PCB Conveyor Jamming often disrupts your electronics manufacturing process. You might notice misalignment, improper spacing, debris buildup, roller offset, sensor faults, motor overload, or lubrication issues causing trouble. These problems can delay production and damage sensitive boards. > Fixing these issues helps you keep your line running smoothly and prevents costly downtime.

Key Takeaways

-

Regularly check for misalignment in your conveyor system. Misalignment can cause boards to drift and jam. Early detection prevents production delays.

-

Keep your conveyor clean and free of debris. Daily cleaning helps avoid jams caused by dust and small parts blocking movement.

-

Inspect and maintain sensors frequently. Clean sensors and secure connections prevent false readings that can lead to conveyor stoppages.

-

Monitor motor performance to avoid overload. Adjust settings and check for jams to keep the motor running efficiently and prevent damage.

-

Implement a preventive maintenance plan. Regular checks, cleaning, and staff training reduce downtime and extend the life of your equipment.

PCB Conveyor Jamming Causes

PCB Conveyor Jamming can happen for several reasons. Understanding these causes helps you spot problems early and keep your production line moving.

Misalignment

Misalignment occurs when the conveyor belt or the guide rails do not line up correctly. You might notice boards drifting to one side or getting stuck. This problem often leads to jams because the PCB cannot move smoothly along the conveyor. Regular checks help you catch misalignment before it stops your line.

Improper Spacing

Improper spacing means the distance between boards or between conveyor rails is not set correctly. If boards are too close, they can bump into each other and cause a jam. If the rails are too tight or too loose, the PCB may tilt or get stuck. You need to set the spacing according to the size of your boards to avoid these issues.

Debris Buildup

Debris buildup is a common cause of PCB Conveyor Jamming. Dust, solder splashes, or small parts can collect on the conveyor. This debris can block the path and stop the belt from moving. You should remove obstructions to keep production online and prevent damage to both the conveyor system and the boards it carries.

-

Debris often causes conveyor belt mistracking.

-

Removing obstructions is essential to keep production online.

-

Preventing damage to the conveyor system and the product it carries is crucial.

Other Frequent Causes

You may also face jams from roller offset, sensor faults, motor overload, and lubrication issues. Roller offset happens when rollers shift out of place, making the belt run unevenly. Sensor faults can stop the conveyor if the system cannot detect the PCB correctly. Motor overload occurs when the motor works too hard, sometimes due to a jam or heavy load. Lack of lubrication can make moving parts stick, leading to more jams. Each of these problems can disrupt your process and cause PCB Conveyor Jamming.

