Boosting throughput in selective soldering demands targeted changes. You can achieve significant gains by focusing on three key areas:

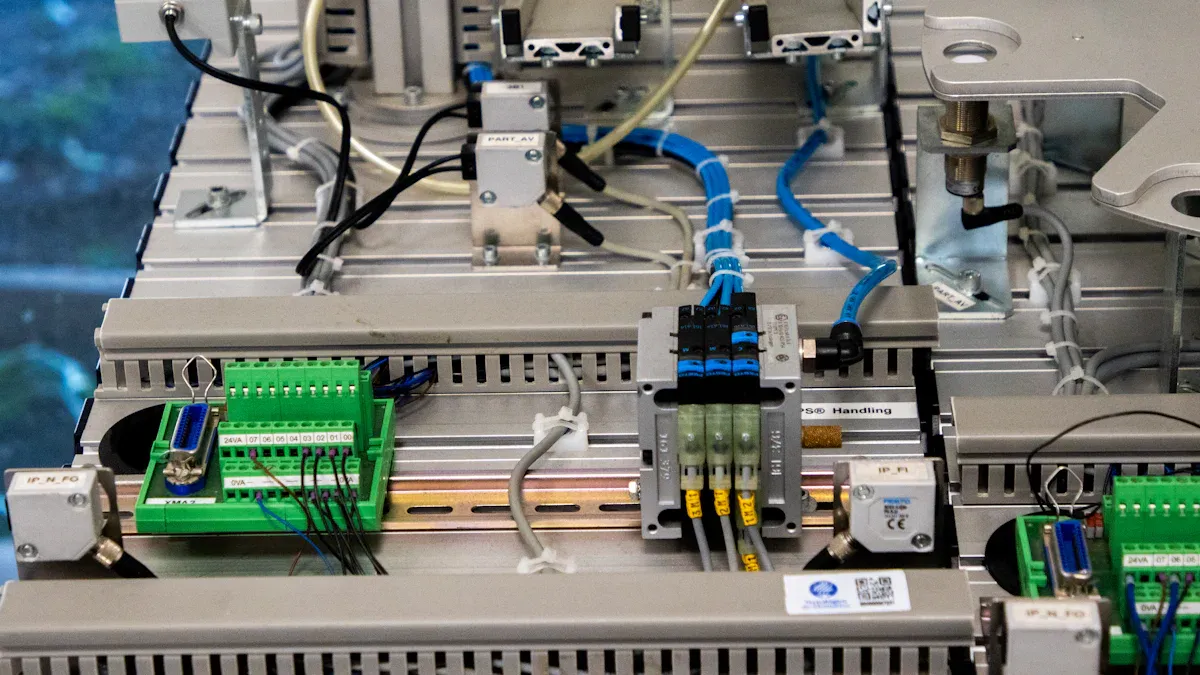

- Process optimization with real-time analytics, predictive maintenance, and condition monitoring sensors reduces downtime and enables dynamic adjustments.

- Equipment upgrades, such as modular machine architectures and advanced thermal management, support rapid changeovers and maintain consistent solder quality.

- Workflow improvements, including automated material handling and digital integration, streamline production flow and minimize manual intervention.

These strategies help you increase throughput, maximize resource utilization, and deliver consistent results for your production line.

Key Takeaways

- Optimize machine settings like solder temperature, conveyor speed, and nozzle choice to improve speed and quality.

