You may wonder, What-Does-SMT-Stand-for-in-Manufacturing? SMT stands for Surface Mount Technology, a process where you place electronic components directly onto the surface of a printed circuit board (PCB). Over the last decade, you have seen SMT become the main choice for building everything from smartphones to electric vehicles. Industry demand for smaller, faster, and more reliable devices has pushed SMT to the forefront of electronics manufacturing.

Key Takeaways

- SMT means Surface Mount Technology, a method to place electronic parts directly on a circuit board without drilling holes.

- This technology allows devices to be smaller, lighter, and more powerful by fitting more parts in less space.

- The SMT process uses automated steps like applying solder paste, placing parts with machines, heating to solder, and inspecting for quality.

- SMT saves time and money by speeding up production and reducing errors compared to older methods like through-hole technology.

- Many modern electronics like smartphones, laptops, and smartwatches use SMT because it supports fast, reliable, and compact designs.

What Does SMT Stand for in Manufacturing

SMT Meaning

When you ask, What-Does-SMT-Stand-for-in-Manufacturing, you discover that SMT stands for Surface Mount Technology. This term describes the full process of mounting and soldering electronic parts directly onto the surface of a printed circuit board (PCB). You do not need to drill holes through the board for each component. Instead, you use special machines to place tiny parts, called surface-mount devices (SMDs), right on top of the board. These parts often have no leads or only very short leads, which makes them much smaller than older types of components.

You see SMT used in almost every modern electronic device. The process involves several steps, such as applying solder paste to the board, placing components with high-speed machines, and then heating the board in a reflow oven to create strong electrical connections. This method allows you to build complex circuits quickly and with great accuracy.

Tip: If you want to design electronics that are small and powerful, you should learn about SMT. It is the foundation of today’s electronics manufacturing.

Surface Mount Technology

Surface Mount Technology changes the way you build electronic products. Instead of inserting wires or leads through holes in the PCB, you attach components directly to the surface. This approach lets you fit more parts into a smaller space. You can make devices lighter and thinner, which is important for products like smartphones, tablets, and wearables.

SMT uses a series of precise steps:

- You prepare the PCB and components, making sure everything is clean and ready.

- You print solder paste onto the board using a stencil.

- Pick-and-place machines position each component exactly where it belongs.

- The board goes through a reflow oven, which melts the solder and secures the parts.

- You inspect the finished board to check for any mistakes or defects.

This process supports high-speed, automated assembly. You can produce thousands of boards in a short time, which helps keep costs low and quality high.

Role in PCB Assembly

When you look at the role of SMT in PCB assembly, you see why it has become the dominant method for building electronic circuits. SMT lets you pack more functionality into a smaller area. You can reduce the size and weight of your products by up to 60%. The process also improves reliability, because the components are less likely to shake loose or break under stress.

Here are some reasons why SMT leads the industry:

- You save money because SMT uses less material and fewer steps than older methods.

- You can automate the assembly process, which means fewer mistakes and faster production.

- You get better performance, since SMT supports high-frequency signals and reduces interference.

- You can design advanced products, such as CPUs and memory chips, that would not be possible with traditional methods.

| Standard/Certification | Description | Importance in SMT |

| ———————————————————————————————————————– | ————————————— | —————————————- |

| IPC-A-610 | Sets quality standards for PCB assembly | Ensures reliable and consistent assembly |

| ISO | Quality management standards | Improves efficiency and quality control |

| RoHS | Restricts hazardous substances | Promotes safe and eco-friendly products |

| UL Listing | Safety standards for electronics | Ensures safe operation in all conditions |

| MIL-STD | Military performance standards | Guarantees durability for tough uses |

When you use SMT, you follow strict standards to make sure your products meet industry requirements. You also use automated inspection systems to catch any problems early. This attention to detail helps you deliver high-quality electronics that work well and last a long time.

If you want to understand What Does SMT-Stand for in Manufacturing, remember that it is more than just a process. It is the reason you can enjoy powerful, compact, and reliable electronic devices every day.

