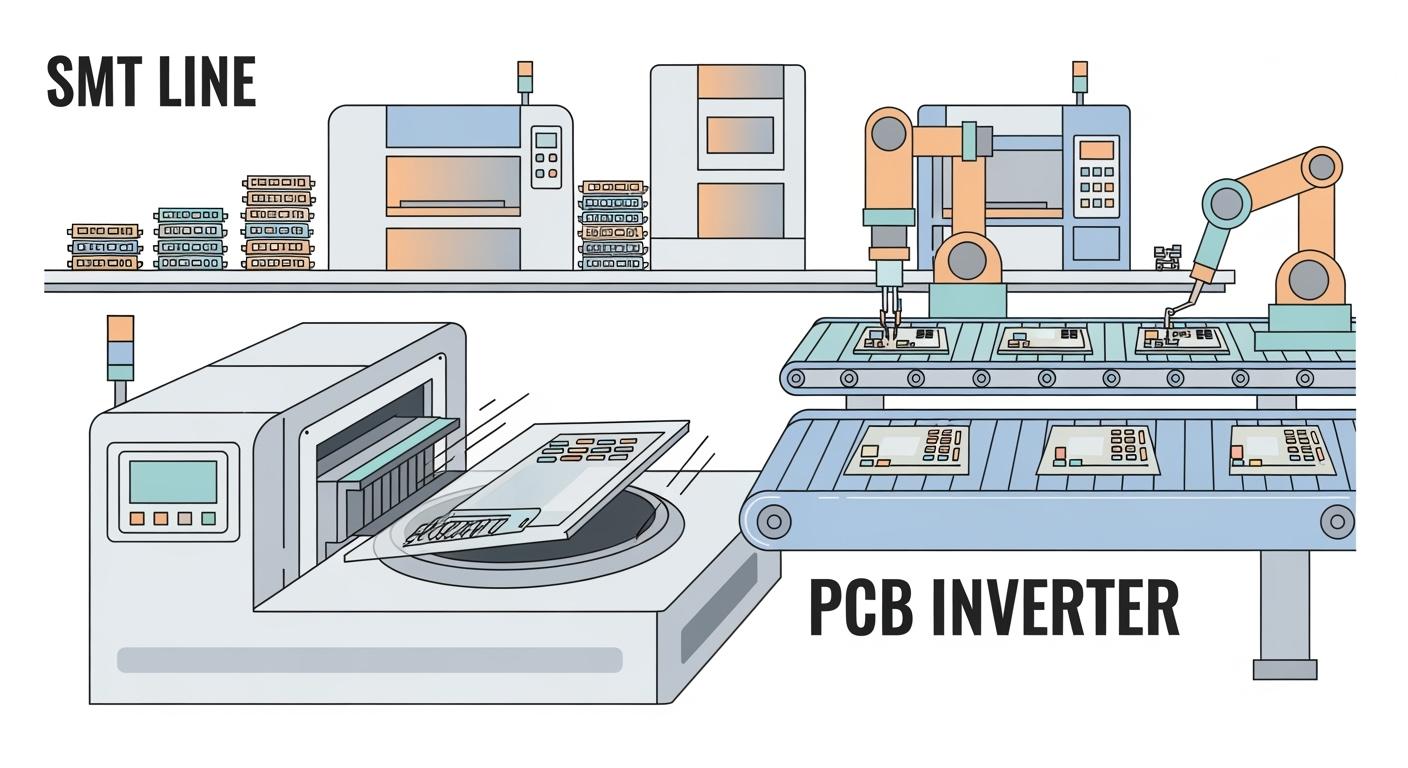

You have to make good choices when you set up your SMT line. A pcb inverter lets you flip boards for both sides. This tool helps your work go faster and smoother. Using machines instead of people gives you many good things:

Machines can put on thousands of parts each hour with the same accuracy.

You will have fewer mistakes and more good products.

Machines do not get tired, so quality stays high.

Picking the right tools changes your results and keeps your work strong.

Key Takeaways

A PCB inverter turns circuit boards over by itself. This saves time and helps stop damage when people handle the boards.

Using a PCB inverter makes work faster. It lets you make more boards without people doing it by hand. This means the products are better.

Watch for things like boards stacking up or getting damaged. These signs show your SMT line might need a PCB inverter to work better.

S&M sells good PCB inverters. They fit with the SMT machines you already have. This helps your whole line work faster.

Take care of your PCB inverter often. Clean it and check its parts. This helps it last longer and work well.

