clean applicators and check for blockages to keep foam height stable.

Monitoring and Storage

Proper monitoring and storage of flux protects its chemical activity and ensures reliable soldering. You should always transport flux in covered vehicles, using shrink-wrapped pallets or crates. If you receive unprotected containers, repack them within one hour or discard the contents.

Store unopened flux drums at 20 ± 10°C with humidity below 70%. After use, place flux in drying cabinets or heated hoppers at 150 ± 25°C. If the flux absorbs moisture, rebake it at 350 ± 25°C for at least four hours. Always remove moisture and contaminants during recycling, and maintain a minimum ratio of new to recycled flux.

Improper storage causes flux to dry out, harden, or lose its chemical activity. These changes lead to poor solder adhesion, weak joints, and clogged equipment. Most fluxes have a shelf life of about one year. Using expired flux increases the risk of defects.

-

Seal containers tightly and store them vertically.

-

Monitor expiration dates and re-qualify flux if used beyond shelf life.

-

Train staff to recognize signs of flux degradation.

Alert: Never use Wave Soldering Flux that shows signs of hardening, separation, or contamination. Always follow manufacturer guidelines for storage and handling.

To achieve optimal soldering quality and minimal residue, you should follow a structured approach. Select the right flux for your application, clean surfaces thoroughly, and control process parameters. Apply flux using the best method for your production volume. Store and monitor flux carefully to maintain its effectiveness. Align your practices with industry benchmarks and regulatory standards. Regularly review your flux management process to drive continuous improvement and long-term manufacturing success.

FAQ

What happens if you use expired flux in wave soldering?

Expired flux loses its chemical activity. You may see poor solder joints, increased defects, and residue buildup. Always check expiration dates and replace old flux to maintain process reliability.

How often should you clean flux applicators?

You should clean flux applicators daily or after each production shift. Regular cleaning prevents clogging and ensures even flux distribution. Dirty applicators can cause inconsistent soldering results.

Can you mix different types of flux in one process?

Mixing flux types can cause unpredictable chemical reactions. You risk poor soldering, residue issues, and equipment contamination. Always use one flux type per process and follow manufacturer recommendations.

How do you know if you applied enough flux?

-

Check for uniform coverage on the PCB underside.

-

Inspect solder joints for proper wetting and shine.

-

Watch for defects like bridging or dull joints, which signal too much or too little flux.