SMT vs. SMD and Through-Hole

SMT vs. SMD

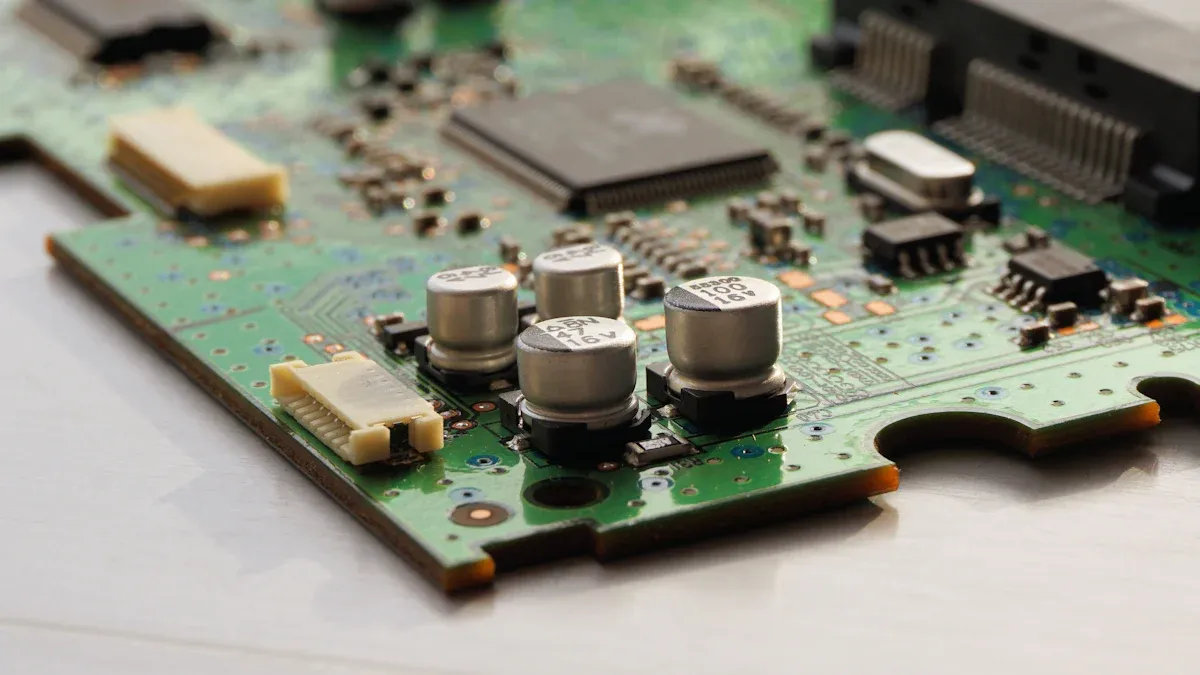

You might see the terms SMT and SMD used together, but they do not mean the same thing. SMT stands for Surface Mount Technology. It is the process you use to mount and solder electronic parts onto a printed circuit board (PCB). SMD stands for Surface Mount Device. These are the actual components, like resistors, capacitors, and chips, that you place on the board using SMT.

Here is a table to help you see the difference:

| Aspect | Surface Mount Technology (SMT) | Surface Mount Device (SMD) |

| ——————– | ———————————————– | ——————————————— |

| Definition | A process for mounting components on PCBs | The electronic parts are designed for SMT |

| Role | Involves solder paste, placement, and soldering | Small, compact parts like resistors and chips |

| Purpose | Enables fast, automated PCB assembly | Allows for smaller, denser circuit designs |

| Example Applications | Smartphones, medical devices, wearables | Resistors, capacitors, integrated circuits |

Note: SMT is the method, while SMD is the component.

SMT vs. Through-Hole

When you compare SMT with through-hole technology, you notice several key differences. Through-hole components have long leads that pass through holes in the PCB. SMT components sit directly on the surface and do not need holes. This change affects size, assembly, and performance.

| Feature | SMT Components | Through-Hole Components |

| ———————— | ————————————- | ———————————— |

| Hole Requirement | No holes needed | Requires drilled holes |

| Component Size | Much smaller | Larger |

| Mounting Location | Both sides of the PCB | One side only |

| Mechanical Bond Strength | Weaker (relies on solder) | Stronger (leads through PCB) |

| Handling and Repair | More difficult | Easier |

| Application Suitability | Compact, high-performance electronics | Durable, prototyping, robust designs |

You use SMT for products like smartphones, tablets, and IoT devices. Through-hole works best for heavy-duty or military equipment that needs extra strength.

Advantages of SMT

You gain many benefits when you choose SMT for your projects:

- Automated assembly speeds up production and lowers costs.

- Smaller components allow you to fit more parts on each board.

- You can mount parts on both sides of the PCB.

- SMT reduces the need for manual labor and drilling.

- Boards become lighter and more compact.

