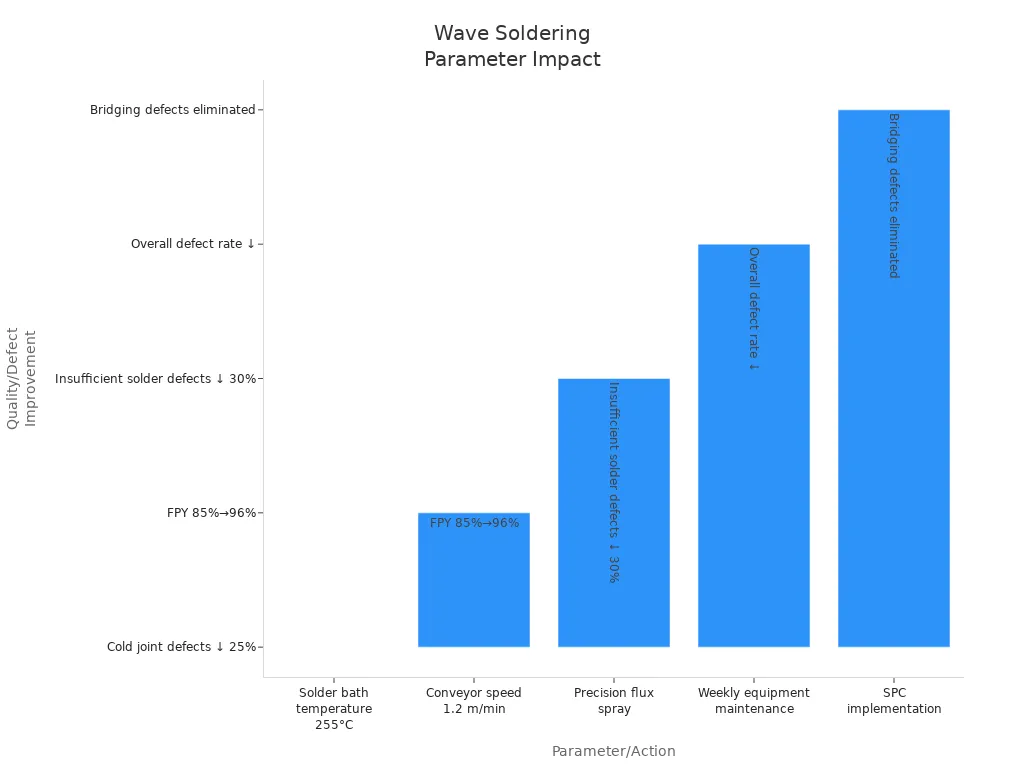

You play a crucial role in optimizing the Wave Soldering Process. Precise process setup directly influences defect rates and product quality. Recent industry data shows that improper setup contributes to nearly 50% of PCB assembly defects. When you tune process parameters carefully—such as solder bath temperature, conveyor speed, and flux application—you statistically reduce defects and improve first pass yield. The chart below illustrates how fine-tuning these variables can boost product quality and minimize defects.

Key Takeaways

-

Carefully control key wave soldering parameters like solder temperature, conveyor speed, and flux application to reduce defects and improve product quality.

-

Follow each process step—flux application, preheating, solder wave contact, cooling, and cleaning—to ensure strong, reliable solder joints.

-

Use proper equipment settings and monitor parameters closely; small changes can cause defects like bridging, cold joints, or insufficient solder.

-

Regularly inspect solder joints using visual checks, Automated Optical Inspection (AOI), and X-ray to catch defects early and maintain quality.

-

Tune your process by starting with baseline settings, then make small adjustments while monitoring results to optimize soldering performance.

-

Prevent common defects by understanding their causes and applying targeted solutions, such as adjusting wave height to avoid bridging or baking PCBs to reduce pinholes.

-

Maintain your equipment and train your team continuously to keep the wave soldering process stable and efficient over time.

-

Use strong process control methods, including documentation, statistical monitoring, and quick corrective actions, to ensure consistent, high-quality solder joints.