What is a PCB inverter in SMT production lines?

PCB inverter function and role

You need to understand the role of a pcb inverter if you want a high-level smt line. This machine flips printed circuit boards by 180°. You use it when you must work on both sides of a board. The pcb inverter helps you move boards from one process to the next without touching them by hand. This keeps your boards safe and clean. You also save time because the machine works faster than people. In a smt production line, the pcb inverter is important for double-sided assembly. You can trust it to flip each board the same way every time. This means you get better quality and fewer mistakes.

Tip: Using a pcb inverter reduces the risk of damage and keeps your workflow smooth.

S&M offers advanced pcb inverters for your surface mount technology needs. The company designs these machines to fit many types of production lines. You can find solutions for LED, smart display, new energy, and medical device industries. S&M focuses on making your work easier and more reliable.

How PCB inverters support SMT automation

Automation makes your job easier. A pcb inverter supports automation by moving boards without stopping the line. You do not need to pick up or flip boards by hand. This means you can run your line faster and with less effort. The pcb inverter works with other machines to keep everything in order. You can set it up to match the speed of your line. This helps you reach your production goals.

You want your high-level smt line to run without delays. The pcb inverter helps you do this by keeping the boards moving. You get more products finished in less time. S&M’s pcb inverters fit well with other SMT equipment. You can trust their machines to help you build a strong and efficient line.

Key scenarios for using a PCB inverter

Double-sided PCB assembly needs

Working with double-sided PCB assembly can be hard. You need to work on both sides of the board. You must not damage the board. A pcb inverter flips the board for you. This keeps your boards safe and your work easy.

Here is a table that shows common problems with double-sided PCB assembly and how a pcb inverter helps:

Challenge Type | Specific Issues |

|---|---|

Handling and Transportation | Warping from uneven support, micro-cracks from vibrations, static damage risk |

Equipment Limitations | Conveyor sagging, lamination press pressure issues, drilling accuracy loss |

Alignment Issues | Layer shift, ineffective fiducials, thermal expansion errors |

Soldering and Thermal Management | Cold joints, warping during reflow, heat dissipation problems |

Many problems happen when you move and flip the board by hand. Using a pcb inverter lowers these risks. S&M makes inverters that fit into your smt line. These inverters help you get better results and fewer mistakes.

Note: Letting the machine flip the board protects it and helps you make more good boards.

High-temperature process transitions

You need to move boards after high-temperature steps like reflow soldering. The board is hot and can break easily. If you touch it, you might bend or crack it. A pcb inverter moves the board safely and keeps things moving.

Rules like UL Certification and RoHS say you must keep your process safe and clean. Using a pcb inverter helps you follow these rules. You make fewer mistakes and your products are ready for markets that want high quality.

Standard | Description |

|---|---|

UL Certification | Makes sure PCBs are safe and work well for many industries like cars and medical. |

ISO 9001 | Shows you care about quality and making customers happy. |

RoHS | Keeps dangerous stuff out of your electronics. |

S&M gives you tools to help you follow these rules. You can trust their machines to move hot boards with care.

Orientation and workflow alignment

You want your boards to go the right way at each step. Sometimes, you need to turn the board for the next machine. A pcb inverter does this without stopping your line. It keeps your work smooth and fast.

You do not get stuck and your team can focus on important jobs. S&M’s inverters work with other machines and help you build a strong line. You save time and make fewer mistakes because the inverter flips the board for you.

Tip: Use a pcb inverter to keep your work neat and your line fast.

A pcb inverter is important for double-sided PCB assembly, high-temperature steps, and keeping your work in order. S&M has the right tools for each job, so you can focus on making good products.

How to identify the need for a PCB flipper conveyor

Signs in your SMT production line

You might see clues that your smt production line needs a pcb flipper conveyor. If boards start to pile up or workers flip boards by hand, things slow down. Sometimes, boards get scratches or bent corners. These problems mean your pcb handling system needs help. A pcb flipper conveyor keeps boards safe and helps your line move. Look for these clues:

Boards stack up at the pcb conveyor.

Workers flip boards instead of checking quality.

Boards get damaged from being handled by hand.

The pcb conveyor stops a lot to turn boards.

Common workflow bottlenecks

Workflow bottlenecks can slow down your production. If the pcb conveyor stops because boards need flipping, you lose time. You might see delays after reflow soldering or before double-sided assembly. A pcb flipper conveyor can fix these bottlenecks. It keeps your pcb conveyor running and boards moving. You make fewer mistakes and your line works better. S&M helps you find and fix these bottlenecks. Their experts look at your smt production line and pick the best pcb flipper conveyor for you.