- Mass production becomes easier and more reliable.

SMT usually cuts assembly costs by 30-50% compared to through-hole for large runs. You see SMT in almost every modern electronic device because it supports high-volume, efficient, and precise manufacturing.

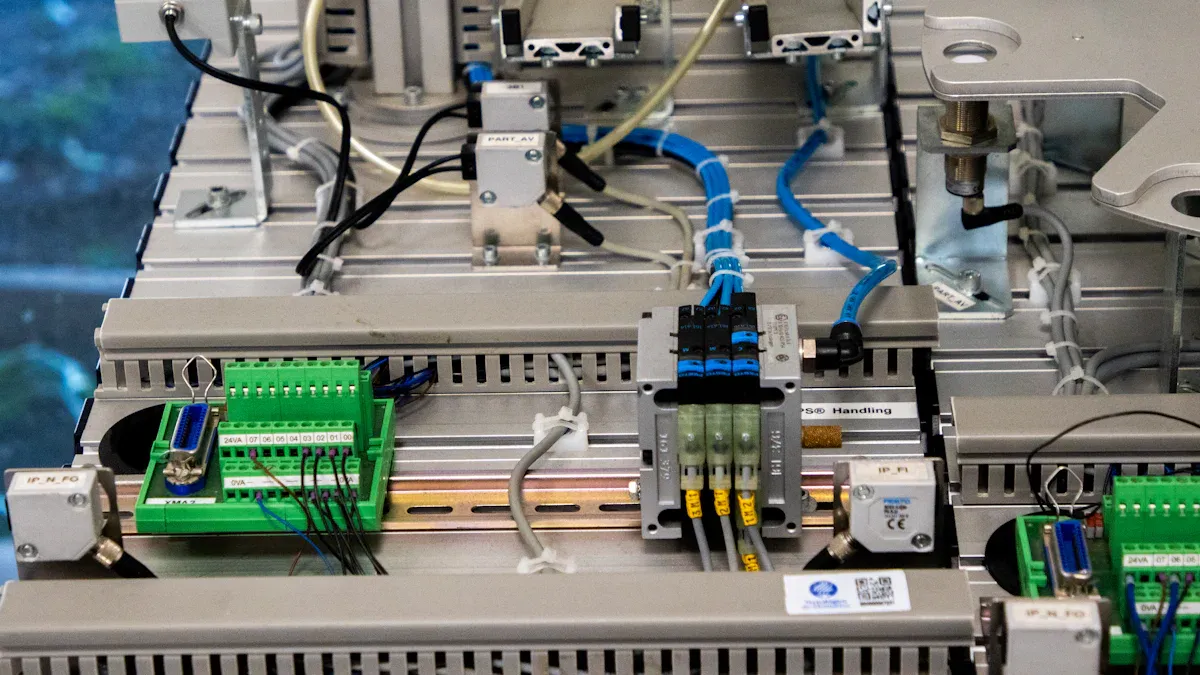

SMT Process Steps

Surface Mount Technology (SMT) uses a series of precise, automated steps to assemble electronic circuits. You can see how each stage builds on the last to create reliable, high-quality printed circuit boards (PCBs). Automation makes the process fast and consistent, helping you deliver products on time and with fewer defects.

Solder Paste

You start the SMT process by applying solder paste to the PCB. This step uses an automated stencil printer. The printer pushes solder paste through a thin, laser-cut stencil onto the copper pads where components will sit. The stencil ensures the right amount of paste lands in the correct spots. You can choose different stencil types, such as laser-cut or electroformed, depending on your needs. Proper solder paste application is critical. If you use too much or too little, you risk poor connections or short circuits.

Tip: Automated vision systems align the stencil with the PCB, so you get precise solder paste placement every time.