Wave Soldering Process Overview

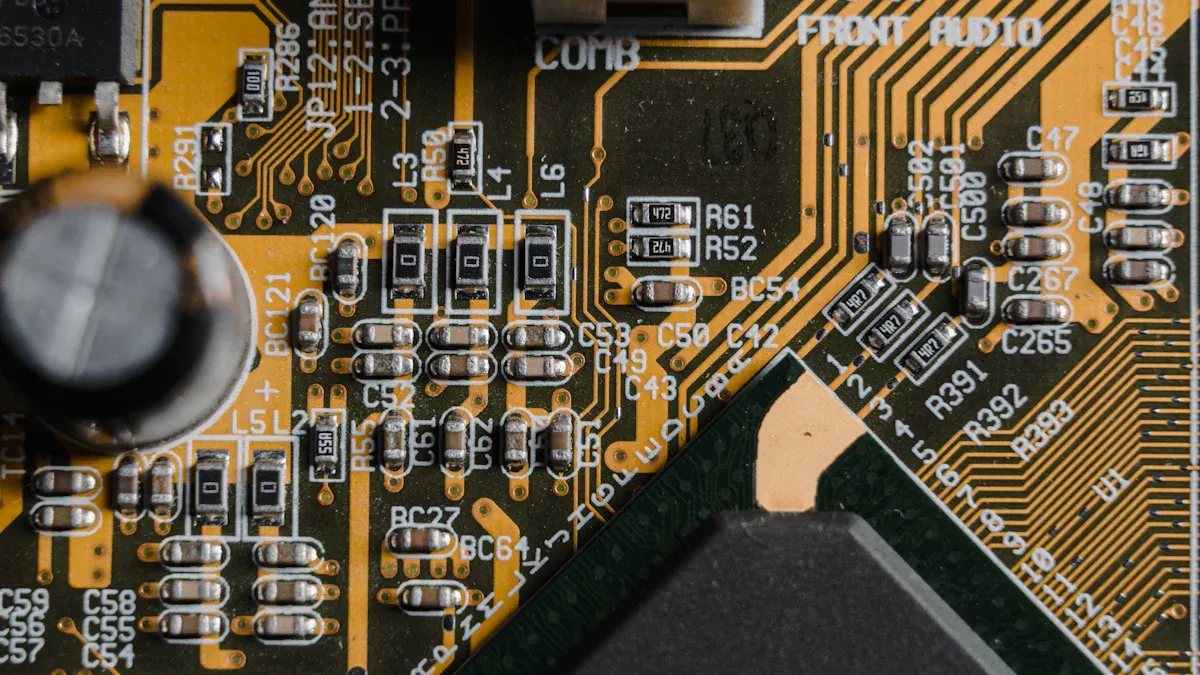

Wave soldering stands as a fully automated method that you use to connect electronic components to printed circuit boards (PCBs). This process plays a vital role in high-volume PCB assembly, especially for through-hole technology. You rely on the Wave Soldering Process to achieve consistent, reliable solder joints while minimizing manual labor and human error.

Key Steps

You can break down the Wave Soldering Process into several main stages. Each stage contributes to overall efficiency and product quality:

-

Flux Application: You spray or foam liquid flux onto the PCB. This step removes oxides and prepares surfaces for soldering.

-

Preheating: You heat the PCB to activate the flux and prevent thermal shock. Preheating also helps reduce solder defects and improves the soldering of dual-in-line package (DIP) components.

-

Solder Wave Contact: The PCB passes over a wave of molten solder. This forms the electrical and mechanical connections between components and pads.

-

Cooling: You cool the PCB to solidify the solder joints and prevent defects like cracking.

-

Cleaning: You remove any remaining flux residues using solvents or water-based cleaners. This step prevents corrosion and ensures long-term reliability.

Tip: Careful control at each stage helps you avoid common defects such as bridging, cold joints, and insufficient solder fill.

Equipment and Materials

You depend on specialized equipment and materials to ensure process reliability:

-

-

Single wave: Best for simple PCBs with only through-hole parts.

-

Dual wave: Handles mixed assemblies, improves solder quality, and reduces defects.

-

Multi-wave/selective: Offers precise soldering for complex boards but at a higher cost.

-

-

Flux: Removes oxides, enhances wetting, and prevents bridging. You must control the amount applied.

-

Molten Solder: Forms the joints as the PCB passes over the wave.

-

Preheaters: Raise PCB temperature to activate flux and reduce thermal shock.

-

Conveyor System: Moves PCBs through each stage at a controlled speed.

You also utilize inspection tools such as visual inspection, automated optical inspection (AOI), and X-ray to verify solder quality.

Process Parameters

You must control several critical parameters to achieve high-quality solder joints:

|

Parameter |

Typical Range |

Impact on Quality |

|---|---|---|

|

Solder Temperature |

Affects wetting and joint formation |

|

|

Preheat Temperature |

90–125°C |

Activates flux, reduces thermal stress |

|

Conveyor Speed |

1–3 cm/s |

Controls solder contact time |

|

4–8 mm |

Ensures proper solder coverage |

|

|

Flux Application |

As specified |

Promotes cleaning and wetting |

|

Cooling Rate |

1–2°C/s |

Prevents cracking and brittleness |

You monitor these parameters closely. Even small changes can lead to defects such as bridging, insufficient hole fill, or cold joints. Advanced systems use real-time monitoring and automated controls to keep these variables within tight limits. You ensure that every board meets IPC-A-610 standards by maintaining strict process control throughout the Wave Soldering Process.

Process Setup Essentials

Preheat

You set the foundation for high-quality solder joints by controlling the preheat stage. Preheating prepares the PCB and components for the solder wave. It activates the flux, removes moisture, and reduces thermal shock. If you skip or rush this step, you risk defects like solder balling, lifted components, and cold solder joints.

Tip: Use a thermal profiler to measure the actual temperature of the PCB as it moves through the preheat zone.

Follow these best practices to minimize defects during preheat:

-

Use thermal profiling tools to monitor and verify the PCB temperature.

-

Apply gradual temperature ramps, limiting the rate to 2–3°C per second, to reduce thermal shock.

-

Bake PCBs and components before soldering to remove moisture and prevent solder balling.

-

Secure all components properly to avoid lifted leads or parts.

-

Test preheat settings with dummy boards and maintain equipment regularly.

By following these steps, you ensure proper flux activation and reduce the risk of common defects.

Conveyor Speed

You control the conveyor speed to manage how long each PCB contacts the solder wave. This parameter directly affects solder joint formation and defect rates. If you set the conveyor too fast, the PCB may not get enough contact time, leading to poor wetting, bridging, or excessive solder. If you go too slow, you risk overheating and damaging components.

Manufacturers have improved first pass yield by adjusting conveyor speed to between 1.0 and 1.5 meters per minute. For example, setting the speed to 1.2 meters per minute, along with a stable solder bath temperature, reduced cold solder joints by 25%. This adjustment also reduced defects such as bridging and insufficient soldering, while increasing production efficiency. You should aim for a soldering time of 3 to 5 seconds at around 250°C to optimize results.

Solder Pot Temperature

You must keep the solder pot temperature within a tight range to ensure proper solder flow and joint quality. If the temperature is too low, solder may not wet the pads and leads, causing cold joints or insufficient fill. If the temperature is too high, you risk damaging the PCB, increasing dross formation, and causing component stress.