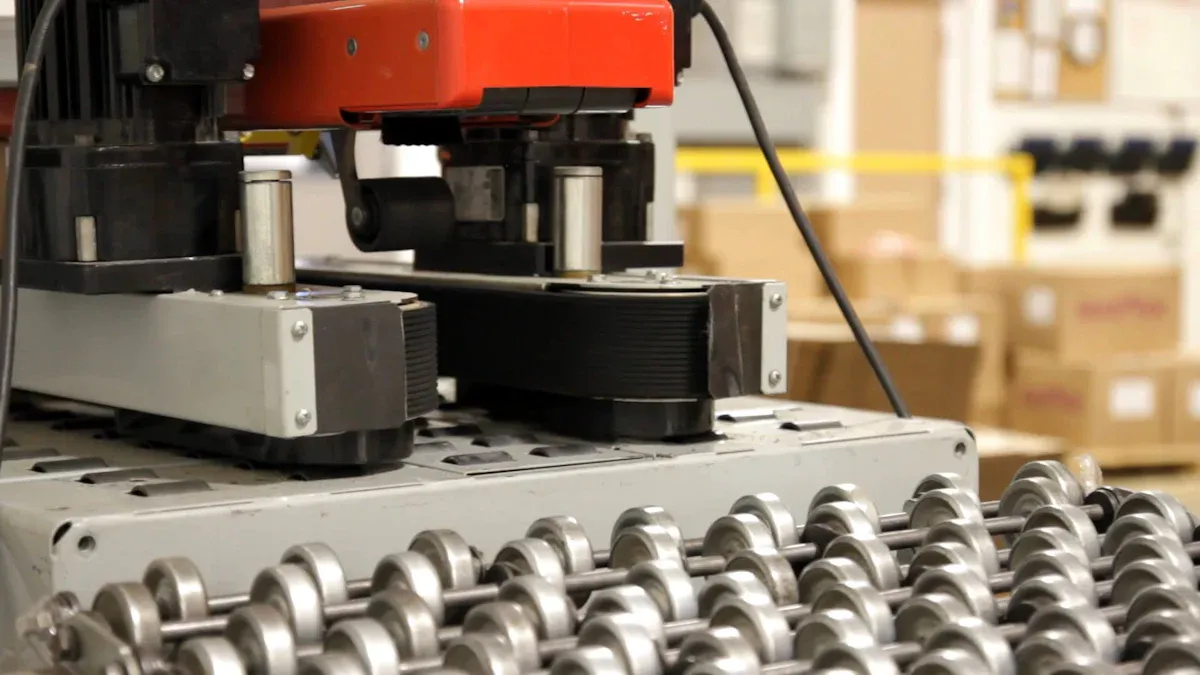

Roller Offset Issues

Problem Overview

Roller offset can create serious problems for your conveyor system. When rollers shift out of their proper position, the belt may not run straight. You might notice boards drifting or getting stuck at certain points. This misalignment often leads to PCB Conveyor Jamming. If you ignore roller offset, you risk damaging both the conveyor and the boards. You should watch for uneven movement or strange noises from the rollers. These signs often mean the rollers need adjustment.

Tip: Check the rollers after any maintenance or heavy use. Small shifts can cause big problems over time.

Roller offset can happen because of vibration, wear, or improper installation. You may see gaps between rollers or notice that the belt does not sit flat. These issues can slow down your production line and increase the risk of jams.

Solutions

You can fix the roller offset by following a few simple steps. First, inspect the rollers for any visible movement or gaps. Use a straight edge to check alignment along the length of the conveyor. If you find any rollers out of place, loosen the mounting bolts and gently reposition them. Tighten the bolts securely to prevent future movement.

-

Inspect rollers weekly for signs of offset.

-

Use a straight edge to confirm alignment.

-

Adjust and secure rollers as needed.

You should also lubricate the rollers after adjustment. Proper lubrication reduces friction and helps keep the rollers in place. If you notice repeated offset, consider upgrading to higher-quality rollers or adding vibration dampers.

|

Step |

Action |

Frequency |

|---|---|---|

|

Inspect Rollers |

Look for movement or gaps |

Weekly |

|

Check Alignment |

Use a straight edge |

Weekly |

|

Adjust Rollers |

Reposition and tighten bolts |

As needed |

|

Lubricate Rollers |

Apply lubricant |

After adjust. |

Regular attention to roller offset helps you prevent PCB Conveyor Jamming and keeps your production line running smoothly.

Sensor Faults

Problem Overview

Sensor faults can cause major disruptions in your conveyor system. When a sensor fails, the conveyor may stop moving or send boards to the wrong place. You might see boards pile up or get stuck, which leads to PCB Conveyor Jamming. Sometimes, sensors give false readings because of dust, misalignment, or electrical noise. Other times, sensors break down from age or harsh conditions. If you notice boards not stopping where they should or the conveyor acting strangely, you should check the sensors first.

Tip: Keep an eye on warning lights or error codes from your conveyor’s control panel. These signals often point to sensor problems before a jam happens.

Solutions

You can solve most sensor faults by following a few best practices. Start by cleaning the sensors with a soft cloth to remove dust or debris. Make sure each sensor lines up with the board path. If you see loose wires or connectors, tighten them to restore a solid connection. Sometimes, you need to replace a sensor that has worn out or failed.

Electromagnetic interference (EMI) can also cause sensor faults. You can reduce EMI by grounding your equipment and using shielded cables. For conveyors in areas with extreme temperatures, use sensors and components that can handle heat or cold. Vibrations and mechanical stress may loosen sensors or damage their mounts. Reinforce mounting points and use flexible cables to prevent these issues.

Here is a quick guide to common sensor challenges and solutions:

|

Challenge |

Solution |

|---|---|

|

Electromagnetic Interference |

Use proper grounding, shielding, and careful component placement to reduce EMI effects. |

|

Extreme Temperatures |

Choose high-temperature laminates and robust components for stable performance. |

|

Vibrations and Mechanical Stress |

Reinforce mounts and use flexible substrates to protect sensors from physical damage. |

Regular inspection and quick action help you avoid PCB Conveyor Jamming caused by sensor faults. By keeping sensors clean, secure, and well-matched to your environment, you keep your production line running smoothly.

Motor Overload

Problem Overview

Motor overload is a common cause of PCB Conveyor Jamming. When the motor works harder than it should, it can overheat or shut down. You might notice the conveyor stopping suddenly or running slower than normal. Sometimes, the motor trips because it tries to move a load that is too heavy. Other times, the problem comes from settings in the variable frequency drive (VFD) that do not match the motor’s needs. If you ignore these signs, you risk damaging the motor and causing more frequent jams.