Component Placement

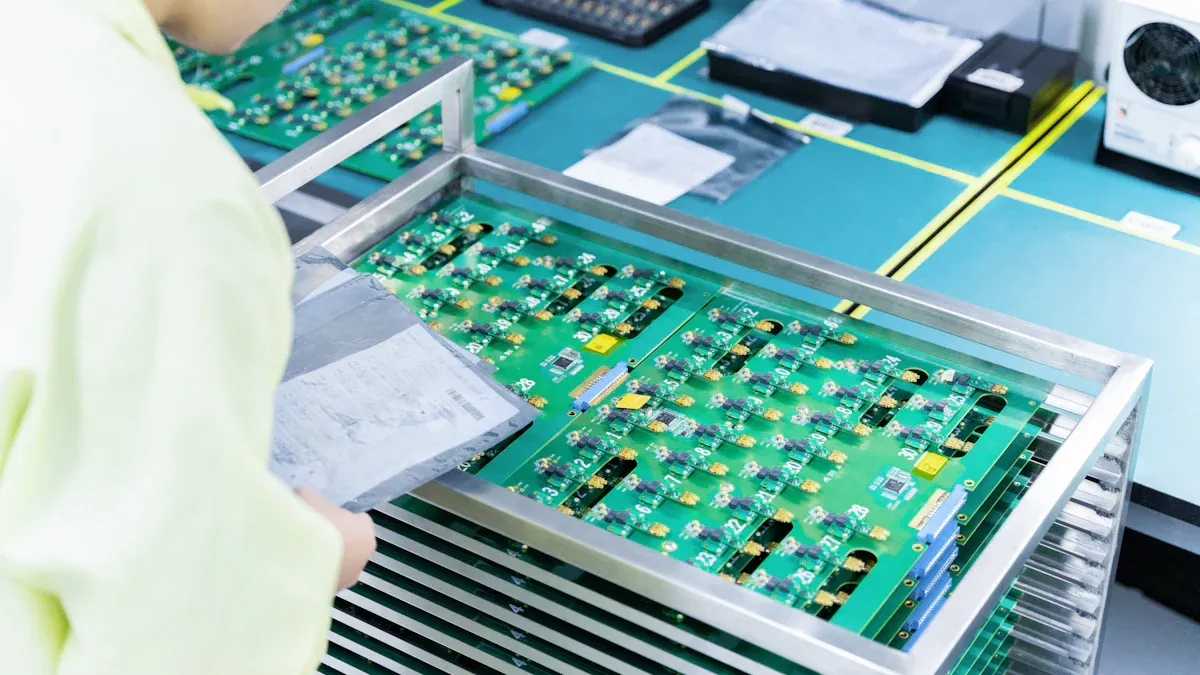

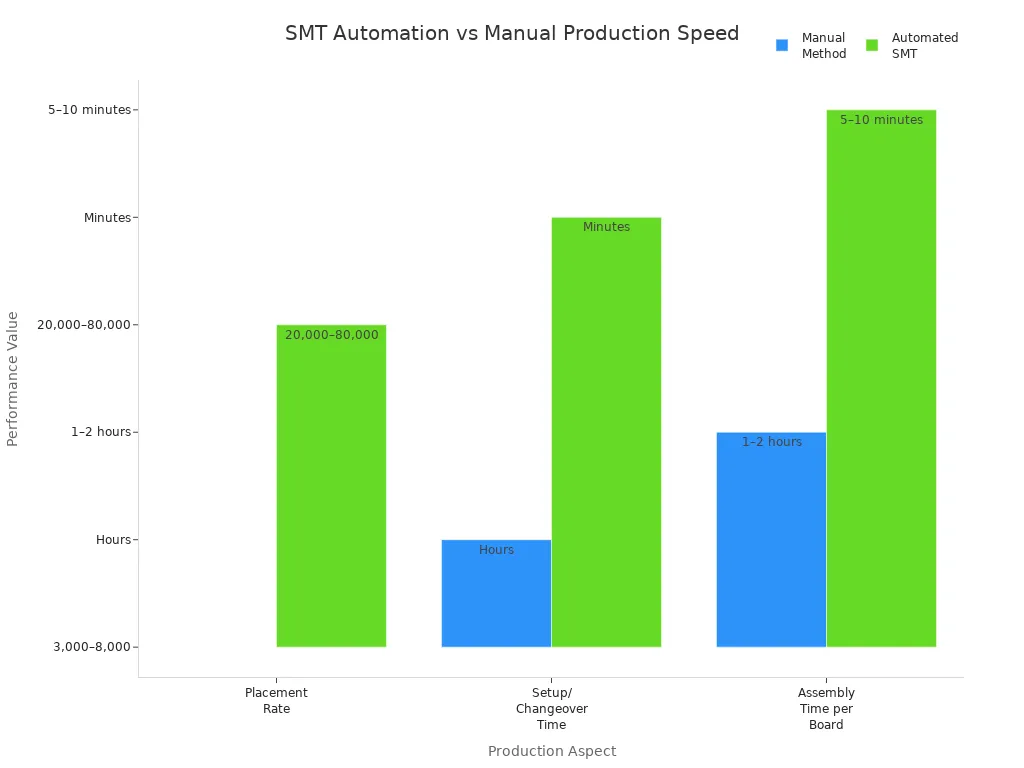

After you apply solder paste, you move to component placement. Pick-and-place machines handle this step. These machines grab tiny surface-mount devices (SMDs) and set them onto the solder-pasted pads at high speed. You can place thousands of components per hour—much faster than manual assembly. The machines use cameras and sensors to check alignment and position each part with micron-level accuracy. This automation reduces errors and keeps your assembly line moving quickly.