Set the solder pot temperature between 245°C and 255°C for most leaded processes. Always monitor the temperature with calibrated sensors. Adjust the temperature based on the type of solder alloy and the complexity of your assembly. Stable solder pot temperature, combined with the right conveyor speed, forms the backbone of a reliable Wave Soldering Process.

Wave Height and Angle

You control wave height and angle to achieve reliable solder joints and minimize defects in the Wave Soldering Process. These parameters determine how the molten solder contacts the PCB and its components. If you set the wave crest too high, solder can flood the board, causing excess solder or tin joints. If the height is too low, you risk poor wetting and incomplete soldering. The angle of the conveyor as it meets the solder wave also plays a critical role. A small angle increases the risk of bridging, while a large angle can reduce solder coverage and cause false soldering.

The table below summarizes how wave height and angle affect common defects and provides recommended settings:

|

Parameter |

Impact on Soldering Defects |

Recommended Range/Notes |

|---|---|---|

|

Wave Crest Height |

Excessive height causes excess solder; insufficient height leads to poor wetting and missing solder. |

|

|

Track Angle |

Small angle increases bridging; large angle reduces solder, causing false soldering. |

5° to 7° orbital inclination |

|

Wave Height Change |

Unchecked changes lead to inconsistent soldering quality. |

Monitor with depth gauge or high-temp glass tool |

You should regularly check and adjust wave height using a depth gauge or high-temperature glass tool. Maintain the wave crest at about two-thirds of the PCB thickness for most assemblies. Set the conveyor angle between 5° and 7° to balance solder coverage and minimize bridging. If you notice defects like point pulling tips or insufficient soldering, review these parameters first. Adjusting wave height and angle often resolves these issues quickly.

Tip: Monitor wave height throughout production. Even small changes can impact solder joint quality and increase defect rates.

Flux Application

You apply flux before the PCB enters the solder wave. This step is essential for cleaning component leads and pads, removing oxidation, and promoting good solder wetting. The method and amount of flux you use directly affect solder joint quality and the occurrence of defects.

Common and effective flux application methods include:

-

Liquid flux, applied before the PCB enters the machine, is standard in most operations.

-

You can use spray, foam, or selective flux applicators to control where and how much flux is applied.

-

Controlled application prevents excess flux, which can cause residue-related defects or improper wetting.

-

Choose the right flux format and application method based on your process and component layout to optimize results.

-

No-clean or water-soluble fluxes help minimize residue, but you must use proper cleaning methods if needed.

Spray application ensures even coverage but requires careful control. Too much flux can leave residues that cause corrosion or electrical problems. Too little flux can result in poor solder joints and increased defects. Always verify flux coverage and adjust your equipment as needed.

Note: In the Wave Soldering Process, proper flux application is just as important as temperature and timing. Regularly inspect flux delivery systems and clean them to prevent clogging or uneven application.

Wave Soldering Process Tuning

Tuning the Wave Soldering Process requires a systematic approach. You need to start with solid baseline settings, make careful adjustments, and monitor results closely. This process ensures you achieve consistent, high-quality solder joints and minimize defects.

Baseline Settings

You should always begin with manufacturer-recommended baseline settings for your equipment and materials. These settings provide a reliable starting point for most assemblies. To establish your baseline:

-

Review Equipment Manuals: Set initial parameters such as solder pot temperature, conveyor speed, preheat temperature, and wave height according to the machine and solder alloy specifications.

-

Profile Your PCB: Use a thermal profiler to measure the actual temperature of the PCB as it moves through each stage. This step helps you confirm that your preheat and solder temperatures match your targets.

-

Document Initial Conditions: Record all baseline values, including flux type and application rate, solder alloy, and board orientation. This documentation allows you to track changes and repeat successful setups.

Tip: Always use a test or dummy board to verify your baseline settings before running production boards. This practice helps you catch issues early.

Fine-Tuning Parameters

Once you establish your baseline, you need to fine-tune key process parameters to optimize soldering results. You should focus on the variables that most directly affect solder joint quality and defect rates. The most frequently adjusted parameters include:

-

Conveyor speed

-

Preheat temperature and ramp rate

-

Wave height and angle

-

Flux application rate

You can use thermal profiling tools, such as thermocouples or specialized profiling boards, to gather data on temperature distribution across the PCB. This data helps you identify hot or cold spots and adjust your settings for even heating and proper solder flow.

You should also consider the complexity of your PCB, component density, and the properties of your solder alloy. For example, a densely populated board may require a slower conveyor speed or higher preheat temperature to ensure all joints reach the correct temperature. Incremental adjustments—such as changing the solder pot temperature by ±5°C or adjusting conveyor speed by 0.1 m/min—allow you to see the impact of each change without introducing new problems.

Note: Regular thermal analysis and empirical testing help you maintain consistent solder joint quality and minimize defects. Customizing your process for each assembly type leads to better results.

Monitoring and Adjustment

Continuous monitoring and adjustment are essential for maintaining repeatable quality in the Wave Soldering Process. You should implement the following steps:

-

In-Process Inspection: Use Automated Optical Inspection (AOI) and visual checks to detect defects as soon as they occur. Immediate feedback allows you to make timely adjustments.

-

Track Touch-Up and Repairs: Document every manual touch-up or repair. Frequent touch-ups may indicate a process issue that needs correction.

-

Integrate Inspection Data: Combine AOI results and repair records into your workflow. This integration ensures traceability and helps you identify recurring problems.

-

Apply Statistical Process Control (SPC): Monitor defect rates and process parameters using SPC charts. This approach helps you spot trends and take corrective action before defects escalate.