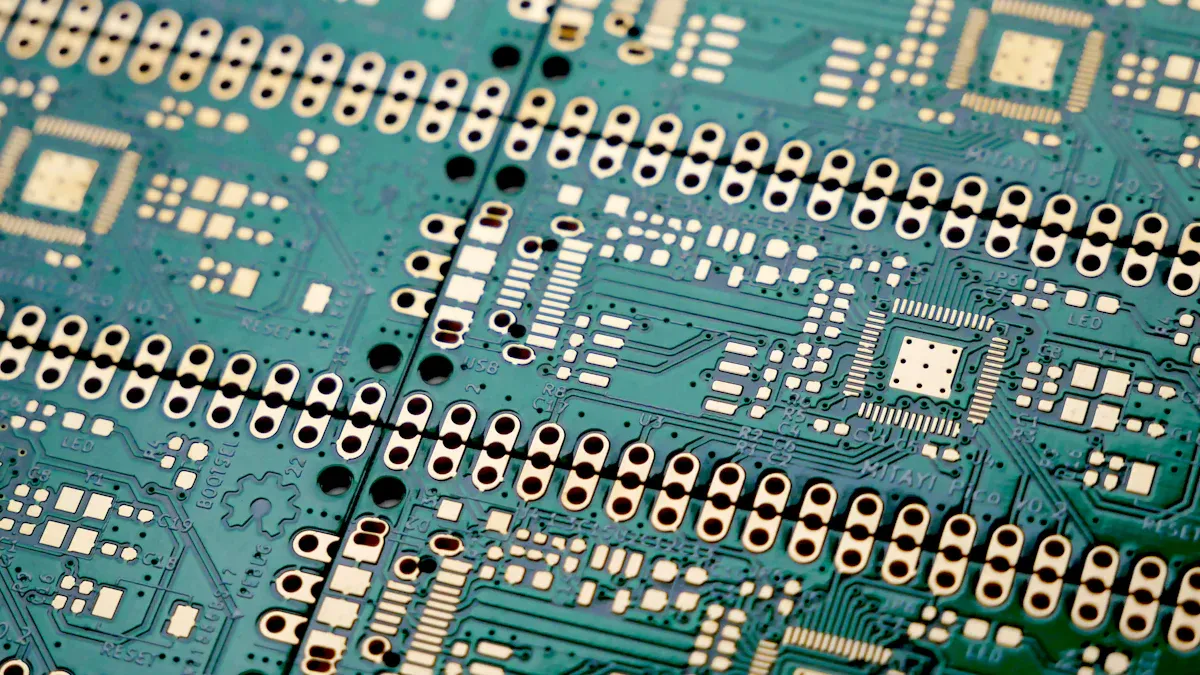

- Design PCBs with manufacturability in mind by adjusting hole sizes and component placement to reduce defects and speed up soldering.

- Invest in high-speed machines and automation to increase production rates and reduce manual errors.

- Apply lean workflow principles and train operators well to streamline processes and maintain consistent quality.

- Use inline inspection and data-driven maintenance to catch defects early and keep equipment running smoothly.

Machine Settings

Soldering Parameters

You can achieve higher productivity by fine-tuning your soldering parameters. Start by setting the solder bath temperature between 250°C and 260°C for lead-free solder. This range ensures proper melting and wetting, which prevents cold joints and oxidation. Adjust the conveyor speed to 1.0–1.5 meters per minute. This speed balances contact time with the solder wave, reducing defects while maintaining a steady flow. Keep the wave height just touching the bottom of the PCB to avoid bridging and skips. Preheat the board to 100–120°C to prevent thermal shock and improve solder wetting. Regular calibration and thermal profiling help you detect inconsistencies early and maintain optimal settings.

| Parameter | Recommended Value | Effect on Throughput and Quality |

| ———————– | —————————- | ——————————————- |

| Solder Bath Temperature | 250–260°C (lead-free) | Proper melting avoids cold joints/oxidation |

| Conveyor Speed | 1.0–1.5 m/min | Maintains throughput, prevents defects |

| Wave Height | Just touching the PCB bottom | Controls solder exposure, prevents bridging |

| Preheat Temperature | 100–120°C | Prevents shock, improves solder wetting |

Nozzle Selection

Choosing the right nozzle type directly affects your cycle time and throughput. Single nozzles minimize downtime from manual changes, but may not suit every board. Jet (wave) nozzles work well for large rows, offering fast, directional soldering with minimal maintenance. Wettable nozzles provide 360-degree movement and high accuracy, making them ideal for boards with closely spaced components. Custom nozzles, designed for specific board profiles, can cover large areas in a single pass and boost speed. Use software tools to optimize nozzle changes and soldering patterns, reducing dead time and improving efficiency.

Tip: Multi-nozzle systems let you solder multiple joints at once, further increasing your production speed.

Maintenance

Consistent maintenance keeps your selective soldering machine running at peak performance. Clean and degrease the machine regularly to prevent nozzle clogging. Monitor solder paste levels to avoid defects. Inspect and clean nozzles to ensure even solder application. Check components like brushes and bearings to prevent unexpected failures. Update your software to maintain smooth operation. Predictive maintenance, using data analytics and IoT sensors, helps you anticipate issues before they cause downtime. Automated diagnostic tools and AI-powered systems can optimize solder paste application and detect anomalies in real time, keeping your line efficient and reliable.

