You can reduce solder consumption most effectively by optimizing your selective soldering process. Technical studies show that adjusting solder wire diameter, flux formula, and tip temperature improves solder flow and joint quality, lowering waste. Automation and real-time monitoring help you fine-tune parameters, cut defects, and minimize rework.

Nitrogen integration, precise temperature control, and targeted flux application play key roles in preserving solder and achieving efficient results.

- Maintain equipment carefully

- Choose appropriate materials

- Train operators regularly

Key Takeaways

- Maintain precise temperature control and use nitrogen atmospheres to reduce oxidation and solder waste while improving joint quality.

- Choose the right nozzle type and size to deliver solder accurately, minimizing waste and improving process efficiency.

- Apply flux carefully in the right amount and place to prevent defects and reduce excess solder use.

- Design PCBs with optimized pad sizes, fewer solder joints, and lower thermal mass to control solder flow and save material.

- Regularly calibrate equipment, monitor dross, and train operators to keep processes consistent, reduce defects, and lower solder consumption.

Reduce Solder Consumption: Solder Pot & Nozzle

Temperature Control

You can achieve significant improvements in solder efficiency by maintaining precise temperature control throughout your selective soldering process. When you keep the solder pot temperature within the recommended range—240°C to 250°C for lead-based solder and 250°C to 260°C for lead-free solder—you ensure optimal solder flow and wetting. This approach minimizes common defects such as cold joints and solder bridges. Preheating your assemblies to 120°C–150°C activates flux and reduces thermal shock, which further supports proper soldering.

Tip: Use thermocouples or infrared sensors to monitor solder bath temperature. Keeping the temperature stable within ±5°C helps you avoid overheating, oxidation, and excessive dross formation. Less dross means you can reduce solder consumption and maintain joint quality.

Integrating nitrogen into your process creates an inert atmosphere that displaces oxygen. This reduces oxidation and dross, allowing you to lower soldering temperatures by 30–50°C and protect sensitive components. Superheating nitrogen is especially useful for high thermal mass assemblies, as it enables efficient heat transfer without requiring larger nozzles or longer dwell times.

Key Temperature Guidelines:

- Preheat: 120°C–150°C

- Solder pot (lead-based): 240°C–250°C

- Solder pot (lead-free): 250°C–260°C

- Dwell time: 2–4 seconds

Nozzle Selection

Choosing the right nozzle type and size directly affects your ability to reduce solder consumption. Jet nozzles, with a minimum diameter of 4mm, deliver solder in one direction and work well for larger areas. They cost less and require minimal maintenance, but lack precision near surface mount devices. Wettable nozzles provide 360-degree soldering and finer accuracy, making them ideal for lead-free solder, though they need more maintenance and cost more.

Custom nozzles allow you to match specific board profiles, optimizing speed and quality. When you minimize nozzle changes, you reduce dead time and improve process efficiency. The right nozzle enables multi-point soldering in a single pass, which cuts down on solder waste and processing time.

| Nozzle Type | Accuracy | Maintenance | Cost | Best Use Case |

| ———– | ——– | ———– | ——– | —————————- |

| Jet | Low | Low | Low | Large areas, simple layouts |

| Wettable | High | High | High | Fine pitch, lead-free solder |

| Custom | Variable | Variable | Variable | Complex board profiles |

Wave Height

You must control wave height carefully to ensure proper solder joint formation without excess solder usage. If the wave is too high, you risk bridging and excessive solder deposits. If it is too low, you may see incomplete wetting and cold joints. Adjust the wave height so it just contacts the bottom of the pad and component lead, allowing for consistent solder flow and minimal waste.

Note: Integrating nitrogen with wave height control further reduces oxidation and dross, helping you reduce solder consumption and improve joint reliability.

By focusing on temperature control, nozzle selection, and wave height, you create a process that uses solder efficiently and produces high-quality joints. Regular calibration and monitoring of your equipment ensure that these parameters remain consistent, supporting your goal to reduce solder consumption in every production run.