-

Root Cause Analysis: Use inspection and repair data to investigate the source of defects. Look for patterns related to pallet design, wave optimization, or thermal profiling.

Alert: Consistent documentation and feedback loops are critical. They help you verify that your process remains under control and support continuous improvement.

You should always update your process documentation after making adjustments. This habit ensures that you can repeat successful setups and quickly troubleshoot issues in the future. By following these steps, you create a robust, data-driven approach to process tuning that delivers reliable, high-quality results.

Common Soldering Defects

Solder Bridging

Causes

Solder bridging happens when excess solder forms an unintended connection between adjacent pads or leads. You often see this defect with fine-pitch components or when process parameters drift out of control. Several factors contribute to solder bridging:

|

Process Parameter |

Effect on Solder Bridging |

|---|---|

|

Too much wave height causes excess solder to flow, creating bridges between pads or leads. |

|

|

Solder Temperature |

High solder temperature increases solder volume and flow, raising the risk of bridging. |

|

Conveyor Speed |

Slow conveyor speed gives more exposure to the solder wave, depositing more solder and increasing bridging risk. |

Other causes include poor fluxing, incorrect preheat, and improper wave separation. As component pitch decreases, the risk of solder shorts rises. Design issues, such as large pad sizes or long leads, also make bridging more likely.

Solutions

You can reduce solder bridging by optimizing your process and design:

-

Adjust the wave height to match the PCB thickness. Keep it at about two-thirds of the board thickness.

-

Set solder temperature within the recommended range. Avoid excessive heat.

-

Increase conveyor speed slightly to reduce solder exposure time.

-

Use the correct flux type and apply it evenly to promote proper solder separation.

-

Review pad and lead design. Reduce pad size and control lead length where possible.

-

Regularly inspect and maintain your equipment to ensure consistent operation.

Tip: Monitor bridging rates using AOI systems. Early detection helps you adjust parameters before defects escalate.

Insufficient Solder

Causes

Insufficient solder results in weak or incomplete joints. You may notice this defect as poor hole fill, exposed leads, or unreliable electrical connections. Common causes include:

-

Low solder pot temperature, which prevents proper wetting.

-

Fast conveyor speed reduces contact time with the solder wave.

-

Inadequate wave height, leading to incomplete coverage.

-

Poor flux application or activation.

-

Contaminated pads or leads.

-

Incorrect stencil thickness or poor solder paste deposition in mixed-technology assemblies.

Solutions

You can address insufficient soldering by focusing on process control and equipment maintenance:

-

Optimize solder paste printing. Select the correct stencil thickness and control paste viscosity for accurate deposition.

-

Use Solder Paste Inspection (SPI) systems to catch printing defects early. Adjust stencil alignment and paste viscosity as needed.

-

Fine-tune conveyor speed and solder pot temperature to ensure complete soldering.

-

Regularly calibrate and maintain your printing and placement equipment.

-

Handle and store materials properly. Control moisture and inspect for oxidation.

-

Bake PCBs before soldering to remove moisture and improve solderability.

A documented case study showed that using SPI data and adjusting printing parameters reduced insufficient solder defects by up to 90%. This demonstrates the value of targeted process adjustments.

Pinholes and Blowholes

Causes

Pinholes and blowholes appear as small or large voids in solder joints. You often find these defects when gas escapes from the PCB during soldering. The main causes include:

|

Aspect |

Explanation |

|---|---|

|

Primary Cause |

Moisture trapped in plated through holes turns into gas during soldering, escaping through molten solder and creating pinholes (small voids) and blowholes (larger voids). |

|

Root Causes |

Insufficient copper plating thickness (minimum 20-25µm recommended), poor plating quality, moisture absorption by PCB material, and irregular surfaces from poor drilling quality. |

|

Process Control Issues |

Inadequate baking or preheating to remove moisture, poor drilling quality causing irregularities, and insufficient copper plating thickness. |

|

Soldering Process Link |

Gas escapes during the last solidification phase of solder at the base of the hole, causing voids. |

Solutions

You can prevent pinholes and blowholes by improving board quality and process control:

-

Ensure copper plating thickness meets or exceeds 25µm.

-

Bake PCBs at the correct temperature and duration before soldering to remove moisture. Avoid excessive baking, as it can cause other issues.

-

Use high-quality drilling and plating processes to minimize irregularities.

-

Preheat boards properly to drive out moisture before they reach the solder wave.

-

Work closely with your PCB supplier to maintain manufacturing specifications and quality standards.

Note: New surface finishes may not tolerate extended baking. Always follow manufacturer guidelines for baking and handling.

Cold Solder Joints

Causes

Cold solder joints occur when the solder fails to bond properly with the pad or lead. You can spot these joints by their dull, grainy, or cracked appearance. Several factors often lead to this defect:

-

Insufficient heat at the solder joint prevents proper wetting.

-

Poor flux activity or uneven flux application leaves oxides on surfaces.

-

Low solder pot temperature fails to melt the solder fully.

-

Fast conveyor speed reduces the time the joint spends in the solder wave.

-

Inadequate preheat does not activate the flux or remove moisture.

-

Excessive vibration or movement during cooling disturbs the joint before it solidifies.

Tip: Cold solder joints often result in weak electrical connections and can cause intermittent failures in the field.

Solutions

You can significantly reduce cold solder joints by making targeted process adjustments:

-

Optimize flux application. Choose the right flux type, apply it evenly, and ensure it has enough activity to clean surfaces.

-

Increase preheat temperature by about 10°C. This step activates the flux more effectively and reduces thermal shock, which lowers thermal stress-related failures by 15%.