PCB Design

Manufacturability

You can boost selective soldering throughput by designing your PCB for manufacturability. Scientific studies show that the size of through-hole technology (THT) holes plays a key role. When you use larger hole diameters, with a Gap-Ratio of 30–40%, you improve vertical hole filling and process robustness. This allows you to shorten solder contact times and lower preheat temperatures. As a result, you reduce the overall soldering duration and minimize thermal stress on your boards. By optimizing hole sizes, you enable faster and more reliable soldering cycles. This approach leads to higher throughput and fewer defects.

Tip: Always review your design for manufacturability early in the process. Small changes to hole sizes or pad shapes can make a big difference in production speed.

Component Placement

Strategic component placement helps you achieve consistent soldering quality and maximize throughput. Balanced pad designs and symmetric layouts promote uniform solder wetting, which reduces defects like tombstoning. You should use automated pick-and-place machines to position components accurately and efficiently. This reduces human error and speeds up assembly. Uniform orientation and alignment of components streamline automated assembly and lower the risk of placement errors. For example, orienting passive components perpendicular to the PCB’s travel direction during soldering helps prevent tombstoning. Maintain clearance around sensitive parts and avoid placing heavy components near board edges. These steps reduce mechanical stress and improve reliability, which supports higher throughput by minimizing rework.

Panelization

Panelization design directly impacts your selective soldering cycle times and product quality. Consider these best practices:

- Use rectangular, symmetrical panels to avoid stress concentration and warping.

- Ensure proper tooling margins for machine handling and alignment.

- Reduce panel size when working with heavy components to prevent deformation.

- Avoid placing v-cuts or tabs near fragile components to prevent fractures.

- Maintain mechanical stability by balancing panel size and component weight.

Proper panelization makes machine registration and handling easier. This reduces defects, shortens cycle times, and increases your overall throughput.

Equipment Upgrades

High-Speed Machines

You can achieve a major boost in selective soldering productivity by investing in high-speed machines. Modern systems, like the Pillarhouse Jade Pro Duplex, use dual-bath technology. This feature lets you switch between different solder alloys quickly, which saves time during changeovers. The Jade Pro also offers advanced preheating from both the top and bottom, along with process aids that help you handle complex, multi-layer PCBs. These upgrades make it easier to transition to lead-free production and handle a wider range of products. Machines such as the SH-3D combine fluxing, preheating, and soldering in one unit, which reduces production time. You benefit from independent temperature control, precise flux application, and flexible module setups. These features help you increase throughput and maintain high quality.

| Feature | Benefit |

| —————————– | ——————————- |

| Dual-bath technology | Fast alloy changeovers |

| Integrated preheating | Better soldering consistency |

| Multi-function system | Shorter production cycles |

| Flexible module configuration | Adapts to different batch sizes |

Automation

Automation transforms your selective soldering process. You can run your line 24/7 with minimal downtime, which leads to much higher production rates than manual assembly. Robotic soldering delivers accuracy and repeatability, so you see fewer defects and less rework. As labor costs rise, automation helps you control expenses by reducing the need for manual operators. You also gain the ability to meet strict quality and volume requirements. Automated systems support scalability and help you stay competitive. By using robots in flexible automation cells, you further increase throughput and lower labor costs.

Tip: Automation not only improves speed but also ensures consistent quality, making it easier to meet customer demands.

Software Integration

Software integration gives you precise control over your selective soldering process. Systems like Nordson SELECT’s Parallel Double Selective Soldering use PhotoScan software for closed-loop process control. This software keeps your soldering parameters stable and repeatable, which leads to higher yields. Dual fluxers and solder pots allow you to process two PCBs at once, doubling your productivity. Closed-loop controls help you maintain process stability, so you can increase throughput without sacrificing quality. Advanced software also makes it easier to monitor, adjust, and optimize your production line in real time.

Note: The SELECT Synchro system uses synchronous motion technology to synchronize processes and boost throughput by up to 40%. You can handle multiple boards with different alloys and nozzle sizes at the same time, making your operation more flexible and efficient.