You may also see warning lights or error codes on the control panel. These signals often point to overload or overcurrent faults. If you hear unusual noises or feel heat coming from the motor, you should stop the conveyor and check for problems right away. Motor overload can lead to downtime and lost production, so quick action is important.

Solutions

You can prevent and fix motor overload by following a few key steps:

-

Lengthen the ramp time on the VFD. This allows the motor to speed up slowly and reduces the chance of overcurrent faults.

-

Extend the deceleration time or add a braking resistor. This helps the motor handle extra energy safely when slowing down.

-

Make sure the VFD and motor are the right size for your conveyor. If they are too small, they will trip often.

-

Double-check all VFD settings. Set the correct motor details and current limits to avoid false overload trips.

-

Inspect the conveyor for jams or anything that could make the motor work too hard.

-

Check all electrical connections. Loose wires can cause overloads or faults.

Tip: Regularly check the mechanical system for binding or jams. Keeping everything clean and moving smoothly helps prevent PCB Conveyor Jamming.

If you follow these steps, you can keep your conveyor running and avoid costly repairs. Proper setup and regular checks make a big difference in preventing motor overload.

Dirt and Lubrication Problems

Problem Overview

Dirt and poor lubrication often lead to PCB Conveyor Jamming. Dust, grease, and small debris can collect on the conveyor belt, rails, and moving parts. These materials block smooth movement and cause boards to stick or slip. You may notice the conveyor slowing down or making unusual noises. Sometimes, sensors and switches stop working because dirt covers their surfaces. Lack of lubrication makes metal parts grind against each other, which increases wear and can cause jams. If you ignore these problems, you risk damaging both the conveyor and your PCBs.

Tip: Watch for sticky movement or squeaking sounds. These signs often mean dirt or poor lubrication is causing trouble.

Solutions

You can prevent and fix dirt and lubrication problems by following a regular cleaning and maintenance routine. Use these steps to keep your conveyor running smoothly:

-

Clean the equipment surface with a soft, lint-free cloth or dust-free paper. Remove dust and dirt from all exposed areas.

-

Inspect the conveyor belt and tracks. Look for loosening, deformation, or damage. Clean the tracks to make sure no foreign objects block movement.

-

Check sensors and photoelectric switches. Wipe their surfaces to remove dust and dirt. Clean sensors help prevent accidental triggering and jams.

-

Lubricate moving parts such as rails, ball screws, and chains. Use specialized lubricants designed for conveyor systems.

-

Check the lubrication system. Make sure all lubrication points have enough clean lubricant. Replace contaminated lubricant right away.

Set up a cleaning schedule for your team. Regular cleaning and lubrication help you avoid PCB Conveyor Jamming and extend the life of your equipment. You should train staff to spot dirt and lubrication issues early. Quick action keeps your production line safe and efficient.

|

Maintenance Task |

How Often |

Tools Needed |

|---|---|---|

|

Surface Cleaning |

Daily |

Lint-free cloth |

|

Belt and Track Inspection |

Weekly |

Flashlight, brush |

|

Sensor Cleaning |

Weekly |

Soft cloth |

|

Lubrication |

Monthly |

Specialized lubricant |

|

Lubrication System Check |

Monthly |

Inspection checklist |

Note: Clean and lubricate equipment before starting each shift for best results.

Delay Timer Challenges

Problem Overview

Delay timer issues often disrupt your conveyor system and lead to PCB Conveyor Jamming. You may notice jams when panels do not move at the right time or when the conveyor stops unexpectedly. Uneven panel sizes, ill-fitting panels, and warpage can trigger timer problems. These challenges slow down your production and sometimes stop the line completely.

Here is a quick look at common delay timer challenges and their impact:

|

Challenge |

Impact on Production |

|---|---|

|

Uneven panel sizes |

Causes jams in SMT machines |

|

Ill-fitting panels |

Delays production by 30–60 minutes |

|

Warpage |

Stops lines for 15–30 minutes per incident |

When panels do not fit or move as expected, the delay timer may not activate correctly. You might see boards pile up or conveyor belts stop for long periods. These problems waste time and increase the risk of damage to your PCBs.

Tip: Watch for panels that look warped or do not fit the conveyor guides. Early detection helps you avoid jams and long delays.

Timer relays play a key role in controlling power flow and timing in your conveyor system. They allow for delayed starts and accurate operation periods, which help prevent motor overloads and keep your system running smoothly.