-

Adjust conveyor speed to provide optimal dwell time in the solder wave. Improved wetting can reduce cold solder joints by nearly 20%.

-

Maintain the correct solder bath temperature. Raising the wave height by about 2 mm improves solder penetration and lowers rework rates by 10%.

-

Control cooling rates after soldering. Keep the rate between 2°C and 4°C per second to prevent thermal shock and excess intermetallic formation.

You should also inspect joints visually and with AOI systems to catch cold solder joints early. Regular equipment maintenance and process monitoring help you sustain high-quality results.

Dewetting

Causes

Dewetting appears when solder initially wets the pad but then recedes, leaving behind irregular, thin films or islands of solder. You may notice exposed copper or uneven surfaces. Several process factors contribute to dewetting:

-

Surface contamination from oils, greases, or flux residues reduces solder surface tension and blocks good bonding.

-

Oxidation of copper pads or component leads inhibits solder wetting.

-

Poor solderability due to damaged plating or low-quality solder paste.

-

PCB design issues, such as small pad size or improper solder mask, limit solder deposition.

-

Incorrect flux selection or application fails to remove oxides.

-

Inadequate temperature profiles during preheat, soldering, or cooling cause thermal mismatch and poor wetting.

-

Poor surface finish quality or incompatible solder alloys, especially with lead-free solders, increase dewetting risk.

Experts recommend performing solderability tests on PCBs and components using clean solder pots to rule out solder purity issues. You should also validate preheat and solder pot temperatures, as improper settings can trigger dewetting. Reviewing material certifications, especially for ENIG finishes, helps ensure plating thickness and gold type support good solder wetting.

Solutions

You can address dewetting by focusing on cleanliness, temperature control, and process optimization:

-

Clean PCBs and components thoroughly using flux-compatible cleaning agents and mechanical methods.

-

Select and apply flux with the right activator strength, solids content, and thermal stability.

-

Optimize temperature profiles. Use a gradual preheat, set the correct peak soldering temperature, and control cooling to avoid thermal stress.

-

Improve surface finish quality by monitoring plating thickness and uniformity.

-

Ensure solder alloy compatibility with base materials and surface finishes.

-

Implement process controls such as Statistical Process Control (SPC), Automated Optical Inspection (AOI), and X-ray inspection to detect defects early.

-

Train your team on soldering fundamentals and defect prevention.

Note: A Design of Experiments (DOE) approach can help you identify root causes by analyzing operator and tool variation.

Tombstoning

Causes

Tombstoning occurs when one end of a component lifts off the pad during soldering, making the part stand upright like a tombstone. You often see this defect with small passive components, such as resistors and capacitors. Common causes include:

-

Uneven heating between the two pads causes one side to reflow before the other.

-

Imbalanced solder volume or paste deposition on the pads.

-

High conveyor speed or improper preheat leads to rapid temperature changes.

-

Poor wetting due to insufficient flux or oxidized surfaces.

-

Incorrect pad design or component placement.

Solutions

You can minimize tombstoning by improving process balance and control:

-

Ensure even preheating and consistent temperature profiles across the PCB.

-

Adjust solder paste volume and stencil design to provide equal solder on both pads.

-

Slow down conveyor speed if you notice rapid temperature changes.

-

Use high-activity flux to promote even wetting.

-

Review pad design and component placement for symmetry and proper alignment.

-

Train operators to recognize and correct placement issues during setup.

Alert: Consistent monitoring and process adjustments help you prevent tombstoning and maintain high assembly yields.

Solder Balls

Causes

Solder balls appear as small, round beads of solder scattered on the PCB surface. You often find them after wave soldering, especially near component leads or pads. Several factors contribute to this defect:

-

Excessive flux application leaves too much residue, which can spatter and form solder balls.

-

Low preheat temperature fails to evaporate solvents in the flux, causing solder to splatter when it hits the wave.

-

High wave temperature melts solder too quickly, increasing the chance of solder ball formation.

-

Fluxes containing antimony or bismuth promote solder flow but also increase solder ball risk.

-

Burning off flux before the board enters the solder wave can cause bridging and solder ball issues.

-

Poor PCB cleanliness or contamination, such as dust or oil, can trap solder and create balls.

-

Inconsistent or insufficient flux application at specific locations leads to non-random solder balls.

Tip: Random solder balls usually point to process issues like too much flux or incorrect thermal profiles. Non-random solder balls often indicate localized flux or heating problems.

Solutions

You can reduce solder balls by focusing on process control and material selection:

-

Choose fluxes without antimony or bismuth, or select those with anti-solder ball additives.

-

Control flux application using tools like a Fluxometer to ensure even and appropriate coverage.

-

Set preheat temperatures high enough to evaporate flux solvents before the PCB reaches the solder wave.

-

Avoid excessive soldering temperatures. Maintain the wave temperature within the recommended range for your solder alloy.

-

Keep PCBs clean and free from contaminants before soldering.

-

Use anti-solder ball fluxes for boards with high thermal mass or sensitive components.

-

Regularly inspect and maintain flux delivery systems to prevent clogging or uneven application.

-

Match your flux type and application method to your PCB design and thermal profile.

Note: Proper flux selection and application, combined with controlled preheat and wave temperature, significantly reduce solder ball defects.

Excessive Solder

Causes

Excessive solder creates large, bulbous joints or leaves solder spikes and icicles on the PCB. You may notice this defect when too much solder remains on leads or pads after the wave. Common causes include:

-

An incorrect conveyor speed allows the PCB to pick up too much solder.

-

Solder depth is set too high, causing excess solder to flood the board.

-

Poor control of wave height or angle increases solder volume on joints.