Flux Application

Amount & Placement

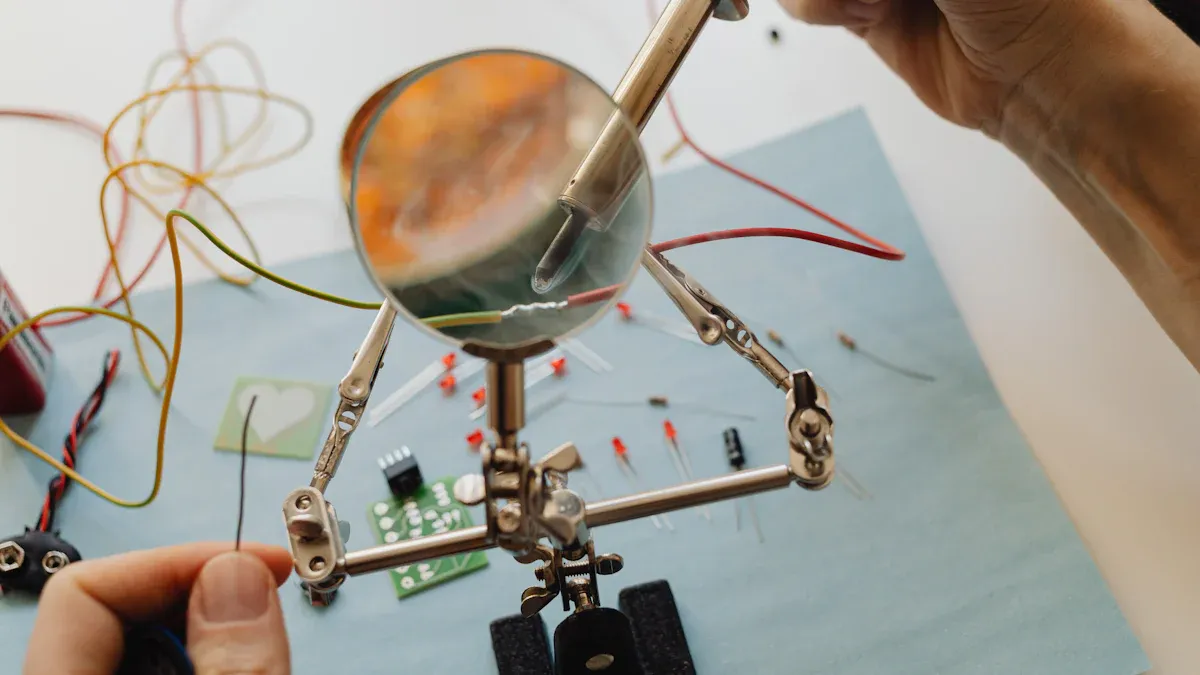

You can improve soldering results by focusing on the amount and placement of flux. When you apply flux precisely, especially at the nozzle edges, you prevent solder stringing and reduce waste. Too little flux leaves metal surfaces exposed to oxidation, which weakens the joint. Too much flux can cause joint weakness and increase solder use. You should aim for just enough flux to remove oxides and promote smooth solder flow. This approach helps you create strong, reliable joints while keeping solder consumption low.

Modern drop-jet flux applicators give you better control over where and how much flux you apply. By optimizing your fluxing program, you ensure that all flux is consumed during soldering, leaving minimal residue. Flux-cored solder wires also help by delivering flux exactly where it is needed, reducing excess and waste. No-clean fluxes minimize residue but require careful placement to avoid contamination. Water-soluble fluxes need thorough cleaning to prevent corrosion.

Tip: Use suitable solder masks with a matte finish and proper thickness. These masks control flux spread and help prevent solder balling. Good solder mask design, including dams between pads, keeps flux where you want it and reduces defects.

Equipment Maintenance

Regular equipment maintenance supports accurate flux application and helps you reduce solder consumption. You should:

- Clean the solder pot daily to remove dross and prevent contamination.

- Inspect and adjust wave uniformity to avoid uneven soldering.

- Calibrate temperature and speed sensors to maintain process accuracy.

- Maintain the fluxing system to prevent uneven application.

- Follow industry best practices to lower defects and improve first pass yield.

A well-maintained system ensures consistent flux delivery and reliable solder joints. These steps help you control costs and improve product quality.

Board Design & Layout

Solder Joints

You can optimize your PCB layout by minimizing unnecessary solder joints. Fewer joints mean less solder required for each board. Review your design and remove redundant connections. This step not only saves material but also improves reliability. Each joint you eliminate reduces the risk of defects and streamlines your assembly process.

Tip: Collaborate with your design team to identify areas where you can combine functions or use shared connections. This approach helps you maintain performance while lowering solder usage.