Workflow Management

Lean Principles

You can drive significant improvements in selective soldering by applying lean manufacturing principles. Lean focuses on eliminating non-value-added activities, standardizing processes, and reducing manual steps. When you adopt these strategies, you streamline your workflow and reduce bottlenecks. The table below highlights how specific lean practices impact throughput in selective soldering:

| Lean Principle / Design Aspect | Impact on Throughput in Selective Soldering Operations |

| —————————————————– | ——————————————————————————————– |

| Elimination of non-value-added activities | Reduces unnecessary process steps, improving flow and throughput efficiency. |

| Minimizing process steps and standardizing processes | Decreases changeover time and handling, leading to faster throughput. |

| Reduction of manual processing (e.g., hand soldering) | Cuts labor costs and throughput delays significantly. |

| Proper design of through-hole pads and fiducials | Ensures quality solder joints and accurate placement, reducing rework and inspection delays. |

You also benefit from smaller solder nozzles and flexible systems, which support high-mix production and faster changeovers. These changes help you increase throughput by reducing labor, defects, and wasted energy.

Training

Operator training plays a crucial role in your selective soldering success. When you invest in comprehensive training programs, you empower your team to operate, maintain, and troubleshoot equipment efficiently. Well-trained operators understand process optimization, solder joint inspection, and thermal profiling. This knowledge leads to higher yields and fewer defects. Continuous skill development keeps your staff updated on the latest technologies, allowing you to fully leverage advanced equipment. You also reduce staff turnover and maintain consistent production quality.

Tip: Hands-on workshops and regular refresher courses help your team master new skills and adapt to process changes quickly.

Scheduling

Effective scheduling ensures that your selective soldering line runs smoothly and avoids unnecessary downtime. You should plan production runs based on product mix, machine availability, and maintenance needs. By grouping similar jobs, you minimize changeover times and keep your workflow steady. Use digital scheduling tools to track progress and adjust plans in real time. This approach helps you respond quickly to changes in demand and maintain high throughput. When you align your scheduling with lean principles and operator skills, you create a balanced and efficient production environment that supports your goal to increase throughput.

Quality and Speed

Inline Inspection

You can increase throughput and reduce defects by using inline inspection technology in your selective soldering process. Inline Automated Optical Inspection (AOI) systems check every solder joint immediately after mass soldering. These systems detect, repair, and verify defects automatically. You avoid manual inspection bottlenecks and lower work-in-process inventory. AOI+Repair systems document all inspection and repair data, which helps you analyze root causes and improve your process. Inline selective wave soldering achieves high-speed automation, with throughput exceeding 1200 PCBs per hour. Solder placement accuracy reaches ±0.02mm, and defect rates drop below 0.3%. You benefit from closed-loop conveyor synchronization and adaptive process control, which optimize parameters for each component. This technology accelerates corrective actions and enhances yields.

- AOI+Repair systems reduce human subjectivity and improve repeatability.

- Programmable parameters like flux deposition and solder dwell time minimize damage and improve joint quality.

- On-demand solder pot heating cuts power consumption by 40%, making your process more energy efficient.

Tip: Inline inspection lets you catch and fix defects early, so you maintain high throughput and consistent quality.

Defect Prevention

You prevent defects by controlling key process variables. Machine capability analysis and process capability studies help you identify and manage variations. You maintain accuracy in flux spraying and control the soldering temperature and time. High-precision equipment ensures reliable solder joints. Modular machine designs let you scale production without sacrificing quality. You use closed-loop controls to keep parameters stable and repeatable. These measures reduce defects and rework, which supports higher throughput. You also minimize downtime by using quick modular maintenance and fast line reconfiguration.

| Control Measure | Benefit |

| ———————– | —————————- |

| Flux Control | Consistent solder joints |

| Temperature Control | Prevents overheating/damage |

| Solder Joint Inspection | Early defect detection |

| Modular Design | Scalable production capacity |

Reliability

You build reliability into your selective soldering process by maintaining uniformity and precision. You keep flux spraying accurate and control soldering temperature and time. High-precision machines and modular designs allow you to expand capacity while keeping quality high. Inline inspection and defect prevention measures ensure stable, repeatable processes. You achieve robust solder joints and reduce component damage, especially with Pb-free soldering. Reliable processes mean fewer defects, less rework, and higher throughput. You meet customer demands for quality and speed, and you support continuous improvement in your production line.

Note: Reliable selective soldering processes help you deliver consistent results and maintain your competitive edge.

Increase Throughput: Common Mistakes

Overcomplication

You may think that adding more steps or features will solve production issues, but overcomplicating your selective soldering process often leads to the opposite effect. Complex setups increase the risk of errors and slow down your line. For example, leaving insufficient room for selective soldering nozzles can cause solder wash-off and defects. Designing boards with parts placed too close together increases the risk of collisions and lowers yields. Using copper traces with different weights or improper component footprints can result in tombstoning and misalignment. When you design your board to the very limit of PCB rules, you raise the risk of manufacturing problems. Keep your process simple and your layouts clear to increase throughput and reduce costly mistakes.