- Automated placement boosts production speed by up to 30-50%.

- You can mount parts on both sides of the PCB.

- Consistent placement lowers the risk of defects.

Reflow Soldering

Once all components sit in place, you use a reflow oven to solder them to the board. The oven heats the PCB in carefully controlled stages. The solder paste melts and forms strong, reliable joints between the components and the board. Multiple heating zones in the oven ensure even temperature and prevent damage to sensitive parts. Automated reflow ovens can process many boards at once, making this step both efficient and consistent.

- Reflow soldering creates durable connections.

- Automated ovens reduce the chance of overheating or cold joints.

- You get uniform results across every board.

Inspection

Inspection is a key part of the SMT process. You use several automated systems to check for defects at every stage:

- Solder Paste Inspection (SPI): Checks the quality and placement of solder paste before you add components.

- Automated Optical Inspection (AOI): Uses cameras to spot misaligned parts, missing components, or bad solder joints after reflow.

- X-ray Inspection (AXI): Looks for hidden defects under large chips like BGAs.

- In-Circuit Testing (ICT): Tests the electrical connections for shorts, opens, and correct values.

- Functional Testing: Makes sure the finished board works as intended.

You can also use manual visual inspection for extra quality control. Automated inspection tools catch most defects early, so you can fix problems before they reach your customers. Manufacturers who use these methods report yields above 99% and on-time delivery rates over 99%. Real-time data monitoring and operator training further improve reliability.

Note: Effective inspection and testing reduce rework costs, improve yield, and ensure your products meet industry standards.

Key SMT Process Steps :

- Solder Paste Printing

- Component Placement

- Reflow Soldering

- Inspection

- Final Assembly

Automation in SMT not only speeds up each step but also increases consistency and quality. You can deliver more products, faster, and with fewer errors. This approach helps you meet tight deadlines and keep your customers satisfied.

SMT Pros and Cons

Benefits

You gain many advantages when you use Surface Mount Technology in electronics manufacturing. SMT helps you build smaller, lighter, and more complex devices. Automated assembly lines let you place thousands of components per hour, which increases speed and reduces costs. You can mount parts on both sides of the PCB, making your designs more compact and powerful.

Here is a table that shows the main benefits of SMT:

| Benefit Aspect | Explanation |

| ———————————- | ————————————————————————————- |

| Reduced PCB Size and Weight | Smaller components help you shrink the size and weight of your products. |

| Increased Manufacturing Efficiency | Automation speeds up assembly and boosts yield, saving you time and money. |

| Improved Electrical Performance | Shorter leads improve signal quality, which is important for high-frequency circuits. |

| Lower Production Costs | You avoid drilling holes and reduce labor, which cuts costs and errors. |

| Higher Component Density | You can fit more parts on each board, even on both sides, for advanced designs. |