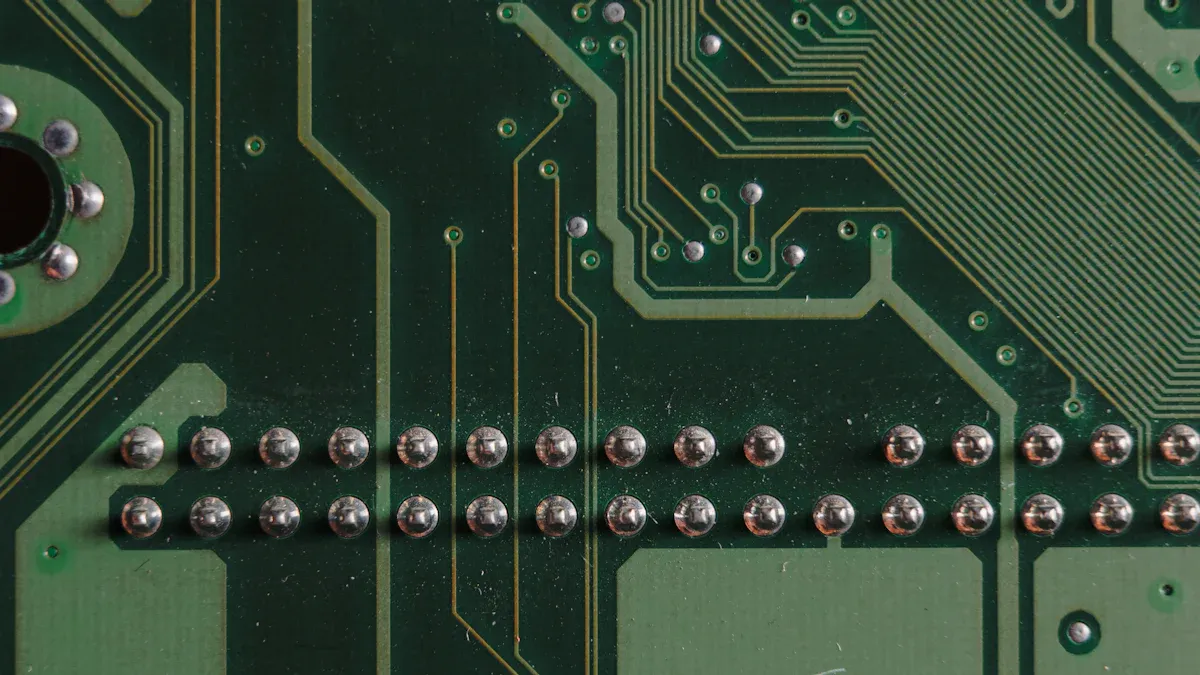

Pad & Hole Size

Proper pad and hole sizing plays a critical role in controlling solder distribution and joint quality. When you align pad sizes with component dimensions and manufacturing tolerances, you ensure enough solder volume for reliable connections without excess. Oversized pads may cause components to float, leading to defects like tombstoning or bridging. Undersized pads can result in weak joints.

- Optimizing drill sizes prevents solder from wicking into vias or holes, keeping solder available on the pad.

- Smaller drill sizes near SMT pads reduce solder paste loss and improve joint strength.

- Stencil design and via tenting help control solder paste application, preventing solder from escaping into holes.

- Adequate annular ring size around holes ensures strong connections and avoids imperfections.

You should balance pad size, component spacing, and production efficiency to achieve the best results.

Thermal Mass

Reducing thermal mass on your PCB helps you maintain efficient solder fill and lower consumption. Large vias and thick copper areas absorb more heat, which can lead to incomplete solder joints and increased solder use. By decreasing via diameter below 0.3mm, you improve the surface tension of liquid solder inside the via. This adjustment prevents solder overflow and reduces waste.

- Tenting vias with solder mask stops solder from flowing into holes, further improving fill efficiency.

- Lower thermal mass allows you to maintain PCB heat, ensuring consistent solder flow and strong joints.

When you focus on board design and layout, you create a foundation that helps you reduce solder consumption and improve product quality.

Equipment & Process Control

Calibration

You need to calibrate your selective soldering equipment regularly to maintain accuracy and reduce solder waste. Proper calibration ensures that temperature controls, solder flow rates, and nozzle movements stay within tight tolerances. This consistency helps you avoid defects and unnecessary solder use.

- Use advanced software with automatic calibration and real-time monitoring. This technology reduces human error and keeps solder quality high.