Solutions

You can solve delay timer challenges by following proven steps. First, check your software version. If your conveyor uses software before version 100.17.000.2030, you may see the conveyor timer restart every time a command (M31) is sent, even if the conveyor is already running. This causes repeated cycles and increases the risk of PCB Conveyor Jamming. Update your software to version 100.17.000.2030 or higher. The new version prevents unnecessary timer restarts and keeps the conveyor cycle stable.

Here is a table showing a common symptom, cause, and corrective action:

|

Symptom |

Possible Cause |

Corrective Action |

|---|---|---|

|

Conveyor timer restarts when already running |

Outdated software |

Update to version 100.17.000.2030 or greater |

You should also inspect timer relays regularly. Make sure they activate and deactivate at the correct times. Timer relays help coordinate sequential control, so each part of your system works in order. They also add safety by delaying motor shutdowns during emergencies.

-

Update software to the latest version.

-

Inspect timer relays for proper operation.

-

Replace faulty relays right away.

-

Train staff to recognize timer issues.

Note: Accurate timer settings and regular checks keep your conveyor running efficiently and reduce downtime.

Preventive Maintenance

Preventive maintenance helps you avoid PCB Conveyor Jamming and keeps your production line running smoothly. You can reduce jams and downtime by following a few key steps. Regular inspection, cleaning, lubrication, and staff education all play important roles.

Alignment Checks

You should check the alignment of your conveyor system often. Make sure the frame is square and level. Confirm that the end pulleys are even and the belt is cut straight. Keep the idlers running smoothly. Replace any worn parts before they cause problems. These actions help your conveyor move boards without trouble.

Tip: Use a straight edge to check alignment and catch small shifts early.

Here is a list of important alignment checks:

-

Check for buildups.

-

Clean your system regularly.

-

Make sure the frame is square and level.

-

Make sure the end pulleys are even.

-

Check that the belt is cut straight.

-

Keep the idlers running smoothly.

-

Replace any worn parts.

Cleaning Routine

Cleaning your conveyor system every day prevents debris from causing jams. Dust and small parts can block the belt and sensors. You should clean feeders and nozzles daily. Inspect conveyor belts for dirt or damage each day.

|

Maintenance Task |

Frequency |

|---|---|

|

Daily |

|

|

Inspect conveyor belts |

Daily |

A regular cleaning routine keeps your equipment safe and your boards moving.

Lubrication Schedule

Lubrication keeps moving parts working smoothly. Add lubricant to rollers and chains regularly. Set up a lubrication system based on how long and how hard your conveyor runs. This schedule helps prevent friction and wear.

-

Regularly add lubricant to the roller and chain to ensure smooth operation.

-

Establish a lubrication system based on the operation time and load to create a reasonable lubrication cycle.

Staff Training

Training your staff helps prevent mistakes that lead to jams. Teach your team how to spot alignment problems, clean equipment, and apply lubricant. Make sure everyone knows the signs of PCB Conveyor Jamming. Well-trained staff can fix small issues before they become big problems.

Note: A strong preventive maintenance plan reduces downtime and protects your equipment.

You can prevent PCB Conveyor Jamming by addressing issues like roller offset, sensor faults, and motor overload. Regular preventive maintenance keeps your equipment in top shape and reduces unexpected downtime. When you follow these solutions, you gain several benefits:

-

Quick cleaning and modular designs cut downtime to just a few minutes.

-

Preventive maintenance extends equipment life and boosts reliability.

-

Lean practices and automation improve production efficiency and first-pass yields.

Stay proactive with maintenance and troubleshooting to keep your line running smoothly and maximize your results.

FAQ

What should you do first when your PCB conveyor jams?

You should stop the conveyor and inspect for visible obstructions or misaligned boards. Remove any debris and check the alignment of rails and rollers. Restart the conveyor after you fix the issue.

How often should you clean your PCB conveyor?

You should clean your conveyor daily. Dust and debris can build up quickly. Regular cleaning helps prevent jams and keeps your equipment running smoothly.

Why does sensor failure cause conveyor jams?

Sensors detect the position of PCBs. If a sensor fails, the conveyor may stop or send boards to the wrong place. You should check sensors for dust, misalignment, or loose wires.

Tip: Clean sensors weekly to avoid false readings.

What lubricant works best for PCB conveyors?

Use a specialized lubricant designed for conveyor systems. Avoid general-purpose oils. The right lubricant reduces friction and wear, helping your conveyor run smoothly.

|

Lubricant Type |

Use Case |

|---|---|

|

Synthetic Grease |

Rollers, chains |

|

Silicone Spray |

Rails, guides |