-

Improper lead length or pad ratio in PCB design traps more solder.

-

Inadequate preheating or incorrect solder temperature affects solder drainage.

-

Using solder with the wrong composition or contaminated solder increases viscosity and solder retention.

-

Grease or other contaminants in the process interfere with solder flow.

Solutions

You can address excessive solder by making targeted process and design improvements:

-

Orient similar components in the same direction to improve solder drainage.

-

Adjust conveyor belt speed to limit solder pickup and promote proper drainage.

-

Control solder depth and wave height to avoid flooding the board.

-

Maintain correct preheat and solder temperature for optimal solder flow.

-

Select flux with the right activity and gravity for your assembly.

-

Use solder with the proper composition and avoid heavily contaminated solder.

-

Design PCBs with the correct lead length to pad ratio.

-

Allow 4 to 6 hours between re-soldering attempts to prevent heat damage.

-

Keep all joints and surfaces clean and free from grease or other contaminants.

Alert: Regularly check your solder pot for contamination and monitor solder composition to maintain consistent results.

Skipping

Causes

Skipping occurs when the solder wave fails to wet certain pads or leads, leaving them unsoldered. You may see this defect as missing or incomplete joints, especially on densely populated boards. Typical causes include:

-

Mismatched flux application rate and conveyor speed, leading to incomplete flux coverage.

-

Incorrect preheater settings that do not match the flux’s thermal requirements.

-

Improper wave height prevents full contact between the solder and pads.

-

Gassing of flux under the board creates bubbles that block solder wetting.

-

Excess solder resist thickness traps flux vapors, forming bubbles.

-

Adhesive contamination on pads prevents solder from adhering.

-

Poor board positioning or warped pallets cause uneven solder contact.

-

Small pads or shadowing from larger components block the solder wave.

|

Cause |

Explanation |

Solution |

|---|---|---|

|

The solder wave does not reach all pads |

Adjust the wave height for full contact |

|

|

Gassing of flux under the board |

Trapped vapors prevent solder wetting |

Improve flux application and preheat |

|

Excess solder resist |

Thick mask traps vapors, forming bubbles |

Ensure solder resist is level with the pad |

|

Adhesive contamination |

Invisible films block solder adhesion |

Control adhesive use and curing |

|

Improper board positioning |

Boards are not flat or misaligned in the conveyor |

Use undistorted pallets and proper handling |

|

Layout issues |

Small pads or shadowing block solder wave |

Optimize pad size and component spacing |

Solutions

You can prevent skipping by optimizing process parameters and PCB design:

-

Match the flux application rate to conveyor speed for full coverage and proper penetration.

-

Adjust preheater settings to meet the thermal requirements of your flux and board.

-

Set the wave height to ensure complete solder contact with all pads and leads.

-

Use backplate adjustments to remove oxide skin from the solder wave before board entry.

-

Employ nitrogen atmospheres to improve solder drainage and wetting.

-

Reduce conveyor speed for sensitive SMD components if needed.

-

Increase spacing between components and pads to prevent shadowing.

-

Avoid excessive flux accumulation under or between components.

-

Ensure solder resist is level with or below the pad surface.

-

Control adhesive use and curing to prevent contamination.

Tip: Regularly review your PCB layout and process settings. Early detection and correction of skipping defects help maintain high assembly yields.

Inspection and Troubleshooting

Visual Inspection

You begin quality control with visual inspection. This method allows you to catch many common wave soldering defects early. Skilled operators use magnifying glasses, microscopes, or visual cameras to examine each PCB. You look for issues such as:

-

Bulbous or sunken joints

-

Cracked or incomplete joints

-

Flux residues

-

Poor hole fill

-

Solder balls

-

Solder shorts and bridges

-

Solder skips

-

Insufficient wetting

You also check for unsoldered joints and dry solder. Visual inspection ensures solder joints are correctly placed and solder is evenly distributed. This step is essential for meeting industry standards like IPC-A-610. You find visual inspection most effective for boards with fewer components. As complexity increases, you may need advanced inspection methods.

Tip: Consistent visual inspection helps you maintain high quality and catch defects before they reach the next stage.

AOI

Automated Optical Inspection (AOI) takes your defect detection to the next level. AOI systems use advanced cameras, programmable lighting, and multi-angle imaging to inspect intricate PCB designs. You benefit from AOI because it:

-

Detects defects invisible to the human eye, such as tiny solder bridges or misaligned components

-

Reduces defect escape rates by up to 90%, lowering the chance of faulty boards passing inspection

-

Completes inspections in 1–2 minutes, compared to 30–60 minutes for manual checks

-

Provides real-time data for immediate process adjustments

-

Preserves board integrity with non-contact inspection

-

Delivers consistent results without fatigue or human error

|

Aspect |

AOI Advantage Over Manual Inspection |

|---|---|

|

Accuracy |

Sub-pixel precision for detecting hidden defects |

|

Defect Escape Rate |

Up to 90% reduction |

|

Inspection Speed |

1–2 minutes per board |

|

Process Feedback |

Real-time data for quick adjustments |

|

Cost Savings |

Early detection reduces rework and field failures |

|

Handling Consistency |

Non-contact, no fatigue |

|

Technology Features |

Advanced lighting, multi-angle imaging, machine learning algorithms |

AOI software uses pattern matching and machine learning to increase detection accuracy and reduce false positives. You can quickly adjust inspection parameters to match design changes, making AOI flexible for different assemblies.

Note: Early detection through AOI helps you prevent large-scale production of faulty boards and supports continuous process improvement.