- Follow a strict quality control protocol. Schedule regular machine calibration and stick to preventative maintenance routines.

- Clean solder pots and nozzles often. Remove dross and replace worn parts like nozzles and heating elements to keep your equipment running smoothly.

- Train your operators in equipment maintenance. Well-trained staff can spot issues early and prevent downtime.

Tip: Consistent calibration not only improves product quality but also helps you reduce solder consumption over time.

Dross Monitoring

Dross forms when solder oxidizes in the pot. If you let dross build up, it can cause clogs, uneven solder flow, and contamination. You should monitor dross levels daily and remove it before it affects your process.

- Use sensors or visual checks to track dross accumulation.

- Remove dross at the start and end of each shift.

- Keep a log of dross removal to spot trends and address problems early.

A clean solder pot ensures stable solder flow and reduces the risk of defects. This practice supports your goal to reduce solder consumption and maintain high-quality joints.

Process Systems

Modern process control systems use automation, robotics, and machine vision to improve soldering consistency. These technologies help you optimize solder application and minimize waste.

- AI-driven process optimization and real-time monitoring catch defects before they become costly problems.

- Automated systems control soldering temperature, flux application, and material selection with high precision.

- Machine vision and X-ray inspection detect issues early, so you can fix them before they lead to excess solder use.

- Sustainable practices like recycling and waste reduction become easier with advanced process control.

| Technology | Benefit |

| ——————– | —————————– |

| Automation | Reduces variability |

| Machine Vision | Improves defect detection |

| Real-Time Monitoring | Enables proactive adjustments |

By investing in advanced process systems, you can reduce solder consumption, increase throughput, and maintain product quality.

Operator Training & Procedures

Best Practices

You play a vital role in maintaining efficiency and quality in selective soldering. Comprehensive training programs teach you how to optimize machine settings and troubleshoot issues. Certification programs confirm your qualifications for specific equipment and tasks. Continuous learning and refresher courses keep you updated on new technologies and methods.

– You learn to run SMT machines effectively.

- Training covers fault identification and minor repairs.

- You gain skills to optimize machine settings and solve programming problems.

- Skilled operators improve machine performance, reduce downtime, and enhance production efficiency.

Despite advances in automation, your expertise remains essential. Regular training on both software and hardware helps you prevent errors that cause defects and downtime. Sufficiently trained operators per shift reduce mistakes and production delays. Ongoing education helps you adapt to new equipment and industry changes, which improves efficiency and helps reduce solder consumption.

SOPs

Standardized operating procedures (SOPs) ensure you follow consistent workflows and material usage. SOP manuals emphasize quality assurance and resource optimization. This standardization minimizes variability and waste.

- SOPs provide step-by-step instructions for consistent execution and compliance with safety standards.

- Standard Work Instructions (SWIs) focus on minimizing variability and improving product quality.

- SWIs include detailed soldering steps to prevent defects and support consistent solder usage.

- Digital work instructions enhance clarity and ensure everyone follows approved procedures.

You benefit from clear SOPs because they help you maintain process consistency and reduce material waste. Consistent procedures lead to optimized solder usage and fewer defects.