Maintenance Neglect

Neglecting regular maintenance is one of the fastest ways to lose productivity. Machines that do not receive scheduled care break down more often and cause unplanned downtime. A 2021 study by the Electronic Manufacturing Services Association found that companies with regular maintenance schedules saw a 15% reduction in operational downtime and a 20% increase in equipment lifespan. When you skip maintenance, you halt your production line, delay deliveries, and risk customer dissatisfaction. Consistent upkeep ensures your selective soldering equipment runs smoothly and helps you maintain high throughput.

Ignoring Data

You have access to valuable process data, but ignoring it can lead to recurring defects and missed opportunities for improvement. Common mistakes include running with low solder bath temperatures, inadequate heating, or excessive solder deposition. These issues cause problems like insufficient hole fill, bridging, and solder balls. If you do not monitor and adjust your process based on real-time analytics, you will see more defects and slower production. Use your data to spot trends, correct issues early, and increase throughput without sacrificing quality.

Increase Throughput: Process Optimization

Path Planning

You can boost your selective soldering efficiency by focusing on path planning. When you group similar components, such as resistors or capacitors, you help the machine follow a shorter, more direct route. This reduces the travel time of the soldering nozzle and minimizes unnecessary movements. For example, arranging integrated circuits in one section and passive components in another allows the machine to complete soldering tasks faster.

Many engineers use software tools that model the soldering sequence as a path optimization problem. These tools help you find the shortest route for the soldering head, much like solving a puzzle. By reducing the total travel distance, you lower the cycle time for each board. This approach leads to higher throughput and less wear on your equipment.

Tip: Review your PCB layout and component placement regularly. Small changes in grouping can make a big difference in machine efficiency.

Flux Chemistry

Optimizing flux chemistry plays a key role in selective soldering. The right flux formula cleans metal surfaces and improves solder wetting, which helps you form strong and reliable joints. You should select a flux with the correct activity level to balance wettability and minimize spattering. Low-spatter fluxes keep your boards cleaner and reduce the need for post-soldering cleanup.

You also need to match the flux to your solder wire and process. Choosing the right flux percentage and formula ensures smooth solder flow and consistent joint formation. This reduces defects and rework, which helps you increase throughput. Alcohol-based fluxes with resin can improve coating adhesion and reliability, especially in humid environments. Avoid fluxes with high acid content, as they can harm joint quality.

- Benefits of optimized flux chemistry:

- Better solder wetting and joint strength

- Fewer defects and less rework

- Cleaner boards and less maintenance

By fine-tuning your flux chemistry and application, you support a stable process and achieve higher production rates.

You can drive rapid gains in selective soldering by focusing on automation, real-time monitoring, and modular equipment. Industry experts recommend integrating AI-powered defect detection, digital twins, and predictive maintenance for higher efficiency. For immediate results, use this checklist:

- Apply strict ESD protection and advanced inspection methods.

- Train technicians thoroughly and follow IPC standards.

- Maintain fixtures and control process parameters.

- Schedule preventive maintenance to avoid downtime.

Keep refining your process and invest in workforce upskilling to sustain long-term improvements.

FAQ

What is the fastest way to increase selective soldering throughput?

You can start by optimizing machine settings and upgrading to high-speed equipment. Focus on path planning and automate repetitive tasks. These changes deliver immediate improvements in cycle time and output.

How often should you perform maintenance on selective soldering machines?

You should follow the manufacturer’s recommended schedule. Most experts suggest daily cleaning and weekly inspections. Predictive maintenance using sensors helps you catch issues early and avoid unexpected downtime.

Can PCB design changes impact throughput?

Yes. Simple adjustments, such as increasing hole sizes or improving component spacing, allow for faster soldering and fewer defects. You should review your designs with manufacturability in mind.

What role does operator training play in throughput?

Operator training ensures your team understands machine operation, troubleshooting, and process optimization. Well-trained staff reduce errors, speed up changeovers, and maintain consistent quality.

Do software upgrades make a difference in selective soldering?

Absolutely! Software upgrades give you better process control, real-time monitoring, and automated adjustments. You can quickly adapt to new products and maintain high throughput with fewer manual interventions.