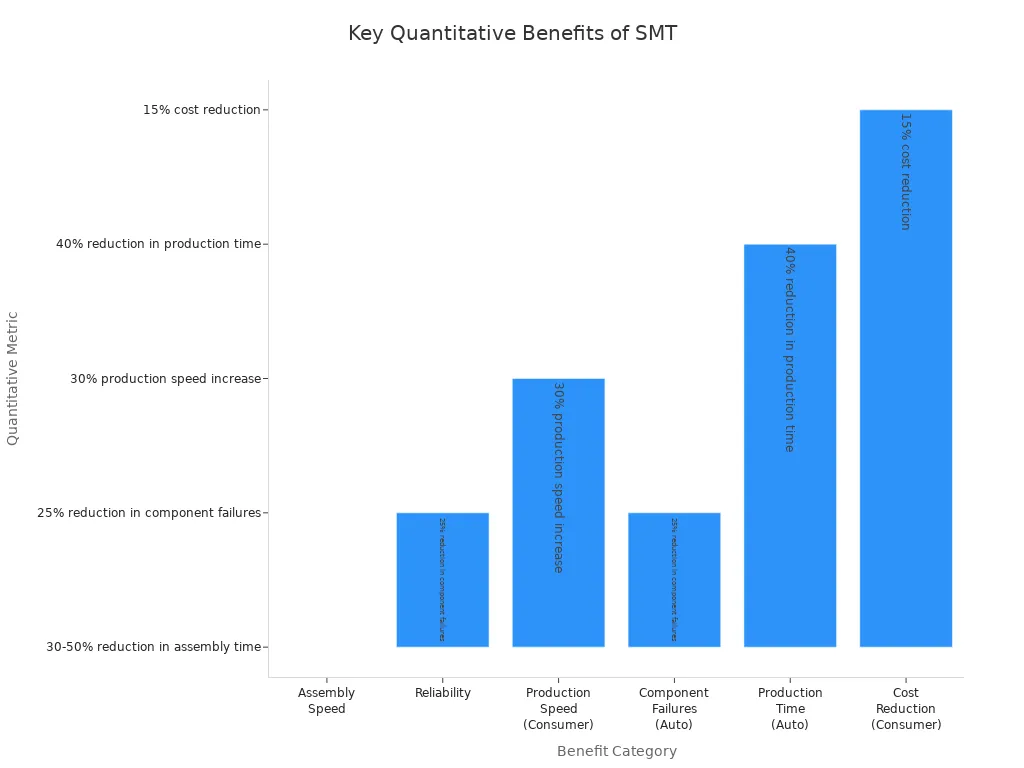

You also see real-world results. In consumer electronics, SMT can cut assembly time by 30% and lower costs by 15%. In the automotive industry, SMT reduces failures by 25% and speeds up production by 40%. Automated inspection tools, like AOI and X-ray, help you catch defects early, keeping defect rates below 100 parts per million in top factories.

Tip: SMT supports eco-friendly manufacturing. You use less material, save energy, and can choose lead-free solder to meet safety standards.

Limitations

While SMT offers many benefits, you also face some challenges. Miniaturization makes inspection, handling, and rework harder. High component density can lead to complex routing and signal issues. You need advanced equipment, such as X-ray and AOI systems, to inspect tiny parts and hidden solder joints.

- SMT components are fragile and have less mechanical strength than through-hole parts.

- Reworking or repairing SMT boards is difficult because of small, closely packed parts.

- High initial investment is needed for pick-and-place machines and reflow ovens.

- Fine-pitch components require precise placement and skilled operators.

- Moisture-sensitive parts need special storage to prevent failures like “popcorning.”

- Soldering problems, such as bridges or cold joints, can occur if you do not control the process carefully.

Through-hole technology still works better for heavy-duty or high-stress uses, such as automotive or aerospace, because it provides stronger mechanical bonds. SMT, however, gives you lower defect rates and better performance in most modern electronics.

Note: You can combine SMT and through-hole methods to balance reliability and miniaturization in your designs.

You now see how Surface Mount Technology shapes the world of electronics. Since the 1980s, SMT has driven the miniaturization of devices by allowing you to pack more power into smaller spaces. Automated processes cut costs and boost efficiency, making advanced products possible. You use SMT every day in phones, laptops, TVs, and smartwatches. When you ask What-Does-SMT-Stand-for-in-Manufacturing, remember that it stands for progress in technology and innovation.

- Phones

- Laptops

- TVs

- Smartwatches

- Gaming consoles

FAQ

What is the main purpose of SMT in electronics manufacturing?

You use SMT to mount electronic components directly onto the surface of a PCB. This method helps you make devices smaller, lighter, and more efficient. SMT also speeds up production and improves product quality.

Can you repair SMT boards if something goes wrong?

You can repair SMT boards, but it takes special tools and skills. The small size of the parts makes repairs harder than with through-hole boards. Many factories use rework stations and microscopes for this job.

Are SMT components more fragile than through-hole components?

Yes, SMT components are usually more fragile. They have less mechanical strength because you attach them only with solder. You should handle SMT boards carefully to avoid damage.

What types of products use SMT?

You find SMT in almost every modern electronic device. Examples include smartphones, laptops, TVs, smartwatches, and gaming consoles. SMT lets you pack more features into smaller products.

Do you need special equipment for SMT assembly?

You need automated machines for SMT assembly. These include pick-and-place machines, reflow ovens, and inspection systems. This equipment helps you place tiny parts quickly and accurately.