Feedback Loops

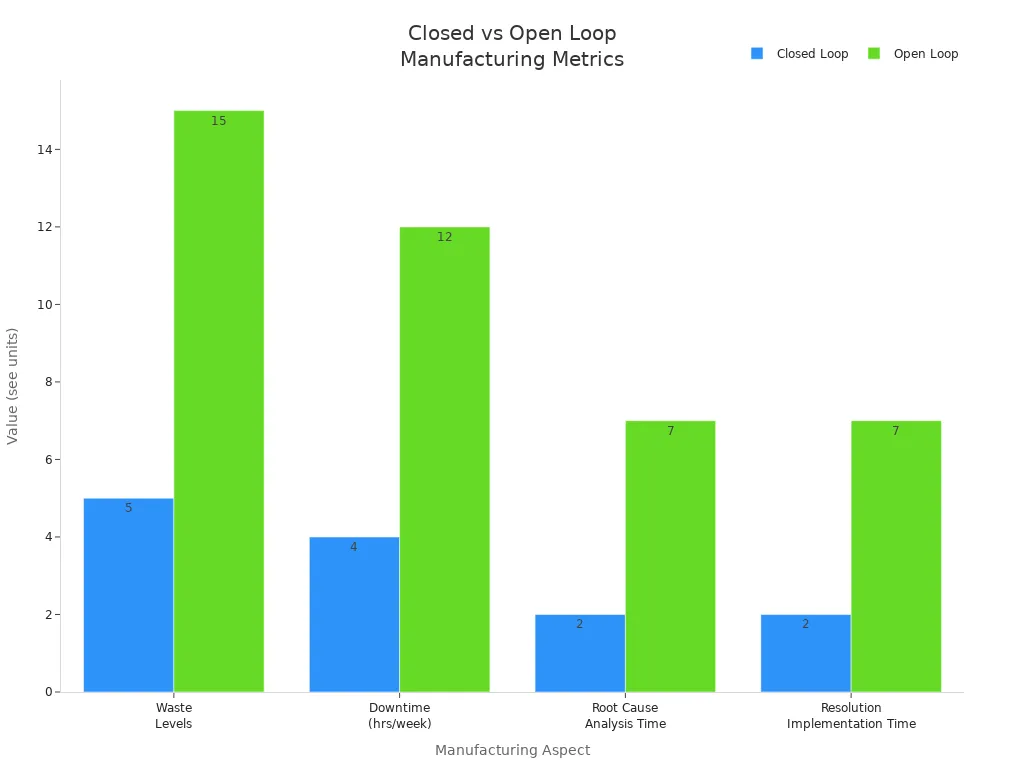

Feedback loops drive continuous improvement in solder consumption practices. You receive inspection results promptly, which enables immediate corrective actions. Regular reviews of inspection processes and defect data help you identify trends and optimize workflows. Ongoing training for inspectors maintains process effectiveness.

| Aspect | Closed Loop Manufacturing | Open Loop Manufacturing |

| —————————— | —————————————————————————— | ——————————————————— |

| Feedback Mechanism | Continuous real-time feedback enabling immediate adjustments | No feedback mechanism, adjustments are manual and delayed |

| Error Detection | Real-time detection and autonomous correction | Delayed detection requiring manual investigation |

| Adaptability | High, with AI-powered autonomous solutions | Low, reliant on manual processes |

| Quality Control Issues | Low due to continuous correction | High due to lack of feedback |

| Waste Levels | Reduced (approx. 5%) | Higher (approx. 15%) |

| Downtime | Lower (approx. 4 hours/week) | Higher (approx. 12 hours/week) |

| Root Cause Analysis Time | Short (1–3 days) | Long (5–10 days) |

| Resolution Implementation Time | Short (2–5 days) | Long (7–15 days) |

You can see that closed loop manufacturing with real-time feedback reduces defects, improves product quality, and supports operational efficiency. These feedback mechanisms help you reduce solder consumption and maintain high standards in production.

You can reduce solder consumption by implementing technical improvements such as automatic nozzle height adjustment, nitrogen atmospheres, and precise wave height control. Immediate action on process controls, including real-time monitoring and defect prevention, strengthens quality assurance.

- Ongoing training helps you evaluate and manage soldering processes, develop audit plans, and apply best practices for continuous improvement.

| Action Step | Benefit |

| —————————————————————————————————– | —————————– |

| Technical upgrades | Lower solder waste |

| Process control | Fewer defects, better quality |

| Continuous training | Sustained improvement |

Start optimizing your selective soldering process today to achieve measurable cost savings and consistent product quality.

FAQ

What is the most effective way to reduce solder consumption in selective soldering?

You achieve the best results by optimizing process parameters. Focus on temperature control, precise flux application, and regular equipment maintenance. These steps help you minimize waste and improve joint quality.

How does nitrogen help lower solder usage?

Nitrogen creates an inert atmosphere. You reduce oxidation and dross formation. This allows you to use less solder and maintain cleaner joints. You also extend the life of your solder pot.

Can board design impact solder consumption?

Yes. When you optimize pad and hole sizes, you control solder flow and reduce excess use. Fewer unnecessary joints and lower thermal mass also help you save solder.

Why is regular equipment calibration important?

You keep your process consistent and accurate with regular calibration. This prevents defects, reduces solder waste, and ensures high-quality joints. Well-calibrated machines support efficient production.

What operator practices help minimize solder waste?

- Follow standard operating procedures.

- Complete regular training.

- Monitor process feedback.

- Address defects quickly.

These habits help you maintain efficiency and reduce unnecessary solder use.