X-ray

You use X-ray inspection to uncover hidden defects that visual and optical methods cannot detect. X-ray systems provide a non-destructive internal view of solder joints and components. This method allows you to:

-

Detect voids, cracks, insufficient solder, shorts, and open joints beneath components

-

Visualize and measure defects with detailed 2D and 3D imaging

-

Inspect concealed solder joints under BGAs, QFNs, and connectors

-

Identify solder quality issues and hidden shorts that AOI cannot see

-

Reveal internal defects such as poor alignment and poor soldering

X-ray inspection is essential for ensuring the reliability and safety of wave-soldered PCBs, especially in high-risk industries like aerospace and medical devices. You gain precise identification of internal defects, which supports early detection, quality assurance, and root cause analysis.

Alert: X-ray inspection complements visual and AOI methods, filling the gap for subsurface defect detection and helping you maintain the highest quality standards.

Electrical Testing

You rely on electrical testing to confirm the integrity of solder joints after wave soldering. These tests help you identify weak connections, hidden defects, and potential failures before products reach your customers. Electrical testing methods simulate real-world stresses and measure joint strength under various conditions.

You can use several reliable techniques to verify solder joint quality:

-

Shock and Vibration Tests: You expose PCBs to mechanical shocks and vibrations. These tests reveal weaknesses that could cause solder joints to fail during shipping or use.

-

Dye & Pry Test: You apply dye to the PCB, then mechanically pry components off. The dye penetrates cracks or defects, making them visible for inspection.

-

Cross-Section Check (Micro-section Analysis): You cut and polish a sample joint to inspect its internal structure. This method helps you detect cold soldering, dewetting, or poor wetting.

-

Shear Testing: You apply force perpendicular to the solder joint. This test measures the maximum force the joint can withstand before breaking.

-

Tensile Testing: You pull components apart to assess how well the solder adheres to the substrate.

-

Bend Testing: You bend the assembly to evaluate flexibility and resistance to mechanical stress.

-

Pull Testing: You apply a pulling force until the joint fails. This test quantifies joint strength.

-

Thermal Cycling Testing: You subject PCBs to repeated temperature changes. This process simulates thermal stress and checks for fatigue resistance.

-

Vibration Testing: You simulate mechanical stresses that occur during transport or operation.

-

Acoustic Microscopy: You use sound waves to detect internal defects or weaknesses in solder joints.

Tip: Combine multiple testing methods to get a complete picture of solder joint reliability. Early detection of weak joints helps you prevent costly failures and improve product quality.

Root Cause Analysis

You use root cause analysis to solve recurring wave soldering defects. This process helps you identify the underlying issues and implement effective solutions. You follow a systematic approach to address each defect type and improve solder joint quality.

|

Step/Defect Type |

Root Cause(s) Identified |

Corrective Actions / Solutions |

|---|---|---|

|

Preparation |

Improper component placement |

Use custom-designed jigs/fixtures to hold components firmly and prevent movement |

|

Flux Application |

Incorrect flux ratio or application |

Control the flux amount and type according to specifications |

|

Preheating |

Insufficient preheating temperature or time |

Increase preheating temperature and duration to activate flux and avoid thermal shock |

|

Solder Wave Contact |

Incorrect solder pot temperature, speed, or angle |

Adjust solder pot temperature, conveyor speed, and PCB angle to optimize solder flow |

|

Cooling, Trimming, Cleaning |

Excessive or insufficient soldering due to lead length or flux |

Trim leads to recommended length (1-2 mm), clean flux residues, and adjust flux ratio |

|

PTH Component Floatation |

Improper manual placement, thermal expansion of solder paste |

Design jigs to press down components, use adhesive under components, or apply selective soldering |

|

Solder Spikes |

Uneven heat absorption, long leads, and insufficient preheating |

Increase preheating temperature, reduce conveyor speed, trim leads to ≤2.5 mm, increase solder temperature |

|

Pinholes |

Moisture in PCB, contaminated leads, trapped air in holes |

Bake PCBs before soldering, avoid contamination, check hole and lead fit, change molding method if needed |

|

Insufficient Soldering |

Incorrect solder pot settings, long leads, and pad design issues |

Adjust solder pot, shorten leads, redesign pads, and add solder mask to separate pads |

|

Excessive Soldering |

Low solder temperature, insufficient preheating, and low flux ratio |

Increase solder temperature, slow furnace speed, adjust preheating, and flux ratio |

You improve solder joint quality by following these steps. You design custom jigs to hold components securely. You control the flux application and adjust preheating to activate the flux and prevent thermal shock. You optimize solder pot temperature, conveyor speed, and PCB angle for better solder flow. You trim leads to the recommended length and clean flux residues. You bake PCBs to remove moisture and avoid pinholes. You redesign pads and adjust the solder mask to prevent insufficient soldering. These actions have proven effective in real production environments, reducing recurring defects and increasing reliability.

Note: Consistent root cause analysis and corrective actions help you maintain high-quality standards and minimize rework in your wave soldering process.

Best Practices

Continuous Monitoring

You need to keep a close eye on your wave soldering process to maintain consistent quality. Continuous monitoring helps you catch small issues before they become major problems. By using proven techniques, you can ensure stable production and reduce the risk of defects. Here are some effective methods you should use:

-

Use statistical control charts to track soldering performance. Review these charts in weekly quality meetings to spot trends and process variations early.

-

Apply Deming’s Plan-Do-Study-Act (PDSA) cycle. This approach lets you refine your wave soldering process step by step, driving ongoing improvement.

-

Provide formal and ongoing training for everyone involved in wave soldering. Well-trained staff improve process quality and reduce errors.

-

Employ problem-solving tools like Pareto charts and cause-and-effect (fishbone) diagrams. These tools help you identify and prioritize the root causes of soldering defects.