Tip: If your line is slow or boards get damaged, a pcb flipper conveyor can help.

Decision checklist for implementation

You need a simple checklist before adding a pcb flipper conveyor. This helps you make good choices. Here is a table with important things to check:

Item | Action | Key Parameter | Acceptance Check |

|---|---|---|---|

Place SiC MOSFETs and gate driver ICs first | Distance < 20mm | Driver output pin faces MOSFET gate pin directly | |

Kelvin Source Routing | Route gate return trace to MOSFET source pin | Kelvin connection at pad | “Power Source” and “Driver Source” do not share path until MOSFET pin |

Gate Loop Optimization | Route Gate and Return traces on adjacent layers | Loop Inductance < 10 nH | PCB viewer shows loop area as a line |

Power Loop Minimization | Place DC link capacitor close to half-bridge | Bus inductance < 20 nH | Positive and negative bus plates overlap heavily |

Isolation Barrier Design | Create “keep-out” zone under isolation components | Creepage > 8mm | High-Voltage DRC ensures no copper in isolation gap |

Decoupling Capacitor Layout | Place C0G/NP0 capacitors at VDD/VEE pins | Trace length to cap < 2mm | Vias connecting capacitors to ground are doubled or tripled |

Thermal Via Stitching | Place arrays of thermal vias under exposed pads | Via diameter 0.3mm, pitch 0.6mm | Solder mask opening allows heat dissipation |

DFM Review for Assembly | Check component spacing for automated pick-and-place | Min component spacing | Consult DFM guidelines for manufacturability |

You can use this checklist to see if a pcb flipper conveyor fits your process. S&M gives you expert advice and helps you improve your pcb handling system. When you pick the right pcb flipper conveyor, your line is smooth, safe, and works well.

Benefits of PCB inverter solutions from S&M

Efficiency and quality improvements

You want your smt production line to run smoothly. S&M’s pcb handling machine helps you reach high efficiency. When you use this machine, you can move boards quickly and safely. You do not need to stop the line for manual flipping. This means you finish more work in less time. Your assembly process becomes faster and more reliable. The pcb handling machine keeps each board safe from scratches or bending. You get better quality because the machine flips every board the same way. Your team can focus on important tasks instead of flipping boards by hand.

Space and cost considerations

You can save space with a pcb handling machine from S&M. The design fits well into your line without taking up too much room. You do not need extra tables or stations for manual flipping. This helps you use your factory space better. You also save money because you need fewer workers for board flipping. The pcb handling machine reduces waste from damaged boards. You spend less on repairs and replacements. Your assembly costs go down, and your profits go up.

Tip: Using a pcb handling machine helps you make the most of your space and budget.

Maintenance and integration tips

You want your pcb handling machine to last a long time. Good maintenance keeps it working well. Here are some tips:

Clean the machine often to remove dust and debris.

Inspect all parts for wear or damage.

Update the firmware when new versions come out.

Choose high-quality components for repairs.

Use surge protection to keep the machine safe from power spikes.

You can connect the pcb handling machine with other machines in your smt production line. S&M designs their machines for easy integration. You get support from S&M if you need help with setup or training. This makes your assembly process smooth and trouble-free.

You now know when to use a PCB inverter in your SMT line. Look for double-sided assembly, high-temperature steps, or workflow delays.

Check your process for slowdowns or board damage.

Think about how automation can help you.

Tip: S&M offers reliable PCB inverters that boost efficiency and quality. Visit S&M’s website to find the right solution for your line.

FAQ

What does a PCB inverter do in an SMT line?

A PCB inverter flips your circuit boards automatically. You do not need to touch the boards. This keeps your boards safe and helps your line run faster.

When should you add a PCB inverter to your SMT process?

You should add a PCB inverter when you work with double-sided boards or see delays from manual flipping. It also helps after high-temperature steps like reflow soldering.

Can you use a PCB inverter with other SMT machines?

Yes, you can connect a PCB inverter with other SMT machines. S&M designs inverters for easy integration. You keep your line smooth and efficient.

How do you maintain a PCB inverter?

Clean the machine often.

Check for loose parts.

Update software if needed.

Tip: Regular care helps your inverter last longer and work better.

Does a PCB inverter help reduce defects?

Yes, a PCB inverter lowers the risk of board damage. You get fewer scratches and bent corners. This means you make more good boards and waste less.