-

Optimize and control critical process variables. Focus on flux application (speed, volume, air knife pressure), preheat temperatures, conveyor speed, solder contact dwell time, immersion depth, and board-wave interaction.

-

Create individual or family group profiles for different PCB types. Tailor your wave soldering parameters to match each profile for better results.

-

Use wave solder optimizers to measure and control solder application variables. Adjust the solder pump speed and solder pot level to maintain proper dwell time and immersion depth.

-

Maintain a team-based, iterative improvement approach. Support from management helps you improve wave soldering quality without large capital investments.

Tip: Regular monitoring and teamwork help you spot problems early and keep your process running smoothly.

Maintenance

You must give regular attention to your wave soldering equipment if you want stable results. Routine maintenance and inspection keep your machines running as they should. Calibrate soldering robots, power supplies, and electrodes on a set schedule. This practice ensures normal operation and stable soldering performance. When you keep up with maintenance, you see fewer soldering failures and a drop in defect rates. Joint quality improves, and you spend less time on rework and repairs. Consistent upkeep protects your investment and supports high-quality production.

Alert: Skipping maintenance can lead to unexpected breakdowns and higher defect rates. Make maintenance a priority in your process plan.

Training

You build a strong process when you invest in training. Teach your team the basics of wave soldering and the reasons behind each process step. Use hands-on sessions and regular refreshers to keep skills sharp. Encourage operators to share tips and report issues. Well-trained staff spot problems faster and help you maintain high standards. Training also boosts morale and reduces turnover, which keeps your process stable over time.

Note: Training is not a one-time event. Make it part of your ongoing improvement plan to keep your team and your process at their best.

Process Control

You achieve consistent wave soldering results when you implement strong process control. This approach helps you reduce variability, maintain high quality, and quickly identify issues before they impact production. Process control gives you the tools to standardize your workflow and ensure every PCB meets your quality standards.

Key Elements of Effective Process Control:

-

Standard Operating Procedures (SOPs):

You create clear, step-by-step instructions for every stage of the wave soldering process. SOPs help your team follow best practices and reduce errors. Update these documents regularly to reflect process improvements. -

Process Parameter Monitoring:

You track critical variables such as solder pot temperature, conveyor speed, preheat temperature, and flux application. Use digital sensors and data loggers to collect real-time data. Set control limits for each parameter to catch deviations early. -

Statistical Process Control (SPC):

You use SPC charts to visualize trends and spot out-of-control conditions. For example, you can plot solder joint temperatures or defect rates over time. This method helps you react quickly to process shifts.

|

Parameter |

Typical Control Limit |

Monitoring Frequency |

|---|---|---|

|

Solder Pot Temperature |

±2°C |

Continuous |

|

Conveyor Speed |

±0.1 m/min |

Hourly |

|

Preheat Temperature |

±5°C |

Hourly |

|

Flux Application Rate |

±10% |

Per Batch |

-

Documentation and Traceability:

You record all process changes, maintenance activities, and inspection results. Good documentation allows you to trace defects back to their source and supports continuous improvement. -

Corrective Action Plans:

When you detect a process deviation, you act immediately. You adjust parameters, retrain staff, or repair equipment as needed. Quick response prevents small problems from becoming major defects.

Tip: Use color-coded charts or dashboards to make process data easy to understand for your team. Visual tools help everyone stay informed and engaged.

You also benefit from regular process audits. These reviews help you verify that your team follows procedures and that equipment operates within specifications. Audits often reveal opportunities for further improvement.

You should encourage a culture of accountability. When everyone on your team understands the importance of process control, you see fewer mistakes and higher yields. You empower operators to report issues and suggest improvements.

Process control is not a one-time task. You must review and refine your controls as your products and technologies evolve. By making process control a daily habit, you build a foundation for long-term success in wave soldering.

You achieve reliable wave soldering results when you follow a systematic process setup and tune each parameter with care. Understanding common defects helps you take quick action and prevent costly rework. Regular monitoring, focused training, and continuous process improvement keep your quality high.

Remember: Consistent attention to detail at every stage sets you apart as a leader in PCB assembly.

FAQ

What is the most critical parameter in wave soldering?

You should focus on solder pot temperature. This parameter directly affects solder wetting and joint quality. If you keep the temperature stable, you reduce most common defects.

How often should you calibrate wave soldering equipment?

You should calibrate your equipment at least once per quarter. Frequent calibration ensures accurate temperature, conveyor speed, and wave height. This practice helps you maintain consistent soldering results.

Can you use the same settings for all PCB types?

No. You must adjust settings for each PCB type. Board thickness, component density, and solder alloy all require different process parameters. Always profile new assemblies before production.

What causes sudden increases in solder bridging?

You may see more bridging if wave height rises, conveyor speed drops, or flux application becomes uneven. Check these parameters first. Equipment wear or contamination can also cause sudden changes.

How do you prevent solder balls?

You should control flux volume, preheat temperature, and solder wave speed. Clean PCBs before soldering. Use anti-solder ball flux if needed. Regularly inspect and maintain your flux delivery system.

Is AOI enough for quality control?

AOI detects the most visible defects. For hidden issues, you need X-ray or electrical testing. Combine inspection methods for the best results.

What should you do if you see repeated cold solder joints?

You should check the solder pot temperature, conveyor speed, and flux activity. Increase preheat temperature if needed. Inspect for contamination on pads and leads.

How can you quickly identify the root cause of a defect?

Use a checklist:

Review process parameter logs

Inspect recent maintenance records

Analyze AOI and repair data

Compare with baseline settings

This approach helps you find the source fast.